| Pages:

1

2

3 |

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Thanks, zed. Safety first.

Sic gorgeamus a los subjectatus nunc.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

@Klute, I have the same Buchi and it's listed as an R110. I too acquired extra motors and a jackstand for a later Buchi. What haooened was I kepot

buying "Buchi rotovaps" used and got motors but no glass. Finally I got a complete setup for $375. I need more of the bakelite rings and washers. I

got a great deal through Sauron on a Parr with controller. I have no intention of hydrotesting it but running an inert gas through it first to check

for leaks might be prudent. Water is practically incompressible and placing pressure on water inside the equipment seems like asking for trouble.

Over-pressuring with Argon would be a more realistic and relatively benign test. I'll email Parr and ask them what they recommend. Anyway, thanks

again Sauron for tipping me to the Parr and other stuff I got from the dealer. The Mcleod Gauge was also a steal at 75.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

@Sauron or to any who can help

First off, nice equipment!!

Now my question: You seem to know considerable amounts about the Rotavapor line, so I think you might weigh in on this.

I am thinking of acquiring a Buchi R-215 Professional model. It's practically brand new and in good working condition I've been told. It comes with a

V700 pump, and V850 controller along with the B-491 heating bath. It's $3K. It is a complete system and it's practically new.

I have another option: I know I can pick up a nice Buchi R-124 for about a thousand, but I'd have to buy another Buchi pump (or my preference, a KNF

Neuberger Laboport UN842.3, 34L/min to 1.5 torr) and then there's a controller for it. Even allowing for getting those used, I'll probably still spend

about two thousand dollars on the whole setup.

Is it worth getting this relative new R-215, or should I save myself a thousand dollars and get the R-124?

PS--I found myself Buchi's equivalent of a Kugelrohr for about $500, any thoughts?

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Nice toys, Sauron. I really like your Parr apparatus.

In reference to pressure testing the Parr vessel, since it is used, I think it would be a good idea to hydrostatically test it prior

to putting it into use with gaseous products. Standard procedure is to test to at least 150% of your planned use pressure. If it is going to warp or

rupture it is far better to find out about its defect using an innocuous liquid than reaction gases in use.

Using liquids is standard practice for the reasons well stated by zed. Pneumatic testing is very dangerous and I have never heard of anyone doing

this for anything but very low pressures.

This thread shows some pictures of hydrostatic testing I did on a homemade pressure vessel. Looks like I went up to about 650 psig (44 bar) on the

tester and about 350 psig (24 bar) on the vessel itself.

http://www.sciencemadness.org/talk/viewthread.php?tid=4566&a...

[Edited on 9-11-2008 by Magpie]

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Thanks @Magpie.

@Chemrox, the Parr 3911 you got through me is a glass vessel shaker and does not need testing, it only goes to 4 bar (60 psig) if you follow Parr's

advice. Parr tests every bottle to 150 psig.

But gkass at best is unpredictable.

The Parr that zed and Magpie and vulture are referring to is the stainless steel 1 liter 4521 upthread, rated at 1900 psig @325 C. An accident with

that at pressure would be a major event.

There's photos of the R110 and EL-130 using same jackstand upthread. But the one Klute is talking about is a Model R, like in the photo with 3 of them

on floor. He just has the different baseplate with adjustable track and big round place for integral water bath. I have a few of those stanbds but

nothing on them but the upright rods.

@Fleaker, I think either of those deals will serve you well. The Buchi pumps and controllers are very good, so are the KNF. The controller I have is a

V-801 programmable one.

I never got my hands on either a 124 or one of the current series like 225. The most recent models I actually owned were RE-111 and EL-131.

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Sauron, are the model references marked anywhere on your equipement? Indeed the number KRV 65/45 was on the motor steel plate with the serial number,

i checked it on the internet and there are a few articles mentionning the use of a "KRV 65/45 Buchi Rotavap", so I just took it for the old name. I

was very surprised to find no info what so ever on theses old models on the Buchi website. I guess they prefer selling the modern electronics and let

evryone forget about these 50 years-lasting models

At work we had these electronic ones (although not Buchis) where you can indeed set RPM and temp, and even configure an automatic "breaking" of vacuum

at a designated time. But we didn't use them that often, so not much maintance.

BTW, does anyone know where one cna buy some seals for the old Buchis, if other brands can fit, or if it has to specificly be a Buchi? I guess they

don't sell these anymore... Any advice?

