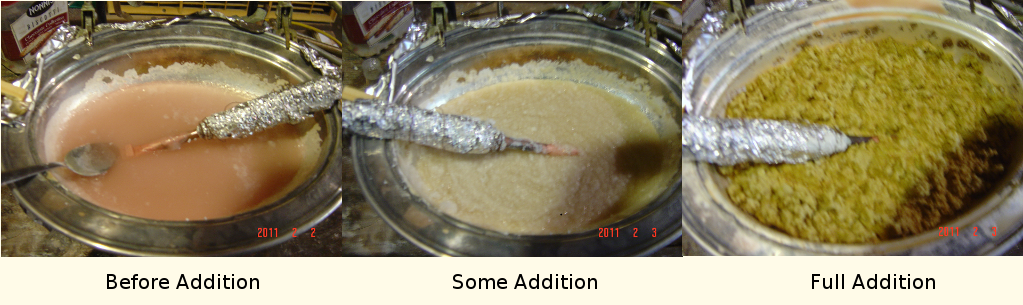

). I set this over

a bunsen burner with clamps, and then used aluminum foil to provide a "skirt" along the perimeter of the basin to help keep the heat in and stop the

sides from cooling (causing caustic to cake up, unmelted). The thermometer was protected by inserting it into a piece of copper tubing crimped at the

end by a vice; the middle portion of the thermometer was further protected (from splattering base) with aluminum foil. The spoon seen in the pictures

below is totally unnecessary. I stopped using it early on; the thermometer is more than sufficient to stir the reaction mixture.

). I set this over

a bunsen burner with clamps, and then used aluminum foil to provide a "skirt" along the perimeter of the basin to help keep the heat in and stop the

sides from cooling (causing caustic to cake up, unmelted). The thermometer was protected by inserting it into a piece of copper tubing crimped at the

end by a vice; the middle portion of the thermometer was further protected (from splattering base) with aluminum foil. The spoon seen in the pictures

below is totally unnecessary. I stopped using it early on; the thermometer is more than sufficient to stir the reaction mixture.

Quote: Originally posted by smuv  |

Quote: Originally posted by smuv  |

Quote: Originally posted by smuv  |

Quote: Originally posted by benzylchloride1  |

| Quote: |

).

).Quote: Originally posted by starman  |

Quote: Originally posted by redox  |