| Pages:

1

2

3

4

5

6

..

24 |

barley81

Hazard to Others

Posts: 481

Registered: 9-5-2011

Member Is Offline

Mood: No Mood

|

|

I think this happened:

The brown solution formed by addition of H<sub>2</sub>O<sub>2</sub> is Fenton's reagent (Iron IV) which decomposed to ferric

ion and oxygen. Since the overall oxidation from ferrous ion to ferric ion with H2O2 consumes H<sup>+</sup>, the ferric ions precipitated

as basic sulfate when the pH grew high enough.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Fenton's reagent doesn't involve Fe (IV).

You're probably right about basic ferric sulphate being formed, though...

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

First, a thought- If we could get iron acetate, and Nd acetate, I read that Nd(III)Ac is non-soluable, while Fe(II)Ac is, and also NdAc decomposes at

temp

But today for me was a bad day. I found in the back of my storage area a rack previously used for long-term growth of crystals by evaporation... 3

bottles, one grey with white crust (still with some liquid) one green with white crust, and 1 labelled as ammonium nitrate, but bone dry and empty.

Trying to scrape out the green, thick crust of the first bottle failed with my tool at hand, so I poured out the liquid of the grey one into my

kitty-litter disposal tub. Taking the bottle with me into the other room (where I had a good plastic scraper), I grabbed my tool and went to jam it in

the bottle at the large, noncrystalline mass in the bottom of the bottle- But it was now distinctly purple, with a white crust. I quickly ran to the

next room, bathing the sample under flouresent light- Back to grey! The sunlight revealed my mystery chemical.

So now I have a gram or two of mostly neodymium sulfate (the chemical I had been toying with more than a year ago) with some minor iron sulfate

impurity, which was partially cleaned out physically by removing the white crust. But I wish I had not thrown out the thick, opaque 5ccs of liquid

Pic related.

[Edited on 11-7-2011 by Wizzard]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Wizz:

I bet you good money that stuff is badly hydrolysed, it looks sooooo like an NdCl3 solution that fell foul due to my neglect, a while back. Try

resuscitation with strong HCl, folloed by filtering. Treat the filter residue with strong alkali to convert to Nd(OH)3, then reapply HCl, filter and

combine with first filtrate. To get rid of the Fe, this thread is now jam packed full of ideas.

My next post will be on exploiting the insolubility of a(n unknown to me) double salt of Nd2(SO4)3 and K2SO4 in sat. K2SO4 solution as a means to

separate Nd from Fe, Ni and Cu.

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

I'm dessicating it right now, I'm not really worried about it- I have a 125g (weight of magnets) batch running right now  Maybe I'll hit with some good 34% HCl when I get home, see what happens- If I can get

it clean enough as either a sulfate or chloride, I'm going to react it with some zinc acetate I have lying around. Thank God for my recent find of an

old photographer's chemical closet Maybe I'll hit with some good 34% HCl when I get home, see what happens- If I can get

it clean enough as either a sulfate or chloride, I'm going to react it with some zinc acetate I have lying around. Thank God for my recent find of an

old photographer's chemical closet

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

So I set out to try and quantitatively isolate the neodymium from neomagnets - Nd2Fe14B. 35 g of magnets were demagnetised by heating and cracked with

a hammer. Only part of the Ni-Cu-Ni protective layer was removed and the magnets dissolved in 155 ml of 36 % HCl, on a low setting hot plate and

covered with an hour glass. The cover material was later found back but the nickel had dissolved, possible small amounts of copper too. Strong, meaty

smell, some suggest of boranes (?)

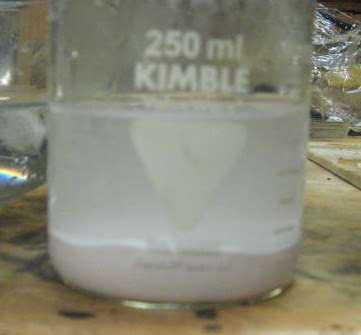

After filtering and washing the filter cake (mainly undissolved boron) the solution was simmered back to about 250 ml of emerald green solution,

covered to prevent loss of salts. To this hot solution, 25 g of crushed (and previously recrystallised) K2SO4 was added, a quantity corresponding to

approx. saturation at 20 C. Immediately a quite large amount of precipitate formed, presumably the unspecified double salt of Nd2(SO4)3 and K2SO4 and

the solution/slurry simmered for a bit, the allowed to cool. No further precipitation on cooling was observed. With flash on, the precipitate can be

clearly seen:

This was filtered off on a coffee filter (which with hindsight was oversized) and the filter cake washed with about 200 ml of sat. (at RT) K2SO4. At

the end the filtrate still tested very slightly positive with oxalic acid solution, showing a slight and slightly yellow precipitate of FeOx. Further

rinsing reduced this signal but only slowly. I believe it due to Fe2+ solution in the large part of the filter slowly seeping into the filtrate.

