Difference between revisions of "Polytetrafluoroethylene"

(Created page with "PTFE seal tape. '''Polytetrafluoroethylene''' or '''PTFE''' or '''Teflon''' is a synthetic fluoropolymer of tetrafluoroethylene,...") |

|||

| Line 4: | Line 4: | ||

==Properties== | ==Properties== | ||

===Chemical=== | ===Chemical=== | ||

| − | PTFE is extremely resistant to chemical attacks, being only affected by molten alkali and strong fluorinating agents such as cobalt(III) fluoride and xenon difluoride. Teflon strips | + | PTFE is extremely resistant to chemical attacks, being only affected by molten alkali and strong fluorinating agents such as cobalt(III) fluoride and xenon difluoride. Teflon strips appear to burn in air, but it's most likely that the pyrolysis products are the one that catch fire. It will however burn when mixed with magnesium powder. |

===Physical=== | ===Physical=== | ||

| − | PTFE is a white solid at room temperature, with a melting point of 327 °C. Its density is 2.2 g/cm<sup>3</sup>. PTFE maintains mechanical properties down to temperatures of 5 K (−268.15 °C), and has good flexibility at temperatures above −79 °C. Teflon materials however are susceptible to creep. When melted, PTFE has the consistency of paste, so items can only be cast via injection. | + | PTFE is a white solid at room temperature, with a melting point of 327 °C. Its density is 2.2 g/cm<sup>3</sup>. PTFE maintains mechanical properties down to temperatures of 5 K (−268.15 °C), and has good flexibility at temperatures above −79 °C. Teflon materials however have poor mechanical properties and are susceptible to creep. When melted, PTFE has the consistency of paste which slowly decomposes, so items can only be cast via injection. |

==Availability== | ==Availability== | ||

Revision as of 14:23, 3 August 2015

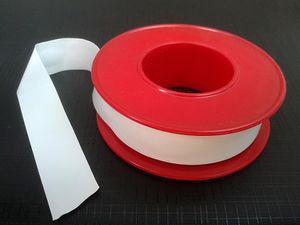

Polytetrafluoroethylene or PTFE or Teflon is a synthetic fluoropolymer of tetrafluoroethylene, well known for its chemical inertness and very low coefficient of friction.

Contents

Properties

Chemical

PTFE is extremely resistant to chemical attacks, being only affected by molten alkali and strong fluorinating agents such as cobalt(III) fluoride and xenon difluoride. Teflon strips appear to burn in air, but it's most likely that the pyrolysis products are the one that catch fire. It will however burn when mixed with magnesium powder.

Physical

PTFE is a white solid at room temperature, with a melting point of 327 °C. Its density is 2.2 g/cm3. PTFE maintains mechanical properties down to temperatures of 5 K (−268.15 °C), and has good flexibility at temperatures above −79 °C. Teflon materials however have poor mechanical properties and are susceptible to creep. When melted, PTFE has the consistency of paste which slowly decomposes, so items can only be cast via injection.

Availability

PTFE is cheaply available as thread seal tapes. Many lab items, such as stoppers, gaskets, sleeves, magnetic stirrers are made of it and can be easily procured online. However, items made of PTFE are expensive, as PTFE cannot be molded like the more common type of plastics.

Preparation

PTFE is made via polymerization of tetrafluoroethylene. This process is difficult and expensive for the amateur chemist.

Projects

Handling

Safety

PTFE, being chemically inert, is non-toxic. Its pyrolysis is detectable at 200 °C, giving off fluorocarbon gases, that in large quantities can be dangerous for humans and are very toxic to wildlife, such as birds.

Storage

No special storage is required.

Disposal

Being chemically inert, PTFE poses hazard to the environment, as it cannot be digested by wildlife.