| Pages:

1

2

3

4

5

6

..

9 |

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

Thank you Metacelsus, so if my calculations are correct I will obtain 10gr of 10%HNO3 solution by mixing 8.46gr H2O and 1.54gr 65%HNO3. That's the

correct ratio to obtain the best SADS, is that correct? (of course I will also add AgNO3 then).

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

you really want around a 25-29% HNO3... read the paper I attached a few weeks ago...

|

|

|

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

I downloaded and read several times the paper you attached, it is very informative on the subject but the author doesn't express himself about the

optimal percentage of HNO3 in the AgNO3 solution, he only says it has to be "slightly acidic". It does say that ignition temperature of SADS increases

up to 280°C when 28% HNO3 solution is used but it's still not clear what is the optimal concentration that optimizes the most and most important SADS

parameters.

[Edited on 19-9-2016 by Tricka90]

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Hmm. I thought he says as close to 30 percent as possible. After 30 percent a different undesirable form is made.

I could be mistaken. Anyways please report back on your results!

|

|

|

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

In the paper you attached he doesn't define any limit about HNO3 concentration. He however advise against using more than 10% w.w AgNO3 concentration

because in that case the formation of silver acetylide–hexanitrate would occur.

Talking about AgNO3 concentration, what do you think is optimal? It seems 5 to 10 % w.w range is ok.

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I don't know. If you read that paper several times you know just about what I do....

|

|

|

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

Do you think that passing too much acetylene gas through the AgNO3 solution would cause any problem?

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

No...

but I don't think you need any more than 3 minutes of time.

|

|

|

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

Thank you MineMan.

What's your yield for SADS? I get about 0.4g SADS for 1g AgNO3 and I think that's pretty bad...

[Edited on 2-10-2016 by Tricka90]

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I think my yield is pretty close to yours maybe about .6.... instead of .4

|

|

|

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

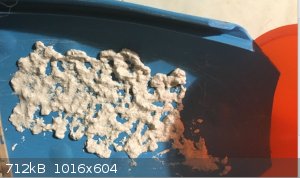

Since it seems like many forum members are having an hard time obtaining fairly pure white SADS I would like to share some tips on optimizing the

whole process to get a powder as white as the one you can see in the attached picture (still wet), even when "dirty" acetylene gas (the one readily

produced from calcium carbide and water reaction) is used.

I'm not an expert, so I'm just gathering all the rules that lead to the attainment of the pure product in the picture below (I'm supposing you're

already familiar with the entire procedure).

- The following proportions between the reagents are recommended: 8.7ml H2O, 1.3ml 65% HNO3, 700mg AgNO3, 1.5g CaC2 in 40ml H20. More than 450mg net

SADS will easily be obtained

- AgNO3 solution must reside inside of a narrow and tall cylinder when reacting with acetylene gas.

- AgNO3 must be as pure as possible, no copper derivatives are allowed, the best choice is nitrating very pure Ag

- H2O for both AgNO3 solution and gas generator must be bidistilled

- AgNO3 solution must be kept in the 65 to 70 °C temperature range during the whole reaction with acetylene

- A mechanical filter such as cotton or, even better, chemically unreactive cigarette filter must be firmly placed inside the tube which transports

acetylene gas. When strongly blowing into the tube, air should come out with difficulty

- All the reactions must be performed with very soft light

- Acetylene gas should not react through AgNO3 solution for more than 4 minutes. More than that will produce just some tens of mg more of SADS but

purity will decrease dramatically

- Filter must be washed before filtering the powder, which must be copiously washed with bidistilled water as well.

- Drying time must be reduced to a minimum (less than 24 h if possible) and performed in a clean, slightly warm, dry (of course  ) and dark location. Water shouldn't be allowed to stay in contact with SADS for

many hours so the powder must be spread out on a surface capable of absorbing water while not allowing for SADS to stick. Filter papers from chemistry

stores are optimal. ) and dark location. Water shouldn't be allowed to stay in contact with SADS for

many hours so the powder must be spread out on a surface capable of absorbing water while not allowing for SADS to stick. Filter papers from chemistry

stores are optimal.

I didn't add any book reference or justifications for any of the rules I listed, so if you're interested feel free to ask.

Hope this helps, have a nice day.