To remedy this, the filter cake, which is typically lavenderish in colour, was transferred as quantitatively as possible into 100 ml of

saturated (at 20 C) K2SO4 and allowed to cool and decant. The supernatant liquid showed very slight white turbidity with oxalic acid solution,

suggesting the unspecified Nd/K/SO4 double salt may be very poorly soluble rather than totally insoluble in sat. K2SO4. Here it is:

The supernatant liquid was decanted off (the double salt is clearly ‘heavy’) and to the thick slurry a solution of 13.5 g of KOH in 100 ml of

water was added and the precipitate changed appearance slightly. The slurry was kept warm for about ½ hour, stirring occasionally. Supernatant liquid

is strongly alkaline. The precipitate, presumably iron, nickel and copper free neodymium trihydroxide is clearly light pink:

Tomorrow this will be washed with warm water until the filtrate runs almost neutral and sulphate free. The purified hydroxide will then be dissolved

in an appropriate amount of hydrochloric acid.

Edit:

I said the hydroxide was ‘lightly pink’ (on the photo) but to the naked eye the precipitate is actually very light blue! Which is what I remember

form a first attempt. Those dangling f-electrons…

And here’s a reference to Na, K, and NH4 neodymium sulphate double salts in the service of recycling NdFeB scrap.

Update:

To cut a long story short after washing the hydroxide till the filtrate tested negative for sulphate and ran at pH = 10.5, it was then transferred

quantitatively into a clean beaker, the volume made up to 50 ml and 17 ml of 36 % HCl (approx. the least amount) was added. Prior to adding HCl the

filter cake was a nice light blue. The resulting solution however, after heating was slightly turbid still, urine yellow in colour and… tested quite

positive for ferric ions! The separation hadn’t been 100 %. Quite disappointing…

This solution was then filtered to clarity and the K2SO4 separation method will be applied once again to see if complete elimination of iron is

possible.

It appears the double sulphates are of the formula M2SO4.Nd2(SO4)3.2H2O with M an alkali metal (http://books.google.co.uk/books?id=walWQrTRNK4C&pg=PA47&...)

[Edited on 8-11-2011 by blogfast25]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | | So I set out to try and quantitatively isolate the neodymium from neomagnets - Nd2Fe14B. 35 g of magnets were demagnetised by heating and cracked with

a hammer. Only part of the Ni-Cu-Ni protective layer was removed and the magnets dissolved in 155 ml of 36 % HCl, on a low setting hot plate and

covered with an hour glass. The cover material was later found back but the nickel had dissolved, possible small amounts of copper too. Strong, meaty

smell, some suggest of boranes (?) |

You know, that's something I noticed too. I was under the impression that Ni and B wouldn't dissolve in sulfuric (in your case hydrochloric) acid

under these conditions, but if left in there long enough it looks like they do. I've had some magnet pieces with small bits of Ni coating still on

them when going into the acid, and couldn't find them after the magnet itself had dissolved. I also noticed that the boron initially separates out as

a black powder, but over time also disappears if not filtered off. Weird.

Quote: Originally posted by blogfast25  | To cut a long story short after washing the hydroxide till the filtrate tested negative for sulphate and ran at pH = 10.5, it was then transferred

quantitatively into a clean beaker, the volume made up to 50 ml and 17 ml of 36 % HCl (approx. the least amount) was added. Prior to adding HCl the

filter cake was a nice light blue. The resulting solution however, after heating was slightly turbid still, urine yellow in colour and… tested quite

positive for ferric ions! The separation hadn’t been 100 %. Quite disappointing…

This solution was then filtered to clarity and the K2SO4 separation method will be applied once again to see if complete elimination of iron is

possible. |

Disappointing indeed  Everything was looking great up until the end there - you did

everything I could think of to get the best product possible. I was excited about this route because of its simplicity and use of a cheap chemical.

