| Pages:

1

2

3

4

..

8 |

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Magpie

Fan curves can be obtained from the fan manufacturer. Determining the duct resistance curve is trickier. As watson.fawkes has indicated this must be

calculated based on duct ID, duct length, number and type of elbows, reducers, increasers, duct smoothness, etc, and airflow.

I calculated my duct resistance to be about 0.75 inches of H2O at 475 ft3/min airflow. This matched a point on my fan curve. On this basis I judged

my hood/duct design and blower selection to be acceptable. Ideally all of this design work is done before any procurement of materials is started.

|

The authoritative reference on this subject the ASHRAE Handbook--Fundamentals, in the chapter entitled "Duct

Design". It explains all the losses and how to compute them. There are excellent worked examples included. Most reasonable reference libraries have

a copy.

@Magpie: Thank you for setting an example of computing an estimate of your duct and fan performance. This is certainly a case where a false sense of

protection is actively harmful.

Having said this, a fume hood for a single operator in a garage is a pretty modest system. Use as few bends as possible, since dynamic losses from

duct turbulence usually dominate in a small system. Use shallow bends (say, 45°) instead of right angle ones if possible. Use long sweeps

rather than tight ones.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

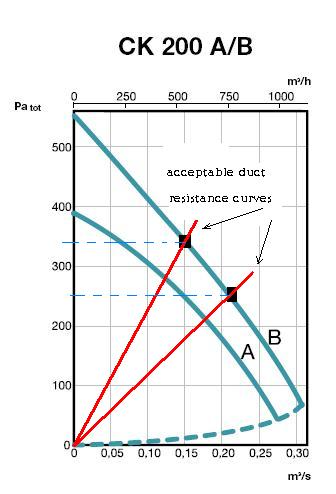

DNA I will comment on the fan curve for the "right fan" first. Now that you have indicated that the motor is outside the flow path I think it is a

viable candidate. Below is shown the fan curve as marked up by me to show two hypothetical duct resistance curves, in red. These curves intersect

fan curve B at 0.15 and 0.21 m3/s, respectively. From the data you posted earlier these are acceptable flows for a hood of 120cm cabinet width. So,

on that basis, a duct system that will produce a resistance curve anywhere on or in between those two red lines would be acceptable.

The duct resistance and likewise the fan static pressure at the two operating points (black squares) I have shown are 250 and 340 Pa, respectively.

In my world these convert to 1 and 1.36 inches of H20, respectively. These seem to be fairly high pressures and I am therefore impressed with the

capabilities of this fan. IIRC you said this fan had a 20cm opening. I think you should be able to assemble a duct system of 20cm ID that would

yield an acceptable duct resistance curve.

Watson.fawkes has told how one can calculate points for a duct resistance curve using the ASHRAE handbook. I recommend you give this a try. If you

give me the parameters of your ducting I will be glad to check your calculations.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

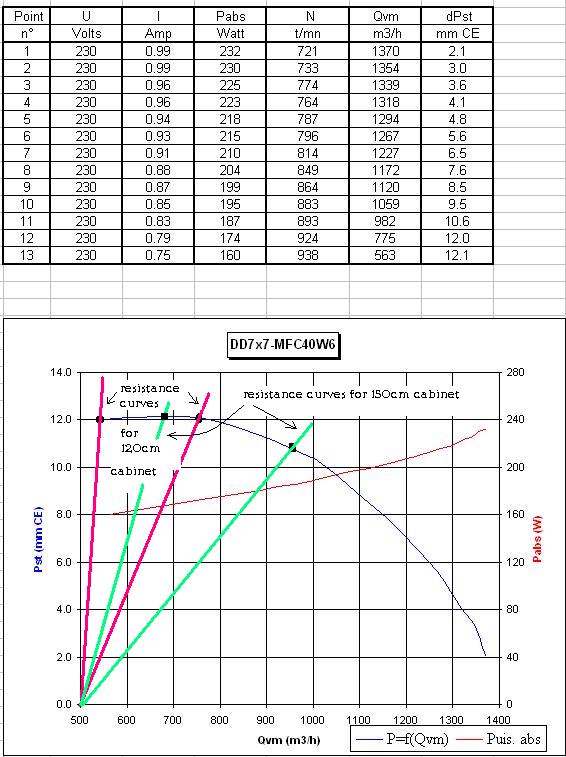

DNA here's my comments for the "left fan:"

1. The manufacturer says it has a "double flow wheel." I'm interpreting this to mean that air flows in from each end. This would put the motor in

the flow path - not good.

