RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Vacuum pumps/compressors as heat source and the incorperation of vortex tube (cooling & heating)

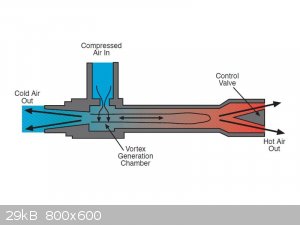

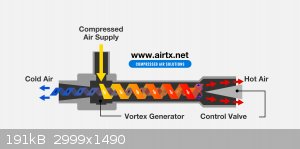

I've seen the "Vortex tube", also called the Ranque-Hilsch vortex tube, discussed a little bit in this forum but it has been about a decade or so

since it was really discussed and even before it was brief.

The vortex tube is pretty simple. Compressed air is injected into a tube at a 90 degree angle where after a little chaos inside the tube, a vortex

jet is created that travels around the outer diameter (of the inside of the tube) rotating very quickly. It then reaches an exit that has an inverted

cone with the tip pointing in towards the shaft and there is a narrow exit around the circumfrence of the cone which allows some air to exit. This

cone can be adjusted to move in or out which effects the temperature and air flow output of the device. The cone ensures that not all aire can exit

the tube, so some air has to move back the opposite direction. This makes the air moving back up the tube spin even faster (as it is in a tighter

"tube"). When the air passes down the tube on the first trip it strips energy from the air returning back from the cone which drops the temp

considerabley.

Now the temps that can be obtained are based on a number of factors from length of tube, diameter of tube, pressure of air and starting temp of air.

I have seen temps as high as 400F and as low as -80F (though I thought I remembered something breaking -100F to maybe -120 to -130 but couldn't find

those again).

Some people think this method of cooling is the most efficient method known and it may be the most efficient where direct, focused cooling is needed,

especially if hot air is also needed in the process.

I was thinking that this might be interesting as a means of providing heating and cooling for some distillations especially those that are done under

vacuum as in most cases less heat is needed and the cold air might be sufficient to use in the condensor without having to use a circulation pump.

While I doubt that the vacuum pump (for the distillation) would be sufficient to keep the pressure high enough to power the vortex tube, it might be

possible to use the same pump to switch between pumping the vacuum chamber (until enough vacuum is drawn) and filling a pressure tank.

This brought me to another idea about how my vacuum pump and my shop air compressor get really hot, hot enough to boil water and hotter. This is good

in my vacuum pump (oil based pump) because if moisture gets into the oil, it quickly boils out. But in many cases when I'm doing vacuum distillation

and the pump is running non-stop, the compressor, I'm guessing, produces enough heat for the distillation process.

Now there are 2 compressor types I'm going to talk about one uses something like a cyinder inside an ICE engine which is the first picture below - and

then there is the type used in air conditioners or heat pumps, dehumidifiers, and they are similar to the ones used in refrigerators (though not

always the same for some reason) - second pic below.

The compressor I have has a pretty flat cylinder head that had fins that are really fragile (over 2/3 have broken off so I've added CPU heat sinks

after grinding/sanding flat). Many of these types of compressors could have a water block placed on top like I did with a CPU heat sink. Mine has

gotten well past 212F when it was not damaged but that was with continuous use and the motor is rated at "2.5hp" in china ratings, so MAYBE 1/3hp

continuous. A water block could be used with either water or a more appropriate liquid (ethelyene glycol, propeleyne glycol, glycerine, oil, etc) to

pump the fluid to an oil or water bath for the distillation. IDK what other ways the heat could be used, suggestions?

Also, with the other type of compressor, the entire outer casing gets very hot and can get over 212 if left on long enough pulling vacuum. Wrapping

some copper tubing around the outside and possibly a bit of fabric (or some type of insulation) wrapped to help keep heat around the coil/compressor,

would allow for heat to transfer to the tubing and then used the same as above.

I would think that if someone wanted to distill water or solvents using vacuum, then using most of these options would probably work without having to

have an external source for heat and no need for cooling with the vortex tube.

I need to look more into how the vortex tube works and the possible benefits and applications but if anyone has seen or heard of some good

applications I'd be very happy to hear about them! Thanks!

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

They are used on some embroidery machines to supply cold air to cool the needle.

If your wondering how I know that I was briefly an embroidery machine minder.

|

|

|

coppercone

Hazard to Others

Posts: 133

Registered: 5-5-2018

Member Is Offline

|

|

I think they require heavy airflow to provide meaningful cooling. I think that unless you have a big screw compressor or a remote loud one youwont get

any meaningful cooling power out of it.

I kinda wanted to build a multistage cooler using them and some kind of precooler but you need tocool alot of air. Iirc there were only a few models

that had reasonable cooling curves in terms of compressor cfm rating.

The smallest one grainger sells is 2 cfm with 150 btu of cooling. Reasonable ones start at 10cfm and probobly go up to 50.

In terms of efficency if you have a non gigantic compressor it makes the peltier look good.

I think you can get like a 60c differential with a good one. Would be interesting to know when the effect tops off, i wanted to find out emperically.

I keep trying to find a use for it too. Been thinking about that one for half a decade lol. Its prettysafe. The best ican come up with is some kind of

sparger cooler since it moves air. You could do minor cooling as you sparge. Still not sure why you would want to though. Also maybe for cooling

dangerous things in a european style flask but at 150btu....

|

|

|

Sulaiman

International Hazard

Posts: 3554

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Online

|

|

I know nothing of the complexity or efficiency of a vortex tube,

but it looks like a very noisy system for a home lab.

|

|

|

Texium

|

Thread Moved

27-11-2023 at 12:31 |