The most recent synthesis is one where some temperatures were closely watched and refined , and the nitration went very smoothly with absolutely no

surging nor red fume production , resulting in an exceptionally pure end product in 90% yield based on ASA . So the conditions are a good baseline

reference for any fine tuning of the process in efforts to get a little better efficiency . I believe it may be ultimately possible to get yields up

around 98% using some adjustments , but a 90% yield process provides a good place to start .

The synthesis followed my rule of thumb proportions which have always produced a good result , for each 1 gram purified ASA , 4 ml 92% H2SO4 , 1.8

grams purified NaNO3 .

In a 1 liter Erlenmeyer 24/40 flask was placed a 10 X 35 mm stirbar and 750 ml of

92% H2SO4 heated with stirring to 80 C .

187.5 grams of purified ASA was added in small portions as fast as it would dissolve in the stirred mixture over the course of 45 minutes , the

temperature gradually rising to about 105 C by the heat of reaction as the ASA dissolved . The flask was loosely stoppered with a hollow glass 24/40

stopper . Supplemental heating gradually raised the temperature to 118 C at the end of 90 minutes and the heating was discontinued . After standing

overnight the sulfonated ASA mixture had cooled and solidified to a dark colored transparent gel filled with small tan cubical? crystals of sulfonated

ASA . The mixture had to be reheated to 115 C to melt and with stirring redissolve so the mixture could be poured into the nitration flask .

Into a 4,000 ml Erlenmeyer flask was placed a heavy ( 62 gram ) 3 inch oval stirbar , and was set upon an old Type 1000 Thermolyne 7.5 X 7.5 stirrer

hotplate . Dry , sifted free of lumps , NaNO3 , 339 grams total was divided into three equal 113 gram portions in preparation for the nitration and

kept in sealed containers .

The hot sulfonated ASA mixture was poured into the 4L Erlenmeyer , the 900 ml of hot liquid not quite deep enough to completely cover the stirbar .

An 18 inch thermometer , 260 C 75 mm immersion , was leaned diagonally in the flask with its tip sitting in the curved bottom outer edge inside the

flask . A 4 inch flexible ventilation duct mounted in an extension ring was positioned next to the flask opening for removal of any fumes by the

remotely located blower whose intake air is drawn through the 4 inch hose and discharged outdoors . A second larger fan was situated next to the low

workbench to pull a gentle draft in the same general direction as the higher velocity intake adjacent the opening of the flask . These sorts of

precautions are essential for safely conducting a nitration on a molar scale . The nitration was conducted outdoors in an area shaded from direct

sunlight .

The stirrer was started and run just below the speed where splashing of the shallow liquid occurred , with portions of nitrate begun with the mixture

at 95 C ,

the decarboxylation foaming occurring instantly on contact from the first addition of nitrate . The additions were made steadily in portions using a

teaspoon ,

adding the nitrate in heavy sprinkles into the vortex , the reaction temperature rising and maintained in the range of 100 to 103 C by regulating the

rate of additions of the solid nitrate . The effervescence of CO2 from decarboxylation

occurred freely with no persistent foaming through the end of the addition of the first of the three portions of nitrate , and midway into the second

portion at 1 hour from the beginning of the nitration . At this midpoint , the effervescence becomes more sluggish and the viscosity of the mixture

is increased , the foaming from decarboxylation causes a volume increase for the mixture , and the additions must be slowed considerably . At the end

of the addition of the second portion , the heat of reaction alone is insufficient and very gentle supplemental heating is added to maintain 103 C .

About 15 grams into the final portion of nitrate , the time from the beginning of nitration will be 1 hour 45 minutes and some picric acid will begin

to precipitate in the thickening mixture , greatly slowing the remaining additions . The stirring speed is increased and the heating is raised to 106

C by 2 hours from the beginning of nitration . The remaining nitrate additions go very slowly and will require as much time as all of the nitrate

previously added . The temperature is very gradually allowed to increase over the remaining additions of nitrate , the following observations were

made for

reference concerning the elapsed times from the beginning of nitration , and the total amount of the third portion of nitrate having been added .

@ 2 hours 15 minutes , 30 grams ,

107-108 C

@ 2 hours 30 minutes , 40 grams ,

109 C

@ 2 hours 45 minutes , 45 grams ,

111 C

@ 3 hours , 55 grams , 113-114 C

@ 3 hours 10 minutes , 60 grams , 114 C

At this point the mixture has become a very thick slurry and additions are suspended for a time . There is an accumulation of solids upon the walls

of the flask and the thermometer is used to scrape the material into the vortex so the mixing can be accomplished . This manual assistance is

required several times during the course of the remaining nitration . Close temperature control is essential to limit temperature to 114 C , as there

are indications of an induction point for decomposition at about 116 C .

