RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

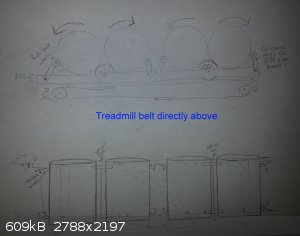

Make LARGE ball mill (4 5gal buckets) with a treadmill & still be able to use treadmill as intended!

So I was trying to figure out how i was going to build a mill for a 5 gal bucket - or even up to 4 buckets at once. It would require a good bit of

building until I realized that I already had something that was 90% finished, had more power than I could ever need, very accurate speed control, was

professionally built (not a fire hazard) and didn't need to be taken apart. A treadmill!

So I thought of ideas on how this could work. I found some old wheels off a baby stroller at a thrift store, these are about 8" diameter x 1" wide,

the "tire" part is super nice soft grippy rubber and the tire is "domed" and gives about 1/8"-1/4" contact when sitting on edge with no weight. I

thought these would be great "drive wheels" for the mill. They would roll on the treadmill belt. They had a 3/8" hole in the center and they

glided/spun very nicely with little friction (it is a hard plastic of some kind). There is a 1.25" extruding ring surrounding the center hole with

the lip around the ring being about 5/8" high - so this would accept a 1.25" bearing perfectly inside of this and epoxy it in place. I'd do this for

all 4 wheels and these will all be in contact with the belt and will be the drive wheels for the buckets.

2 2x4 of about 7ft long will be used to hold the 4 drive wheels. holes will be drilled about 1/2" from the top of the 2x4's width (so about 1" of the

wheel is below the bottom of the board) on both boards, directly across from each other. I'll either use a metal rod (size of the ID of the bearing

hole) to hold the wheels and put nuts on the outside of the 2x4 to keep the rod in place. The width will be wide enough so that the buckets rest on

the 8" wheels - offset

I also have 8 roller blade wheels, 2 of which will be used for each bucket and they can be adjusted to accept smaller than standard 5 gallon buckets.

These wheels roll freely and are used to support the bucket and keep it in place.

There would be a few braces keeping the 2x4"s at proper distance apart. I mentioned an axel on the 8" wheels but those aren't 100% necessary, I did a

trial without them and it worked fine.

Now you will need to secure this setup so it doesn't slide off the treadmill belt when it is running, not hard to do, use a rope and clips to attach

to the vertical "beams" that the control rests upon. If you are worried about is sliding from side to side, it's possible to place a bumper on the

side of the treadmill (off the belt) where one would stand when waiting for the belt to slow/stop.

Here is a pic of the design. I've made a smaller model that can run 2 buckets and isn't near as sturdy as my final design.

[Edited on 7-25-2018 by RogueRose]

|

|

|

CouchHatter

Hazard to Others

Posts: 146

Registered: 28-10-2017

Location: yes

Member Is Offline

|

|

That looks like it can handle a LOT of media!

If you can get ahold of paint or pickle buckets, they're a lot thicker than the hardware store brands.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by CouchHatter  | That looks like it can handle a LOT of media!

If you can get ahold of paint or pickle buckets, they're a lot thicker than the hardware store brands. |

I don't know about pickle ones but I have some that coconut oil came in and it is very thick (maybe 120 mil vs 70 mil standard).

I didn't include the way to modify it so it can handle smaller bottles as well, like 1 gal bottles (ones maple syrup comes in is very thick walled).

I had build a couple mills and they were a PITA to change sizes and didn't work well with mixing sizes and having the motor be one speed, unless I

worked out a gear ratio. With this, I can put a pulley on the axel that connects the 8" wheels to turn the gallon jugs at a different speed. and

when it isn't being used it stands up in the corner with the treadmill (which collapses as well). It was free so I thought I'd give it a try.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

I just found this seller on ebay that has some REALLY good prices on steel balls from carbon steel, chrome, stainless, etc in any size you might

realistically want in quantities from 10 to 10,000

https://www.ebay.com/str/BC-Precision/Slingshot-Ammo/_i.html?_storecat=745152719

I'm torn between getting steel balls or ordering aluminum oxide or Al2O3/ZrO balls or rods from china. The latter won't spark if I'm doing things

that are volitile, but you never know what you gonna get ordering from alibaba.

|

|

|

Deathunter88

National Hazard

Posts: 508

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

For non-sparking you really want to be using lead media, not ceramic.

|

|

|

Loptr

International Hazard

Posts: 1347

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

Your arrows are going the wrong way.

"Question everything generally thought to be obvious." - Dieter Rams

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

You won't believe how many times I switched the arrows thinking it was one way, then the other. But I am correct that each barrel will roll the

opposite way (when they are on the same drive wheel), correct?

Well if lead is best, I have plenty of it but I just need to make some moulds. I do have a couple 1.5" thick Al blocks (3" x 10" x 1.5") but IDK the

best way to drill a spherical hole. I think aga did something awhile back with a washer welded onto a bolt or something, but I fear I will have less

success, though I do have a drill press now instead of a hand drill, so that should help.

|

|

|

Loptr

International Hazard

Posts: 1347

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

In order for the arrows to go the opposite direction, something would have to be squeezing between the two buckets going up, otherwise, assuming the

tread is coming from the right, the left bucket would roll clockwise, and the right bucket would go counter clockwise.

[Edited on 26-7-2018 by Loptr]

"Question everything generally thought to be obvious." - Dieter Rams

|

|

|