Making your own vacuum pump is tres difficile!

I'm not saying you're stupid for trying, just that you may find the time/effort ratio.........

well....

good luck

| Quote: |

| Quote: |

| Quote: |

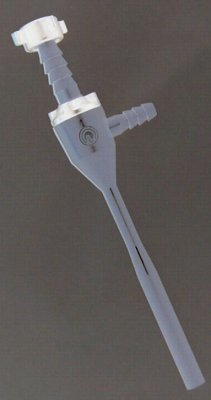

in the smaller space, and makes a "low pressure

zone" that sucks in the air.

in the smaller space, and makes a "low pressure

zone" that sucks in the air.

| Quote: |

| Quote: |

| Quote: |

I wonder if he'll

ever walk again?

I wonder if he'll

ever walk again?

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

Lol! That's EXACTLY what I tought!

Lol! That's EXACTLY what I tought!

| Quote: |

seems like it doesn't like pressure.. or maby i degreased poorly..

seems like it doesn't like pressure.. or maby i degreased poorly.. This fluctuation may depend (guessing)

on the form of the nozzle. I think nozzle should be symmetrical (kinda hard to make this with a hammer)

This fluctuation may depend (guessing)

on the form of the nozzle. I think nozzle should be symmetrical (kinda hard to make this with a hammer)

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

*lol*

*lol*