| Pages:

1

2 |

k89

Harmless

Posts: 3

Registered: 1-8-2008

Member Is Offline

Mood: No Mood

|

|

Dry distillation of Copper Acetate

I read somewhere that some metal acetates like copper acetate,on dry distillation, give acetic acid.

I've dry distilled copper acetate (at 300 C) to get a greenish liquid.

It is probably an acid because it bubbles with potassium carbonate.

Iit smells nothing like acetic acid.

Why is it greenish?

I've done this experiment three times with similar results each time.

BTW,the copper acetate was made by precipitating copper hydroxide from copper sulphate using NaOH ,dissolving in excess of glacial acetic acid and

boiling off the excess acetic acid and water to get (dark green)copper acetate crystals

[Edited on 1-8-2008 by k89]

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

I'm assuming you washed the resulting sodium sulphate from the precipitate of copper hydroxide. Any 'left over' NaOH would need to be removed too.

Pardon me if this is a stupid question. Any left over sodium sulfate or hydroxide reacting to give sodium acetate would leave a water rich salt

behind, which may contain enough water to dissolve the copper acetate. Does a bit of the material color a clear flame yellow?

Have you weighed the materials you are using, and do the weights correspond to what you should get? How many moles of copper are you starting with,

and how many do you have at the end?

Anyway, a green liquid that contains copper at 300 C and doesn't decompose sounds interesting.

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Cu salts of aliphatic carboxylic acids - "soaps", including especially Cu naphthenate which is used as a wood preservative and is made by

precipitation from naphthenic acid (made from the naphtha fraction of petroleum distillates), answer to that description, being an intense green

color.

|

|

|

kclo4

National Hazard

Posts: 916

Registered: 11-12-2004

Location:

Member Is Offline

Mood: No Mood

|

|

The green is possibly, and sounds very likely that it is a contaminantion of some sort of copper salt coming over.

How did you distill it, would that be possible?

What color was the oxide left in the distillation flask? I wouldn't be to surprised if some acetic anhydride formed.

Could you perhaps tell us more about the physical properties of your distillate? I.e if it freezes easily or if it requires very low tempuratures, if

it mixes with water or forms two layers?

Thanks!

|

|

|

k89

Harmless

Posts: 3

Registered: 1-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Mr. Wizard

I'm assuming you washed the resulting sodium sulphate from the precipitate of copper hydroxide. |

Yes,I washed the hydroxide precipitate thrice with tap water.Isn't this enough to remove NaOH as well?

| Quote: |

Have you weighed the materials you are using, and do the weights correspond to what you should get? How many moles of copper are you starting with,

and how many do you have at the end?

|

No , I dont have any apparatus for taking weight measurements.Haven't done the flame test ,but I doubt that any sodium salts are present after the

washings.

| Quote: |

The green is possibly, and sounds very likely that it is a contaminantion of some sort of copper salt coming over.

|

With an excess of potassium carbonate the green liquid gives a bluish-green precipitate and turns colourless. (sorry I forgot to mention this earlier)

This indicates the presence of a copper salt.

I use a basic distillation setup - A conical flask sealed with a one hole cork.A long glass tube through the cork connected to the receiver.

There wont be any copper salt contamination unless a salt sublimes into the receiver.

But which copper salt is volatile enough to end up in the receiver?

I didnt use a condenser for this.The receiver was cooled by submerging it in a vessel containing cold water.This might explain why there were no

salt deposits anywhere.

The residue in the flask was reddish (Cu2O?)

I added water to the green liquid.Acetic anhydride should be hydrolysed to acetic acid.But the smell remained the same.

Also , I did not see two layers , so it is probably miscible with water.

I was working with very a low quantity of it in a test tube(approximately 5 ml)

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by k89

I use a basic distillation setup - A conical flask sealed with a one hole cork.A long glass tube through the cork connected to the receiver.

There wont be any copper salt contamination unless a salt sublimes into the receiver.