2. This is not a fan curve but an envelope that includes all the fan curves for the different mechanical and electrical configurations that this fan

could have. You really need just the curve for the particular configuration (wheel size, rpm, etc) that you would have.

3. No matter what configuration you have you would be trying to operate in the far left end of that envelope to meet the flow requirements of 540-756

m3/h for a 120cm cabinet width. That's not the best place to be on a fan curve in my understanding.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Talking about hoods, Magpie, you wanted me to show my hood.

I have an old picture. The sash is ready but not yet put into the hood, and the blower has been ordered. however I will be very busy next weeks, so

will take some time.

This is the hood itself, not yet the fan and sash (sash is ready though).

http://img147.imageshack.us/my.php?image=p1090617jc5.jpg

http://img49.imageshack.us/my.php?image=p1090619rv9.jpg

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Looking very nice Jor! At some point you will have to give us all the details.

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

Just off topic, how the f*ck is everyone getting these acros bottles...I thought you could only order there as a company and not as a private person.

Almost every fumehood picture I've seen it has acros bottles in it...

I e-mailed the company for another graph but they haven't replied since yesterday...

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

Here are the specs of the squirrel cage the correct ones.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by DNA

Just off topic, how the f*ck is everyone getting these acros bottles...I thought you could only order there as a company and not as a private person.

Almost every fumehood picture I've seen it has acros bottles in it...

I e-mailed the company for another graph but they haven't replied since yesterday... |

I can order from Merck, Acros, Fisher and even Aldrich. But not by myself. impossible. A single person is just like an annoying fly to them.

How can you order? Find a small supplier who can sell to individuals. Ask this company to order from the big ones. I buy all my things through a small

supplier, and he adds 1 euro to the price per chemical.

|

|

|

panziandi

Hazard to Others

Posts: 490

Registered: 3-10-2006

Location: UK

Member Is Offline

Mood: Bored

|

|

I made a fume hood. I constructed two H frames (front and back) and joined them with side bars, also placed struts across the bottom for storage of

bulky equipment, the work surface inside the hood was a stainless steel sink and draining board unit. The sides were tinted plexiglass as was a

stationary front. The roof and back was plyboard and a false back was installed to distribute air flow. My fan was a blower similar to the one on the

first page of this thread but the motor is exposed to the fumes. I have not yet linked the ducting to the fan or installed a sash. I am currently

looking at these fans

https://www.machinemart.co.uk/shop/range/details/ventilators...

What do people think of these?

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

You'dd better post specifications of that fan, concerning the pressure drop so to see if the face velocity is okay.

Since a lot of air movement is okay, but then still your fan also needs the power.

Simplified sayd, your fan might move a lot of air with no resistance but as soon as you add a duct to it there will be to much resistants for the fan

to still move all that air threw your duct...therefor we need to know the pressure drop. It also depends on the size of your hood.

Please post the measurements.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

DNA I have marked up the fan curve you posted for the "left fan." As I suspected using this fan for a 120cm wide cabinet would place you way to the

left on the curve, an unstable region, and not the best place to be. I also placed the resistance curves for the 150cm wide cabinet on the diagram in

green. This improves things a little.

I'm also concerned about the fairly low static pressure that this fan is able to develop - only 12mm of H20. To move this much air with only that

amount of pressure would require a large duct diameter. I'm guessing at least 25cm, possibly larger.

I want to thank chemoleo for cleaning up the "Tour My Lab Thread" by moving the fume hood posts to the beginning of this thread.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

The following references contain recommendations on face velocity for fume hoods. I've lifted them from the footnotes of the relevant sections of

Industrial Ventilation Design Guidebook.American Conference of Governmental Industrial Hygienists. Industrial

Ventilation: A Manual of Recommended Practice, Metric Version. 23rd ed. Cincinnati, OH: ACGIH, 1998.