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

@Klute

The Model R110 is prominently identified as such as are the EL-130s. on faceplate of motor head control box (see pics). They all read BUCHI Rotavap

R-110 and so on, Rotavap was a Buchi trademark.

The later RE-111 series were similarly marked.

The very old Model R (and I assume EL) generally say nothing, the transitional R (and EL) might say Model R - I will have to look at mine.

The motor plate stuff is nothing but a part number for the motor perhaps from the OEM because you can take it to the bank that Buchi did not

manufacture the motors, they were outsourced. So anyone on the Net referring to this model by that number is mistaken. All Model R's are referred to

simply as Model R. All stationary seal Buchis are referred to as having R-type seals. That is just to distinguish them from the rotating seal EL type

models. This continued until the entire glassware and seal system was changed in the 200 series still being sold. That only happened around the turn

of the century.

I am not aware of any third paerty source for the seals. Sorry.

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

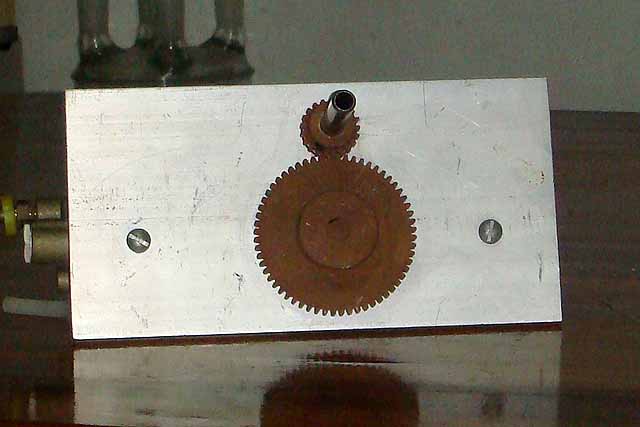

Aldrich Kugelrohrs Old and New Models

Also in this shipment were two Kugelrohrs, one old and one new model.

The new model has a shielded stainless steel air oven with thermostat and a sealed heating element. A thermocouple allows temperature control with

good precision and an oven thermometer is also supplied.

The new model motor is electric, heavily geared down for torque, and vacuum takeoff is under the Firestone style valve. The rotation is continuous and

unidirectional. The specimen I have is immaculate.

The old model has an unguarded aluminum alloy air oven without any built in temperature control or t/c but you can add an external controller and a

thermocouple easily enough. There is an oven thermometer. I picture it here with new model motor because that is how I intend to use it, note that the

height is perfectly compatible with the centerline of the oven flask.

The Al shell was not so impervious to chemicals if spilled and the bare heating element was a hazard. Adding a closely fitting SS liner closed at

bottom would correct both deficincies.

In case anyone is wondering this is Aldrich's answer to Buchi's rotavap design.

The old model motor is a pneumatic one and reciprocates back and forth, it was originally made as an automotive windshield wiper motor. When Detroit

and Japan changed the design of such things Aldrich was left high and dry. Note the stainless steel tube down the axis of the small gear. That is the

vacuum takeoff. Normally these air motors come in an Aldrich black metal housing intended for ringstand or lattice mounting. And they normally have a

silencer in back because like all pneumatic drives they are noisy.

The new model Kugelrohr was introduced in the late 80s and now sells for almost $5000. Ouch! I was happy to get this one for $700.

The new model Kugelrohr has interchangeable PTFE bearings for oven flask news of 24/40 and 14/20 sizes, so will handle flasks from 50 ml to 2000 ml.

Flasks are filled to 1/3 nominal capacity, because of the horizontal orientation.

The old model oven would handle flasks to 4 liters according to Aldrich, but the old and new ovens look same dimensions to me. Maybe the electric

motor does not have the torque of the air motor? I do not know.If that is the constraint then there is little advantage to the old model unless you

already have compressed air service in the lab.

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

and old model

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

And old model motor, back view

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

and front view

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

And closing for the nonce, another view of the Parr SS316 1 liter pressure vessel.

[Edited on 10-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Christmas is also coming early for me too. Although I have no fundamental lab stuff as of yet, I saw a BNIB Buchi M (HB140?) on ebay for just under

£300 after checking labx (I think) and seeing used ones for £650, I decided that I should make a useful aquisition  (especially as organic is what I like best (especially as organic is what I like best  ). Now for the difficult part... ). Now for the difficult part...

