Hoffit

Harmless

Posts: 21

Registered: 12-8-2019

Member Is Offline

Mood: Excited

|

|

Ethylene glycol purification

I was reading some older messages and found some thread where a few people found it difficult to purify ethylene glycol from car coolant. I have no

100% glycol available locally, so here goes some of my lab notes and reasoning behind choices summarized.

(Note that this is not an optimal method, this was mostly to practice on several basic skills. Been out of lab for way too long. If you go for rough

purification, just simple distill it with vacuum or without and that's it).

Starting material: 1liter of blue liquid, specified as >75% glycol with corrosion inhibiters and surfactants.

Step 1: Distill off water, assuming 25% or so water. Simple distillation

-above 100C there is no water right? Wrong. After some 50ml of liquid it was distilling at 150C (about 40% glycol in water if you look at vapor/liquid

diagrams. Liquids don't boil at exact points in mixtures, see Raoult's law for ideal case!)

-Don't want to go too high in temperature. Stop.

Step 2: Vacuum distill

-with short path condenser. Why? Just wanted to try out a new toy where it is not that good (lean the limits!). I'd really go for normal simple vacuum

distillation unless I had a new toy needing some testing out. It needed some really cold water due to short condenser!

-my diaphragm pump pulls pressure to about 0.2atm, got fraction from 139-148C. At first it seemed to stabilize at 139C that matched roughly what I

calculated from Clausius-Clapeiron equation (145C). My pressure meter is not that accurate so any stabilizing point is good point to start at. I can

always get fractions if it has multiple stable points.

-I did not distill to completion for multiple reasons (including corrosion inhibitor being benzotriazole that may or may not be explosive at high

temperature and boils at around 350C or so if my memory serves well)

-result: a clear runny liquid, somewhat like water. Done? Nope.

Step 3: Get rid of water?

-Time to use Dean-Stark. Unfortunately I have only a clavenger adapter that can be used to remove heavy phase too.

-Reflux with toluene (due to around 80C azeotrope). I did not use xylenes that I have way more in stock due to higher boiling point (toluene 111C,

xylenes I have 138-140C ie. I have mostly m- and p-xylene mixture)

-Remove the water collected. My clavenger has pretty low volume before returning light phase. A lot of cloudy tolune returning. Not good. I hope I get

my replace Dean-Stark (or actually a clavenger with a valve to choose heavy/light return). Warm temperature of the clavenger does not help either.

-finally a slightly cloudy return and water collects very slowly.

-done finally? Nope. Somewhat cloudy means some water and I still need to separate toluene.

Step 4: Removing toluene (with water?)

-distill it off? Nope. Previously we had the risk of some benzotriazole contamination. Benzotriazole is very soluble in tolune and slightly soluble in

ethylene glycol. That is one reason I used tolune instead of something like acetone or petroleum ether (mostly hexanes) to remove the water.

-Remove toluene with a separating funnel.

-Shake a couple times with small portions of toluene to get rid of any benzotriazole and water (that is slightly soluble in toluene).

Step 4b: Ŕecycle toluene

-quick fractional distillation with 200mm vigreux column.

-discard the cloudy stuff (has water), get the "dry stuff" (still a bit cloudy)

-I did not distill to completion (may contain benzotriazoles)

-Even if boiling was mostly at around 111C (+-1C or so) it seems pretty clowdy. Dry with 3A molecular sieves that cleared it up.

Step 5: Redistill ethylene glycol

-fractional distillation with 200mm vigreux column

-same pump, same pressure of about 0.2atm

-some toluene (cloudy) at 56C (stabile point for long time)

-surprisingly temperature dropped and dropped gradually to about 50C (less vapor at end does not keep up the temperature?)

-finally a fraction at about 144C (+- some difference, collect this as product)

Done? Good enough for my intended use. I'll re-purify it more if needed.

The result? A viscous liquid (not quit as viscous as glycerol but definately viscous unlike water. Viscosity will rise when it cools more.)

Lessons for real process?

-I'd probably use just fractional (vacuum) distillation from the beginning.

-I'd use the better pump (or finally finish the aspirator) to get better vacuum ie. lower temperature

-just throw in bunch of molecular sieves to remove water. Toluene method was quite slow. Recycling the sieves with stuff that boils around 200C is not

fun why I did not use that in the first place. (chemical methods like salts could be way better too!)

-worry about benzotriazole? I would not unless I wanted a reagent that is not contaminated with it (possibly). I took this as a practice. That's why

after all the research I ended up removing water with toluene (that is at the same time used to extract benzotriazole).

-If I'd repeat it again, I'd start with a fractional (vacuum) distillation instead of the short path that just needed the first try

-water..water...water.. If you are aiming for anhydrous ethylene glycol there is a lot of work to do. In every my step (including final distillation)

there was water.

Did I remove all the benzotriazole? No idea. Never measured it. This was more a practical though experiment trying to remove it.

