RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Distilling NO2 from Ca(NO3) - Copper or SS tube for NO2 gas?

I've been trying to figure out the best way to make some HNO3 form some questionably pure Ca(NO3)2 and I'm going to try thermal decomposition of the

compound in an old 1.5 gallon air compressor tank that has threaded connections on which I can attach tubing to direct the gas. The tank is a little

rusty on the inside which is why I'm not using it. I haven't cut it open yet (going to cut a 3.5"-4" diameter hole in top to fill/empty it) so IDK how

bad the rust is, it is a very thick tank though. I should be able to remove most of it.

Since the decomp temp is near 1100F, the gas is going to be really hot and IDK the best material to handle this and I have easy access to 1/4" or 3/8"

ID copper tubing or some 1/4" ID SS tube (brake line). I plan to use a coil of at least 10 ft, maybe 25ft, in a 55 gal drum filled with water & a

pump running water through a radiator to keep the water temp down. I could run the gas through a final condenser (glass, copper or SS) with chilled

water, before it goes into the bubbler (glass rod with fritted end, like a stone bubbler).

I'm not sure how the SS or copper will react with the hot NO2. I guess I could get some glass tube and make a long coiled condensor (connecting many

tubes together making a 5-15ft coil which would be in the drum) but that would be more work and have to order the tube. I would think the glass would

be more resistant but less effective in cooling, but a long glass coil could be more useful in other reactions as well, maybe cooling NH3 gas as well,

which I think reacts with copper.

I've considered using something other than the air tank, like using a 3" ID cast iron nipple maybe 6" long with caps on both ends & a hose barb on

the top. This would be preferable but the cast iron is only rated to 180F! which seems ridiculous for cast iron - some black pipe is rated to 300F

but IDK if that is just for plumbing applications. It may work for my uses, IDK - anyone know about this stuff?

I don't know how well NO2 absorbs into water but it seems a better option than having to use an acid, then filter and have possible contaminates and

then have to distill.

My heat source will be either wood or propane until I get my electric heating element set up. The electric heat would work well with the 3" pipe and

with insulation, it shouldn't need a lot of energy to keep the reaction going once it is up to temp, at least I don't think it should.

Has anyone ever tried to make HNO3 from NO2 and is there anything I should know before trying this? It will be done outside, in open air - closest

building about 300-400 ft away, and always breezy.

IDK if this reaction would work better using H2O2 but I can easily use 35% H2O2 if that would be a better option than using plain water.

|

|

|

VSEPR_VOID

National Hazard

Posts: 719

Registered: 1-9-2017

Member Is Offline

Mood: Fullerenes

|

|

The copper piping would corrode. If you have assess to sulfuric acid and a glass filter than you could react the salt with the acid and filter out the

insoluble calcium sulfate. Decomposing your salt to NO2 and then producing HNO3 from the fumes is not very efficient, especially price wise if you

have to construct such a complicated metallic apparatus. It would be much better to simply purchase a glass distillation set up for 50-150 dollars

from China. If you do not have assess to sulfuric acid you could use sodium bisulfate, which is a pool chemical.

Within cells interlinked

Within cells interlinked

Within cells interlinked

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

I guess I could use sulfuric acid or sodium bisulfate, I have both but would need to get more H2SO4. I just had a really bad time trying to extract

the liquid from the CaSO4 when I mixed the two.

As for the NaHSO4, how would I make HNO3 with that and Ca(NO3)2? Would I dissolve it in water then add the nitrate? Wouldn't this method make Sodium

Nitrate?

I am ordering some new glassware and at least a 300mm Liebig and possibly a graham condenser.

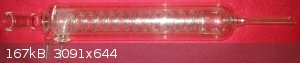

I do have these two pieces of glassware, one which I'm pretty positive is just a condenser, the other I'm not sure what it is for certain.

This is about 19" long and is some type of condenser. It has a coil that runs down the center (gas channel) then at the bottom it exits into a water

jacket where it exits at the very top hose barb. It has no ground glass joints so that is odd.

This is a strange piece of glassware, about 12-13" long. The green dots indicate where the water jacket inlets/outputs are - they are ~11mm on the top

and then a 8mm on the bottom side. The blue dots feed the coil and the two dots on the top are 8mm and then there is a 18-19mm opening on the far

left which I assume is for a plug/bung.

|

|

|

VSEPR_VOID

National Hazard

Posts: 719

Registered: 1-9-2017

Member Is Offline

Mood: Fullerenes

|

|

I have done this multiple times. Do not add any water. This will just dilute your acid. Conduct a dry distillation of calcium nitrate and sodium

bisulfate. This will form, depending on how much you use, calcium sulfate or sodium calcium sulfate. This is also much safer than using H2SO4 and is

far cheaper.

Within cells interlinked

Within cells interlinked

Within cells interlinked

|

|

|