Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

esterification of 1-octanol with formic acid (n-octyl formate)

Originally I wanted to prepare octyl acetate because of claimed orange scent. But checking databases I found only not much interesting scent

properties of the acetate:

http://www.thegoodscentscompany.com/data/rw1003462.html

Odor Type: floral

green earthy mushroom herbal waxy fruity apple

So I checked other esters of 1-octanol and the only one which attracted me was its ester with formic acid

http://www.thegoodscentscompany.com/data/rw1007161.html

Odor Type: fruity

fruity rose orange waxy cucumber

Especially the rose and orange seemed very interesting for me

So I tried to acquire any practical experimental reports and I found only interesting esterification using B2O3 which has a dual role as a catalyst

(boric acid ester with alcohol, then reesterification with the organic acid) and dehydrating agent (so no water is created in the reaction). As the

catalyst I wouldn't use H2SO4 because of formic acid decomposition into H2O+CO. Avoiding H2O presence in the reaction would shift the equilibrium

towards ester product so the reactant alcohol could be consumed completely. Such a long chain alcohol if part of it unreacted couldn't be washed out

using water. So the way to go is to react it completely so at the end it is not present in the reaction mixture and then no need to remove it.

Unfortunately I was unable to find my B2O3. I just remember that I acquired 3x500 g of commercial B2O3 somewhat like 2 months ago but although that I

was unable to find it. I should organize and catalogize all my chemicals and equipment as now they are around all the house without system. I was able

to find all the H3BO3 but none of the B2O3 and dehydrating H3BO3 seemed to me too much work to do and finally the product in a form of hard glass

pieces difficult to pulverize (bad reactivity then).

For anyone interested here the B2O3 method of esterification (the pdf also attached for future)

https://cdnsciencepub.com/doi/pdf/10.1139/v87-411

Attachment: v87-411.pdf (245kB)

This file has been downloaded 184 times

They used anhydrous formic acid. I have only 85% formic acid in stock. My first idea was to use more of B2O3 which would dehydrate the 85% formic

acid. But I was unable to find B2O3 so I had to try different way. In the above link after the esterification they used 2 interesting steps in the

workup: they just filtered the reaction mixture through K2CO3 to remove unreacted acid and then used P2O5 to remove unreacted alcohol (? dehydration

of alcohol into alkene? how much stable is any ester in the presence of P2O5?). No need to wash with water.

So what I did was classical esterification using isohexanes and Dean-Stark trap adapter.

Some thoughts worried me:

[0] Azeotropic distillation would remove water but also some formic acid and I did not know how big excess of the formic acid is necessary. I wanted

to perform the reaction quantitatively so no unreacted 1-octanol present at the end (because it is hard to remove it then, better approach would be to

let it completely react).

[1] I was not sure whether K2CO3 couldn't decompose the ester. If I let them in contact for too long the ester could be decomposed, if too short then

it would not remove acid(s). In case of ester decomposition the level of 1-octanol would increase which is hard to remove, the purity of the product

would degrade and the 1-octanol could interfere with the scent of the ester.

[2] Whether the treatment with P2O5 is really necessary.

So here are quick answers according my limited experience:

[0] using 1,5 excess of the 85% formic acid was enough (todo - maybe the excess could be even further reduced?) and the alcohol was esterified

completely according my calculations.

[1] I used NaHCO3 instead which does not decompose the ester. But it seemed to be useless and maybe it is not necessary.

[2] I did not use P2O5. All the alcohol was esterified and was not present. Last drop of water or maybe a little of formic acid was removed during

distillation step in isohexanes fraction.

So now the experiment itself:

formic acid M=46.03 g/mol

1-octanol M=130.23 g/mol

n-octyl formate M=158.24 g/mol

the synthesis was performed at 0,5 mol scale

0,5 mol 1-octanol 65,1 g

0,75 mol formic acid 34,5 g = 40,6 g 85%

p-toluenesulfonic acid 1,0 g (catalyst)

