| Quote: |

| Quote: |

| Quote: |

Quote: Originally posted by Waffen SS  |

Quote: Originally posted by Waffen SS  |

Quote: Originally posted by Waffen SS  |

Quote: Originally posted by Magpie  |

Quote: Originally posted by entropy51  |

| Quote: |

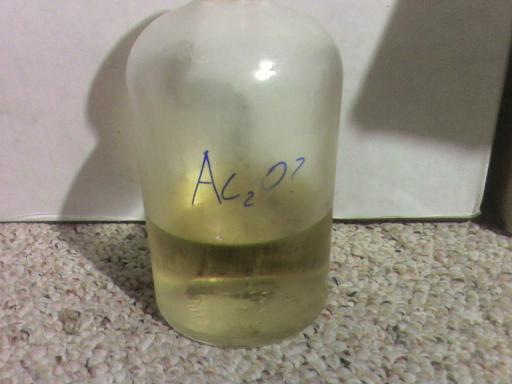

Up close and it's one of

those smells that makes you instantly shout "fuck!" and jump back from.

Up close and it's one of

those smells that makes you instantly shout "fuck!" and jump back from.