| Pages:

1

..

35

36

37

38

39

..

68 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Good work, LL. Nice pictures. There are a lot of things that can be done reasonably well with a drill that would normally be done with a lathe. I have

used a drill in the past to turn a piece of small round stock down, for instance, and other small tasks as well.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

EFP

Thank you, here's left: Liner diameter Cu 28/30,5 mm and plast container for pressing 30,5x45 hi 42. Plast is a connector for water pipes.

Furthermore, the assembly for EFP caliber 22 mm. Plastic (24,2/35 hi 40) becomes integral part of EFP. This happens pressing pressure ... ...LL ...LL

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

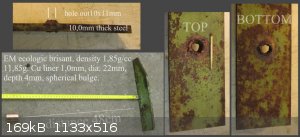

EFP 22

Ladies and gentlemen, here it is. The first attempt failed, but the second attempt, yes. It really works. Construction steel is destroyed by other

experiments, but I finally hit that target. For 22 mm diameter x 0.56 can shoot through steel 12.3 mm. Here was using 8mm. Yes, it's small, but it's

just research... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Nice results you have there. What was the explosive you used? Also, the thickness of your liner was only 0.56mm right? Seems very thin, at only about

2.5% of the diameter, compared to some of the patent and explosive literature suggestions, but you can't argue with results.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

EFP

This is a misunderstanding. Liner is 1 mm thick soft copper. It is on the picture. EM is an ecological high explosive. VoD about 7450 m / s. EM is the

official meeting as a patent application. The composition will not be published. I'm sorry. But that's okay, mainly that it works... ...LL ...LL

[Edited on 2-1-2015 by Laboratory of Liptakov]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

EFP

Here is a successful attempt. Overcome 10 mm mild steel... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

22.3mm Diameter Liner EFP Experiment

A Canadian quarter was used this time. A ball peen hammer, vise and an appropriately sized nut were used again to form the curved dish.

EFP Liner Specifics:

Diameter: 22.3mm

Depth: ~4mm

Thickness: 1.58mm

Mass: 4.4g

Composition of coin/liner (according to Wikipedia):

94% steel

3.8% Cu

2.2% Ni plating

Stand-off:

30cm

Explosive Used:

14.2g of 80% ETN Plastic Explosive

80% ETN / 10% Polybutene / 10% Paraffinic mineral oil

Initiation:

7.6mm aluminum casing

0.8g PETN

0.3g lead azide

bit of basic lead picrate flash igniter

Core burning safety fuse

Casing:

~0.5mm thick side wall polypropylene pill bottle

Backing Plate:

~15mm thick disc/slice of softwood broom handle

Target:

3/8 inch (~9.5mm) mild steel plate

Penetration:

>8mm

The slug did not go completely through, but it came very close. If the explosive had been 90-95% ETN instead of 80%, or if there had been stronger

confinement and a stronger/denser backing plate, the slug would likely have easily penetrated the 3/8" target. More standoff might have resulted in

complete penetration, but then the hole would have been smaller in diameter as well. Using a copper liner would have resulted in a certain increase in

performance as well.

The 80% ETN plastic explosive was used because it has very desirable handling properties, and although not an optimized explosive for shaped charge

applications it is a good general purpose explosive.

The curve of the liner was not perfectly symmetrical (because the press wasn't lined up right during pressing), the liner was not perfectly centered

in the casing and the blasting cap was not centered properly, all because of being in a rush. The charge performed reasonably well, but it is obvious

that for best results things should be as symmetrical and well centered as possible.

Here are a few pictures and also a few stills from a video taken of the blast:

Pre-blast set-up

Stills

Results: (the slug was easily remove with fingers from the target)

[Edited on 4-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Interesting work, but somewhat unfulfilling by your own admissions of substandard workmanship (no offense intended). A more detailed pic of the slug

would be quite interesting as the great Dr. Liptakov did not recover his slug. I would suggest a soft backstop to collect the slug in future

experiments, all details matter.