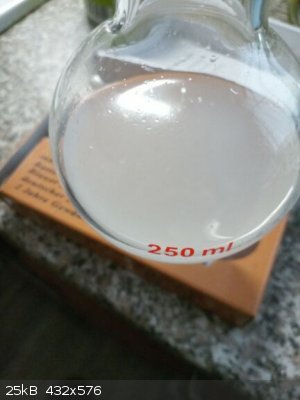

To a 250 ml RBF was placed 1,0 g p-toluenesulfonic acid (catalyst) + 65,1 g 1-octanol (0,50 mol) + 40,6 g 85% formic acid (0,75 mol) and boiling

stones (5 glass balls). Everything dissolved and mixed well while rotating in a hand into a clear transparent colorless mixture which after 2-3

minutes spontaneously lost its transparency and become an emulsion (very likely the esterification already proceeded at some extent even at room

temperature). The flask was put into an oil bath. Dean-Stark trap attached, condenser on its top, an takeoff adapter to which a hose leading outside

of the building was attached (formic acid could decompose to CO but I avoided using H2SO4 and used PTSA catalyst). The oil bath and the reaction was

slightly heated WITHOUT reflux (just to perform the partial esterification as much as possible) for 1 hour. Then allowed to cool to 40 C and only then

20 ml of isohexanes (b.p. 60-65 C) added through the top of condenser. The Dean-Stark trap used had a volume of 10 ml, the volume of isohexanes must

be higher to not only fill the trap but to reach the reaction flask too.

The reaction was refluxed, oil bath T 170-190 C, 8 ml bottom phase collected in the trap in first 10 minutes of reflux. After 20 minutes of reflux the

glass balls stopped to jump regularly and did it only rarely (the nice continuous high frequency sound of dancing glass balls hitting the bottom of

the glass flask were gone and only occasional). The increasing of the level of the trapped bottom phase dropped significantly, circa 20 ml collected

totally at the time. The bottom phase was always drained only partially, when it reached 10 ml only about 5 ml were drained into preweighed flask.

That way less isohexanes in the trap and more in the reaction flask which could improve the performance. Refluxed for 15 more minutes, not more bottom

phase collected. Oil bath temp 210 C at the end and the border level in the 10 ml Dean-Stark trap at 8 ml (so most of the isohexanes in the reaction

flask). No immiscible drops in the distilling part of the apparatus (glass arm of the trap) observed anymore, all liquids flowed smoothly (previously

there were a lot if tiny droplets of immiscible liquid).

Then heating turned off and the reaction let to cool to room temperature. Then bottom phase drained into the preweighed flask and its weight was 27,0

g.

0,5 mol of formic acid should react = 23,0 g and 0,5 mol reaction water should be produced = 9,0 g. The water from 85% formic acid = 0,15 x 40,6 g =

6,1 g. Total water removed 15,1 g assuming 100% esterification (quantitative reaction).

27,0 g bottom phase collected which should be 15,1 g water and 27,0 g - 15,1 g = 11,9 g formic acid. In the reaction flask should be the rest of

formic acid which = (0,85 x 40,6 g) - 11,9 g = 34,5 g - 11,9 g = 22,6 g which matches nicely (0,5 mol of formic acid = 23,0 g), the trapped

water-formic acid bottom phase contains certainly also a little of dissolved isohexanes too. I suppose at the beginning the bottom phase is richer in

water and close to the end less water and more formic acid. Maybe at the end only excess of formic acid but I did not check that.

The workup was done by adding 2,0 g of fine NaHCO3 powder to the flask, stoppered and occasionally swirling in a hand. Only negligible formation of

CO2 bubbles observed. Maybe this step is unnecessary.

Then the mixture was filtered through a filter paper and glass funnel into clean 250 ml flask. The reaction flask and NaHCO3 was washed with 5 ml of

fresh isohexanes and with this was flushed the filter paper and funnel and these washings were dropped directly into the product (to increase the

yield).

Then isohexanes were distilled off on an oil bath. Also circa 3 ml of forerun removed. There was a gap between distillation of isohexanes at which the

temperature dropped in the distillation head when there was no distillate (big gap between b.p. of the isohexanes and the ester). The forerun was

captured firectly into the flask with the isohexanes fraction and forerun volume was only approximated by counting the drops (60 drops). There was a 1

small drop of immiscible liquid in this fraction (maybe water from air moisture captured when filtering or maybe some of unreacted formic acid).

Then it was let to cool down and new clean air condenser was attached. Distillation resumed and main fraction collected. I wanted to record boiling

points but it was too much dependent on the rate of distillation. It was very visible how much drops returned back into the distillation flask, in a

scale 10 times more than drops from the condenser. That was due to very high b.p. around 200 C. Next time I would distill it under vacuum. The T in

head varied more than 20 C depending on the distillation rate and massive condensation on the glass of the head.

Yield 66,7 g = 0,42 mol = 84%

What to do better: NaHCO3 treatment seemed to be unnecessary (in the provided link/attached pdf they used anhydrous K2CO3 which I was afraid of).