But which copper salt is volatile enough to end up in the receiver?

|

That's rather academic, because with that simple set-up some mechanical entrainment of tiny particles of the copper acetate by the evading distillate

is not unlikely to happen. No sublimation of a copper salt is thus needed for traces of copper to be found in the distillate.

To actually prove some copper compound or other has effectively distilled over (through evaporation, not entrainment) you would have to use a short

distillation column, like a Vigreux or something like that...

Was the Cu (II) acetate anhydrous or the monohydrate?

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by k89

| Quote: | Originally posted by Mr. Wizard

I'm assuming you washed the resulting sodium sulphate from the precipitate of copper hydroxide. |

Yes,I washed the hydroxide precipitate thrice with tap water.Isn't this enough to remove NaOH as well?

... |

Not always, many hydroxides and hydrated oxides really retain alkali hydroxides strongly. Plus tap water can introduce contaminates of its own.

Deionized or distilled water is your friend, at least until you've established a process's details after which you can try switching to tap water.

blogfast25 is correct that it is not unlikely that you had some mechanical carry-over of copper compounds. This is even more likely given you were

doing dry distillations, during which crystals of the substance being heated can decrepitate or otherwise fragment into fine particles. As you said

nothing about dehydrating the solid copper acetate, it most likely was the dihydrate, meaning that water would be boiling off during heating, most

certainly disrupting the physival structure.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

One way of 'washing' a fresh precipitate of Cu(OH)<sub>2</sub>.n H<sub>2</sub>O is to boil it: it loses its 'crystal water'

very quickly leaving you with a much smaller volume of black CuO (which also precipitates well, as it's quite dense). The blue Cu (II) 'hydroxide' is

incredibly voluminous and can create the illusion that the few traces that were carried over (assuming that is what happened) represent quite

a bit of copper.

|

|

|

k89

Harmless

Posts: 3

Registered: 1-8-2008

Member Is Offline

Mood: No Mood

|

|

The acetate was a dihydrate.

The color was probably caused by mechanical carry over of copper salts.

Thank you all for the help.

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

Copper Acetate (CuAc2) is a monohydrate salt (CH3COO)2Cu.H2O; MW: 199.5; Copper Content : 31.8 %.

CuAc2 has got relatively low solubility in water ( as compared to other metal acetates such as Manganese, Cobalt, Nickel etc.) IIRC it is about 6 %

(w/w) at room temperature. And yes, CuAc2 is votile enough to get carried over to distillate. Even a trace of CuAc2 in water / Acetic Acid / Acetic

Anhydride will impart distinct greenish colour to it

gsd

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

The Wiki method to copper acetate and distillation

I found photographing this extremely difficult. The colour changes didn't seem to show up very well on the camera and I've had to take over 200 photos

to find some that look right. Even then, they're not very good.

I don't know if this is the camera or some optical property of the salts. The camera is a Canon Z100fd. I absolutely hate the thing and am only using

it because the other one has sand in it. This one has a remarkable tendency to blur, produce images covered in noise, not focus or do weird things

with the colours anyway.

I decided to give the Wiki method a go as it says "Citation needed" over the method and someone is asking about it on the discussion

page.

I've been up since 6am yesterday, and it's now 7.30am the next day. I've just finished doing this and thought I'd upload the photos.

Some of you may enjoy this thread I found whilst searching around.

------------------------------------------------------------------------------------------

I weigh out some dry copper sulphate

I add to this the appropriate amount of glacial acid (acetic). The sulphate remains unchanged but becomes a paste. I begin dripping in 10% ammonia and

a vivid blue appears. This produces a lot of fuming and the solution warms up.

It's greener than that. I simply can't get the camera to show it. The mixture is now a slurry of aqua / mint green sand. It is thick, but easily

stirred. There is a lightly sparkling suspension.