Another interesting idea would be to use something like a plated liner, if done correctly you could maybe get some data about the forming process by

cutting it in half.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

If those free to experiment with such technologies could fire the EFP into a sufficiently deep container of water (swimming pool? Series of garbage

bags filled with water???) and then recover the projectile. To see somewhat more clearly what the projectile shape was after explosive forming?

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Metacelsus

International Hazard

Posts: 2531

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

Would the projectile survive impact with water? I guess the experimenter will have to find out.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fulmen  | Interesting work, but somewhat unfulfilling by your own admissions of substandard workmanship (no offense intended). A more detailed pic of the slug

would be quite interesting as the great Dr. Liptakov did not recover his slug. I would suggest a soft backstop to collect the slug in future

experiments, all details matter.

Another interesting idea would be to use something like a plated liner, if done correctly you could maybe get some data about the forming process by

cutting it in half. |

Ha, you must think this is a contest of the type where the guy with the most inches wins. I actually thought it was a fairly successful test. I simply

pointed out a few things that I thought were significant and might be useful to others trying to make their own charges. Penetration depth is not

necessarily the be all and end all of EFPs. Yes, it is normally how Monroe effect conical shaped charges are judged, but there are other aspects which

are important with EFPs. The BEST EFP might be different from situation to situation. Yes, using a bent quarter in a plastic pill

bottle casing is not cutting edge technology.

I imagine most would break up or at least be damaged since they are traveling at the speed of a very high powered rifle bullet. I remember seeing the

episode of Mythbusters years ago where they were trying to determine if hiding under water would save you from a bullet. I found the following summary

of that episode here:

http://mythbustersresults.com/episode34

"Hiding underwater can stop bullets from hitting you.

partly confirmed

All supersonic bullets (up to .50-caliber) disintegrated in less than 3 feet (90 cm) of water, but slower velocity bullets, like pistol rounds, need

up to 8 feet (2.4 metres) of water to slow to non-lethal speeds. Shotgun slugs require even more depth (the exact depth couldn’t be determined

because their one test broke the rig). However, as most water-bound shots are fired from an angle, less actual depth is needed to create the necessary

separation."

[Edited on 4-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

I have run plenty of Copper & Lead projectiles into water, at speeds up to 1,100 m/sec. Yes, they deform. A projectile with a round nosed shape

such as these would deform less, compared to one with an open, cup shaped nose (expanding copper jacketed bullet). Much less than on impacting an 8mm

thick piece of mild steel...

http://youtu.be/QfDoQwIAaXg

This high speed video is instructive, unfortunately the maker did not list velocities and target materials.

[Edited on 4-1-2015 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

You could be right, pretty much the only exposure I have had to this is that Mythbusters episode. There is a lot of discussion on the net in various

places about the MB's episode and what actually happens when a bullet hits water. A common assertion, which makes sense I think, is that when the

bullet hits water at an angle (like on the MB show), that the side hitting the water first undergoes extreme deceleration causing huge shear forces

which can tear the bullet apart. Hitting the water straight on should reduce the shear forces a lot. Also, more blunt nosed projectiles are apparently

more immune to being torn apart when entering water at high velocity, as Bert said.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

That's life, son

I honestly wasn't trying to belittle your work, recovery of the slug was a huge plus (more pics?). But with all such charges the performance should be

closely tied to the accuracy it is made to, although EFPs might be less sensitive than SC. In that sense this WAS a huge success as you got quite

decent performance with a fairly crude setup.

A repeat with a more (or even less) accurate setup would provide interesting data on this.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Fair enough, some people do seem to feel the need to bring out their rulers a lot more than others though.

Oftentimes things that were measured shouldn't have been, and things that should have been were not.

Sometimes I may be too quick to react to people's comments.

