• Mn3+ causes red and green colors in octahedral sites. Muscovite mica from Brazil containing is red as is Mn3+ in beryl from Utah, synthetic

orthopyroxene, and piemontite from Whitewater, California. Andalusite containing Mn3+ is green. In the amphibole, tremolite, from New York, it

produces a violet color.

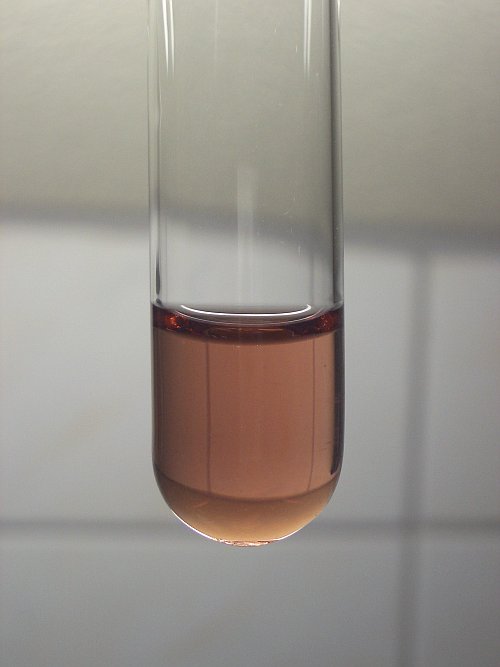

• Mn2+ usually results in a pink color in octahedral sites. Rhodonite from Minas Gerais, Brazil, is a pyroxenoid containing Mn2+and has the typical

pink color of Mn2+ minerals. Rhodocrosite from Colorado has a high concentration of Mn2+ and a bright red color. At lower concentrations, Mn2+ causes

pale pink color. When the Mn2+ is in a tetrahedral site, then yellow-green color results such as is the case with willemite.

• Fe2+ in forsterite from San Carlos, Arizona, and in phosphophyllite from Bolivia is the ion responsible for the green color. In some minerals with

high concentrations of Fe2+, such as fayalite or orthopyroxene, the color is brown.

• Fe2+ in the square planar site of gillespite or eudialyte produces a rasberry red color.

• Fe2+ in the eight-coordinated site of pyrope garnet from Tanzania produces the near-red color.

• Fe3+ in octahedral sites causes only pale color when the Fe3+ ions are isolated from each other by intervening silicate ions, etc. Pale purple

color is found in phosphates such as strengite and sulfates such as coquimbite. Yellow-green can be found in ferric silicates such as andradite garnet

from Italy.

• Fe3+ is in the tetrahedral site of plagioclase feldspar from Lake County, Oregon, produces a pale yellow color. In an unusual variety of diopside

containing Fe3+ in a tetrahedral site, it produces bright orange color in thin section.

• Co2+ in synthetic olivine and cobaltian calcite from the Kakanda Mine, Zaire, causes a typical reddish color. In tetrahedral sites, Co2+ causes

blue color such is found in some spinels.

• Ni2+ in synthetic olivine has the green color typical of Ni2+ in an octahedral site. If all the nickel is forced in to the larger M2 site by

appropriate chemical substitution (in this case in a LiScSiO4 olivine), the color is yellow, typical of Ni2+ in large, distorted sites.

|

and possibly with Mn2O3 and/or

MnO2. It's beige in colour.

and possibly with Mn2O3 and/or

MnO2. It's beige in colour.

.

.

.

.

to one and the colour disappears altogether. Adding NaOH to the (hot) second one and whitish-pink Mn(OH)2

precipitated.

to one and the colour disappears altogether. Adding NaOH to the (hot) second one and whitish-pink Mn(OH)2

precipitated.

?

?