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Nice product,

I really like your tip about no more than 4 minutes. My best batch of SADS did not go off with hard grinding in a mortar and pestle. See if yours is

the same  ? ?

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Looks like an excellent product indeed and detailed write up, SADS when properly made is a very useful initiator with excellent properties. I must

say, from my own experience (using very similar process) I used to get a snow white product, with pearl gloss with most batches of calcium carbide,

though one particular batch of carbide was a really dark grey (with granular black lumps in between) and no matter how careful the synthesis was

performed, the first bubble of acetylene produced immediately resulted in a dark brown precipitate. The crude carbide product can contain many

impurities, some of which cannot be removed easily and likely form a complex with Ag+ as well. Looking for a visually clean batch of calcium carbide

may reallly be of help due to differences in batch puritity.

|

|

|

Tricka90

Hazard to Self

Posts: 52

Registered: 14-8-2016

Member Is Offline

Mood: No Mood

|

|

Thank you MineMan and nitro-genes, I'm happy you like the product.

@MineMan: The tip about avoiding long time exposure to acetylene gas isn't my idea, I read it in Matyas' Primary Explosives book where it's stated

that if acetylene is passed for enough time, simple Ag2C2 may start forming.

In practice, if you carefully pay attention to the colour of the precipitate during its formation from the beginning to the end, you'll see that it

gradually assumes a more grey and brownish tinge as the reaction proceeds.

@nitro-genes: I agree with you, having high purity calcium carbide is key, if even the first precipitate formed is not fairly white it is a clear

indication that acetylene should undergo a purification process if high quality SADS is to be obtained.

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Looking forward to the det tests!

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Right....finally i've gone and and done it out of pure curiosity: dilution of SADS with KClO3. A rather perilous and unknown path in the

general direction of "courting disaster"

The SADS was a fresh batch from a procedure I've described earlier on this same thread and formed at exactly @ 65C. A potent sweet point for the pure

stuff. Now to see if one can further enhance the performance with the aid of potassium chlorate. The chlorate is also from DIY electrosynthesis origin

and has been meticulosly recristallised and ball milled to a fine powder. I presume it is quite pure in reasonable framework.

Sample mixtures of 100mg each were weighed in proportions to account for resulting dilutions that contained 0, 15, 20, 25, 30, 40 50 % of

KClO3. The samples were homogenised in the dry state very carefully with a plastic pestle in stainless steel vessel until presumed to be

well mixed.

"Organoleptic" evaluation of performance was then commenced by picking up a small amount of the respective sample on the tip of a wooden safety match

and then being lit with a butane torch. Resulting sound effect and the degree of shattering of the wooden match was used as a relative scale to assess

the potency of the sample. Amount of samples tested was not strictly equal, but I tried to get the maximum amount of every mix to stick on the match

tip without it falling apart or off under it's own weight. So they are more or or less comparable in terms of amount. The scales could not pick up the

amount of sample so it must have been on the order of about 1mg.

So the results were quite interesting and in some ways unpredictable. What struck me with the greatest amazement was the fact that all of the mixtures

up to 50% chlorate content by mass remained detonable in the tiniest of amounts just like pure double salt. Of course the power of the mixtures

started to steer down starting from about 25% of chlorate content and upwards. At 50% chlorate content the mix was basically unable to damage the tip

of the match and only scarred the surface, leaving a sooty stain. I do think that even above 50% chlorate content the mixture will still remain

detonable, but as the performance had dropped below any practically acceptable level, did not go any further with the dilution this time.

The sweet spot of dilution mixtures seems to lie quite predictably in the range between 15-20% chlorate content by mass.

These samples caused by far the most damage to the wooden match and were characterised by a sharp and unbelievably strong sound even in these tiny

amounts. I can not assure that the 15-20% dilutions are far superior compared to pure double salt in terms of "match shattering" performance, but they

definately are not inferior according to the results at hand.

Of course nothing is known about the stability, sensitivity or viable storage time of these mixtures yet. So I will assume the worst at the moment and

so should everyone else.

Exact science is a figment of imagination.......

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Nice idea to mix KClO3 with SADS.

Next step AgClO2 /SADS  or AgNO2/SADS or AgNO2/SADS

It seems there is a SADS/SANC variant using Ag perchlorate instead of nitrate --> SAPC.