Hopefully you have more luck with precipitation round 2. Everything was looking great up until the end there - you did

everything I could think of to get the best product possible. I was excited about this route because of its simplicity and use of a cheap chemical.

Hopefully you have more luck with precipitation round 2.

In other news, I took my less pure sample of Nd2Ox3 (the yellowish top vial from the last picture of my last post) and tried heating it to

decomposition last night. I used a fused silica crucible heated with a blowtorch from below. I placed the 1.7g of oxalate into it, and after about 5

minutes of strong heating the color started darkening quite a bit. To cut to the chase, the final product is now completely grey and was reduced in

mass to 0.9g. This pretty much confirms that iron(II) oxalate made it into my precipitate, and was decomposed to a fine iron powder upon heating. So

that failed as well

It's possible I didn't heat the crucible enough to reach the decomposition temperature of the Nd-oxalate, since I stopped after it was clear that it

was contaminated with iron. I couldn't find a reference for the temperature at which it decomposes - did you ever find anything mentioning this? I'll

try the same procedure on my other, pure white Nd-oxalate sample soon and see what I come up with. It would probably help to loosely cover the

crucible next time, to help keep the temperature up.

I wish I could see the rest of that paper, looks like it's chock full of ideas. I'd be really interested in reading it.

==Edit==

On further reading, I came across the following reference which I don't really understand:

"To separated only Nd from the solution the U.S. Bureau of Mines has developed a technique using H2SO4 dissolution followed by precipitation of the Nd

using an addition of NH4OH. In this process the Fe remains in solution..."

Source: http://www.osti.gov/bridge/servlets/purl/10190438-P7QwV3/web...

Are they saying aq. ammonia supposedly selectively precipitates out the Nd? Would it not also drop out iron hydroxide at the same time?

[Edited on 11-8-2011 by MrHomeScientist]

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

That might be worth trying. They mention the iron impurity is taken left as jarosite- That's got potassium hydroxide written all over it.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Ni and Cu are indeed slightly soluble in HCl or H2SO4, although as solvents for these metals they're hardly ideal (HNO3 is). If the alloy contains

some borides and/or intermetallics involving boron, then some dissolution of the boron must take place.

I may have been asking a bit much of the double salts method, considering the initial molar ratio Fe/Nd is about 7! Wait and see with round 2. BTW,

Glauber salt, Na2SO4, can also be used, as per that linked reference.

I read that the minimum firing temp. for Nd oxalate to oxide is about 700 C, attainable with a decent crucible (with lid) and a hot blowtorch. Not

sure about firing times, though. I'm not keen on the oxide because the only method to dissolve it is with conc. H2SO4 and that leads back to the

treacherous Nd sulphate.

I can't wholly see the *.pdf theyr're referring )'i/O error has occurred!') to but I can assure you that selective precipitation of Nd from Fe (or

vice versa) is NOT possible. I believe instead they're referring to the ammonium sulphate/neodymium sulphate double salt, by creating (NH4)2SO4 in

situ. But when I tried to saturate a bit of NdCL3 solution with (NH4)2SO4 I didn't get any precipitate...

|

|

|

kmno4

International Hazard

Posts: 1495

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | I'm not keen on the oxide because the only method to dissolve it is with conc. H2SO4 and that leads back to the treacherous Nd sulphate.

|

It is of course not true. Nd2O3, even heated to 1000 C and cooled is easily soluble in dilute acids (this is typical for lanthanides)

Quote: Originally posted by blogfast25  | | I can't wholly see the *.pdf theyr're referring )'i/O error has occurred!') to but I can assure you that selective precipitation of Nd from Fe (or

vice versa) is NOT possible. |

Also not true. It is easy to remove contamination of Fe as Fe2O3xH2O from Nd salts.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by kmno4  | It is of course not true. Nd2O3, even heated to 1000 C and cooled is easily soluble in dilute acids (this is typical for lanthanides)

(snip)

Also not true. It is easy to remove contamination of Fe as Fe2O3xH2O from Nd salts. |

Re. the first statement, how easy/difficult Re2O3 dissolves in strong acids must depend on the degree of calcination and concentration of the acid,

surely?

RE. the second point, what do you mean? That Nid(III) can be separated from Fe(II) without oxidising Fe(II) to Fe(III)? That sounds like a hat trick

to me! By selectively precipitating Nd(OH)3? Similar to the removal of Fe2O3.nH2O from MnSO4 solutions? Like here: http://www.sciencemadness.org/talk/viewthread.php?tid=17931#... ? That would be very interesting kmno4! I would indeed stand corrected...

