| Pages:

1

..

34

35

36

37

38

..

68 |

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Nice work. I do second Vlads suggestion of increasing the standoff, also it would be interesting to place soft targets in between at intervals to see

how the slug deforms during flight. Not sure if it's possible as the targets would need to withstand the blast without representing any noticeable

resistance to the slug, but it would be fun to try it.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Cu tube

Interesting idea, option. But: the shock wave has tremendous power. At a distance of 30 cm fractured (broken) 20 mm thick oak plank. When 10 g ETN. It

is my experience. Produce suitable partitions will be challenging. At a distance of 10 cm from the epicenter almost impossible. I think in amateur

conditions. In expensive (equipped) laboratory is easier to use a high speed camera. I recommend using a 1 mm thick copper plate. From the Cu tube.

This material is very suitable for directional charges. Annealed copper. Much better than 0.55 mm Cu. Tested. Excellent results for diameter 20-30 mm

... ...LL ...LL

|

|

|

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I know it's a long shot, and a heavy blast shield with a hole barely large enough for the projectile would be required for sure. But it would provide

useful data with little investment...

[Edited on 26-12-14 by Fulmen]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

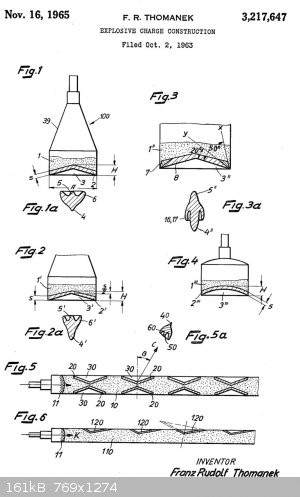

Thanks everyone. I found a few things this morning which are informative I think.

From, "Standoff sensor antennae for munitions having explosively formed penetrators

US 5070786 A" the following can be read. I have also attached the patent.

"Those skilled in the art recognize that certain anti armor munitions employing EFP warheads, such as a Miznay-Shardin type of warhead, generally

require five to six charge diameters of standoff distance from armor surfaces at the time of detonation to properly form the penetrating, molten metal

jet used to defeat the armored target."

Except for the fact that EFPs don't form a jet the way conical shaped charge penetrators do, from what I understand, this seems reasonable.

Attachment: US5070786 Standoff Sensor Antennae For Munitions Having EFPs.pdf (454kB)

This file has been downloaded 519 times

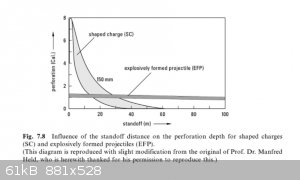

I also found a nice graph in, "Chemistry of High-Energy Materials" By Thomas M. Klapötke, which shows how, unlike conical shaped charges, EFPs can be

used effectively at very long standoffs (even over 100m in many cases for practical devices).

The following is a copy/paste from one of the Wiki pages on shaped charges,

"Misznay-Schardin effect

As opposed to the cylinder/cone of the Munroe effect, which produces a narrow jet, the critical aspects of this weapon are a relatively large sheet of

explosive, with a sturdy metal backing plate. The basic principle is that the main force of the explosion is directed away from the backing plate. The

explosive wave, in general, is broader than a Munroe effect, producing a more-or-less flat wave rather than a jet.

If objects of considerable mass, but still less dense that the backing plate, are in front of the "open" side of the explosive, they will be propelled

forward by the expanding shock wave. This is the principle in the U.S. M18A1 Claymore mine, which is a book-sized device, with a mildly concave

backing plate, a sheet of explosive over it, and metal fragments on the surface of the explosive. Detonating the charge sends a fan-shaped blast and

fragmentation pattern in the direction of the target.

Since the wave is straight or diverging, there is no critical standoff requirement as with the converging Munroe effect."

Well, I definitely didn't have a "sturdy metal backing plate", hell that wooden disc/bushing I was using to plug the end of the charge and align the

blasting cap wasn't even glued in place. Also notice that there is not nearly the same need for precise control of standoff distance with an EFP, at

least once a bare minimum is obtained.

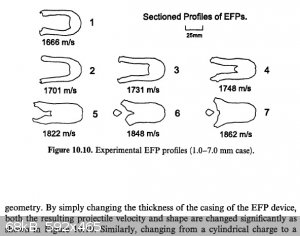

Here is something interesting regarding the effects of casing thickness of cylindrical EFP charges on performance, taken from, "Explosive Effects and

Applications", edited by Jonas A. Zukas, William Walters, William P. Walters.