Anyway, I took a depth gauge and more carefully measured the penetration depth this morning and when excluding the bulged up steel around the

periphery of the hole penetration is about 7.2mm not 8mm. The diameter is however ca. 16mm. Assuming a perfectly cylindrical hole, the volume can be

calculated as follows:

V = pi/4 * D^2 * depth

V = 3.14159/4 * (1.6cm)^2 * 0.72cm

V = 1.45cm^3

The volume is quite high and if desired a lot more penetration could be obtained by creating a slug that was smaller in diameter and had more length.

At the small scales of our tests, the ease of slug formation and performance increase that comes from using a copper liner over a steel liner could

very well be even more significant than it is with larger EFPs.

Attached below are a few pictures of the slug. The slug has an uneven distribution of mass which is characteristic of when there is asymmetry in the

liner and/or charge or uneven confinement, etc.

Mass of unaltered quarter: 4.50g (Wiki gave 4.4g, which is the value quoted above)

Mass of recovered slug: 3.85g (0.65g of material is missing)

[Edited on 4-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

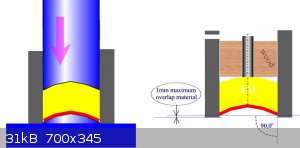

EFP 22

On the overall, final performance thus affects everything. My assembly was buried in the sand. Therefore, performance is noticeably larger. Also Cu

liner is important. Henning work I can really appreciate. It's evolution, it is challenging. It's dangerous. It's a heroic job. It's like working for

Moss.. Flying slug must be made exactly. Established exactly in the package. On the tenth of a millimeter. You need to use special forms, steel (or

duraluminum) products, tools. For the energetic material to be pressing. No need 20% inerts. ETN can be clean. Because itself is like wax. PETN about

maybe 5% plasticizer, I do not know, I've never seen PETN. Great Dr. Liptakov... not use the nitro or nitroesters. But it is not so much important. What is important is precision production, I think. Precise positioning and

centering of the detonator. Tolerance estimated at a maximum 0.5 mm from the exact center. not use the nitro or nitroesters. But it is not so much important. What is important is precision production, I think. Precise positioning and

centering of the detonator. Tolerance estimated at a maximum 0.5 mm from the exact center.

The overlap any material package must be zero. Max 1 mm... ...Dr. Liptakov, Tel

Aviv ...Dr. Liptakov, Tel

Aviv

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thanks for the kind words LL, but performance is only larger if you measure it in terms of penetration. The volume of the hole you produced in your

last test was about 0.95cm^3, while mine was about 1.45cm^3. So actually my charge did far more damage to the target. We don't know exactly how much

more than 0.95cm^3 your charge was capable of, however, since it penetrated right through.

Ok, I think I feel my ego kicking in.

I think my next charge will have a steel casing, thick steel backing plate and a copper liner. Parts will be made to high precision and possibly also

an upgrade to an explosive with a higher Gurney velocity value. If it is inches you want, it is inches you will get.

Really though, shouldn't we just go back to making really deep pin holes with conical shaped charges if depth is the only important thing?

I personally have found that PETN is easier to press to a dense cohesive mass than ETN is. I also noticed that a plastic explosive is much easier to

load into a shaped charge at high density and with good uniformity than a crystalline or granular explosive is.

[Edited on 4-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

A mile wide and inch deep, or an inch wide and a mile deep?

How about trying for a symmetrical dispersion of multiple, precisely formed fragments derived from a single liner, once you've optimized performance

of a single projectile?

Wire grid over the liner, precision shaping of liner & forming/propelling charge, multiple initiation points... So many possibilities.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

That's the spirit, Hennig. You are of course right in that there are more to this than penetration, if it's diameter you're looking for then by all

means go for that.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thanks, I feel a little more spirited lately.

Well, both are important, of course it really does depend on application. Even though the volume of the hole produced in my test was high, I would

like more penetration and there are several ways of getting it. One of the easiest ways is to simply increase the size of the charge, which would

increase penetration depth as well as hole diameter. If there is a specific target that needs to be completely penetrated to do any real damage, and

it is X inches thick, then of course the charge must be able to penetrate at least that thickness.