I vacuum filter the result until no more liquid is dripping. Then lightly rinse it with some cold, distilled water. You may be able to see there are

whitish lumps in the cake still. Given how dilute the ammonia was, I'm not sure how these could be dry copper sulphate. This is the best picture of it

in terms of it's colour. I would be interested to know why this method alone is up on the Wiki, as it seems complex and wasteful compared with the

others.

Back with the weird colours again! You'll just have to trust me, it's green! I'm going to try putting it under vacuum distillation.

That is horrendously bad! The camera is either having a fit or the salt is like Ferric Chloride, changing colour depending on the type of

illumination. That is a 100ml flask.

I begin heating and, as we might expect, water is first collected, at approximately 45C. The temperature sits still here, but then start gradually

rising, over an hour as each drip comes through. As it rises, I note that the drips are forming swirls in the receiver as they splash into it - as

you'd see adding brine to distilled water. I suspect the distillate is building in salt concentration. When it begins approaching 62C, I see a

definite green tint in the drops leaving the tip of the condenser, and switch to another receiver.

There is a very small quantity of white powder in the base. At the time, I suspect this is the last of the water leaving, and am waiting for the

temperature to sit still at a specific point. But it doesn't. It floats up towards 70C, and then back down towards 45C - all in a continuous band.

I see that the column and condenser are clouding up with a white, dust like, solid coating. I see 'snow flakes' of the powder sputtering into position

around the thermometer and worry the column is on it's way to clogging. But it never does. You can see the problems I am having with the camera here,

as I know a number of you have seen this room in other photos, and the walls are bright white. Yet they appear yellow here. All of the colours in the

flask are also tinted yellow. The whitish powder on the side of the flask is A4 paper white.

There are numerous colours all over the insides, ranging from green to yellow to white to grey.

Inside the receiver, I also see white, with a hint of bluey / green. It is quite obviously spraying out as a mist or vapour as opposed to dripping.

You can see where drips are cutting through the layer.

Looks like it's clogged, but it's not.

Traces of brown appeared at the edges of the flask early on. As the still head has now cooled back to 45C, despite continuous heating, this is the end

of the process. This is clearly a decomposition product.

This is green in person. Giving it a sniff, it smells like acetic to me.

This also smells acetic like. But neither is as intense as the glacial acid used at the start. The one above is close however. I wonder if those

swirls I saw were acetic?

VIEWERS! PREPARE YOUR SPECTROSCOPIC TECHNICOLOUR PERL AND DEAN GOOGLES FOR SOME EXCITING CHANGES!

That IS blue. As soon as the glass was opened to the atmosphere, it all began rehydrating again, quickly!

Lined, but not clogged. Interesting the way it goes from green to blue.

There is a free running, fine chocolate powder in the flask.

I had to get a photo of this fast. On emptying the powder out, it immediately began to glow and smoulder.

Conclusion

Use the glacial and peroxide method, or glacial onto the hydroxide.

If you're thinking of distilling it, you may want to look into sublimation instead.

I couldn't find the triple point of the acetate.

[Edited on 9-2-2011 by peach]

|

|

|

a_bab

Hazard to Others

Posts: 458

Registered: 15-9-2002

Member Is Offline

Mood: Angry !!!!!111111...2?!

|

|

Nice experiment. The pyroforic copper powder is the most exciting feature though.

|

|

|

plante1999

International Hazard

Posts: 1936

Registered: 27-12-2010

Member Is Offline

Mood: Mad as a hatter

|

|

the copper acetate decompose to acetone an other organic product but arrond 20-60% is acetone

|

|

|

entropy51

Gone, but not forgotten

Posts: 1612

Registered: 30-5-2009

Member Is Offline

Mood: Fissile

|

|

Woelen has given a nice preparation for copper acetate which does not require glacial acetic acid. It was so easy that even I could do it.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

What is the reference for that claim?