[Edited on 26-12-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

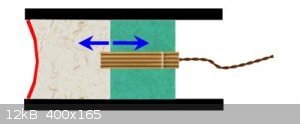

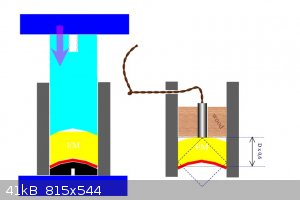

counterweight

It occurred to me to use less plasticizer. Around 5-10% only. For ETN (PETN) can be pressed. In the solid pipe. Copper or steel pipe. I estimate the

pressure of 300 kg (20 mm dia). With hardwood logs. Further: Other explosives could make a counterweight. (green in the pic.) It may be less

efficient. Around 3-4000mps. It's just a suggestion.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Yeah, that was one of my next moves. I was going to try only 5% inerts, which should be fine since the explosive doesn't have to be a mouldable

plastic explosive like Semtex. I noticed that Markx uses a very small amount of inerts for his shaped charge tests also. I may try casting some

ETN:TNT tetrolite into one as well.

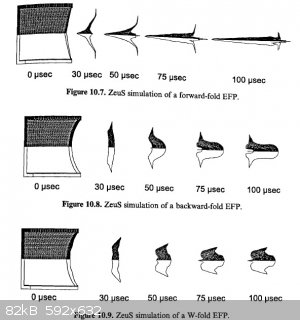

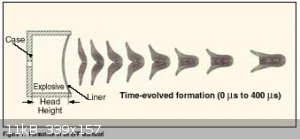

Examining the standoff issue a little more. The following jpg image is of a page from, "Explosive Effects and Applications", edited by Jonas A. Zukas,

William Walters, William P. Walters. It looks as though full slug formation happens in about 100 microseconds. If we assume a slug velocity of 1500m/s

that would mean that the slug is fully formed in 15cm (if I did that right). Yeah, a little more standoff than the 10cm I used probably wouldn't hurt.

[Edited on 26-12-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Ah, yes....good to see the thread awaken again. And also delighted to see someone trying out the things I've been lacking time for lately

I see from the EFP test pictures of Hennig that the standoff is likely too small...seems that the coin hit the witness plate flat on without having

time to form into a more ergonomic projectile. I guess there is ample room for experimentation with the standoff. I would be very surprised if the

optimum lies in the the range of 10 CD with such small designs. It may hold true to bigger charges, but since the forces at play do not scale well I'm

more inclined to thinking that the optimum may lie well beyond the 10 CD limit here....

Waiting with great anticipation

Exact science is a figment of imagination.......

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I think you and VladimirLem, LL, and Fulmen are most likely right. Your point about things not scaling well could be more true than I originally

thought. I don't imagine that 50cm would be needed, but I might try doubling it and going with 20cm for the next test. Also, according to the

"Explosive Effects and Applications" and others, slug formation would be faster and more complete, and slug velocity would be higher, with a strong

dense casing. A steel back plate and casing is really the way to go, but I would prefer not to go that route for safety reasons. A test could be

performed though, if steps were taken to ensure safety.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Hennig Brand  | | I think you and VladimirLem, LL, and Fulmen are most likely right. Your point about things not scaling well could be more true than I originally

thought. I don't imagine that 50cm would be needed, but I might try doubling it and going with 20cm for the next test. Also, according to the

"Explosive Effects and Applications" and others, slug formation would be faster and more complete, and slug velocity would be higher, with a strong

dense casing. A steel back plate and casing is really the way to go, but I would prefer not to go that route for safety reasons. A test could be

performed though, if steps were taken to ensure safety. |

True that, I too would keep the upgrades on confinement as a last resort if all else has failed, but judging from how well small shaped charges of

mine have worked with harmless plastic cases I foresee no immediate need to escalate into the ever so dangerous metallic confinement. Keeping a thick

steel back plate propelled by HE from not inflicting terrible collateral is a serious task and if ever attempted, should deserve full attention and

commitment on the side of safety precautions.

Exact science is a figment of imagination.......

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

It seems from reading that a sturdy casing, in particular a sturdy dense back plate, is much more important in the case of EFPs. From the wiki quote

above,

"As opposed to the cylinder/cone of the Munroe effect, which produces a narrow jet, the critical aspects of this weapon are a relatively large sheet

of explosive, with a sturdy metal backing plate. The basic principle is that the main force of the explosion is directed away from the backing plate.