BS7258. Laboratory Fume Cupboards. London: BSI, 1994.

ANSI. Fundamentals Governing the Design and Operation of Local Exaust Systems. ANSI Z9.2-1979. American National Standards Institute, New York,

1979.

Summarizing the Guidebook, the upshot is that a good target range for face velocities in the hood is 0.4 - 0.5 m/s. 0.3 m/s should be

considered a bare minimum for ideal circumstances.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes, watson.fawkes, I think it is good to keep in mind that proper face velocity is the starting point for good hood design.

The Dutch standards posted by DNA above come in pretty close to what you have found, ie, 0.25 - 0.45 m/s.

For my design I chose a face velocity of 1 ft/s, which is 0.3 m/s. But as you say I have seen more modern US recommendations for up to 1.5 ft/sec

which would be 0.46 m/s.

Then the designer has to know what is the largest sash opening, including any bypass, with which he will be working. Once that area, A, is known the

design air flowrate, Q, can be easily computed from Q =VA, where V= face velocity.

Then you try to find a fan that will give you the airflow Q that you need at a sufficient pressure to balance your duct resistance.

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

Thank you Magpie, I'll go and buy the "right" fan which has an external motor, protection against moisture and still has a good pressure drop.

In the meanwhile I made pictures of my fumehood (see "tour my lab") and I made a more clear picture of what standards are needed and for what sizes of

fumehoods and what kind of fumehood etc.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

from DNA above:

| Quote: |

I found a table for airsuction in fumehoods after searching for a while.

It might be useful for the people that already made a fumehood and ofcourse the people planning on making one. The information below is for the

industry and university's in The Netherlands as defined by the law.

Standard fume hood:

Cabinet width 100 cm: 450 - 630 m3/h

Cabinet width 120 cm: 540 - 756 m3/h

Cabinet width 150 cm: 675 - 945 m3/h

For all above mentioned sizes with the sash opened for 50cm there should be a flow of 0,25 - 0,45 m/sec.

|

There's something not quite right here. The flows all compute for the face velocity of 0.25m/s, but the flows for the 0.45m/s don't compute, eg:

Q=AV = (120cm)(50cm)(0.45m/s)(3600s/h)(m/100cm)(m/100cm) = 972m3/h. The table gives 756 m3/h. Same discrepancy for the other 2 cabinet widths.

This should be resolved.

[Edited on 11-9-2008 by Magpie]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by DNA

Cabinet width 100 cm: 450 - 630 m3/h

Cabinet width 120 cm: 540 - 756 m3/h

Cabinet width 150 cm: 675 - 945 m3/h

For all above mentioned sizes with the sash opened for 50cm there should be a flow of 0,25 - 0,45 m/sec.

|

| Quote: | Originally posted by Magpie

There's something not quite right here. The flows all compute for the face velocity of 0.25m/s, but the flows for the 0.45m/s don't compute, [...]

|

The upper limit flows are all computed for 0.35 m/s.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

I can now get a fan, wich moves 500m3 per hour. It makes almost no sound wich is good. The motor is made from stainless steel, and it's not spark

proof. Therefore no ether, acetone, etc. They are not toxic anyway, so that's outisde the hood. However the metal will be rusted in a year I think.

But I'm moving away in 1 or 2 years, so that's not a problem.

A vent pipe will have to go up like 3-4 meters, then the fan will be constructed right under the roof, and then a short pipe will go out. I think I

will lose some power, because of the 3-4 meters up. But how much? 50-100m3? or more?

The fumehood is 80 cm wide, 1 meter high,55 cm deep. No baffles, no bypass. See picture on post I posted in this topic a few days ago.

So what do you think magpie, buy it or not?

DNA, please tell me where you buy your sparkless, moisture protective motor!!

Here these are sparkless motors, used in ships:

https://www.marinestore.nl/Boordcomfort_en_Accessoires_Venti...

Magpie, doe you think these are suitable for me, taking the 4 meters of pipe going up into consideration? Although its Dutch, I think you can

understand quite some of the page. However these are 24V. I'm really not good at electronics, how to convert to 230?