@ 3 hours 30 minutes , nitrate additions cautiously resumed , 113 C reaction temperature

@ 3 hours 45 minutes , 70 grams , 112 C

@ 4 hours , 85 grams , 112 C

@ 4 hours 30 minutes , 113 grams completion of addition 110 C , Supplemental heating very slightly reduced , reaction allowed to continue

@ 5 hours , slowly finishing reaction has cooled to 100 C and reaction appears complete , the temperature is subsiding

and the mixture is thinning as the temperature falls . Supplemental heating discontinued completely .

@ 5 hours 10 minutes , 97 C , mixture is now much thinner and is a free stirring smooth slurry with no foam whatsoever ,

a suspension of fine yellow reflective crystals of picric aicd suspended in a water clear colorless supernatant liquid of spent acid and bisulfate in

solution

@ 5 hours 20 minutes , 92 C , cautious and gradual dilution of the stirred mixture was begun by streaming water from a wash bottle onto the inner

walls of the flask and allowing the stirred mixture to be gradually diluted , limiting the temperature rise to 100 C , a total of about 1 liter of

water was added . The dilution was accompanied by a fair amount of red fumes being evolved , believed to be the result of decomposition of

nitrosylsulfuric aicd present in the spent nitration mixture .

The total volume of the diluted mixture was at the 2,000 ml graduation on the flask .

@ 6 hours , 74 C , ice is added to bring volume of diluted mixture to 2800 ml ,

and to speed cooling .

@ 6 hours 15 minutes , 23 C

Flask is placed in refrigerator to complete the precipitation .

The crude picric acid is filtered and blottered , and the still damp crystals are redissolved in 5200 ml boiling distilled water . On slow cooling ,

excellent crystals are formed , which after filtering and drying , are obtained 198 grams from the first crystallization , 83% yield based upon ASA ,

of exceptional quality picric acid .

An additional second crop of crystals ,

16 grams is obtained by boiling down the filtered liquid from the first crystallization to a volume of 1300 ml , and allowing to cool .

Yet a third crop of maybe 2 grams can be obtained by concentrating to 300 ml and cooling .

There was absolutely no dark colored impurity produced to tint the solutions or to precipitate and contaminate the product . The picric acid produced

was

absolutely free from any contamination byproducts . |

). I took the still hot solution outside, to a place where

constant wind was blowing and started adding 47mLs of 65% HNO3(slightly lower concentration than required, but it’s the best I could get my hands

on) dropwise. There was a big amount of brown fumes produced, as well as white vapour (mostly evaporated water I believe) and the mixture started

foaming a bit, but I think it was fine as no runaway occurred (which was the result of my first attempt with TNP, but that’s a different story).

After each 2 - 4ml addition the mixture was stirred with a glass rod and swirled for 20-30s. With the last 10mLs of HNO3, there were not as many fumes

produced and the mixture was a lot "calmer" but still it felt quite hot (90+°C I guess). After the final addition it was swirled for a few minutes

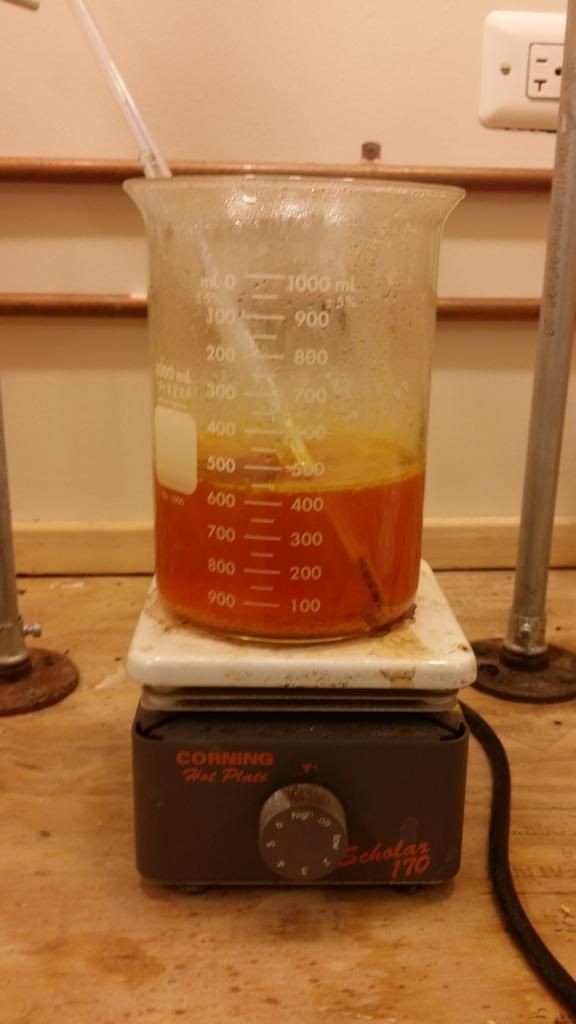

longer and a very dark red colour solution was obtained. It was then put into a 90°C water bath where heating was applied for 1,5 hours. The colour

changed to black during this time. After heating, there were 500mLs of ice-cold distilled water added, and to my surprise the solution didn't change

colour to the typical picric-yellow(like orange juice), but instead to red with dark-orange precipitate floating in it. Here's a photo of how it

looked like (sorry for the shitty quality, it was taken in the afternoon with my phone camera) -