Edit:

This paper puts the solubility product (Ksp) of Nd(OH)3 at about 2 E-19. The Ksp of Fe(OH)3 is about 2.8 E-39, that’s a lot of orders of

magnitudes lower and would indicate that a mixture of Nd3+ and Fe3+ salts could be separated by adding freshly separated Fe(OH)3 to the solution.

I’ll test tube test that today…

[Edited on 9-11-2011 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

I test tubed the idea of separating Nd3+ from Fe3+ by adding freshly precipitated Fe(OH)3.nH2O to such a solution on a few ml of the Fe 3+

contaminated NdCl3 solution described above. After allowing equibrium to be attained and plenty ferric hydroxide was left as precipitate, that

solution was filtered (several times - some ferric hydroxide kept coming through) and the clear filtrate was that typical colour of a fairly strong Nd

solution and tested very positive with oxalic acid but completely negative for Fe3+!

This opens up another avenue for this separation, as I can’t see any impediment to using the principle on a more concentrated Fe3+ solution. One

would dissolve the magnet material in HCl, oxidise all Fe to Fe [+III], adjust the pH with ammonia to about 4 - 5, add an adequate amount of fresh,

clean ferric hydroxide, allow to equilibrate, then filter. The filtrate should contain all the Nd and no Fe. Then precipitate Nd as hydroxide or

oxalate.

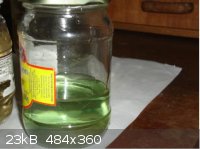

I also repeated the double salt method on the rest of the contaminated sample and this time obtained a nice blue Nd(OH)3 which dissolved in about 10

ml 36 % HCl (suggesting there is no more than 5.6 g Nd there) and that solution showed the typical colours of an NdCl3 solution: greenish under strip

light, kind of orangy under incandescent light. But the solution still tested positive for Fe3+!

|

|

|

Arthur Dent

National Hazard

Posts: 553

Registered: 22-10-2010

Member Is Offline

Mood: entropic

|

|

How volatile is NdCl3? Iron contamination can be removed from Manganese Chloride by the fact that Ferric Chloride is highly volatile at very high

temperature. I was able to refine some dark tea-colored Manganese Chloride solution contaminated with iron simply by boiling it until very little

liquid was left.

As the solution was boiling away, it slowly became lighter and lighter until it was nearly colorless. Upon cooling, the resulting pink-ish gunk looked

very much free of iron impurities and was dissoved in distilled water. After evaporation, it produced very clean, beautiful Manganese Chloride

crystals.

Could this process be applied to a solution of Neodymium Chloride/Ferric Chloride ? Perhaps this substance would act in a similar way? Maybe something

to be attempted?

Robert

--- Art is making something out of nothing and selling it. - Frank Zappa ---

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Arthur Dent  | How volatile is NdCl3? Iron contamination can be removed from Manganese Chloride by the fact that Ferric Chloride is highly volatile at very high

temperature. I was able to refine some dark tea-colored Manganese Chloride solution contaminated with iron simply by boiling it until very little

liquid was left.

As the solution was boiling away, it slowly became lighter and lighter until it was nearly colorless. Upon cooling, the resulting pink-ish gunk looked

very much free of iron impurities and was dissoved in distilled water. After evaporation, it produced very clean, beautiful Manganese Chloride

crystals.

Could this process be applied to a solution of Neodymium Chloride/Ferric Chloride ? Perhaps this substance would act in a similar way? Maybe something

to be attempted?

Robert

|

Perhaps Robert but remember that we're talking Nd2Fe14B here: that's a lot of iron. NdCl3 isn't particularly volatile but the hydrate is likely to

hydrolyse severely on strong heating.

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

I'm a bit worried about the excess sulfuric acid reacting with whatever gunk is left over after it's made salts of the iron and Nd- Does anybody know

what could possibly be left to react? Does boron react? Is there some slow-reacting, previous unmentioned impurity?

I took the 'slush' from my large batch (it looked like silver/blueish snow slush) and transferred it to a new vessel- I then added 98% Sulfuric, and

it's been slowly bubbling for a few days now... I'm going to re-filter and crystallize by evaporation.

