AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Air Flow Path to Ochre-pigment Colored FeO(OH))

The basis for the preparation of Ochre-pigment colored FeO(OH) (see https://en.wikipedia.org/wiki/Ochre and https://en.wikipedia.org/wiki/Iron(III)_oxide-hydroxide) in this thread can be found in this fully free

available 2008 reference: "Air Oxidation of Ferrous Iron in Water" by Ahmet Alıcılar, et al, at http://www.jieas.com/fvolumes/vol081-5/3-5-11.pdf.

“Abstract: Air oxidation of ferrous iron in water was studied...Thereafter, the experiment was successively repeated by blowing air to the solution

without and with inert packing. Lastly, the catalytic effect of ferric hydroxide was investigated. While the maximum yield of 86 % is catalytically

achieved by blowing air at a neutral medium, the oxidation was almost completed in an alkaline solution even at stationary oxidation was almost

completed in an alkaline solution even at stationary atmosphere. The reaction was first order with respect to Fe2+. “

And further:

“Oxidation of iron is achieved by addition of chemical oxidants. However, it can be easily and low cost carried out by contact with air (Wong,

1984). During oxidation of Fe2+ salt aqueous solutions, poor soluble compounds including Fe3+ oxides are formed (Domingo et al., 1994). The

composition of precipitate formed depends on numerous parameters such as temperature, pH, concentration, feed rate and anion nature (Das & Anand,

1995; Tolchev et al., 2002)....The oxidation kinetics of Fe(II)(aq) species has been previously reviewed by many workers (Wehrli, 1990; Zhang et al.,

1992). The stoichiometry for the overall oxidation of Fe2+ ions by O2 is given by Eq. (1) (Burke & Banwart, 2002).

O2(aq) + 4Fe2+ + 6H2O ↔ 4FeOOH(s) + 8H+ (1) “

Related 2014 work: “Synthesis of Goethite α-FeOOH Particles by Air Oxidation of Ferrous Hydroxide Fe(OH)2 Suspensions: Insight on the Formation

Mechanism” by Ezequiel R. Encina, et al, to quote from the abstract:

“In this work, the formation process of α-FeOOH by air oxidation of Fe(OH)2 suspensions has been studied. The effects of the air flow rate, as well

as of the reactant concentration ratio, R (=[(OH)−]/[Fe(II)]), on the reaction product were analyzed. It has been found that the morphology and the

size of the α-FeOOH particles can be modified by means of the air flow rate. Furthermore, by performing a detailed microscopic analysis of the

morphology of the initial, intermediate, and final reaction products, we have obtained evidence of epitaxial growth of α-FeOOH on the Fe(OH)2

substrate. It is suggested that the similarity between the anion arrangements in both phases facilitates this process. Based on these results, a

pathway for the formation of α-FeOOH in highly alkaline medium is proposed in which the size and shape of the initial Fe(OH)2 particles plays a

significant role in the formation the α-FeOOH particles obtained upon completion of the oxidation process."

A more insightful net equation than Eq(1) as to reaction steps is likely presented in http://www.scielo.mec.pt/scielo.php?script=sci_arttext&p... and especially Eq (4) and (5) with OH- acting on so-called green rust (Fe(OH2):

Fe(OH)2 + OH- -> FeOOH + H2O + e- (4)

2 FeOOH <-> Fe2O3.H2O (5)

So, OH- acting on Fe(OH)2, implies possible creation of nano-particles of iron oxyhydroxide (FeO(OH)). Also, related comments, per this 2019 work

noting prior less facile preparation paths and potential issues with ‘“Recent, novel approaches” at https://www.tandfonline.com/doi/full/10.1080/21655979.2019.1... , to quote:

“FeOOH nanoparticles are commonly synthesized at very high temperature and pressure that makes the process energy consuming and non-economic.

Recently, novel approaches were developed for the fabrication of these particles at room temperature. But, the main problem with these methods is that

the prepared structures are aggregates of ultra-small nanoparticles where no intact separate nanoparticles are formed. “

Finally, a historical comment found in Atomistry (http://iron.atomistry.com/ferrous_hydroxide.html) on Fe(OH)2, to quote:

“It [referring to Fe(OH)2] can even decompose water, slowly in the cold but more rapidly on boiling, the solution becoming turbid in air, and

possessing a distinctly ferruginous taste.