Treatment with P2O5 seems to be unnecessary because the esterification performed quantitatively (only calculations, I do not have GC to validate

this). No need to have anhydrous formic acid, Dean-Stark trap + isohexanes (b.p. 60-65 C) were powerful enough. Better to vacuum distillation than

normal pressure distillation (during normal pressure the recorded temperatures not valid due to massive condensation everywhere and only a little of

vapor passing into condenser.

some properties of the ester:

http://www.thegoodscentscompany.com/data/rw1007161.html

octyl formate

Molecular Weight: 158.24086000

Specific Gravity: 0.87200 to 0.87600 @ 25.00 °C

Boiling Point: 87.00 to 89.00 °C. @ 20.00 mm Hg

Boiling Point: 198.00 to 199.00 °C. @ 760.00 mm Hg

Odor Type: fruity

Odor Strength:medium

Substantivity:4 hour(s) at 100.00 %

fruity rose orange waxy cucumber

Odor Description:at 100.00 %. fruity rose orange waxy cucumber

Luebke, William tgsc, (1988)

My personal experience: the scent is interesting but not much intensive. It resembles me something floral. I can identify also very weak orange and

roses too, but only thanks to the literature information, without it it would be hard for me to tell the scent. I'm also curious why some information

claim 1-octyl acetate as orange scent but big databases claim something else. But I do not plane the acetate ester synthesis. For me it was

challenging enough the esterification with 85% formic acid (remove the water present in 85% acid and reaction water and avoid decomposition of the

formic acid into CO+H2O where both are bad CO poisonous and H2O I was trying to remove as much as possible). The acetate ester could be prepared the

same way as formic acid ester. Maybe more of acetic acid would stay in the reaction mixture and require treatment with K2CO3 (with a risk that part of

the ester will hydrolyze into long chain alcohol which is hard to remove, maybe then P2O5 treatment necessary to remove the alcohol?).

the esterification performed very quickly at some extent at room temperature, in 2-3 minutes the formerly clear transparent liquid become an emulsion

water + formic acid as a bottom phase in the Dean-Stark trap apparatus

after the reaction the mixture again crystal clear, transparent, colorless

distillation at atmospheric pressure, not good idea, massive condensation on the glass of the head so vapor barely reached the condenser, I was able

to approximately count the drops at the PTFE sleeve used in the joint, 10 times more drops falling back than the number of drops coming from air

condenser, I suggest vacuum distillation (I wanted to do normal distillation to record boiling point range but the recorded T was not valid and varied

very much depending on the rate of condensate dropping from air condenser)

collecting the main fraction

isohexanes fraction + circa 60 drops of forerun (left, 250 ml FBF), main fraction (middle, amber flask, capped), remainder from the distillation flask

(right, circa 10 ml, transferred into 20 ml beaker, there are also glass balls used as a boiling stones)

detail of the isohexanes fraction, there are some tiny drops of immiscible liquid which is water + formic acid (circa 0,1 ml)

|

|

|

MichaelBijanAfghani

Harmless

Posts: 19

Registered: 15-11-2021

Member Is Offline

|

|

You don't even have to add an acid catalyst to make formate esters. Formic acid alone is a strong enough acid to self-catalyze the reaction. Just mix

formic acid and the alcohol and you're good to go. I have a YouTube video on making isopentyl formate, which smells like cherry candy.

https://www.youtube.com/watch?v=BkQwunQxl8g

Source: Vogel's Practical Organic Chemistry, 5th ed

Michael Bijan Afghani

[Edited on 15-11-2021 by MichaelBijanAfghani]

|

|

|

Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi MichaelBijanAfghani, you are right. Thank you for your tip to nice ester, I did not yet synthesize isopentyl formate. I did only isoamyl acetate

decades ago as a preparation problem for chemistry olympiad, it had banana scent while 1-pentyl acetate smells to me like pears.

You refluxed your esterification reaction for 24 hours. In my setup the esterification completed in 1 h scale (catalyst + azeotropic distilling out

water). I used only 85% formic acid and at the end it was OK.

With 1-octanol there is a problem how to remove unreacted alcohol, it won't wash out with water. So the best approach is react it all.

I would certainly not use H2SO4 as a catalyst with formic acid because of decomposition.

Here ethyl formate which distills out from the reaction thus shifts equilibrium towards the product (at the end only diluted formic acid stays in the

reaction flask).

|

|

|

|