| Pages:

1

2 |

pneumatician

Hazard to Others

Posts: 409

Registered: 27-5-2013

Location: Magonia

Member Is Offline

Mood: ■■■■■■■■■■ INRI ■■■■■■■■■■ ** Igne Natura Renovatur Integra **

|

|

Quote: Originally posted by zed  | Ummm. I'm thinking shock. Sledge hammer impact.

Thermal Shock, is a possibility too.

Or, lapidary equipment. Grind it up via Carbide (or Diamond) Grinding wheel.

You don't like tumbling/ball milling?

[Edited on 15-4-2021 by zed] |

thermal shock is the LAST option for me and maybe useless for the end result I are searching...

tumbling/ball milling I already say:

https://www.sciencemadness.org/whisper/viewthread.php?tid=15...

|

|

|

Morgan

International Hazard

Posts: 1660

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

I tried to find specific uses for a titanium mortar and pestles but couldn't locate any information. But I wonder what buyers are using them for as

surely it's not just for the novelty?

However I did run across this unusually hard alloy of titanium and gold though and another ratio that's magnetic.

"When we tried to grind up titanium-gold, we couldn't," she recalled. "I even bought a diamond (coated) mortar and pestle, and we still couldn't grind

it up."

https://phys.org/news/2016-07-lab-titanium-gold-alloy-harder...

Tidbit

https://www.sigmaaldrich.com/catalog/product/aldrich/z553328...

[Edited on 15-4-2021 by Morgan]

|

|

|

barbs09

Hazard to Others

Posts: 113

Registered: 22-1-2009

Location: Australia

Member Is Offline

Mood: No Mood

|

|

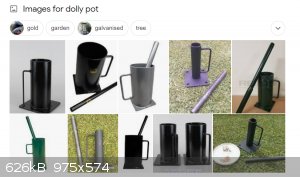

I assume the material you are crushing is quartz (Mohs =7), potentially for gold extraction?? Make a Dolly pot. Old timers (and not so old timers)

use to use them to crush quartz vein material prior to panning for presence / absence of gold. These don't need to be a highly technical affair.

Cheers AB

|

|

|

unionised

International Hazard

Posts: 5102

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Why?

If you tell us what rocks, and why you want them powdered it will help us to help you.

|

|

|

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I smell marketing BS.

- "It is about 3-4 times harder than most steels,"

Big deal, most steels aren't very hard. In fact this could be said of any tool steel and even plain carbon steel with the proper heat treatment.

- "It's four times harder than pure titanium"

Titanium Grade 1 (commercially pure, 99,5% Ti) has an ultimate strength of around 250MPa. So we're talking of 1500MPa or thereabouts. Now don't get

me wrong, that's pretty impressive for a titanium alloy. But considering the price and density of gold I don't expect it to leave the lab anytime

soon.

[Edited on 16-4-21 by Fulmen]

We're not banging rocks together here. We know how to put a man back together.

|

|

|

pneumatician

Hazard to Others

Posts: 409

Registered: 27-5-2013

Location: Magonia

Member Is Offline

Mood: ■■■■■■■■■■ INRI ■■■■■■■■■■ ** Igne Natura Renovatur Integra **

|

|

why? why in the labs technicians want to reduce to dust rocks??

Gold and Silver ores, platinium sulfites, Gold sand... The Silver ore of the pic is fucking hard. The white dots are impacts with a heavy hammer and

the tool bounce back! So I need to go outside or destroy the floor of the house :-)

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by pneumatician  |

why? why in the labs technicians want to reduce to dust rocks??

Gold and Silver ores, platinium sulfites, Gold sand... The Silver ore of the pic is fucking hard. The white dots are impacts with a heavy hammer and

the tool bounce back! So I need to go outside or destroy the floor of the house :-) |

Are you being serious or are you trolling? You can't crush hard rock on a soft surface, even if you are using a hard hammer. Much of the energy is

being absorbed by the softer material which is why the hammer bounced back.

Second, that rock looks like limestone.

So is your plan to extract PM's from ore? What quantites are you looking to process - couple lbs, hundreds or tons?

Anyway you look at it, the best option would be to find a piece of hard steel to place the rock on and then either hit it hard with something like a

pic-axe or a sledge hammer. I'd suggest a hammer & hit it as hard as you can. If you need to contain it, get some plastic bags and put the rock

inside that then smash it. I've done this before with rocks, boro glass & quartz glass and it works well. I used about 8-10 plastic bags from

the grocery store. Nest the bags, put rock in, twist bag closed, turn bag inside out (while twisted closed) and repeat. You should be able to get 3-4

layers for each bag this way.

If you are going to be crushing lots of ore, look into some AR400 or AR500 steel.

[Edited on 4-16-2021 by RogueRose]

|

|

|

pneumatician

Hazard to Others

Posts: 409

Registered: 27-5-2013

Location: Magonia

Member Is Offline

Mood: ■■■■■■■■■■ INRI ■■■■■■■■■■ ** Igne Natura Renovatur Integra **

|

|

Quote: Originally posted by RogueRose  |

Are you being serious or are you trolling? You can't crush hard rock on a soft surface, even if you are using a hard hammer. Much of the energy is

being absorbed by the softer material which is why the hammer bounced back.

Second, that rock looks like limestone.

So is your plan to extract PM's from ore? What quantites are you looking to process - couple lbs, hundreds or tons?