Bert, there are indeed a lot of possibilities. I find these explosively formed penetrators very interesting and fun to work with.

[Edited on 4-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

12mm

Blade diameter 22.3 (x0,56) = 12.48 mm, steel Through the target. This means at least 10 mm passed through. Also: In 1990, EM was Oktol, liner from

Tantalum was reached aperture diameter of 1.2 x D. (EFP course) ...I slowly am going to target steel 12 mm thick... And I have not even PETN. I do not even ETN. Maybe that detonate only flash No.9.

And to light a cigar. Also shooting at a greater distance ... And I have not even PETN. I do not even ETN. Maybe that detonate only flash No.9.

And to light a cigar. Also shooting at a greater distance ... ...LL ...LL

[Edited on 4-1-2015 by Laboratory of Liptakov]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That 0.56D factor you are using is a rule of thumb and actual results will depend on many things. Heavy/dense confinement and backing plate, such as a

steel backing plate and steel casing, could greatly improve performance, especially with a small scale device. Heavy steel confinement is often not

used in practise, from what I understand, because the weight increase would not be worth the performance increase and the danger to those using the

device would be much greater also. I expect a significant improvement in performance by simply upgrading the casing and backing plate, when working at

scales as small as I am currently.

You haven't stated what explosive was used in your tests so I don't know what was used. I assume the detonation velocity is at least 4500m/s because

much below that the EFP effect gets very poor from what I have read. Everything I have is homemade with the exception of the fuse I guess, but I can

make that as well if I had to.

edit:

Ok, I see where you said detonation velocity is 7450m/s.

[Edited on 5-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Hennig, perhaps you could try the test with much larger standoff before the metallic confinement upgrade....say in the order of 70cm to even 1m.

Judging from the impact crater it still seems to me that the slug formation is incomplete and partial. Since you have the means to test without

burying the setup it might be quite easy to rig up that experiment and compare the craters. Maybe it's just the formation stage that is limited by

unscalable effects in small settings. Just my 2 cents

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1335

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

capturing

If I had the opportunity to shoot freely, open space, I will shoot at 70 cm. For dia. 20-25 mm. Bert: plastic garbage bag, it is a very good idea.

(ingeniously simple) Ordered bags behind. The first bag may be no water, I think. I suggest wood shavings. Not sawdust. The first bag may be

polystyrene beads. It is sold in building. The second bag (width, depth 50 cm for alls), I suggest mineral wool (building). 3. sack of wool as well.

Fourth bag of water. A total of 2 meters. 1. bag distance 100cm. As ballistic chamber. Capturing EFP projectile is a very interesting idea ... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I actually planned on using 50cm+ as the standoff, but when I got to the site and was setting up I got worried that I would miss the target so I went

with only 30cm. Not as easy and cheap to reload this gun as it is to reload a .22 cal for instance.

More standoff should give more penetration you are right (smaller diameter, longer, slug). There was also very little confinement in my last test.

More confinement does give better slug formation and higher slug velocities according to, "Explosive Effects and Applications". I posted a diagram

from the text a page back in this thread showing slug formation with different amounts of confinement.

edit:

Made a few copper liners today. A 3lb piece of scrap copper pipe, 3 inch diameter, 1-1.2mm wall thickness was used as the source of copper. A

hydraulic press and homemade cutter/punch were used to cut out copper discs and then they were formed by pressing between a ball peen hammer and steel

nut the same way the coins were shaped. Some dies for pressing should be made, something like LL did, to ensure consistent symmetrical liners (I may

make a set soon). I am going to do a test the same as the last test except that a copper liner will be used. The thickness of the copper liners is

also a bit less which is likely a good thing.

[Edited on 5-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

| Pages:

1

..

35

36

37

38

39

..

68 |