[Edited on 16-9-2008 by Jor]

[Edited on 16-9-2008 by Jor]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Jor,

Right now all I really know about your fume hood and system is that: 1) it is 80cm wide, and 2) your ducting may be up to 4m long. I will need to

know the following before I can comment on the suitability of any given fan:

1. You say you have a sash. What will be the open area with the sash in place when you are working in the hood with the fan on? (When and if your

sash is completely closed your hood will draw no air.)

2. What will be the duct inside diameter? Is the duct smooth?

3. How many elbows will the duct have? What type are the elbows, ie, 90 degree, 45 degree, 22.5 degree, short radius, long radius, etc.

4. Will there be an outlet louvre or screen?

5. What is the fan curve for the proposed fan?

So, you really have to see (on paper) the whole system before you know if it will perform as intended.

| Quote: |

Although its Dutch, I think you can understand quite some of the page. However these are 24V. I'm really not good at electronics, how to convert to

230?

|

Jor I am prejudiced against motors that are inline with the flow. I don't think it mattters so much whether or not they are sparkless as long as the

motor is outside the flow path.

I am also predjudiced against battery operated fans. I think these fans are meant for short term duty likely exhausting a bilge before starting a

marine engine, or where the battery is being continuously charged. I just finished a project today where my fan was operating for almost 2 hours

straight. I would be concerned that a battery operated fan would have quit on me.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Magpie

Jor,

Right now all I really know about your fume hood and system is that: 1) it is 80cm wide, and 2) your ducting may be up to 4m long. I will need to

know the following before I can comment on the suitability of any given fan:

1. You say you have a sash. What will be the open area with the sash in place when you are working in the hood with the fan on? (When and if your

sash is completely closed your hood will draw no air.)

2. What will be the duct inside diameter? Is the duct smooth?

3. How many elbows will the duct have? What type are the elbows, ie, 90 degree, 45 degree, 22.5 degree, short radius, long radius, etc.

4. Will there be an outlet louvre or screen?

5. What is the fan curve for the proposed fan?

So, you really have to see (on paper) the whole system before you know if it will perform as intended.

| Quote: |

Although its Dutch, I think you can understand quite some of the page. However these are 24V. I'm really not good at electronics, how to convert to

230?

|

Jor I am prejudiced against motors that are inline with the flow. I don't think it mattters so much whether or not they are sparkless as long as the

motor is outside the flow path.

I am also predjudiced against battery operated fans. I think these fans are meant for short term duty likely exhausting a bilge before starting a

marine engine, or where the battery is being continuously charged. I just finished a project today where my fan was operating for almost 2 hours

straight. I would be concerned that a battery operated fan would have quit on me. |

Ok I know the following for now:

1. When the windown is maximum open, it will be about 45 cm working height.

When it is completely closed, it's about 4 cm. So incase there goes somethign wrong, I can close it to the 4cm for very effective ventilation, with a

speed of at least 4 m/s at opening. But I will generally work at 40-45cm height. So that's where i want the 0,35-0,45. A little more is not a problem

I think.

2. Probably about 150mm-160mm diameter duct size. Not sure what material I'm going to use. Maybe a relatively flexible duct (Polyvinyl chloride, the

ones wich look like the aluminium ones), but I don't think these are resistent to bromine/chlorine. Otherwise standard duct, don't knwo the material.

3. Im not sure yet. Ii will probably buy the following:

http://www.growcenter-noord.nl/box-silent-air-500-m3-p-818.h...

If I can put it upside down (wich I think must be possible), then one 45 degree angle is enough. If not (unlikely), it's going to be 2 90 degrees

angles.

4. I don't understand question 4.

5.I don't understand 5 (I do not have great English. If someone can explain me I will answer).

Again, my goal is not a hood wich works like a commercial one. I'm happy with a capture of about 99% of the fumes, not 99,9999% like real hoods. And I

can always close the sash in case there is a violent release of lots of toxic gas.

What is teh problem with a motor in the inline of flow? I cannot find a motor with an external motor. Corrosion is not a problem, I accept it can be

destroyed by fumes in 2 years.

But I found some fans with external engine:

http://www.airflux.be/details.asp?language=nl&productID=...