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

The white sublimate seems likely to be cuprous acetate. Yellow colors could be CuOH or something close to it. To the extent that there is copper in

the receiver, it seems likely to have passed over as cuprous acetate; on contact with water and air, the following happens (according to Gmelin,

referencing Berzelius; I paraphrase):

Hydrolysis: CuCH3COO + H2O -> CuOH + CH3COOH (CuOH is apparently yellow, though I think I have also seen claims that the pure substance is white)

Oxidation: 2CuOH + O + 2COOHCH3 -> 2Cu(OH)(CH3COO) + H2O

Following this, if you have acetic acid in the solution, you also get the conversion of the monobasic cupric acetate to the regular Cu(CH3COO)2 that

you started with. Rather clever of the cupric acetate to pass over and re-form itself like that! However the last reaction is really an equilibrium;

at higher temperatures the monobasic cupric acetate and acetic acid tend to predominate, which is why you can't just boil a solution of cupric acetate

to dryness to obtain the material.

| Quote: | | I suspect the distillate is building in salt concentration. |

What colorless salt solution would you have here? I would suspect instead that you are getting acetic acid, following on the initial run of water (or

maybe even backwards...). Cu(CH3COO2) + H2O -> CuOH(CH3COO2) + CH3COOH proceeds easily. I think the difference in index of refraction is enough to

give you the little visible swirls.

| Quote: | | What is the reference for that claim? |

In trying to answer this question myself, I came upon the following:

http://article.pubs.nrc-cnrc.gc.ca/ppv/RPViewDoc?issn=1480-3...

They claim acetone as a main product for copper acetate decomposition, with acetic acid and methane as minor constituents, and CuO as the end result

for the copper. Frankly however, this is at odds with the older authors (not to mention the experiment peach conducted), and I'm not sure I believe

the result. It is possible that starting with anhydrous cupric acetate would lead to quite different results than what peach saw, since the initial

conversion to monobasic acetate along with release of acetic acid requires some water. I suppose differences in the rate of temperature increase could

also account for discrepancies.

|

|

|

kmno4

International Hazard

Posts: 1495

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Thermal decomposition of Cu(CH3COO)2 x H2O was investigated experimentally in many publications (interested can start their search in Thermochimica

Acta and Journal of Thermal Analysis and Calorimetry).

The only interesing product of pyrolysis is Cu(I) acetate as white sublimate, in low amounts (<5%).

The rest are: acetic acid, water, CO2/CO/C and Cu/CuO.

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

I recommend the old paper 'Observations on the Phenomena and Products of Decomposition When Normal Cupric Acetate is Heated' (Journal of the Chemical

Society, Volume 81, Part 2), from 1902. Lots of detailed observations on colors, exact temperatures at which things started to distill and so on. The

products described there match what kmno4 indicates, except that traces of acetone are also mentioned (0.01% or so).

However... their approach consisted of slow heating, and it seems that they generally held the acetate at whatever minimum temperature was required

for some reaction to proceed, even if it took hours to complete. They mention running one experiment for a week (at which point decomposition was

still incomplete) and another for nine and a half hours. It's entirely reasonable to suppose that faster heating (16C per minute is mentioned in the

earlier paper I linked) would reach temperatures sufficient to produce other products, like acetone, long before decomposition to lower-temperature

products was complete.

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

This is the glassware from the distillation attempt, the day after. There's a solution of copper sulphate in the top left as a reference for

the colours.

Yep, I also agree that kmno4 has got it; having had a chance to sleep on it, that seems right.

I don't know about the acetone. I couldn't smell it but, if it's produced in such small amounts, I doubt it'd be possible over the acetic anyway.

It took me about 3 hours to do the 30 or so grams in there.

Anyway, I decided to give electrolysis a go as well. The level of conductivity is stupidly low so, again, it takes a long time. It's

not like sulphuric. I thought I'd try electrolysis as I'd not only just run out of peroxide but also thought it was nice in terms of variables. The

only things in the process are copper from mains cables (which are produced to a high standard) and the acetic, so not a lot of options for

contaminants.