Anyway you look at it, the best option would be to find a piece of hard steel to place the rock on and then either hit it hard with something like a

pic-axe or a sledge hammer. I'd suggest a hammer & hit it as hard as you can. If you need to contain it, get some plastic bags and put the rock

inside that then smash it. I've done this before with rocks, boro glass & quartz glass and it works well.

If you are going to be crushing lots of ore, look into some AR400 or AR500 steel.

[Edited on 4-16-2021 by RogueRose] |

Are you being serious or are you trolling?

"find a piece of hard steel to place the rock on and then either hit it hard" :-) this is what I make, with a piece of girder (steel).

Are you being serious or are you trolling?

the rock is a silver ore from a mine in open air.

not lb not tones, you not have idea of what I are doing or try to do?

conclusion until now, nobody here try to make a dust from a sample whitout any pollution fromm the mortar, etc used.

Color is important to detect what is in the sample, but a lot of "foreing" matter from the sample can inducce to error & and not being able to

know that there is exactly, basically because i'm not testing with pounds or tons, and well, the quantity here is not important, more quantity more

pollution from the method of reducing to dust, no?

|

|

|

pneumatician

Hazard to Others

Posts: 409

Registered: 27-5-2013

Location: Magonia

Member Is Offline

Mood: ■■■■■■■■■■ INRI ■■■■■■■■■■ ** Igne Natura Renovatur Integra **

|

|

so Ti + Pt = 16? times harder?

& Ti + Pt with a bit of Sb, 44? times more harder???

[Edited on 17-4-2021 by pneumatician]

|

|

|

Morgan

International Hazard

Posts: 1660

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

I really don't know how they are measuring hardness, just what I read.

"The team measured the hardness of the beta form of the crystal in conjunction with colleagues at Texas A&M University's Turbomachinery Laboratory

and at the National High Magnetic Field Laboratory at Florida State University, Morosan and Svanidze also performed other comparisons with titanium."

https://phys.org/news/2016-07-lab-titanium-gold-alloy-harder...

Apparently there're some steels that are 4 times harder than others if you go by this Vickers hardness chart at the bottom.

"The fact that there are many ways to measure hardness, producing different numbers for the same specimen, graphically demonstrates that each method

has it pros and cons. I won't go into that, however. As far as steel is concerned, numbers are usually given in either Vickers or Rockwell. With the

figure from before you can easily convert from one scale to the other."

"Once more: No hardness test can compete with a tensile test; the latter gives far more information and numbers useful for calculations. But hardness

tests are relatively cheap, easy to do, and in particular applicable to very small samples and samples with weird shapes."

"Just to put hardness in perspective, the following table gives the Vickers hardness of some common materials. Note that there are variations for one

and the same material not only for steel but for almost everything. The number given thus must be seen as a typical harness."

https://www.tf.uni-kiel.de/matwis/amat/iss/kap_3/backbone/r3...

|

|

|

zed

International Hazard

Posts: 2277

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Your response was in another string.

Ball Milling will reduce that stuff to dust. It might take a while.

Just turn it on, and let it tumble.

Don't even need ball bearings or carbide balls really.

Just the broken-up stones falling on each other, until they have ground each other into dust.

[Edited on 18-4-2021 by zed]

|

|

|

pneumatician

Hazard to Others

Posts: 409

Registered: 27-5-2013

Location: Magonia

Member Is Offline

Mood: ■■■■■■■■■■ INRI ■■■■■■■■■■ ** Igne Natura Renovatur Integra **

|

|

I send a email to Emilia Morosan here:

https://www.morosan.rice.edu/contact-me

maybe if not is an industrial secret come here to explain something about this alloy.

|

|

|

barbs09

Hazard to Others

Posts: 113

Registered: 22-1-2009

Location: Australia

Member Is Offline

Mood: No Mood

|

|

Its not clear to me whether you have pounds or tons of ore to crush: but prior to fire assay or digestion an analytical lab will likely use a jaw

crusher to do an initial size reduction. Any tungsten or Fe contamination will be negligible and is likely not considered important for precious

metal assays. Industrial scale gold processing plants will often also have a jaw crusher in its primary crush circuit prior to introducing the ore to

a ball or SAG mill.

Just a quick google search found an inexpensive example of such a jaw crusher

https://www.911metallurgist.com/equipment/mini-rock-crusher/

Cheers, AB

|

|

|

OldNubbins

Hazard to Others

Posts: 136

Registered: 2-2-2017

Location: CA

Member Is Offline

Mood: Comfortably Numb

|

|

Contamination from processing equipment is magnitudes less than impurities already present in the ore.

Kind of like separating out the fly shit from the pepper.

|

|

|

MadHatter

International Hazard

Posts: 1332

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Rock Tumbler

As stated, a rock tumbler, a.k.a. ball mill reduces to

dust if allowed to tumble for sufficient time. Even

at Moh's hardness 7 quartz will eventually reduce

to sand or something similar to diatomaceous earth.

It's a matter of patience.

As for mortar and pestles even the fused alumina

would take some time depending on how much

force is applied. Fused alumina can have a hardness

of 9 on the Moh's scale as this is basically corundum.

Comparable to ruby or sapphire.

Zed, you called it right.

[Edited on 2021/4/20 by MadHatter]

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

| Pages:

1

2 |