). I took the still hot solution outside, to a place where

constant wind was blowing and started adding 47mLs of 65% HNO3(slightly lower concentration than required, but it’s the best I could get my hands

on) dropwise. There was a big amount of brown fumes produced, as well as white vapour (mostly evaporated water I believe) and the mixture started

foaming a bit, but I think it was fine as no runaway occurred (which was the result of my first attempt with TNP, but that’s a different story).

After each 2 - 4ml addition the mixture was stirred with a glass rod and swirled for 20-30s. With the last 10mLs of HNO3, there were not as many fumes

produced and the mixture was a lot "calmer" but still it felt quite hot (90+°C I guess). After the final addition it was swirled for a few minutes

longer and a very dark red colour solution was obtained. It was then put into a 90°C water bath where heating was applied for 1,5 hours. The colour

changed to black during this time. After heating, there were 500mLs of ice-cold distilled water added, and to my surprise the solution didn't change

colour to the typical picric-yellow(like orange juice), but instead to red with dark-orange precipitate floating in it. Here's a photo of how it

looked like (sorry for the shitty quality, it was taken in the afternoon with my phone camera) -

Never mind, this time I'll use more than twice as much HNO3 as well as more H2SO4. The mixture will also be heated with an oil bath to 115

centigrades after adding HNO3.

Never mind, this time I'll use more than twice as much HNO3 as well as more H2SO4. The mixture will also be heated with an oil bath to 115

centigrades after adding HNO3.

This time, I added phenol-sulphonic acid to

nitric acid and not vice versa, like most "recipes" say. I also used a room-temperature oil bath during nitration. The phenol-sulfonic acid had ~80°C

and the nitric acid had room temp. After first 25mLs the mixture only turned red but no vigorous reaction happened. I stirred the mixture very

thoroughly, and I was expecting a runaway nitration to occur. I added another 25mLs, which caused the reaction to start, with fuming and simmering. By

this time, I knew that everything is going well because the nitration seemed much smoother and calmer than the latter. There wasn't any foam and it

had a beautiful deep-red colour. I slowly added the rest of phenol-sulphonic mix with occasional stirring, a few mLs at a time, just enough to keep

the reaction running. The temperature didn't rise above 100°C during the whole reaction. After addition, the reaction vessel was completely filled

with TNP crystals (yay!), and being heated to 115°C a large amount, again, of NO2 gas was produced, which could barely escape through the thick layer

of crystals (stirring was necessary). I didn't heat it for a long time though, because I didn't place my hotplate on a spot with good ventilation

(outside ofc) which affected my yield significantly. I diluted the mix with ~300mLs of d-water and the mixture turned to a nice picric-yellow colour.

This time, I added phenol-sulphonic acid to

nitric acid and not vice versa, like most "recipes" say. I also used a room-temperature oil bath during nitration. The phenol-sulfonic acid had ~80°C

and the nitric acid had room temp. After first 25mLs the mixture only turned red but no vigorous reaction happened. I stirred the mixture very

thoroughly, and I was expecting a runaway nitration to occur. I added another 25mLs, which caused the reaction to start, with fuming and simmering. By

this time, I knew that everything is going well because the nitration seemed much smoother and calmer than the latter. There wasn't any foam and it

had a beautiful deep-red colour. I slowly added the rest of phenol-sulphonic mix with occasional stirring, a few mLs at a time, just enough to keep

the reaction running. The temperature didn't rise above 100°C during the whole reaction. After addition, the reaction vessel was completely filled

with TNP crystals (yay!), and being heated to 115°C a large amount, again, of NO2 gas was produced, which could barely escape through the thick layer

of crystals (stirring was necessary). I didn't heat it for a long time though, because I didn't place my hotplate on a spot with good ventilation

(outside ofc) which affected my yield significantly. I diluted the mix with ~300mLs of d-water and the mixture turned to a nice picric-yellow colour. ). I forgot to add HCl, so a lot of TNP was left dissolved in water and discarded. I

also lost some grams inside the filter paper, because I didn't use enough water for purification (250mL dissolves only around 20g of TNP) /facepalm.

Normal yield would be around 35 grams - 72% of theoretical yield.

). I forgot to add HCl, so a lot of TNP was left dissolved in water and discarded. I

also lost some grams inside the filter paper, because I didn't use enough water for purification (250mL dissolves only around 20g of TNP) /facepalm.

Normal yield would be around 35 grams - 72% of theoretical yield.