Maybe Ag chlorate can do aswel --> SACC

Your testing is a bit rough/arsh/primitive...would be better to get a sand crushing test with 10-50 mg of the various mixes...result would be more

relevant, comparable to each other and of better scientific value.

Also not using very much material and not so costy.

Eventually the sand may be extracted with HNO3 to recover the silver nitrate  . .

Also the % mixes into your study must hold a little more steps:

0, 5, 10, 15, 20, 25, 30, 35, 40, 45, 50

Then it would be perfect.

I have played a few days ago with snap it everywhere bangers (the tiny paper bags containing 4 to 5 grit stones (3mm diameter) and covered with silver

fulminate)...the favourite sport of my brother and I is to open the bag cautiously and to boost the charge (when un-boosted you can snap it between

your fingers without risk or pain) with 1-5 mg SADS/SANC...it turns then into an interesting detonating device...making your ears ring when trowed

into a room...it makes a white thunderball (5-10 cm diameter) with a loud report...against a white wall it makes a radiant spot of black silver.

Of course when boosted it can hurt the fingers when snaping.

If you let the bag fall from 1m it detonates (propelling the grit onto the ground...so better wear glasses.

You can make booby traps with it, if someone walks onto it bang...under the wheels of a car with tape...bang when the wheel rol onto it.

The fun is that it is upgradable by joining more bags together...but caution...the power increases to the power 3 when doubled.

Also for storage...into cotton whool...no big quantity into the same place...and no rude handling.

[Edited on 28-1-2017 by PHILOU Zrealone]

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by PHILOU Zrealone  | Nice idea to mix KClO3 with SADS.

Next step AgClO2 /SADS  or AgNO2/SADS or AgNO2/SADS

It seems there is a SADS/SANC variant using Ag perchlorate instead of nitrate --> SAPC.

Maybe Ag chlorate can do aswel --> SACC

Your testing is a bit rough/arsh/primitive...would be better to get a sand crushing test with 10-50 mg of the various mixes...result would be more

relevant, comparable to each other and of better scientific value.

Also not using very much material and not so costy.

Eventually the sand may be extracted with HNO3 to recover the silver nitrate  . .

Also the % mixes into your study must hold a little more steps:

0, 5, 10, 15, 20, 25, 30, 35, 40, 45, 50

Then it would be perfect.

I have played a few days ago with snap it everywhere bangers (the tiny paper bags containing 4 to 5 grit stones (3mm diameter) and covered with silver

fulminate)...the favourite sport of my brother and I is to open the bag cautiously and to boost the charge (when un-boosted you can snap it between

your fingers without risk or pain) with 1-5 mg SADS/SANC...it turns then into an interesting detonating device...making your ears ring when trowed

into a room...it makes a white thunderball (5-10 cm diameter) with a loud report...against a white wall it makes a radiant spot of black silver.

Of course when boosted it can hurt the fingers when snaping.

If you let the bag fall from 1m it detonates (propelling the grit onto the ground...so better wear glasses.

You can make booby traps with it, if someone walks onto it bang...under the wheels of a car with tape...bang when the wheel rol onto it.

The fun is that it is upgradable by joining more bags together...but caution...the power increases to the power 3 when doubled.

Also for storage...into cotton whool...no big quantity into the same place...and no rude handling.

[Edited on 28-1-2017 by PHILOU Zrealone] |

So many options on conducting a bit of pyrotechnical mischief

I do admit that the approach was insistently primitive, but I was not in the mood to mess up my perfectly good saturday afternoon with a coupious

amount of unknown primary energetic mix going sideways on me and then having to explain the lot to the intern at the ER  To my defense I can say that at least I'm not drawing any far reaching conclusions

from the "results". To my defense I can say that at least I'm not drawing any far reaching conclusions

from the "results".

But there is promise to the claim of sustainabilty if these dilutions hold up to the test of time in terms of stable and prolonged function. Only time

will tell....

