nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Using reflux condenser in a distillation column?

I am researching alcohol stills so that I can translate any of the design features into a glassware setup to improve water-ethanol separation.

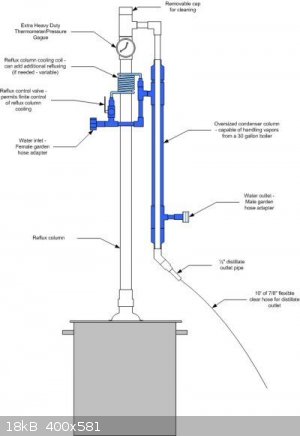

I've came across an interesting design used in many so called "reflux stills". These usually employ a packed column but some even have an additional

feature on top of the column they call "precondenser". This is simply a spiral condenser with precisely controlled water flow (the spiral goes from

outside of the column but I guess a Graham-type condenser might be more effective).

I watched several videos about using reflux stills and people said "we know from engineering" that if water temperature coming off the precondenser is

"just right" (60-65 °C), the vapour temperature at the head "must be perfect" and need not to be measured.

I however have not found the theory or reasons why that should be. Of course, the precondenser improved reflux ratio, but how is this superior over

taller column?

I guess the alcohol stills don't have precise heat input control as lab heaters provide (hotplates, heating mantles), thus they have to use active

cooling with precise flow control (using a needle valve) to counterbalance the extra heating.

In other words, the reflux stills seem to care less about the heat input as the cooling in the column is controlled, not the heat.

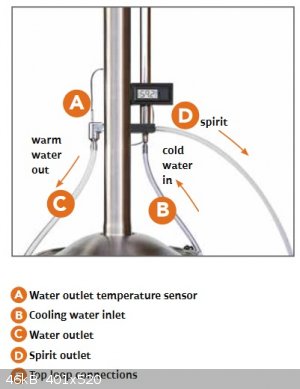

One such device is called "Turbo 500" and is quite popular among brewers. Some claim to be able to produce almost azeotropic ethanol from just a

single run (going from about 20% ABV mash).

This is very interesting and I think this can be applied to glassware-type fractional distillation setup more common in labs.

The column will be insulated, of course, but a short reflux condenser might be added on top of the fractionating column.

The collant water might flow through a condenser, then through precondenser (the reflux column bit). Finally the output temperature will be measured

with a simple thermocouple probe injected in the tubing.

Unfortunately, the fractional distillation texts I've read never mention something like adding reflux to the column as they are more concerned about

column insulation and heat control.

Could McCabe-Thiele model be applied to such a setup? Does the precondenser behave as a theoretical plate?

[Edited on 2-12-2018 by nimgoldman]

|

|

|

Sulaiman

International Hazard

Posts: 3558

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I am very slowly making a similar still.

https://www.sciencemadness.org/whisper/viewthread.php?tid=69...

although the design has changed slightly as I've learned a little more since then,

My still is far from ready but I have two observations;

there are many 'details' not covered in simple texts,

so if possible learn by using a tested/published setup.

Most is covered in Vogel's Practical Organic Chemistry which is in the library

http://library.sciencemadness.org/library/index.html

In this case the challenge is to maintain a constant reflux while allowing just a small flow through to the product condenser.

Not too difficult to monitor and periodically adjust,

not so easy for un-attended operation - which is what I want.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

If you want unattended operation, a magnetic takeoff may be the way to go.

They remove a fixed proportion of the reflux rather than just tapping stuff off at a more or less constant rate like other PTO heads.

I have one sitting around somewhere.

A big vacuum jacketed silvered 45/50 jointed thing about the size of a 2 liter bottle with a pivoted funnel controlled by a magnet inside to redirect

the flow based on a timer.

(I need to get an electro-magnet and control circuit cobbled together before I can try it out, but I've heard good things.)

These are usually expensive, and the little ones (24/40 and smaller) are hard to find used, but converting one of those PTO heads with the vertical

cold finger condenser to magnetic control is probably practical with a Dimroth condenser, some PTFE tape, a small stir bar and a little creativity.

On the idea of controlling the reflux with an adjustable condenser, Chemetix has experience with building and using such stills on a lab scale, and he

gets some very impressive reflux ratios.

There are photos posted somewhere on this board recently; it's an interesting set-up, and some pretty sweet looking glass-work too.

|

|

|

Sulaiman

International Hazard

Posts: 3558

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

One day I hope to buy or make a partial take off head, definitely the sensible approach,

but for now I will doggedly stick to my present approach - until I give up.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

XeonTheMGPony

International Hazard

Posts: 1636

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

better design uses a small coil just after the bottom of the reflux column, you set out going water to be at 81c, as this removes allot of the water

befor the vapors hit the main column.

And if you spent any time on your boiler you can maintain its temp pretty accurate as well.

https://cgproducts.johnsoncontrols.com/MET_PDF/125690.PDF

to control the thermostatic discharge of the condensing loop.

[Edited on 3-12-2018 by XeonTheMGPony]

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Some practical advice for novice distillers:

1) Do not overengineer your still. Keep it stupid simple. Having temperature control probes for feedback, automatic valves for reflux control and all

kinds of regulating mechanisms/cooling coils in strange locations on the device is usually going to make it very difficult to operate smoothly. And

seldom gives superior results. Unless you know very exactly what you are doing from the beginning on....and in that case you usually do as the first

two sentences at the beginning of my statement suggest

2) Stop trying to CONTROL the temperatures.....you do not need to force the temps. They are selfregulating according to boiling points of the

fractions in the respective region of the apparatus (boiler, column, head). Trying to control temperatures is going to force the apparatus out of the

operation mode where it is trying to do what it was designed to do best.

3) Forget about an unsupervised fully automatic approach as far as practical purposes are concerned in an amateur setting. It is a very bad idea! The

universe will find mystical ways to mess up your intricately designed operation. I guarantee that...

If you think you can design ways to counteract all of these dangers then bare in mind that with every countermeasure you add to your design at least

three unpredictable ways for the universe to bypass them are created. It is a lost cause.

4) Avert from using glass as the main constructional component in your design. It is only a matter of when it will break and not if....consider the

consequences that follow. An occasional sight glass is OK, but a transparent column, although visually appealing, is utterly impractical on setups

that scale a bit larger than a tabletop lab assembly.

5) In case a palatable product is the objective, the automatic separation of fractions according to feedback from thermometers is not a viable option.

Unless you have reliable 0,01C accuracy and active compensation against atmospheric pressure changes. Knowing your setup you could separate by volume,

but no two runs are the same.

As for the generic and in my opinion most practical setup: boiler at the bottom, condenser at the top, packed column in between. Energy pumped into

boiler is removed by the condenser at the top, condensed reflux flows down the packing, efficient separation happens, a small part from reflux flow is

taken off as product below the condenser at the top of column. No fancy controls, bells or whistles. Achieving azeoptropic product is no problem.

Exact science is a figment of imagination.......

|

|

|