I want to make pentafluoro aniline from pentafluoro benzoic acid.

the procedure posted by S.C. Wack looks atractive to me, however I'm afraid the poorly nucleophilic oxygenes of C6F5COOH would hinder any reaction that include protonation of the COOH...

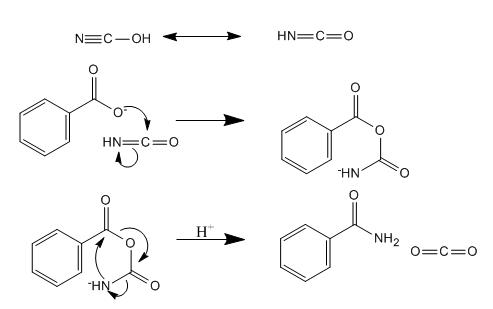

the only way I found 'till now that uses (relatively) simple reagents is this:

C6F5COOH ---> C6F5COCl (using SOCl2)

C6F5COCl ---> C6F5COONH2 (by addition of hydroxyl amine)

C6F5COONH2 ---> C6F5NH2 (-CO2 by heating with K2CO3)

any thoughts anyone?

Are you sure you should make any aniline if you are that ignorant of

its properties?

Are you sure you should make any aniline if you are that ignorant of

its properties?