mnick12

Hazard to Others

Posts: 404

Registered: 30-12-2009

Location: In the lab w/ Dr. Evil

Member Is Offline

Mood: devious

|

|

3,4-dihydroxy-5-methoxybenzaldehyde synthesis

Well I thought I would share my attempt at synthesizing 3,4dihydroxy-5-methoxybenzaldehyde from 5-bromovanillin. This was my second attempt, and I

plan on trying it again some time soon. My motivation for trying this procedure was to see if I could effectively scale down some of the already known

procedures.

Reagents

sodium hydroxide 6.12gr (.153mol)

5-bromovanillin 5.00gr (.0217mol)

Precipitated copper powder 60mg, which is easily prepared by reacting zinc dust with a copper sulfate solution, then dissolving the excess zinc in a

suitable acid.

Procedure

Sodium hydroxide (6.12gr) was dissolved into 75ml of tap water. The warm NaOH solution was transfered to a 250ml rbf. Next the 5-bromovanillin

(5.00gr) was added to the NaOH solution. This produced a turbid orange-ish solution which had a small amount of white material floating on the

surface. Then the precipitated copper (50mg) was added to the solution, no changes were observed. The flask was then transfered to a sand bath, and

set up for reflux. After 2hrs of reflux the solution had cleared up and turned a brighter orange color. It was then allowed to reflux for another

16hrs, by which time it had developed a hardly noticeable green-ish color. Total reflux time was 18hrs.

The flask was left to cool to rt, and as it cooled some crystalline material precipitated. Next the solution was acidified with sulfuric acid. As the

ph decreased the solution started to precipitate material. The solution was then extracted 3x10ml of ethyl acetate, filtered to remove the copper

powder then the filtrate was washed once with 10ml of ethyl acetate. The now amber colored extract was placed in a 250ml rbf, where the solvent was

stripped under vacuum. Once the solvent was removed the aldehyde was dissolved into a minimal amount of DCM placed in a glass dish and allowed to

evaporate. The final yield was 2.71gr of pleasant smelling brownish crystals.

Now just a few notes.

Its probably a good idea to filter the solution while it is still warm, I ended up loosing a small amount of my aldehyde from doing the filtration

later on. Also when stripping the solvent under vacuum it is a good idea not to remove all of it, since when the aldehyde starts crystallizing there

is alot of bumping. And finally I dont think I needed to reflux it as long as I did, 6 or 8 hours would probably work.

Now for the pictures!

Water, NaOH, Cu, and the 5-bromovanillin

After mixing everything

Refluxing

After cooling

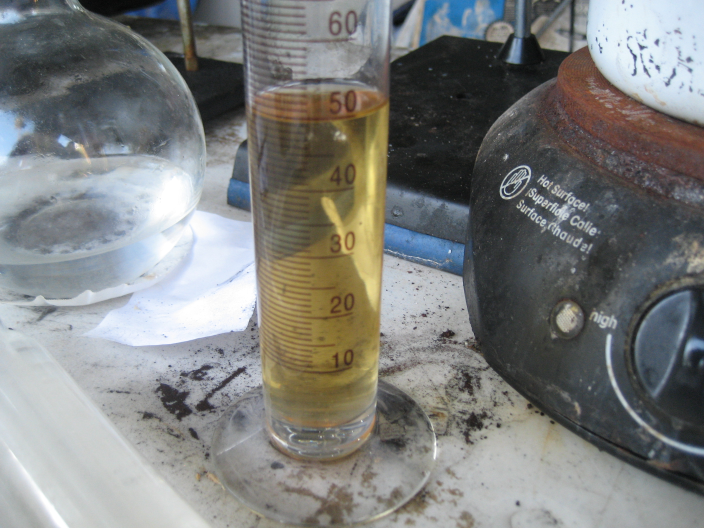

Ethyl acetate extract

The finished product, 2.71gr of impure 3,4-dihydroxy-5-methoxybenzaldehyde.

So theres my attempt at synthesizing 3,4-dihydroxy-5-methoxybenzaldhyde. The yield was not as good as I hoped it would be, but that is due to my own

error and not the procedure. All in all it was quite a simple procedure and encourage others to try it.

Questions and comments are welcome!

Thanks

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

This is a pretty interesting write-up. I think before you proceed any further, you need to rigorously purify a small quantity of the purported

3,4-dihydroxy-5-methyoxybenzaldehyde and do a melting point or something to make sure you are not simply isolating starting material.

It seems to me you have done almost no purification, you only extracted with ethyl acetate, then you took up the residue of evaporation into DCM and

then simply evaporated the DCM; what was the point of the DCM part?

Also, next time use more solvent for extraction, especially with a solvent like EtOAc which has a fair solubility in water. I think next time you

should do an extraction with 3x30mL or more of EtOAc.

A good purification would be recrystalization from a mixture of a hydrocarbon and either ethyl acetate, DCM, or Ether. You might need to do a few

crystallizations to get a product pure enough for a good mp. I also recommend fractional crystallization because if you add enough of the hydrocarbon

you will eventually precip the starting material as well.

FYI (if you don't have this data already): The melting point is listed to be 132-134c as opposed to 164-66 for the starting material.

Just a closing statement: I cannot express enough how important it is to be positive you have isolated exactly what you think you have made before

proceeding further in a synthesis or repeating a procedure. A couple small scale recrystalizations to get an analytical sample are really worth it in

the long run.