I have sourced (but not yet purchased) a fairly cheap, 2 stage, vacuum pump that pulls to 25 microns (i.e. less than 1torr) and now have a problem...

Having no access to dry ice or LN2, how am I supposed to stop the nasty chemicals from getting into the vacuum pump and destroying it? I assume an

aspirator is no good for a buchi (besides I have no running water (or a lab for that matter... yet.) and would rather not have the hassle of setting

up a recirculating system.

My best thought as of yet is to have a flask (with washbottle head type thing) submersed in the lowest temp salt ice bath I can attain (probably

CaCl2.6H2O => -52C IIRC) and then a column/gas wash bottle filled with activated carbon (granular to minimise effect on flow?) and KOH pellets (if

the vapor is acidic) before letting the vapor reach the vacuum pump. Is this sufficient? Any suggestions are welcome, thanks in advance.

[Edited on 16-11-2008 by DJF90]

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Without any cold trap, and using an oil pump like that, you will quickly contaminate the pump oil and vacuum will go to hell.

For rotavap you do not need a 2-stage pump or 1 torr. An aspirator pump will do fine at 20-30 torr, and a PTFE diaphragm pump like Buchi makes or KNF

Neuberger, even better. Both are impervious to solvents and corrosives and are preferred for rotavap work. Save your 2-stage oil pump for when better

vacuum is needed. But you will always need a cold trap and so dry ice is a necessity. Not a luxury.

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Thats not the answer I was looking for but I thank your honesty. I may actually be able to aquire dry ice, but only in 10kg loads and for ~£30. I am

fine with the pricing of this, but am unsure if I will be able to make the best use of it before it sublimes... Seems silly to buy 10kg if I can only

manage to use 500g. Could I possibly store it in a thermos flask in an expanded polystyrene box in the freezer? How long could I store it like this

for? Unless you have a better method? I was looking for a ptfe diaphragm pump but it was way too expensive

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

That's a ripoff price for dry ice and a ridiculous minimum order.

If you cannot find a better source here is your alternative:

1. Buy an empty new gas cylinder and outfit it with a CO2-rated valve and dip tube. The shop that sells you the cylinder should furnish and install

the valve and dip tube. The dip tube is essential.

Purchase a "Frigimat Jr" (Scienceware, Bel-Art) dry ice snow making tube and cone and poly bags to catch the snow. $100-$150 US. Aldrich, Cole Parmer,

and others distribute this, I do not know who is UK distributor. Check the maker's web site.

Follow the directions for attaching the tube and using the device. Typically it will say Open valve 3/4 of a turn - that is three quarters of 1 turn

NOT three or four turns!

Cryogenic gloves are a good idea.

This way you can make dry ice on demand in finely divided form perfect for acetone slurries. and when you have as much as you need, just close the

valve.

The cylinder and valve with dip tube should cost you less than 10 Kg dry ice.

Getting the cylinder filled with liquid CO2 is very cheap.

Refills same.

At least that is how it is where I am.

I can also order solid blocks of dry ice to my door anytime.

Very cheap.

Liquid N2 is a pain in the ass requiring special dewars ets. Usually not needed unless you need to go below -75 C.

[Edited on 16-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

They also make machines to produce cylindrical blocks of dry ice but they are more expensive (2-4X) and the snow is better for lab purposes.

Garage chemist does not like this, saying he got a disappointing amount of dry ice snow from a cylinder of liquid CO2. However, here the CO2 is cheap,

so I could care less about alleged inefficiency. What matters is getting the dry ice when I want it, in the form and quantity I want, and not paying

for solid blocks only to have them sublime off before I can use them!

Sic gorgeamus a los subjectatus nunc.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

A aspirator is perfectly suited for a Rotavap. All the ones we had at work used aspirators. A recirculating station is very easy to build and use.

Using a such mechanical pump for a rotavap is a waste IMHO becasue you will never have to use such a vacuum. At best get one of those very though low

vacuum ones. But I would still vouche for an aspirator, honestly.

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Buchi teaches a very simple rule for rotavap use. You want the bath 20 C hotter than the bp of the solvent, you want the cooling water 20 C and you

want the vacuum at a level where the solvent boils at 40 C.

This means 20 C coolant, 40 C bp for solvent and 60 C bath.

They provide a convenient chart of required vacuums for 40 C bp for many solvents in the manual for the V-800 series digital vacuum controller.

