| Pages:

1

2

3 |

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

You know what? I had no idea you could filter this stuff! Everywhere I looked they hydrazine would appear as a fairly clear (or slighly cloudy ethanol

solution).

I'm going to try this tomorrow. I need to get a few disposable jars and funnels since I really don't want to reuse stuff that was in contact with

hydrazine...

And 10 grams? That's a lot. More than any yield I've seen! If I can get 10 grams that is a lifetime supply as far as I am concerned.

BTW, thanks for all the help. I really appreciate this.

Edit: Ok, so add 50ml of ethanol, and slowly (like 2 grams at a time?) of sodium hydroxide and stir for a few minutes before adding more. That'll take

about 15 minutes of constant stirring to get it all in. I'll keep stirring for 30 minutes, albeit I cannot hand stir with a covered container. I think

I might have caught a whiff of the strangely sweet smell of hydrazine when I was working on it yesterday, but the smell was extremely faint and it

could have been my anxiety making me sense things that weren't there.

[Edited on 13-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Yea, I only filtered it after my mix wouldn’t settle out, but it cleaned up the product alot.

That procedure would work perfectly, and after all sodium hydroxide additions and the 30mins of stirring filter the solids, wait for ~20mins for most

of the ethanol to pass through and wash the solids with 20-30ml ethanol, wait another ~20 mins and perform one final wash with 20ml ethanol, let it

fully filter over 20mins.

The filtrate is now ready to be brought up to 60-65C (you don’t strictly need a water bath, but it would help if you don’t have a great hot plate)

then mix in the nickel nitrate/dextrin solution quickly with stirring (I used a 10ml syringe, but you could also just dump it in), let the mix stir

for a minute or so before hot filtering the NHN (hot filtration is very important, it gives a much better product).

Then you can wash and dry the NHN, I used a steam bath for drying it because I'm impatient, also if you don’t fully dry the product it becomes

incredibly weak

Also, I got a whiff of hydrazine when I was making hydrazine sulphate a year or two ago, it smells very similarly to ammonia IIRC

[Edited on 13-12-2021 by fredsci93]

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

In that case I probably didn't smell hydrazine and was just imagining it. I did smell my ammonia (common household cleaner, 6% solution) and it didn't

anything like what I thought I smelled.

Nitrogen Dioxide is still my biggest bane. I made some fuming nitric acid (now sitting in my freezer in a bag full of carbonate and bicarbonate to

clear up) and I got some nasty bit of nitrogen dioxide in my lungs. It isn't the worst time, but I wonder why I used my one-neck boiling flask instead

of two... I got got another whiff of that when blowing into my end product with a long straw. I know that fuming nitric fumes a lot more than regular

nitric acid... but WOW, that stuff smokes like a chimney!

OK. So I'll recap once again. Stir for 30 minutes while adding, wait for 20 minutes, filter, pour more ethanol, wait another 20 minutes, filter, etc,

etc.

I hope it works this time.

I can put my NHN in a glass baking pan and wait however long it needs to dry out. What I normally do when drying it is put several layers of paper

towel on it to draw out the moisture. I won't hand press or anything. I don't want to have any of my end result be inextractable because it was stuck

to some paper towel.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Paper towels are my usual choice but they Usually take days to fully dry the NHN, steam bath works very well though

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

I measured out my supply. Turned out I just have 9.6 grams of sulfate. I'll just half the hydroxide and ethanol and hopefully I'll make it work.

Also I added water to my 2nd batch of nickel nitrate crystals. They were not 100% dry, but I did manage to dilute them with 80ml of dextrinated water.

I took a pH reading after adding it to my other supply.

I think the reason why it's so dark is because it could stand to use a little more water. That will also cause the pH to drop if it is too acid. What

do you think?

Edit: on another reagent note. My fuming nitric acid synthesis appears to be a great success. I took my nitric acid out of the freezer and took a

gravity scale measurement... it came back at 1.518! Granted it was at zero C, maybe even less. I need to wait for it to reach room temp again before

doing another reading, but given the pure silky white fumes, I think I am looking at a nice Keto-RDX synthesis.

[Edited on 13-12-2021 by ManyInterests]

[Edited on 13-12-2021 by ManyInterests]

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

Yeah this doesn't seem like it's working. While freebasing I mixed for 30 minutes before letting it settle for another 35 minutes. The stuff is very

murky and when I poured it into a filter I had to squeeze the filter paper in order to get anything.

