Difference between revisions of "Zinc plating"

m (→Relevant Sciencemadness threads) |

|||

| (One intermediate revision by one other user not shown) | |||

| Line 3: | Line 3: | ||

==Galvanization with a battery== | ==Galvanization with a battery== | ||

| − | Galvanization is the process of applying a thin zinc coating to a piece of metal prone to oxidation in order to prevent damage. Normally, industrial processes use the hot-dip method of galvanization, which involves submerging the desired object in molten zinc. However, this process | + | Galvanization is the process of applying a thin zinc coating to a piece of metal prone to oxidation in order to prevent damage. Normally, industrial processes use the hot-dip method of galvanization, which involves submerging the desired object in molten zinc. However, this process can also be done via an electrochemical process, which can be done at home easily with household items. |

'''Materials needed:''' | '''Materials needed:''' | ||

| Line 58: | Line 58: | ||

[[Category:Electrochemistry]] | [[Category:Electrochemistry]] | ||

| − | [[Category: | + | [[Category:Techniques]] |

[[Category:How-to]] | [[Category:How-to]] | ||

Latest revision as of 21:11, 2 December 2018

Zinc plating has many practical purposes, the most important being protection of corrosion susceptible metals.

Contents

Galvanization with a battery

Galvanization is the process of applying a thin zinc coating to a piece of metal prone to oxidation in order to prevent damage. Normally, industrial processes use the hot-dip method of galvanization, which involves submerging the desired object in molten zinc. However, this process can also be done via an electrochemical process, which can be done at home easily with household items.

Materials needed:

- Desired metal object

- A power source

- Alligator clips

- A vessel that may be filled with water

- A zinc salt OR an acid

- Zinc metal

- A file (optional)

Procedure:

If you have a zinc salt, such as zinc sulfate, dissolve enough into the solution to saturate it. If you don't have a zinc salt handy, you can make one yourself by adding zinc metal to an acid. File down parts of the zinc source to make zinc powder. (This step is optional, but greatly speeds up the dissolution.) Dissolve as much of the zinc into the acid as possible.

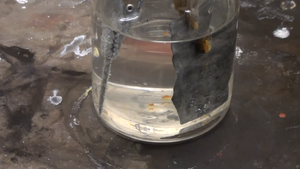

Connect the negative terminal of the power source to the object you wish to plate, and connect the positive terminal to a piece of zinc metal. Place both terminals directly into the zinc solution, not allowing them to touch, and allow a coating of zinc to build up on the object.

For a more even coating, use a low current and remember to rotate the object in solution.

Penny alchemy

It is possible to plate objects with zinc and turn them brass without using an electrical current. This is often used in a demo known as "penny alchemy," which produces pennies that are silver and gold.

Materials needed for all demos:

A penny or some other piece of clean copper

A beaker with 100 mL water

A hotplate

A bunsen burner

- exact amounts are not critical here.

Zinc salt method

Produce a 1 molar solution of any zinc salt. For zinc sulfate heptahydrate this will be about 30 grams, for zinc chloride tetrahydrate, 20 grams, for zinc nitrate hexahydrate, about 25 grams. Place some zinc strips in the solution, heat it to boiling, and place the pennies on top of the strips. It will take about 10 minutes until they turn gold. Turning the pennies over is recommended.

Zincate method

Produce a 5 molar solution of sodium hydroxide (about 25 grams) and add in some zinc powder. Heat to a boil and place the pennies on the powder. It will take about 10 minutes until they turn gold. Turning the pennies over is recommended.

Turning the coin brass

Once plated with zinc, the penny should washed with water to remove any remaining zinc salts. It is then placed over a Bunsen burner (this is tricky) for just the right amount of time for the zinc to melt into the copper cladding, turning it into brass. Do it too long and the zinc burns right off, and do it too short and the zinc will darken instead of melting.

A better way to do this is to place the penny directly on a hotplate at 300 degrees Celsius and wait for it to turn coppery again, then rinse it in a bath of cold water to turn it brass.

Removing the copper from a penny

(Experiment done by myst32YT)

To remove the copper plating of a penny without affecting the zinc, you must first mix approximately 1g of Ca(OH)2 and 0.5g of S powder in water. Add some dish soap to ensure a slurry, then bring the mixture to a boil. Once it is at a boil, dip the penny in for 30 seconds. When you pull it out, it should be darkened and heavily tarnished (though any exposed zinc should still be shiny). Clean the copper residue off with the appropriate cleaner and you should have a shiny zinc penny.