The explosive wave, in general, is broader than a Munroe effect, producing a more-or-less flat wave rather than a jet."

This doesn't mean that reasonable results can't be obtained with more user friendly casing materials however.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Always beware of taking Wikipedia quotes too literally, even at the best of times. Even people who should be knowledgeable about explosives and

related matters so often perpetuate the erroneous myths around shaped charges ("jet is liquid", "jet melts the target", etc.).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Good advice, and patents the same way. Was there anything in particular that stood out as being in error in the particular section quoted? I think the

patent I posted is definitely inaccurate on at least a couple of points. Both Wikipedia articles and patents generally have a lot of fairly accurate

information, but there can be found a lot of errors in both from time to time.

Wikipedia is not the most high quality reference, but it is often a good starting point. The Wiki articles often have good references in them as well.

More tests to follow, just drying some ETN at the moment.

[Edited on 27-12-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

plate

This is it, what I wrote. When the diameter 1.8 cm, will cause strong nuclear forces and constraints. The test must be done in a polystyrene box.

Buried in the sand. Especially, if will be use supporting plate. Maybe 2cm thick the lead plate?... ..LL ..LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Interesting idea you have there, LL.

Found another picture which would indicate that more standoff is definitely needed for proper slug formation. This one comes from the "USAF Research

Laboratory". It may be hard to get a definitive answer it seems.

So for 400 microseconds and an assumed 1500m/s:

Distance required for proper slug formation = 0.0004s * 1500m/s * 100cm/m = 60cm

Well hell, I might as well try 50cm or more standoff; except for a little more difficulty in aiming the device this is still very close range for this

type of shaped charge.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

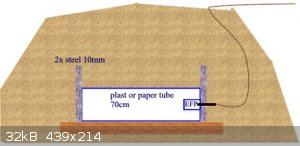

pit

My opinion, I prefer a bit more. Maybe 80 cm. Still, it must be in the sand. Or in the snow. Snow is nonsense. It must be a pit 90x30cm. Depth 40-50

cm....LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

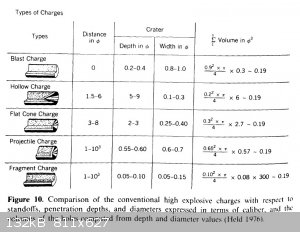

Found something very interesting in, "Fundamentals of Shaped Charges", by Walters and Zukas.

"In general, the hole volume remains approximately constant for various shaped charges of the same diameter and at a given standoff. For example, for

shaped charges of various liner materials and various wall thicknesses, the penetration depth varies, but the hole diameter also varies such that the

hole volume is practically unchanged (Klamer 1964). This is because the hole volume varies directly with specific explosive energy. Thus, for a fixed

explosive energy, the hole volume is fixed, and the hole depth times the hole area remains approximately constant.

Further, Held (1976) observed that the hole volume remains approximately constant for a variety of explosive devices. In figure 10, several

conventional high explosive charges are compared with respect to standoffs, penetration depths, and crater diameters, all expressed in calibers."

It is a trade-off between hole depth and hole width, since hole volume remains fairly constant, so it really just depends on what one is trying to

achieve.

Attached below is the associated table taken from the text. The 0.19D^3 value for volume, in the table, is particular to those sets of experiments and

is not a universal constant.

[Edited on 28-12-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I had my first attempt at an EFP charge today using Hennig brands coin method of forming a liner from a coin in a vice with a ball hammer. I used an

Australian 20 cent piece which are 2.85cm in diameter and 2.5mm thick and are 75% Copper which is a good liner material the remaining 25% being

Nickel.

The charge casing was a 4 cm long tough cardboard tube with 2.85cm internal diameter and 3.2mm outside diameter.

The actual charge was 25 grams of hand pressed PETN and the target was a 1/4 inch steel girder/plate offcut from a building site.

The standoff used was 50cm which I realize now is probably much too short.

The plate was only badly dented/dimpled where it was hit. The dimple is 3.5mm deep and 2 cm in diameter which leads me to believe that the standoff

wasn't far enough as it seems the coin has inverted but only partially formed a slug as the dent diameter is only .85cm smaller than the original coin

size (second picture).

I think I will double the standoff distance next time and use the same plate to see how much of a difference I get and whether it will penetrate the

whole plate thickness.

Would Pentolite be better suited for a charge like this or should I stick with the straight PETN?