I was told I needed to put some water in to start. I squirted 2ml of distilled water to see it would do anything.

Well, that finishes my supply of hydrazine sulfate... I need to make more. This time try to use HCI to reduce the amount of sodium sulfate and

hopefully extract as much hydrazine sulfate as possible.

Edit: I think the sweet smell I was smelling while trying to freebase is the ethanol. It does have a sweet scent to it. That's good that I didn't

breath in anything toxic.

Edit2: I will try to see if this works anyway. I double filtered it, sequeezed the stuff out, and I hope what I have is freebase hydrazine and not

just ethanol.

Edit3: Nope it's a giant dud. I need to make more hydrazine sulfate. I'll make one normal sized batch and I hope I will succeed...

[Edited on 13-12-2021 by ManyInterests]

[Edited on 13-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

How much ethanol did you use, surely some should pass the filter, my mix was super gloopy and even it filtered in time, also water is not a

requirement, I haven’t heard of adding water to it before. if it can’t filter I would recommend adding ethanol to thin it out.

btw how much sodium hydroxide did you use?

Also you need to be very careful with KetoRDX's synth it is the single hardest nitration I have ever done. It always takes forever and takes huge

amounts of ice, each time I have underestimated it had had to make a dash to the supermarket or service station, and when it fails it shoots Fuming

nitric acid everywhere, it is seriously difficult to control, it's a wonderful product but just keep in mind failure is nearly certain if you let your

guard down for a second, or at any point underestimate how much heat the process generates (temperature monitoring is a must and enough ice for 3-4

SALTED ice baths is required) if the ice isn’t salted or the ice has gone above -10C it is useless and the reaction will slowly heat up while you

wonder what could be wrong until the temp is 20C and the reaction is basically fucked, it's not a fun reaction, but good luck to you, it's a very

interesting product.

(when I made my largest batch not only did I screw it up a bit, it took from 11am to 8pm, due to poor cooling mostly since I assumed a -10C ice bath

could cool a mix down to 0C however the reaction continuously produced heat from DNU decomposition)

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

I used 9.6 grams of sulfate (all my supply) 6.22 grams of sodium hydroxide. I put in 2ml of water first and then around 32ml of pure ethanol.

This is getting really frustrating... I wish I heard of CHP from the start (I am sure making concentrated ammonia and ammonium perchlorate aren't that

hard...). I am committed now to make NHN. I believe my nickel nitrate is perfect. All I need is just one freebased hydrazine! Just one batch!

Edit: I might not do Keto-RDX but regular RDX. I made a beautiful batch of fuming nitric (around and 18 grams of HDN. This is what is so frustrating

about freebasing hydrazine... it should be simpler than the other synthesis I have done, but it is being a giant pain. I realize that RDX is a tough

thing to make, but I am confident in my ability to do it. I made sure my HDN is both dry and acetone free.

I will freeze my nitric acid in a solid block of ice, and make sure I have other ice ready for anything.

[Edited on 14-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

First, that's a slight excess of sodium hydroxide you should use 5.9g, not that that was the problem though, if it wasn’t filtering then you need to

thin it out with ethanol, or if filtration is somehow impossible try let the solution sit for a day or so and decant instead.

Also did you add the sodium hydroxide directly to the hydrazine sulphate? I wouldn’t recommend that, it's not great since it causes local heating

maxima at the hydrazine sulphate-sodium hydroxide interface which can decompose the hydrazine or cause some boiling.

I recommend when redoing the reaction using extra ethanol, adding the sodium hydroxide to the hydrazine sulphate in ethanol and using less sodium

hydroxide, for the filtration if it really, really will not filter, calcium sulphate style, then get a diaphragm pump for doing a vacuum filtration or

add even more ethanol (don’t go super crazy but it's not that detrimental if you have a large volume of ethanol).

CHP isn’t easier, it's a fair bit more difficult synthesis and the preparation of the sodium perchlorate starting material is pretty difficult

(unless you have a perchlorate cell) since you need to convert sodium chlorate to perchlorate which takes a very long time and is low yielding, I'd

stick with NHN unless you have a good source of perchlorate

edit: DNH is a bitch to dry from experience, how'd you get it dry?