Of note- A great way to get the nickel plating from the magnets is crack them into a few pieces (2-3-4 per magnet) and heat with direct heat from a

torch- The nickel with mostly peel itsself off, the magnet material will take on a blue hue, making pieces without coating easier to spot.

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

As extensive research have been done with various chemicals in an attempt to isolate pure neodimium based compounds, all seemed unsuccesful and as

there must had been noticed, all attempts were based on stoichometric quantities to the reagents into account (I so did I in the following) I took the

previous information and added to some studies performed with iron compounds to create a theory that stochoimetry is only appliable to foresee

reaction routes but if not treated with equilibrium constants they fail at determining the behaviour of non-abc elements (the old ones everyone

knows). Thus Nd holds to merit for being long undiscovered rare earth.

First, some iron compounds considerations (stoichometric), since much of the reactions with magnets indeed involves iron!!

Fe + H2SO4 - >FeSO4 (green solution which easily provides beautyful crystals when crystalized)

Then picking recrystalized salt:

FeSO4 + 2 NaOH --> Fe(OH)2 + NaSO4

First of all, stoichometric obtention of the products is already not likely to occur, althogh that deviation just to a little extent (runs

unnoticeable)

The hint here is to add much more NaOH than necessary stoichometrically to keep pH high enough to prevent formation of hybrids which absolutly occur,

unnoticeable.

By the Schirkorr reaction mechanisms, the one which occurs at low temperatures in water

2Fe(OH)2 + 2H2O --> 2Fe(OH)3 + H2

FeII hidroxide is supposed to be a green-white gel. But stoichometric obtention of the same, from chloride or sulphate yield a greyish blue gel, with

some very brillant blue micro (visible) incrustations which I assume are hybrids form the precipitation method.

The oxidation to FeIII in water is aided by atmospheric oxygen but this route seems not to form FeII hidroxides only.

When heated in oxygen free water, Fe(OH)2 goes into Fe(OH)3 and rapidly changes into magnetite (Fe3O4 - not Fe2O3). Thus the color of the hidroxide

gel goes from greyish blue to greyish black.

But now the important part: does FeII hidroxide only turns into FeIII at high temperatures?

Reacting FeII produced before with sulfuric acid yields a dark brown solution just like a much certain product from the reaction oh hematite (Fe2O3)

with sulphuric acid. It should be green FeSO4, but the multistep reaction with sulphuric acid gives ferric sulphate.

Reacting Fe2(SO4) with NaOH to precipitate iron hidroxide again gives a very dark brown iron III hidroxide as product - oxidation really occurred to a

great extent.

Notice in the Schirkorr reaction route into magnetite described above it is not seen intermediary brown colorations, as verified experimentally.

By the last into considerations, reacting a hot solution of brown ferric sulphate with 98% concentrated sulfuric acid gave back again a green

solution!!!

Maybe when sulfuric acid ionized it reduced ferric iron back into ferrous iron, the solution standing with very excessive sulfuric acid.

The mentioned schirkorr reaction are for those who pretend to extract Fe and Nd out of solution as oxides. The schirkorr reaction resembles copper

hidroxide reaction into CuO but I did not test it for neodimium: the reason for getting my hybrid hidroxide contamined results

Into the dissolution of the magnets:

77g magnets where mashed with a big rock (found the big rock more worthy tham a hammer  ) and thrown into a becker with all the Ni coating. ) and thrown into a becker with all the Ni coating.

Stoichometrically it was put to react:

0,1424Nd + 0,9971Fe + 0,0712B + 2,4214HCl --> 0,9971FeCl2 + 0,1424NdCl3 + 0,0712B (s)

295g 30 - 33% threads hydrochloric acid were used. Water was adjusted to sustain just a good saturated solution of the chlorides. By the end of the

reaction the acid was weak and could not dissolve the magnet completly: this was commonly mistaken as boron...

The nanometric particles of boron for sure reacted with water, acid and everything in its path! And could now be found in solution. As said, boron in

this condition would react with everything on a little extent with each, but methods would further diminish its presence later, but not completly as

expected stoichometrically, again. @_@

It was not put excess acid. Before calibrating the necessary water to suspend all the precipated from the acid bath, the so formed grey-purple (yea,

strong purple) precipitat diluted to join the supernatant already dark purple solution. Foaming was noticed probably due to boron - that bastard

><

This foam, or even the dark purple turned yellow-green when exposed to atmospheric air. So the solution was keep closed at most steps.

