I just had something really interesting happen!

I've tried to do this synthesis 4 or 5 times now, and the last time I tried, I finally succeeded in making some potassium. However, it was only a

bunch of very fine particles that I was unable to coalesce. I was going to post a writeup of my results on here, but I wanted to try it once more to

see if I could get some larger balls of potassium first.

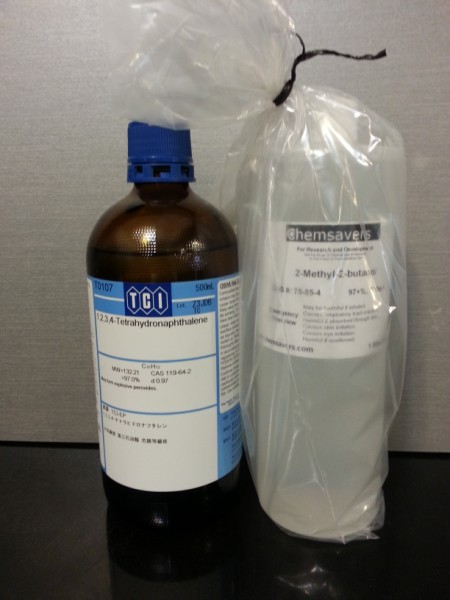

So, on this most recent attempt, I had 4.8 grams of magnesium (1/2 powdered and 1/2 turnings), 10 grams of potassium hydroxide, and about 35 ml of

highly pure paraffin oil (Tiki Torch Fuel). I also added all of the tertiary butyl alcohol - about 2ml - right away since that was how I did it the

last time I got potassium (unlike all the other times I added it a little bit at a time and never got potassium). I started the synthesis like normal,

heating it up to 200+ Celcius.

Now, I normally get quite a bit of that weird white smoke coming out of the solution as it heats up, but this time was different. There was A LOT of

it this time. After about 5 minutes on the hotplate, I started seeing a few fairly large sparks in the flask. I got a bit afraid at this point, so I

turned off the hotplate. All of a sudden, the whole bottom of the flask lit up quite brightly - but not white light like magnesium burning, more of an

orange flame. There wasn't really a flame though, sort of like something burning without oxygen. After about 5 seconds, the burning completely

stopped, and my flask and condenser were covered in black soot.

My thought was that I must have heated it up too quickly or something, and the magnesium on the bottom of the flask got too hot and started to burn.

However, it got even weirder. I let the flask cool down for a while and then looked in the bottom part that wasn't covered in soot. There were tiny

little balls of potassium floating around. I might be mistaken, and it could have been magnesium powder, but they were floating, very bright/shiny,

and I'm pretty positive they weren't there before. I dumped the contents out in my sink, and poured some water on it (I didn't really realize at the

time that there was potassium in it). When the water hit it, there were tiny little sparks everywhere. It looked exactly like when I added some water

to the potassium I got in my last synthesis.

I'm not sure what else it could have been besides potassium... But the flask was only on the hotplate for 5-10 minutes. Am I just going crazy?  It took 3-4 hours before I saw potassium last time. Maybe it was actually magnesium

that caught on fire in my flask, and it was hot enough to accelerate the process...? I'm not sure. It took 3-4 hours before I saw potassium last time. Maybe it was actually magnesium

that caught on fire in my flask, and it was hot enough to accelerate the process...? I'm not sure.

|

It took 3-4 hours before I saw potassium last time. Maybe it was actually magnesium

that caught on fire in my flask, and it was hot enough to accelerate the process...? I'm not sure.

It took 3-4 hours before I saw potassium last time. Maybe it was actually magnesium

that caught on fire in my flask, and it was hot enough to accelerate the process...? I'm not sure.

http://v.youku.com/v_show/id_XNTAxODAzMTc2.html

http://v.youku.com/v_show/id_XNTAxODAzMTc2.html

Anyone have the links to the

rest of it? Thanks!

Anyone have the links to the

rest of it? Thanks!