[Edited on 28-12-2014 by greenlight]

[Edited on 28-12-2014 by greenlight]

[Edited on 28-12-2014 by greenlight]

[Edited on 28-12-2014 by greenlight]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

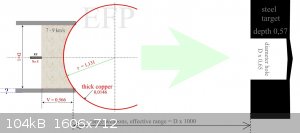

EFP

Liner 2.5 fat? 28mm diameter? This is wrong. Thickness should be 28,5x 0.0146 = 0.41 mm thick Cu liner. Maybe one millimeter. Maximum. The slug will

not shape. 2.5 mm is too much. It is a waste of PETN. That there could be a steel matrix. Or stone. This is not EFP. In one book is described liner

for diameter 68 mm. Copper is 1.8 to 2.2 mm thick. Here is a modified scheme... ...LL For dia. 28,5x0,57 is target thick 16mm. 75%= 12mm steel through. For dia. 18mm x 75% = 8mm tuti durch in durch. ...LL For dia. 28,5x0,57 is target thick 16mm. 75%= 12mm steel through. For dia. 18mm x 75% = 8mm tuti durch in durch.

[Edited on 28-12-2014 by Laboratory of Liptakov]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Straight PETN, of the same density, would accelerate the metal more for a given charge weight, but it is much more difficult to work with because it

must be pressed which can be difficult to do properly, especially for the amateur, requiring more equipment and skill. The Gurney velocity of cast

50/50 pentolite is reasonably close to midway between that of TNT (1.63g/cc) and PETN (1.76g/cc). The Gurney velocity value quantifies how effective a

particular explosive is at accelerating metal (thanks go to Dany for explaining this to me). Pentolite is an extremely convenient material for shaped

charge filling, however, allowing maximum densities and great uniformity to be achieved with relative ease.

If your charge was only hand pressed, the density would be quite low producing much lower performance than if it was well pressed using some sort of

mechanical advantage or machine.

The thickness of your liner seems high too, but I need to do a little research to know for sure. Soft steel is, by the way, a fairly good liner

material; not quite up to copper, but still quite good.

edit:

Here is a patent which specifies liner thicknesses of 5-10% of the charge diameter. Perhaps your liner isn't too thick after all.

Attachment: Explosive Charge Construction (EFP) US3217647.pdf (443kB)

This file has been downloaded 594 times

[Edited on 28-12-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

US 3 217 647

Patent from Thomanek US 3 217 647

It is very interesting. He says something else. Liner thick 5% from diameter. The bow depth 10 to 30% from diameter. Therefore 20%. For diameter 28 mm

is depth = 5.6 mm. And thick liner = 1.4 mm. I enclose a picture of a patent.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The patent specified 5-10% of the diameter for the thickness, so Greenlight was a little below the upper limit, but really at the scale he was working

at it probably is too thick. The optimal platter thickness really has a lot to do with how thick and how powerful the layer of explosive is as well.

The hand pressed (low density) PETN is the biggest problem I would say.

Good point LL, I just measured one of my bent dimes with the depth gauge on a Vernier Caliper and the bow depth was about 11% of the diameter, so it

is at the lower end of the 10-30% range. I guess I could give them a little more curve then.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks for the info guys, should I keep the coin the same thickness and put a larger thicker charge behind it using better a explosive composition or

should I try to mill the coin thickness down to something like LL stated (1.4mm).

Would I get better results using a thicker more powerful charge of pentolite or is it not worth it?

[Edited on 29-12-2014 by greenlight]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

lens liner

It should be observed tolerance. For further experiments I recommend 20 mm diameter and 1 mm thick sheet. Copper or soft steel. Steel suggest anneal

red glow. Then processed into the shape of the lens depth 4 mm. And then again anneal when steel will be used. Best to use a cast ETN. Height cylinder

EM= 12 - 20mm. For PETN: Press on the highest possible density. With 5% plastificator. Cylinder height maximum 20mm.

LL

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

pressing

To be a good result, it is necessary to use a steel tools production liner and the same steel tools for stamping. The pipe may be thick plastic.

Pressing connect liner, pipe and EM. For D = 20 mm estimate the pressing pressure of 3 tons. D x 0,6 for cilinder is minimal. I thing... ...LL ...LL

[Edited on 29-12-2014 by Laboratory of Liptakov]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

liner EFP

This post is designed especially for today's youth. Only by using hand drills can produce tools for making the liner. Without a lathe. The image is a

1000 words. The diameter is 22 mm liner from 1 mm Cu. Or 1 mm mild steel. It's all work for one afternoon. Any questions?... ...LL ...LL

|

|

|

| Pages:

1

..

34

35

36

37

38

..

68 |