Since hydrochloric acid is a monoprotic acid it was used for direct dissolution of thew magnets because its faster and forms less ionic agregates

than sulphuric acid - except by the agency of that boron!!!

It was calculated that within that mass of 77g of magnets a volume of 0,34cm³ consisting of pure boron would remain in the vessel, thats pretty a lot

and had to get off.

The hidroxides were then precipitated following the reaction:

0,9971FeCl2 + 0,1424NdCl3 + 2,4214NaOH --> 0,9971Fe(OH)2 + 0,1424Nd(OH)3 + 2,4214NaCl

A little more sodium hidroxide was added to neutralize any possibly formed boric acid into borax.

Water was adjusted to 3,2L to get all borax so prepared into solution, the hidroxides decanted, the supernatant thrown away.

Again, water was adjusted to 3,2L, the hidroxides decanted and the supernatant thrown away.

It would be expected that since the hidroxides are pure nothing else would remain in the vessel... I can tell thats not true - the hidroxides were not

pure.

The hidroxides were then reacted with stoichometric ammounts of sulphuric acid: First considering only ferrous sulphate would form, but then it was

decidedly added more acid as to consider formation of ferric sulphate.

So obscure was the iron already and so are the neodimium compounds!

0,9971Fe(OH)2 + 0,1424Nd(OH)3 + 1,7076H2SO4(aq) --> 0,4986Fe2(SO4)3 + 0,0706Nd2(SO4)3 + H2O

Heat evolved from dissociation of sulphuric acid and reaction with the hidroxides, raising the temperature to about 60ºC.

A greyish mass with a slight pink hue remained at the bottom after decanting. The supernatant was brown but translucid and did not resemble true

ferric sulphate produced with hematite: I was obviously an hybrid.

Considering sulphuric acid dissociation constants:

H2SO4 - > H+ + HSO4- 2,4x10^6

HSO4- -> H+ + SO4- 1x10^(-2)

I does not dissociate completly!

But when reacting with strong bases:

HSO4- + OH- --> SO4(2-) + H20 the equilibrium is strongly changed, favouring formation of sulphate anion.

As iron hidroxide is not a strong base :/

hence the intriguing compounds described.

The greyish pink precipitate at the bottom was not, so, anything even close to pure neodimium sulphate, but something precipitated by it. At this

point the solution had a volume of about 1 Liters: more than enough to dissolve both salts if they did it in time.

The solution was allowed to settle and the supernatant recovered at another becker. This collect supernatant was boiled until reaching a volume of

about 700mL and then was re-added to the becker containg the grayish pink precipitate and mixed together au bain marie, at 100ºC for 40min.

The solution was stirred and then filtrated when still very hot. The filtrate was collected and washed with boiling hot water au bain marie then

filtrated again. The filtrate was collected and washed with boiling hot water au bain marie then filtrated again (third time). All filtrated liquid

were kept for analysis excpet for the last.

The resulting filtrate powder was set to dry in filter paper and its appearence is always yellowish no matter what light I expose it to: seems its

very contamined with iron or Pr.

Last, the first filtrated liquid kept for further analysis was brought to a boil and reduced in volume from 700mL to about 300.

After a much longer period of time than expected this brownish solution gave green crystals!!

and

Those green crystals when washed gives transparent crystals. Thats absolutly a sign of contamination.

Second filtrated liquid:

I came to a conclusion that its very important to add very excess acid when making such solutions to counteract hydrolisation speed of the new formed