------------------------------------------------------

Negative on the top, positive on the bottom. Bit of tubing along the positive to shield it on the way down. This is so the salt forms at the bottom

and stays there. If it floats back up to the negative at the top, 'snot' ensues from that electrode.

I tried various different power supplies, ranging from 4 to 19Vdc and fractions of an amp to a couple of amps.

I think I ruined this attempt by playing with the electrodes whilst it was going, encouraging the salt to start mixing in the beaker. The result,

jellyfish like tails of copper began forming and floating down. They're mesmerising to watch but, once they start forming, it gets a lot worse.

I ran this for about 12h. I expect the current flow was around 0.1A, before the copper snot appeared. Afterwards, I believe the

copper bridges were partially shorting the supply and heating the solution, as it got hot enough to steam. The copper shorts tend not to touch the

coil at the bottom. As they get closer, gas evolution on them increases, making them float upwards and appear to be swimming.

The sludge at the base is from me swirling the top electrode to knock it off. You can also knock sludge off electrodes by momentarily reversing the

polarity (diode with a resistor across it). Using a pulsed power supply can also help avoid bonding. But the stuff should be avoided in the first

place by keeping the electrodes further apart.

Do not attempt to microbake the bulk of the solution off, even small amounts of it will go ape shit!  John has conducted this experiment for you, and does not recommend a repeat. John has conducted this experiment for you, and does not recommend a repeat.

Half a gram, sir?! For real!? For keeps!?

Conclusions

Don't touch the beaker or electrodes at any point once it's started.

Expect it to take absolutely ages.

I think you'd probably need something on the order of 100 to 200V to get a decent current through this; decent as in, a single amp.

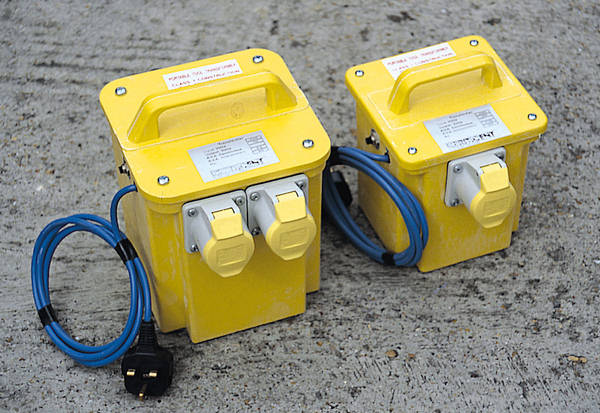

Don't connect your experiment directly to the rectified mains. You need an isolation transformer involved to float the voltage. A yellow box site

transformer could be a good candidate. Do you use them in the US? I just realised, I've not consciously thought about it before.

------------------------------------------------------

A 3-15Vdc, 25 amp supply turned up in the post this morning. I thought I'd give it another go. This time, exercising more restraint with regards to

poking at it and I'll probably leave it going a lot longer. I'll see how it goes.

In the Mark 2 version, I have modified the electrodes a little.

Since I'm using strands of conductor, if they get eroded through near the plastic tubing, the rest of it becomes useless, and you shouldn't be poking

around with it once it's going as it'll mix the salt with the rest of the solution. To this end, I've made the electrodes into a coil, with no

sections bridging.

I made the coils like flat pancakes, to keep them as far apart as possible. I then bent the centre of each up a little (towards each other). I was

thinking that this would encourage them to erode from the free end towards their supply, rather than the supply being cut off with lots of wire left

dangling.

I formed two little arms on the top coil to help it stay in place at the top.

Computer sez no

Jar sez yes

[Edited on 12-2-2011 by peach]

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

I let that go for 24h in total.

I kept checking back every now and again to note the voltage, current and temperature. For all intents, the voltage stayed between 14.8 and 15.1Vdc

throughout the entire thing. And the current, the needle was barely off the first mark. At it's peak it reached what I would estimate to be 0.3A.