At over 60 C water baths become inefficient because of vaporative losses. Oil baths are a mess with rotavaps because of shedding hot oil from spinning

flask.

Low boiling solvents do not require heat at all.

If you pull too much vacuum you will find your condenser will not work very well (unless you switch to dry ice/acetone in a Dewar condenser.)

So follow the 20/40/60 rule and your rotavaping will be happier.

If you can't invest in a digital controller, get a manometer or McLeod gauge and a Cartesian diver type manostat.

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

I guess I had better read up on the threads regarding use of an aspirator. The recent activity regarding use of alternative fluids to create vacuum

seems to be interesting, and it would be superb if such low vacuums (regarding the theory) could be attained using such a simple setup.

The only problem with a recirulator pump is that the water gets contaminated (as it doesnt just go down the drain any more), which may cause pump

damage if care isnt taken to prevent this. What are the solutions everyone else with a recirculating station have come up with? Thanks in advance.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

I would not advise spending too much time on "alt fluids" . Ice water works great and for rotavaps you do not need any better vacuum than c.25 torr

anyway.

The problem of contamination of water is dealt with very simply: change out the water. Do that daily. If you are just stripping solvents, and your

trap is worth a damn, very little will get into the aspirator water. If you are doing a reaction that releases a lot of hydrogen halides,which will

not condense in a cold trap, put a large caustic scrubber in between the cold trap and the pump, or change out the pump water after every run, or

both.

Don't forget to protect your system from suckback.

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

It seems as if I have plenty of time to sort everything out as I do not even have simple glassware yet, I only bought the buchi because it was

(relatively) cheap and I happen to have the money at the moment. It is a small rotovap though, it was hard to tell from the look of the pictures but

the seller described it as being ideal for handling volumes from 30ml to 250ml - perfect for the scale I aim to be working on. What I need now is to

buy a quickfit setup in 19/26 size, as this is ideal for the scale yet again, and most work should be sufficiently done in a 100ml RB flask (with

occasional 250ml use and maybe 500ml for preparing reagents).

I was going to buy a good 0.001g lab balance today but it was based in canada and I didnt fancy having to pay import/export taxes and any other

"hidden" fees  Heating mantles I intend on making myself, possibly a magnetic

stiffer also. ATX power supply needs some components to finish, and some sort of fumehood will be constructed (when I can find somewhere to set up

lab). So much to do and so little time to do it, uni work keeps me busy most of the time. Hopefully I can get ahead during the end of term holidays Heating mantles I intend on making myself, possibly a magnetic

stiffer also. ATX power supply needs some components to finish, and some sort of fumehood will be constructed (when I can find somewhere to set up

lab). So much to do and so little time to do it, uni work keeps me busy most of the time. Hopefully I can get ahead during the end of term holidays

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

The ordinary benchtop Buchi handles flasks from very small to 3 liters. To the best of my knowledge Buchi does not make a smaller rotavap than that,

and why would they need to? In the US the standard vapor duct is 24/40 while in EU it is usually 29/42 and either way adapters can take those down to

14/20 or 19/24 easily. What model number did you say yours is? 144 wasn't it? or 114? That is a 4th generation model from 1990s. The water bath

ought to be about a foot wide and 8-9 inches deep and have an automatic overflow and thermostat.

Plenty of good used Glas Col heating mantles around and cheap. Very little point in DIY there.

Back to rotavap: other companies have made micro-rotavaps in the past but I would shy away from any brand but Buchi. A lot of the glassware is

special. Consumables like seals are essential. Some non standard brand may be long out of business and you will be SOL for spares and support. Whereas

Buchi is still supporting all their old models.

[Edited on 18-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Not sure about the model, I think its a HB140 though? its quite small, and the description of the waterbath sounds about right. Pictures right here. I

will post my own when I recieve and assemble it

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&ssPageNa...

It'll be more than sufficient for my needs.

[Edited on 17-11-2008 by DJF90]

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

I don't think it is a Buchi. Sounds like a Heidolph micro-vap. Made in Germany, more likely outsourced from a German company and built elsewhere, my

guess would be China. I do not know present status, but you might want to check on Web and see if there is an agent in your country and whether or not

you can get glassware and parts/supplies. If the seller represented this as a Buchi and it is not, get your money back.

The eBay listing you linked to is kaput, finito, removed, gone.

[Edited on 18-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

| Pages:

1

2

3 |