solved ions, when dealing with weak base metals.

~~~Poppy

[Edited on 11-10-2011 by Poppy]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Wizzard:

Elemental boron does not react at all with HCl or H2SO4, AFAIK. ‘Magnet boron’ may be partly present as borides and those would blow off

as boranes, explaining that typical meaty smell you get when reacting the magnets with acid.

Thanks for the tip on removing the coating: it will be used on my next attempt.

Poppy:

I suggest using H2O2 or even HNO3 to oxidise all Fe (II) to Fe (III), instead of relying on oxidation by air oxygen.

At a guess I’d say your top photo is of Nd(SO4)3 heavily contaminated with Fe2(SO4)/Fe2O3 as main contaminant. Does it look any different under TL

lighting and incandescent lighting?

I suggest trying to purify it as follows: suspend it in a little water and add some strong alkali and simmer it: the alkali converts the Nd sulphate

to Nd(OH)3.nH2O. Filter and wash cake properly. Dissolve the cake in the minimum quantity of HCl. There’s no need to filter. You now have a

contaminated NdCl3 solution.

Separately prepare quite a quite large amount of fresh, thoroughly washed Fe2O3.nH2O and add some of it to the Nd bearing solution. Some of it will

dissolve, then add some more. Allow standing overnight, making sure that some of the Fe2O3.nH2O doesn’t dissolve. You should thus obtain a NdCl3

containing suspension of Fe2O3.nH2O that is almost neutral (pH ≈ 7).

Filtering this solution you should find ALL the NdCl3 in the filtrate and ALL of the Fe (III) in the filter cake.

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

I'll try purifying the yellow mass I got from picture above but I think the major other part is still inside the vessel with brown liquid and green

crystals. The crystals have grown even more and I'll post a picture of them soon.

Blogfast,

you suggest some species might be hidrated iron oxide?

(Fe2O3 .nH2O or FeOOHHOH and all the heck of strange formulas iron can get in such conditions.) but I cant find a specific way to afford Fe2O3.nH2O

Between trying to react hematite with water and conc. alkali but nothing occured.

I will verify your method, thanks for advice

~~~Poppy

I need a credit card again so I can visualize internet books

After testing the method you said I guess I'll have to calcinate everything and start reaction all over, at least the componentes should be boron free

by now.

[Edited on 11-10-2011 by Poppy]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Poppy  | you suggest some species might be hidrated iron oxide?

(Fe2O3 .nH2O or FeOOHHOH and all the heck of strange formulas iron can get in such conditions.) but I cant find a specific way to afford Fe2O3.nH2O

Trying to react hematite with water and conc. alkali but nothing occured.