This means you could meet the peak current capacity of the process at this voltage with a wall adaptor. A laptop power supply is about 19Vdc @ 3A.

The temperature rose to 38C. This was a lot less than the first try due to the lack of direct copper bridges between the two.

I was planning to leave this going for 24h and, as luck would have it, I noticed the electrodes stopped fizzing and the temperature beginning to fall

around this point. Emptying it all out, I discovered the electrode had done what I thought it would - eroded through at the supply end; but with a

fair bit of the rest gone.

By not touching the electrodes or jar at all, and letting it run longer, it has yielded a usable amount of the acetate. Not a lot (7g once vacuum

dried), as the amount of copper falling back was still significant. But it's clean, and if you don't have much to use at home, all it takes is some

acetic in some form or another.

Also, check out the last two photos. That is exactly the same pile of salt in two different places. One is teal greeny blue, the other is copper

sulphate blue.

|

|

|

slinky

Harmless

Posts: 39

Registered: 14-9-2010

Member Is Offline

Mood: No Mood

|

|

awesome pictures peach

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

US2073686

| Quote: |

Proocess for manufacture of acetic anhydrid, which comprises heating to a temperature between 200-450c a mixture of cupric acetate with copper salt of

a strong of hydrochloric acid and sulfuric acid

|

Attachment: US2073686.pdf (113kB)

This file has been downloaded 1297 times

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Interesting patent. Looks like it would be easy enough to try... but reading it, I suspect it is worthless. Among other things:

- the single example provided is not written as if it was actually executed (quantities that really should be given as a single concrete value are

listed as a range)

- the author suggests drying cupric acetate and cupric sulfate separately and then combining them before performing pyrolysis. No mention is made of

any process or step for achieving intimate admixture of the two solids (which I have to think would be essential).

- no yields are given

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

| Quote: |

Band 61 B5, Seiten 125-6.

2.2.7.2 Thermische Zersetzung

Die Zersetzung von AgCH3COO, die bereits von Chevenix [1] beim Erhitzen über einer Kerzenflamme (starker Geruch nach Essigsäure) beobachtet wurde,

setzt bei 210°C ein (Dunkelfärbung), erfolgt hauptsächlich zwischen 220 und 240°C und ist vollständig bei etwa 300°C [2]. Beim Erhitzen im

offenen Rohr oder im bedeckten Porzellantiegel werden als Zersetzungsprodukte im wesentlichen Essigsäure und Ag neben wenig C02 und C beobachtet

entsprechend 4AgCH3COO ->4Ag + 3CH3COOH + CO2 + C [3 bis 5]. Von Kachler [2] werden als Reaktionsprodukte gefunden (in Gew.-%, nach vorstehender

Gleichung berechnete Werte in Klammern): 64.61 Ag (64.67), etwa 26 bis 27 Essigsäure (26.95), 4.09 bzw. 8.42 CO2 (6.59) und 1.21 C (1.79). Auch bei

thermogravimetrischer Untersuchung wird als Zersetzungsprodukt (bei 280°C) metallisches Ag und kein Ag2O erhalten [6]. Erfolgt die Zersetzung jedoch

unter streng wasserfreien Bedingungen, so werden als Zersetzungsprodukte nur Ag2O und Essigsäureanhydrid erhalten nach 2AgCH3COO -> (CH3CO)2O +

Ag2O. Bei der Zersetzung von 2.1077 g trocknem AgCH3COO bei 300 bis 400°C in einem Quarzgefäß unter Argon (1 atm) werden nahezu quantitativ Ag2O

(96% der Theorie) und Essigsäureanhydrid (93%) gebildet neben wenig Ag (0.012 g) und CO2 (0.016 g) [7]. Die primäre Essigsäureanhydridbildung ist

bereits von Kanewskaja, Schemiakin [8] bei Untersuchung der thermischen Zersetzung von AgCH3COO (im Gemisch mittrocknem Sand) unter einem CO2-Strom

von 20 bis 25 Torr angenommen worden. Zwar fanden diese Autoren nur wenig Essigsäureanhydrid neben viel Essigsäure (entsprechend den früheren