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

Magic Muzzlet

Hazard to Others

Posts: 146

Registered: 22-7-2010

Member Is Offline

Mood: No Mood

|

|

As I understand after you acidified you did not filter the mixture? Or is that what you meant in your notes. The precipitate was probably

bromovanillin, next time you should filter before extraction if you did not. I have tried this but the bulk of the starting material would never react

and i got alot of starting material to filter.

I personally cringe at thinking about ever trying this again, but if you succeeded I may need to try it again!

Nevermind i misread and saw you filtered. I need to read more carefully.

[Edited on 7-10-2010 by Magic Muzzlet]

|

|

|

mnick12

Hazard to Others

Posts: 404

Registered: 30-12-2009

Location: In the lab w/ Dr. Evil

Member Is Offline

Mood: devious

|

|

Hey thanks for the responses.

Currently I am recrystallizing .75gr of the crude material from a 1to1 mix of ethyl acetate and benzene. Once I get a pure enough sample I will do a

mp test.

@smuv: The reason why I rinsed the flask with DCM was an attempt to dissolve some of the material from the inside of the flask where it had adhered

itself during the distillation. Yeah I think using more ethyl acetate would have been a good idea, if I try this again I will definitely do a better

extraction.

thanks

|

|

|

crazyboy

Hazard to Others

Posts: 436

Registered: 31-1-2008

Member Is Offline

Mood: Marginally insane

|

|

Do you have a reference for this procedure?

|

|

|

Ebao-lu

Unregistered

Posts: N/A

Registered: N/A

Member Is Offline

|

|

you may saturate the aqueous phase with sodium chloride for better extraction

also you can try a Beilstein test with copper wire http://en.wikipedia.org/wiki/Beilstein_test , but it can be still positive because of traces of starting material even after purification, so

compare it with same test with pure starting material to see the difference

[Edited on 12-10-2010 by Ebao-lu]

|

|

|

mnick12

Hazard to Others

Posts: 404

Registered: 30-12-2009

Location: In the lab w/ Dr. Evil

Member Is Offline

Mood: devious

|

|

Hmm well I have a quick question.

The synthesis of 5-hydroxyvanillin is quite long and does not provide very good yeilds. So I was thinking of trying the synthesis of syringaldehyde

from 5-bromovanillin, but the procedure I was planning on doing requires copper (I) bromide. Now I have seen other papers which claim any copper (I)

salt will work. So my question is, could I use copper (I) chloride instead of the bromide for the ullmann? The reason why I ask is my only supplier of

copper bromide wants me to buy 500gr which is much more than I could ever want or need.

Thanks!

|

|

|

entropy51

Gone, but not forgotten

Posts: 1612

Registered: 30-5-2009

Member Is Offline

Mood: Fissile

|

|

Quote: Originally posted by mnick12  | | So my question is, could I use copper (I) chloride instead of the bromide for the ullmann? The reason why I ask is my only supplier of copper bromide

wants me to buy 500gr which is much more than I could ever want or need. |

CuBr is easily made by refluxing

CuSO4, NaBr and Cu. This is OTC since CuSO4 and NaBr are available in the hardware stores.

The prep is in Vogel.

|

|

|

IPN

Hazard to Others

Posts: 156

Registered: 31-5-2003

Location: Finland

Member Is Offline

Mood: oxidized

|

|

If that synthesis with copper (I) bromide catalyst is one of those NaOMe substitution reactions then the chloride should do fine.

I have made syringaldehyde from 5-bromovanillin according to the procedure in Synthesis 308 (1983) using copper (II) chloride. Yield was 72% using

homemade copper (II) chloride (CuO + HCl, dehydrated at 120C forming a dark brown powder most likely containing CuO/CuCl) and mol-sieve dried DMF.

Also you can greatly improve the yield of the 5-hydroxyvanillin synthesis by using a protective atmosphere of nitrogen/argon as the aldehyde is very

easily oxidized when in alkaline solution.

My yield on the same procedure (DE2248337) was 80% with a total reaction time of 50h using N2.

|

|

|

Sandmeyer

National Hazard

Posts: 784

Registered: 9-1-2005

Location: Internet

Member Is Offline

Mood: abbastanza bene

|

|

Quote: Originally posted by IPN  |

Also you can greatly improve the yield of the 5-hydroxyvanillin synthesis by using a protective atmosphere of nitrogen/argon as the aldehyde is very

easily oxidized when in alkaline solution.

My yield on the same procedure (DE2248337) was 80% with a total reaction time of 50h using N2. |

In addition to using N2 atmosphere during the reaction -- as IPN already said, a good idea would be to degas DMF prior to the reaction -- by bubbling

N2 through it.

|

|

|

mnick12

Hazard to Others

Posts: 404

Registered: 30-12-2009

Location: In the lab w/ Dr. Evil

Member Is Offline

Mood: devious

|

|

Yes I like the idea of an inert atmosphere, but alas I do not currently have a cylinder of N2. One alternative I was considering though was the air

canisters paintballers use, I have one and I know some of the more serious paintballers fill them with N2. I guess it is simply a matter of finding

the correct fittings.

And as an update, the recrystallized material has a large amount of crystals with identical shape to recrystallized 5-bromovanillin, suggesting my

yield was even lower than I reported (if any).

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Nice description of an experiment, but... a minor side note: It is nonsense to talk about yields before doing the characterization. The yield of a

product is the ratio between the mass of the reaction product and the theoretical output of the reaction. So you can not talk about yields until you

have a product, and you can only talk about having a product once it is characterized. I know this all sounds obvious, but I saw too many examples

demonstrating this is not obvious to all. Talking about yields before even measuring the mp or doing a TLC is like talking about winning a lottery

prize and not buying the ticket.

|

|

|