In the meantime one can do a more refined spectrum scan in the range between 10-20% chlorate content and refine the assessment method for brisance of

the samples. I fear that quartz sand would be a medium of too high hardness for this mix, especially if one tests amounts in the range of 50mg as

would be used in the intended initiation devices and hence it would possibly distort the results since resolution between the samples might be too

small and overlapping. So what I would opt for is a nice soft limestone fraction in the range of say 250 microns with a very narrow particle size

ditribution. Lucky me that my assistant has to handle and characterize the quality control of about 2 shipments of 30 tons of the stuff every week at

work

I guess there is more on the topic coming in near future...

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1334

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Interesting testig of SADS - KClO3. However for more precise results always is good metal plate. If all energy is discharge to plate, thus without

hole, is measurement pretty precise. For 1 mg estimate Alu can Cola or 2 - 3 layers of this material. In metal arises impact with a memory and it is

possible easy measurement. Impact without hole, this is important. All energy must be discharge to metal. Without spend in hole. Best is annealing

metal, aluminium or copper. Both have a good memory on the shockwave. Thickness can be 0,1 to 0,5 mm for very small samples about 1 mg to 10 mg of EM.

........LL..........

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

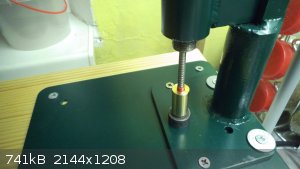

Thanks to the moderately affordable luxury of a chinese mini lathe I've been tinkering on the setup of sand crushing test equipment....

First one is going to need a sample forming set...like the one below:

Which is put together like that:

Allrighty then....let's weigh a sample into the tube:

Compact it moderately to fix it in the tube:

Attach the fuse holder and a lenght of visco:

And we have a sample ready for testing and evaluation....of course for that we are going to need a sand cell to contain the evaluation medium.

Like the one below...the "nr 36" cell....yup, looks aboot right:

Can be dissasembled for easier filling and amptying of sand and test samples:

So for further steps one is going to lower the sample into the cell and add a preweighed fraction of evaluation medium to cover the sample

(granulometry must be known and tightly conrolled). Then assemble the cell and light the fuse. After the "pop", disassemble cell, remove sand and

separate sample parts: fuse holder, end cap, etc. Weigh the sand to be sure none has been lost and perform sieve analysis to evaluate how much sand

has been reduced in grit and relate that to the "potency" of the sample. This should give better scientific value than comparing mangled match tips

Exact science is a figment of imagination.......

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Really nice setup markx!

Where did you bought it and for what price?

Would be nice to get a standard procedure and setup between forum members.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I did not buy it....made it all from scratch today at work

Bits and pieces picked up from workshop metal scrap dumpster and adding a little value and function...

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1334

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Oh my God...super science aparatus for international research of all primary materials. Los Alamos Laboratory device. I am waiting on the first

results.......... ....LL ....LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Update.....

The "nr 36" cell is officially complete and ready for testing:

![WP_20170131_007[1].jpg - 1.1MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56590)

It was missing the bottom in last post, so I had to "fabricooble" one

And a dedicated sample holder that threads in dead center:

![WP_20170131_001[1].jpg - 1.2MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56592)

![WP_20170131_002[1].jpg - 1.1MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56594)

![WP_20170131_003[1].jpg - 1.1MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56596)

![WP_20170131_004[1].jpg - 1MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56598)

![WP_20170131_005[1].jpg - 1MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56600)

Turned out pretty good.....it's awesome how much possibilites open up if one owns a small lathe and a welding apparatus

As for the testing medium I'm going to use 250/100 micron limestone sand fraction and brisance shall b related to the amount of fraction passing

through 100 micron sieve after testing. One can accumulate several repetitions on a single sieve and get an averaged and more representative result

for the mesured sample mix. This prevents the extra work of sieving each sample and averaging afterwards.

The sand bulk in drying process....porosity makes it hard to get the moisture out, but it's moving along and shall be ready to use tomorrow:

![WP_20170131_009[1].jpg - 1.2MB](http://www.sciencemadness.org/talk/files.php?pid=473282&aid=56604)

[Edited on 31-1-2017 by markx]

Exact science is a figment of imagination.......

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Wow! You work fast and ingeniously!

I'm more than eager to see first results.

Sand will dry faster in a kind of tumble drier or into a fluidized bed (warm air from under through the sand that is lifted up (fluidized) a little

and fall back down).

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

| Pages:

1

2

3

4

5

6

..

9 |