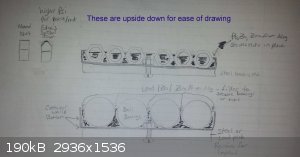

Proposed grinder - hammer-mill/grinder combo

The bottom of a metal container is filled with ball bearings so that they completerly cover one layer. A space needs to be left in the center to

insert a nut from the under-side later (connector to other metal plates). A metal like Pb, Zn, or Zinc-Aluminum alloy is poured in this container to

fill bottom of container to about 60-66% full, leaving 33-40% of bearing exposed for grinding. I think nuts could also be used in place of bearings,

these won't give the smaller impact point of the point of a sphere (so lower PSI per point) but the sides could be ground down to narrow them and

reduce the surface contact area. The nuts also allow for the filler metal to fill the void where the bolt thread would go, securing the nut in place.

I suggest a metal backing plate of min 1/4" steel on the back of this container if it is going to be used as a hammer mill or being dropped

repeatedly. On top of the metal backing plate, I propose a cylindrically shaped weight of a heavy metal (or even sand I guess) to give more weight

to the apparatus.

Zinc can be mixed with lead (melted) easily and even copper poweder would work for weight. Concrete is also an option I guess, it just depends how

compact it needs to be.

As for the containment vessel, anything with a steel plate bottom would work (as long as sparking isn't an issue) and maybe have a way to change the

grinding plate depending on what is being ground.

The top of the vessel needs a simple lid or even fabric cover to keep dust from coming out, I'd suggest fabric for some types of the hammer/drop

grinding. A metal (or wood even) lid would be fine and a bearing could be placed in the middle with a steel rod shaft (threaded end to connect)

attached to the grinding apparatus, protruding through the lid/bearing and connected to a crank handle or pulley (or direct drive motor).

I've tried this on a small scale (a 6oz SS measuring cup, ball bearings & lead) and it works much better than the ball mill I have for grinding

chunky compounds say the size of rock salt - much faster for the initial break down. It may not get to super-fine size a ball mill can get (never

tried it long enough), but I suspect it will if designed correctly.

[Edited on 8-4-2017 by RogueRose]

|