Go to the blue link 'technische documentatie' for technical details in English.

For me only the 160MD and 160LD are interesting.

[Edited on 16-9-2008 by Jor]

[Edited on 16-9-2008 by Jor]

[Edited on 16-9-2008 by Jor]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Jor...

4. I don't understand question 4. |

Is the exhaust opening just a plain open rectangular or circular hole, or is it covered with screening or similar that will add to the flow

resistance.

| Quote: |

5.I don't understand 5 (I do not have great English. If someone can explain me I will answer). |

Fan curves have been given earlier, they show the relationship between flow volume and pressure/flow resistance. You need that to calculate the flow

rate in your proposed design.

| Quote: |

What is teh problem with a motor in the inline of flow? I cannot find a motor with an external motor. Corrosion is not a problem, I accept it can be

destroyed by fumes in 2 years. |

Explosion or fire from flammable fumes, and corrosion. A little HCl in the exhaust air can trash you motor in much less than 2 years, it can happen

in weeks.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Jor,

Here's what I came up with for your hood:

Assumptions:

1. open face width: 80cm

2. open face height: 45cm

3. required face velocity = 0.35 m/s

4. required airflow, Q = AV= (0.80m)(0.45m)(0.35 m/s) = 0.126m3/s=454m3/h

5. duct ID = 150mm (smooth)

6. 2 short radius (r/d=1) 90 degree elbows

7. 1 entrance and 1 exit

7. duct length = 4m

8. fluid = air at standard pressure and temperature

Calculated duct resistance = 9.3mm H2O.

This is not much resistance. But if your duct is a corrugated flexible tube like a dryer duct then it will not be smooth, but very rough. This will

increase your resistance - how much I can only guess. Maybe someone else knows.

So now we need to see your fan curves of any proposed fans. These are published by the fan manufacturer. Examples of what they look like are shown

in the above posts.

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

I'll soon be getting my new fan, with the outside motor.

They are being sold at conrad electronics especially for the dutch people.

And what is the difference between having a circulair or rectangular opening magpie?

I'll also get something else then this flexible tube for a dryer.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Can you please give me the link of the fan you will buy at conrad? This is, because I see now (yesterday I was tired!  ) that the company I gave with external motor in in Belgium... They use other voltages

and also huge shippings. ) that the company I gave with external motor in in Belgium... They use other voltages

and also huge shippings.

And is it ok to add you to msn DNA? So we can talk about the subject more easily.

Thank you very much Magpie for the calculations. Becuase I need a 454 m3, I will go for something like 500m3. But not important just said the motor

would be trashed in WEEKS, now that's a bad thing. Need to find an alternative.

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

http://www2.produktinfo.conrad.com/datenblaetter/550000-5749... here are the datasheets of the fans that conrad has.

You can also see these fans are being used for ventilation of bathrooms (waterproof) and kitchens and several places in the house at the same time, so

if you would use it just for one cabinet of 1 m3 then it will definately have a nice flow

There is a fan of 980 m3/h for 185 euro.

Motor is outside, the fan is placed in line with the duct and it it's metal is coated to be resistant for compounds passing by and it has explosion

proof thing and also another iso certificate.

So the fan I'll be getting has 580 Pa

[Edited on 17-9-2008 by DNA]

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

wow that's very nice! External motor, not expensive and also spark and corrosion proof!

I think I'm getting the AXC 150B, the one with 530m3, and AXC 160A with 440m3. The PDF says the product is suitable for long ducting, and can overcome

wuite some presuure. Not sure what is the best one for me. Wich one would you guys choose (Magpie  ?) First going to eMail them and ask if they have them both in stock, as I cannot find it to be in the online

catalogue. ?) First going to eMail them and ask if they have them both in stock, as I cannot find it to be in the online

catalogue.

DNA! Your fan is much cheaper here:

http://www.auerhaan-klimaattechniek.nl/klima/documentatie/me...

However you need to login and they request a company name, that might be a problem. I might just ask my mother to order, because she is a dentist. Not

sure if you can.

Same model, costs 87!

[Edited on 17-9-2008 by Jor]

|

|

|

| Pages:

1

2

3

4

..

8 |