[Edited on 14-12-2021 by fredsci93]

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

The first thing I did was make a chlorate cell. I have MMO and titanium anodes and cathodes. But at any rate. I will try again, and give it more time.

Right now I am prepping to make more hydrazine sulfate. I will follow your advice and give it a day or so if that's what it means to make it freebase.

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

| Quote: | | edit: DNH is a bitch to dry from experience, how'd you get it dry? |

I left it on a plastic plate with a paper towel underneath it and more paper towels over it. I pressed and squeezed it and replaced the paper towels

as needed. I then left it for several days to try.

When I squeeze my HDN I don't get any wetness on the paper towels at all. I do see the sparkly bits of HDN on it. I dispose of the paper towels by

burning them.

Edit: One thing I noticed is that I saw no precipitate from my hydrazine sulfate when I added the sulfuric acid. Something must have went wrong.

On a plus note, my HCI is very, very clean.

[Edited on 14-12-2021 by ManyInterests]

|

|

|

Triflic Acid

Hazard to Others

Posts: 486

Registered: 27-9-2020

Member Is Offline

Mood: Slowly Oxidizing into Oblivion

|

|

Ive had decent success making ethanolic hydrazine from NaOH and N2H6SO4. works quite well. Only thing is that it can often be a pain to get it to

work, becuase of how insoluble hydrazine sulfate is. Also, a mod should probably move this to EngMat

There wasn't a fire, we just had an uncontrolled rapid oxidation event at the power plant.

|

|

|

Texium

Administrator

Posts: 4508

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

No

|

|

|

Texium

|

Thread Moved

15-12-2021 at 10:46 |

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

OK, now try a galvanic cell synthesis (see here for prior comments http://www.sciencemadness.org/talk/viewthread.php?tid=151055...) as a path to Nickel nitrate salt.

You will need a nitrate (say KNO3) and react it with (NH4)2SO4 (from the action of NH3 on aqueous MgSO4, the latter sold as a hydrate under the name

Epsom's Salt), freeze to separate out the sulfate leaving aqueous NH4NO3).

Use a microwave for lab work only, add a solid piece of Nickel metal to dilute H2O2 plus NH4NO3, a piece of activated carbon (burned food as in bread

works) and a bit of NaCl.

Microwave on and off for a few minutes and see if you can any coloration development. Take precaution on exposure to fumes (see Safety comment

below).

If yes, you have Nickel nitrate (or related salt, like Nickel nitrate diammine, Ni(NH3)2(NO3)2 or a hexamine, all of which decompose on heating

releasing NH3 and eventually the nitrogen oxides before the last NH3 leaving just Ni(OH)2, see "Ni(NH3)2(NO3)2—A 3-D Network through Bridging

Nitrate Units Isolated from the Thermal Decomposition of Nickel Hexammine Dinitrate") .

Logic: Anodic corrosion of the Nickel (anode here) introduces Ni++ ions. The NO3- is converted into the powerful nitrating •NO3 radical (see my

prior comments here http://www.sciencemadness.org/talk/viewthread.php?tid=152782...) created from the battery cell electrons acting on H2O2:

e- + H2O2 -> •OH + OH-

•OH + NO3- = OH- + •NO3

where •NO3 is a powerful nitrating species (see https://authors.library.caltech.edu/75832/1/acp-17-2103-2017... )

NH4+ = H+ + NH3

H+ + e- = •H

•H + .•H = H2

where the free ammonia could become captured by nickel ions or escapes.

No exposure to toxic nitrogen oxides or even the need for HNO3.

However, per Wikipedia https://en.wikipedia.org/wiki/Nickel(II)_nitrate on safety to quote:

"Safety

Like other nitrates, nickel nitrate is oxidizing. It is also irritating to the eyes, skin and, upon inhalation of the dust, respiratory tract. It may

cause skin allergy. Nickel nitrate is a carcinogen, along with most other nickel compounds. The nickel ion is also toxic to aquatic organisms."

[Edited on 28-12-2021 by AJKOER]

|

|

|

ManyInterests

National Hazard

Posts: 838

Registered: 19-5-2019

Member Is Offline

|

|

Thank you for that. That sounds like an extremely interesting way to synthesize Nickel Nitrate! When it comes time to buy a new microwave, I'll use my

old one to make a batch of nickel nitrate that way.

