| Pages:

1

2 |

1281371269

Hazard to Others

Posts: 312

Registered: 15-5-2009

Member Is Offline

|

|

I was looking at pumps on eBay recently - there seem to be a lot of air pumps that have the same flow rate as the water pumps of double the price.

With an air pump, there would be no need for a reservoir and no risk of the coolant heating up - especially in the winter, when the air outside is

around 0-10C. Wouldn't this be a more effective setup for all but very low bp distillations?

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

Air pump? Do you mean fan, blower or compressor?

Fluid moving machinery is rated in volumetric flow rates. So if you have a pump which pumps 1 kg/hr of water and an "air pump" which pumps 1 kg /hr

of air at STP conditions then the air pump will be about 750 times bigger in size corresponding to the difference in densities. The power consumed

will however be approximately same in both cases.

From your post it appears that you intend to do away with water altogether from the cooling system. In that case just read few posts upthread why it

is impracticable to do so.

gsd

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Even as an oversimplification this doesn't fly.

11cfm water pump, ~20kg, moves about 5kg/sec of water.

8500cfm fan, ~21 kg, moves about 5kg/sec of air.

To be fair, a normal fan is not designed to operate against pressure. But even if you want to compare instead with an 8500cfm air compressor (which

will achieve higher output pressures, than a regular water pump will), you're still looking at something on the order of a 500kg trailer-mounted unit,

maybe 25x the size of the water pump.

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

I don't think the added complexity of an air system is ever worth it. You are dealing with glassware under *pressure*, because gasses are

compressible. Any appreciable flow rate of a cooling gas will require a fair bit of pressure on the input.

And lord forbid that you do a vacuum distillation, then the pressure differential is greater than 1atm in the case that you pull a near full vacuum.

Flying glass comes to mind....

Not to mention the specific heat capacities differ significantly as mentioned quite a few times.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I know this thread is old, but I thought I might share a home build example of an evaporative cooler. A few years ago I was making quite a bit of

beer, rum, whisky and vodka for my own use. I learned that keeping the fermentation cool/slow was one of the most important aspects of the process in

order to produce a quality beer or wine and subsequently a quality distillate. The problem was that during those years I was living in an apartment

with no temperature control and the temperature usually fluctuated between 22C and 30C. I liked to run my fermentation at about 20C, which meant a

long fermentation, but good quality fermentation. Also the temperature should be held fairly constant, because temperature fluctuations also stress

yeast resulting in higher levels of undesirable compounds and off flavours.

My solution involved placing the plastic fermenter/bucket in a large plastic storage container which was half or less full of water. The fermenter was

wrapped in a cotton towel and wrapped in the top of the towel was a polyethylene hose with many holes drilled in it (weeping hose). A small

centrifugal pond pump sat in the bottom of the reservoir/storage container and fed water to the weeping hose which kept the towel surrounding the

fermenter saturated with water. The excess water flowed back into the reservoir by the force of gravity. A powerful computer or power supply type fan

was used to force air into and around the fermenter to increase evaporation/cooling of the water.

The pump and fan were controlled by a simple on/off controller. I made a copy of the webpage where I obtained the circuit and I have attached it below

(I used the second circuit). I hope the author doesn't mind, but it really is just a simple op-amp comparator circuit. With good components and

careful adjustment the circuit was able to easily keep the temperature on setting by plus or minus 0.5C. The thermister I used was out of an old 240V

Honeywell electronic household thermostat (I got about 10 of these thermostats for free because they were taken out of a rental property, and each one

had two good quality Honeywell glass thermisters inside). The thermistor was attacked to the end of a copper pair (wire) and placed in the bottom of

thin glass tubing which had been sealed shut at that end by melting with a propane torch. The thermistor in tube was placed in the reservoir water.

Unless the temperature got up close to 30C and/or there was high humidity I was almost always able to maintain the fermentation temperature very close

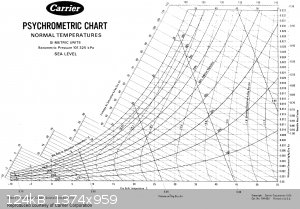

to 20C. The way the unit was set up normally allowed keeping the reservoir water temperature just a degree or so above the wet bulb temperature of the

ambient air. A metric psychrometric chart is attached.

An improvement would likely have been to simply take the plastic top of the storage container and cut a hole in its center for the fermenter and one

at one end for the fan and another at the other end for air to escape. This would help guide the forced air around the fermenter and provide better

fluid contact.

BTW, a little bleach was added to the reservoir water to keep the bacteria from taking over.

Attachment: Thermostat Circuit (Evaporative Cooling, Heating, etc).pdf (396kB)

This file has been downloaded 472 times

[Edited on 19-8-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hennig Brand  |

The pump and fan were controlled by a simple on/off controller. I made a copy of the webpage where I obtained the circuit and I have attached it below

(I used the second circuit). I hope the author doesn't mind, but it really is just a simple op-amp comparator circuit. |

It had been a long while since I went through that document and I really didn't give the author nearly enough credit. I just used it today to build a

controller for the blower on a wood stove and was very impressed with how well written and useful the thermostat design document was.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

For the Low Water alarm, how about one of these :

http://www.ebay.co.uk/itm/Water-Level-Sensor-Horizontal-Liqu...

For the refill valve, maybe the gubbins from an automatic plant waterer, or a fuel shut off valve for a car from the scrapyard.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

I'd use an automotive air conditioner pump and coil to cool water in a reservoir and use the recirculating pump to run my condensers. Swamp coolers

don't work worth shit in damp air.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Small scale cost is maybe not much of a factor often times, however, evaporative cooling, if the amount of required cooling can be obtained, is an

extremely simple, low tech, low cost solution (especially large scale with large volumes!!!). Large scale it is often a very cost effective way to

perform initial cooling, even if lower temperatures are needed, before moving onto much more expensive options like refrigeration cycles.

Even in some small scale applications, like fermentation temperature control, it can be very simple, cheap and effective.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Maker

Harmless

Posts: 46

Registered: 1-11-2015

Member Is Offline

Mood: No Mood

|

|

Holy thread revival Batman

Nice cooler, is it still in use? It looks like it would work nicely as a TIG torch cooler too, now I have two reasons to make one.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Oh my, until you mentioned it I didn't notice how long ago the last post was made. I came across this thread again when googling. Yeah, I was pretty

proud of it at the time and it did work really well. The amount of temperature drop is limited, and dependent on ambient air temperature and humidity,

but it can still be very effective for some applications. I don't have it up and running right now, but I do have the "kit" stored for possible later

use.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

watch out for legionnaires disease, slug any evaporative coolers with Br or Cl before use (depending on pH)

Add media to column to help add surface area

add a drift eliminator to the top to help with spray

|

|

|

| Pages:

1

2 |