Did I remove all the water? I'd doubt I did. Viscosity really changed when most of the water was removed but if I needed anhydrous ethylene glycol

I'd at least use some molecular sieves. This has kept on holding the water so much on some typical water removal methods!

Is this the way to do it? Once again: NO. This was a practice using a set of skills to do it. Far from optimal.

Why not just distill it at 196C? Oxidation may or may not be issue at high temperature. Why not break benzotriazole chemically? Just because.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Nice write-up, very accurate and informative. Here's the lesson ppl can learn from reading this: buy pure Chems if possible to save yourself time

money stress and disappointment. This write-up is a great example of why sometimes just using crude product straight from the bottle works

better/easier.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1636

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

and why to research things first befor doing! an hour with some books can save an entire day, a lot of aggravation and mess in the lab!

Good experience and write up.

|

|

|

Hoffit

Harmless

Posts: 21

Registered: 12-8-2019

Member Is Offline

Mood: Excited

|

|

That is so true. Cleaning up non-pure materials can be a lot of work. Also choosing the material to purify can make a huge difference. Some components

are just difficult to separate while others can be very simple. For some materials I've tried out several sources to see which one behaves the best

and then stick to it. For example, I have a source for ethyl acetate that is quite cheap (but a lot of work to purify) and a source that costs more

but saves time by a huge amount. (locally no nail polish removers seem to be ethyl acetate any more)

If you can get pure products, buy pure products, unless you are taking it as a challange or learing experience.

I think people have sometimes troubles with high boiling point liquids (like 197C for ethylene glycol). Vacuum can help there a lot. I used only up to

about 200W power for 1 liter round bottle in the heating mantle. Vacuum lowers boiling point, some insulation helps a lot (column is still 140C or

so!) and heat seems to transfer much better from mantle to round bottle than for example from hot plate to an erlenmayer. (and round bottles are safe

for vacuum unlike normal erlenmayers)

Ethylene glycol seemed a bit bumpy on distill under heavy stirring. I guess it could get very bumpy or even dangerous with low stirring or some

boiling stones.

This was a good practice run before more difficult ones like purifying and drying glycerol. Fortunately I now have a proper dean stark trap. Clavenger

had too short section to be effective and recycling liquid near bottom kept it warmer too. That makes a lot of difference in how soluble water is in

toluene and how easily it separates.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1636

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

I never used vacuum for distilling antifreeze, it is low enough to be of a non concern, but a heating mantle and boiling chips is a must at minimum.

|

|

|

MaeBorowski

Harmless

Posts: 12

Registered: 8-3-2021

Location: six feet under

Member Is Offline

|

|

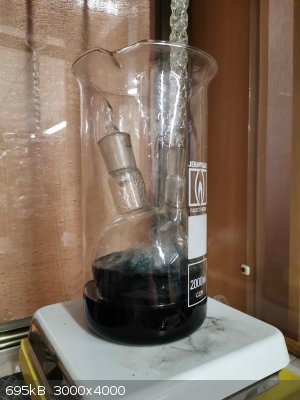

Successful distillation of antifreeze

This saturday I did the distillation of used antifreeze obtained from my father.

It is green liquid which contains ~half water and ethylene glycol and a little of bitrex, dye, unknown inhibitors, and maybe diethylene glycol.

Distillation is my favorite lab work so I wanted to do it.

Some points are omitted because I have been digging around with the vacuum setting in the installation for a long time. I will say briefly —

the safety flask and the Wurtz had to be thrown to hell, because they did not allow the pressure to be lowered normally.

Based on 10.4271/921637 and my boundless curiosity, I decided to perform this process under vacuum. Fortunately, fortnight ago one little

water-jet pump settled in my lab and water was cold enough.

About 250 cc of dirty antifreeze was placed in 500 cc RBF with two joints. The flask was put on sulfuric acid bath and started to heat up.

Water began to distill off pretty slow, about .5 d/s. I recommend distill water off as fast as you can. The drop catcher was a little colder than rt

so I think the pressure was about 12-15 mm Hg. After the water left, distillation abruptly stopped. The water looks a little blue, because after

turning on the vacuum, the contents frothed and spat a little into the receiver. Other time, no problems with the foam were observed.

The receiving flask was replaced with a new one, the bath temperature was raised a little and the intermediate fraction was distilled until there was

no water drops in the condenser.

Next, the receiver was replaced with the nice 100 cc pear-shaped flask and pure ethylene glycol was distilled on a temperature ~100°C with a speed ~1

d/s. The bath temperature ranged from ~110 to 140°C. The distillation was stopped when receiver filled up. A small partially solidified residue

remains in the distillation flask. The time was ~23.45 IIRC

This product had a slight onion-like smell (?) but without lacrimatory action. I think it is pure enough for most purposes. The wasted time wasn't

adequate compared with 100 cc of stuff with a price about 2.5$/l but it was my first vacuum disillation and I'm glad

[Edited on 18-1-2022 by MaeBorowski]

please leave comments about my English in PM

|

|

|