Iwill verify you rmethod, thanks for advice

~~~Poppy

|

Fe(OH)3 has a very small solubility product (Ks about 10<sup>-39</sup> and ferric ions hydrolyse easily (much more easily than Nd3+), so yes, hydolysed species are likely to contaminate your (top photo) sample.

and ferric ions hydrolyse easily (much more easily than Nd3+), so yes, hydolysed species are likely to contaminate your (top photo) sample.

Hematite (Fe3O4) does not react with alkali AT ALL. Iron oxides (II and III) are not oxoacid formers and cannot react with alkalis.

I think most of your Nd is in the stuff shown in the top photo: even the quantity (for 75 g magnets) seems to roughly fit the observation.

Mixing fresh ferric hydroxide with the dissolved contaminated sample, making SURE there's Fe(OH)3.nH2O/Fe2O3.nH2O left over should cause any Fe3+ in

that solution to precipitate as Fe(OH)3.nH2O/Fe2O3.nH2O. That's what my preliminary test showed. The method is also used for cleaning Mn2+ solutions

from Fe3+ contamination.

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

Fe(OH)3.nH2O/Fe2O3.nH2O is common rust found from oxydised iron metal.

Preparation of this would require reacting pyrophoric iron with water. Otherwise large iron metal clumps would retain its metallic interior.

Not confident enough on my yellow mass content I will try this method soon.

[Edited on 11-10-2011 by Poppy]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Poppy  | Fe(OH)3.nH2O/Fe2O3.nH2O is common rust found from oxydised iron metal.

[Edited on 11-10-2011 by Poppy] |

No, no, no, I'm talking precipitated Fe(OH)3. Take any iron salt, dissolve it in water and (carefully!) add peroxide to it. Then cool, dilute

somewhat and add alkai (like NaOH) to precipitate Fe(OH)3. Wash profusely to get rid of Na+, OH- and other anions.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I'm really interested in this iron hydroxide method!

I also tried it last night on test tube scale, and I don't have my notes on me but here's a quick rundown.

I took 3mL of the magnet solution and added NaOH solution to it until no more precipitate formed. The precipitated hydroxides were initially green,

and any exposed to air (e.g. on the filter paper) quickly turned brown. This is surely iron(II) hydroxide being oxidized to iron(III) hydroxide.

(Remember that my magnet solution at this point contains both iron(II) and iron(III) sulfate, as well as Nd sulfate.) I filtered and washed the

precipitate of hydroxides. While still wet, I scooped this into a test tube of 6mL of magnet solution and stirred it around a bit. I also added a few

mL of water to rinse the goopy hydroxides off the side of the tube and down into the solution. After letting this sit and settle overnight, the color

of the solution is a much lighter pink than it initially was. This of course might just be due to dilution from adding the extra water, though.

I then realized that I don't have any thiocyanate to use to see if anything actually happened! Are there any other methods to test for iron(III)? I'll

try testing for iron(II) with ferricyanide like I did before, while I'm at it, and report back. Hopefully, if it turns out to be free of any iron,

that would mean it's not necessary to convert everything to iron(III) first.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Hi MrHS:

The iron HAS to be present as Fe (III) because FE9OH)2 isn't as insoluble.

To check for Fe w/o KSCN, add some adic and a piece of Zn or Al: both reduce Fe (III) to Fe (II), then test with ferricyanide.

I'm running a larger test with this ferri hydoxide method overnight: fingers crossed!

[Edited on 10-11-2011 by blogfast25]

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

Gentleman, lend me this opportunity to correct myself:

Fe(OH)3.n H2O / Fe2O3n.H2O IS NOT RUST

It is in fact a byproduct of the reaction of FeIII ions into FeIII hydroxide followed by the autoprotolysis of hydroxide molecules

(OH)(-) + (OH)(-) --> (O)(2-) + H2O

2Fe(3+) + 3O(2-) --> Fe2O3

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Poppy  | Gentleman, lend me this opportunity to correct myself:

Fe(OH)3.n H2O / Fe2O3n.H2O IS NOT RUST

It is in fact a byproduct of the reaction of FeIII ions into FeIII hydroxide followed by the autoprotolysis of hydroxide molecules

(OH)(-) + (OH)(-) --> (O)(2-) + H2O

2Fe(3+) + 3O(2-) --> Fe2O3

|

Poppy: you're looking too far afield: there are no O<sup>2-</sup> in solution.

Fe(OH)3 (Fe2O3.nH2O is just a different notation, really) forms most easily by adding alkali to a Fe3+ bearing solution:

Fe<sup>3+</sup>(aq) + 3 OH<sup>-</sup>(aq) + n H2O(l) === > Fe(OH)<sub>3</sub>.nH<sub>2</sub>(s)

£$$%&*())__%^&*(^%$£$

Well, this separation method based on adding ferric hydroxide to the Nd3+/Fe3+ solution works well. I’m inclined to say ‘it rocks!’, actually.

Two such separations were carried out on 2 lots of about 250 ml of ferric contaminated Nd3+ solutions, both with great success. In both cases the pH

went up slowly to about 4 after addition of the ferric hydroxide (in both cases the same lot of ferric hydroxide was used). The supernatant solution

then filtered to clear, testing negative for Fe3+ (KSCN) and very positive for Nd3+ (against oxalic acid).

This is roughly in line with Ksp = [Fe3+] x [OH-]<sup>3</sup> ≈ 10<sup>-39</sup>: at pH = 4; [OH-] =

10<sup>-10</sup> and thus [Fe3+] ≈ 10<sup>-9</sup>. Of course there are some subspecies at play like

FeOH<sup>2+</sup> and maybe Fe(OH)<sub>2</sub><sup>+</sup>.

A few tips:

• Once the pH drop below 3, the [H2O+] concentration becomes low (< 0.001 M) and reaction slows down a lot. Help reaction along by heating the

slurry and keeping it warm for a bit.

• Heating also helps the Fe(OH)3 particles to grow, allowing for faster filtering.

• Don’t try and squeeze the last bit of Nd3+ from the filter cake: Fe(OH)3 has a tendency to peptise at low ionic strengths: it then starts

running through the filter as a colloid.

Then another batch of 4 magnets, 27.7 g by weight were dissolved in 122 ml of HCl 36 %, in a 1 L beaker on a low hot plate setting. After reaction had

stopped, the solution was diluted to about 200 ml and filtered. The latter may not even be necessary here but because I didn’t get the cover off I

didn’t want further contamination with Cu2+.

The solution was then iced and slowly oxidised on icebath with 100 ml of 9 % H2O2. It was diluted a bit more and then simmered to decay excess H2O2.

At that point large amounts of ferric hydroxide started to precipitate: hydrolysis is pushed by heat. The pH was till low and I added the same ferric

oxide slurry recovered from the filter of the last separation and kept the solution warm for some time. It’s now cooling and I will read pH

tomorrow: at pH >= 4 the separation should be complete!

[Edited on 11-11-2011 by blogfast25]

|

|

|

| Pages:

1

2

3

4

5

6

..

24 |