As to why this reaction happens with the formation of a basic salt, I refer to my prior provided theoretical background in this thread https://www.sciencemadness.org/whisper/viewthread.php?tid=15... for the key reaction:

2 Fe + O2 + 2 H+ --> 2 Fe(ll) + 2 OH-

where H+ is consumed and OH- is created. In the current context per my opinion, I would similarly describe the reaction mechanics as:

2 Fe + O2 (g) + 2 H+ (aq) + 2 OH- (aq) --MgSO4(aq) --> 2 Fe(II) + 4 OH- ->2 FeO.H2O (or 2 Fe(OH)2)

FeO.H2O (aq) + ½ O2 --MgSO4(aq) --> [Fe(III)O]+ + OH- -> FeO(OH)

Of further significance on likely some surface chemistry per a source, to quote:

“We propose that redox cycling of iron at the surface of crystalline Fe(III) (hydr)oxide phases, i.e. reduction and oxidation of surface iron

without transfer into solution, may be an important pathway of transformation of thermodynamically stable atmospheric Fe(III) (hydr)oxides into less

stable and thus more soluble phases."

Source: https://www.sciencedirect.com/science/article/pii/0304420395...

------------------------------------------

DISCUSSION OF STEPS TO FACILE CREATE COLORFUL FeO(OH)

1> Induce pit corrosion on a source of iron, more efficiency performed in a galvanic cell setting. I employed commonly available stainless steel

(at least in appearance) nails together with graphite rods (or use US quarters which are composed of a corrosive resistance Ni-Cu alloy, albeit less

efficient per my experimentation). A rapid path is to add the nails to acidic 3% H2O2, the noble graphite rods, and a touch of MgSO4 (as an

electrolyte), Microwave for 2 minutes. Further treat with an air source (like a fish tank air pump). Note, coloration induced changes in the solution

and check the nails for visible signs of pit corrosion.

2> Rinse the nails (do not remove any Fe2O3) and perform a new experimental run omitting the acidic H2O2 employing only air in the presence of

aqueous MgSO4.

More precisely in my Stage I, I used three small stainless steel nails which were added to a mix of 100 ml of 3% H2O2 (which was likely stabilized

with phosphoric acid) together with 50 g of MgSO4∙7H2O. The mix was microwaved for 120 seconds and allowed to stand followed by hours of aeration

using an air pump. Per attached pictures below, the formation of Fe(OH)2, FeOOH (to account for turbidity) and a basic salt (basic magnesium

phosphate) may be apparent. Another less likely possibility is the very rare mineral amakinite, (Fe,Mg)(OH)2 (see Wikipedia on Fe(OH)2 at

https://en.wikipedia.org/wiki/Iron(II)_hydroxide and https://en.wikipedia.org/wiki/Amakinite). Importantly, the nails, themselves, appear to have undergone some pit corrosion.

In my Stage II, I remove the possible influence of stabilizers found in H2O2 by performing an experiment where the steel nails, now showing signs of

pit corrosion, were combined again the same amount of MgSO4∙7H2O and treated over time with just air from an air pump with the final picture taken

some 30 hours of aeration.

RESULTS

Pictures [separately in the process of being attached] below describe the results at various stages. The picture with two reaction vessels is worth

commenting on as it displays, with the acidic H2O2 path in lieu of pure air, an apparent present of also a fluffy salt, which I would surmise to be a

basic magnesium phosphate courtesy of the H3PO4 in the H2O2.

[Edited on 16-8-2020 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

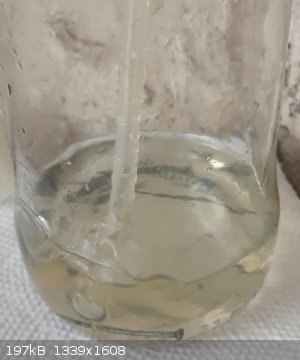

Starting Step 1 Picture

[Edited on 16-8-2020 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Ending Step 2 Picture

[Edited on 16-8-2020 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Picture with H2O2 (far right) versus just air treatment with existing pit corrosion

[Edited on 16-8-2020 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Intermediate view

[Edited on 16-8-2020 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Good view of the coloration upon shaking. Note, with time, sunlight or freezing, the particles fall out of solution, so not a classical nano-particle

suspension (as was noted above).

[Edited on 16-8-2020 by AJKOER]

|

|

|

|