Angaben von Kachler [2] und Iwig, Hecht [4]), doch ist dies auf die leichte Hydratisierung des Essigsäureanhydrids zurückzuführen, die sowohl durch

H2O-Spuren in dem schwer zu trocknenden Silberacetat als auch durch H2O erfolgen kann, das beim teilweisen Zerfall der Essigsäure gebildet wird.

Für die vollständige thermische Zersetzung von AgCH3COO in Gegenwart von H20 muß auf etwa 230 bis 340°C erhitzt werden. Abweichend von der

trocknen Destillation wird neben den Hauptprodukten der Zersetzung Ag, Essigsäure und CO2, kein Kohlenstoff gefunden [2].

Über die Darstellung von Ag-Schwamm durch Erhitzen einer getrockneten Paste von AgCH3COO im Tiegel auf 400 bis 500°C s. [10].

...

[1] R. Chevenix (Ann. Chim. [Paris] 69 [1809] 5/58, 19, 22; Ann. Physik 32 [1809] 156/201, 167, 179). — [2] J. Kachler (Monatsh. Chem. 12 [1891]

338/49, 340). — [3] K. Birnbaum (Ann. Chem. 152 [1869] 111/21, 119). — [4] F. Iwig, 0. Hecht (Ber. Deut. Chem. Ges. 19 [1886] 238/42). — [5] J.

Redtenbacher, J. Liebig (Liebigs Ann. Chem. 38 [1841] 113/40, 131).

[6] D. A. Edwards, R. N. Hayward (Can. J. Chem. 46 [1968] 3443/6). — [7] A. D. Kirschenbaum, A. G. Streng, M. Hauptschein (J. Am. Chem. Soc. 75

[1953] 3141/5, 3143).— [8] S. J. Kanewskaja, M. M. Schemiakin (Ber. Deut Chem. Ges. 69 [1936] 2152/7, 2154). — [9] V. I. Yakerson (Izv. Akad. Nauk

SSSR Otd. Khim. Nauk 1963 1003/11, 1007; Bull. Acad. Sei. USSR Div. Chem. Sci. 1963 914/21, 916). — [10] T. Yamanaka, H. Nidorikawa (Japan.P. 6720

[1956] nach C.A. 1958 10462).

http://www.sciencemadness.org/talk/viewthread.php?tid=9&...

|

| Quote: |

The JACS article uses inert gas sweeping, which is often necessary to get yields of desired pyrolysis products from salts. Yield 600 mg on heating 2.1

g at 300-400C 2-1/2 hrs

The other refs above:

DE556247

US2073686

Proc. Chem. Soc. 20 (1957)

Zhur. Neorg. Khim. 5, 558 (1960)

Izv. Akad. Nauk SSSR, Otd. Khim. Nauk 1003-1011 (1963)

Ber. 69B, 2152 (1936)

http://www.sciencemadness.org/talk/viewthread.php?tid=8024&a...

|

I think same result will achive with copper acetate too.

Intresting patent ,but there is no AC2O in decomposition components

With thanks to@ solo

[Edited on 17-7-2011 by Waffles SS]

|

|

|

kmno4

International Hazard

Posts: 1495

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

| Quote: | | (J. Am. Chem. Soc. 75 [1953] 3141/5, 3143). |

It is about Ag salts, but if it would go like this :

2 Ag(CH3COO) + 3/2 S -> Ag2S + (CH3CO)2O + 1/2 SO2

, then what about Cu acetate (anhydrous) ? It is interesting in itself, not beacuse of stupid Ac2O.

Does anybody know something about this reaction ?

|

|

|

| Pages:

1

2 |