The initial process you mentioned of making ammonium nitrate using potassium nitrate and the (NH4)2SO4 is not something I thought of. I did see a

video where someone made ammonium nitrate by mixing azeotropic nitric acid/HNO3 with ammonia water (they used the 6% household concentration. I know a

brand that is 6% ammonia with the rest being water. No other detergents or additives). I didn't think to use straight KNO3 to do that. That would make

the process of obtaining ammonium nitrate much easier, since I will need some for experiments in the future.

The only question I have is this: When you say a dilute H2O2. How dilute are we talking about? 15% 10%? I can experiment with the proportions of the

others, but I will assume that a slight excess of nickel metal would be preferable as to use up all the nitrates in the process. Which is what

happened in my previous nickel nitrate synthesis with the nickel metal + 68% HNO3 + 3ml of 35% H2O2.

|

|

|

Texium

Administrator

Posts: 4508

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Alright AJKOER, but have you actually DONE this reaction? Because if not, don’t go talking about it like it’s a known method that will certainly

work! I’d love to see someone try it out, but I have serious doubts that a bit of burnt bread will magically allow you to make nitrate radicals…

Edit: To be clear, this method that AJKOER proposes depends on the formation of nitrate radical from hydrogen peroxide and nitrate anion under these

so-called galvanic conditions. None of the references that he cites as you wade back through his posts actually support this happening. It is pure

conjecture, and unproven.

[Edited on 12-31-2021 by Texium]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Yes, thank you Texium, as I should I noted a disclaimer.

First, the mechanism noted by Texium which I cited and demonstrated with pictures here http://www.sciencemadness.org/talk/viewthread.php?tid=151055... has worked, but not with the nitrate radical, per se. However, I have use KNO3 in

place of NaCl for the galvanic dissolution of Sterling Silver (as AgCl is insoluble and cannot serve as an electrolyte in the associated

electrochemistry.

And yes, as well documented the nitrate radical, .NO3, is claimed to be the major nitrating species occurring in nature. To quote the source at https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6104845/ :

"Oxidation of biogenic volatile organic compounds (BVOC) by the nitrate radical (NO3) represents one of the important interactions between

anthropogenic emissions related to combustion and natural emissions from the biosphere. This interaction has been recognized for more than 3 decades,

during which time a large body of research has emerged from laboratory, field, and modeling studies. NO3-BVOC reactions influence air quality, climate

and visibility through regional and global budgets for reactive nitrogen (particularly organic nitrates), ozone, and organic aerosol. Despite its long

history of research and the significance of this topic in atmospheric chemistry, a number of important uncertainties remain."

And yes, Activated Carbon (as created here by the carbonizing food) is more noble than nickel (and, in fact, in a cell employing HOCl and not H2O2, I

did accomplish the anodic dissolving of Tungsten see http://www.sciencemadness.org/talk/viewthread.php?tid=153380... ), a lab verification with H2O2 is recommend possibly with a bit of Ascorbic acid

(for secondary oxygen REDOX reaction).

On the concentration question, while only the presence (at any concentration) of the respective metals and electrolyte is required, having a small

surface area anode relative to a much larger area cathode will accelerate galvanic based corrosion. The issue with H2O2 as a radical source may take

longer at low concentration, but it is a trade-off of expensive/availability of say H2O2 versus differences in preparation time.

Note: Photolysis based routes using nitrate, NO3-, should be mindful of a breakdown to NO2-,..., albeit, I am not citing this as occurring here in a

galvanic cell setting.

Also, a general disclaimer, my suggested path does not promote any reagents or use of equipment for which I have any financial interests.

[Edited on 31-12-2021 by AJKOER]

|

|

|

Texium

Administrator

Posts: 4508

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Stating a lot of facts that are of tangential relevance to your claim, at best, does not mean that your untested method works, or even should work.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Personally, based on my experience, I suspect Nickel is likely hard to dissolve with any concentration of H2O2 (like Tungsten) and, as such, I would

recommend first experimenting by simply adding a small piece of Ni metal to 6% or higher Chlorine Disinfecting Bleach (neutralized to HOCl see

preparation discussed here http://www.sciencemadness.org/talk/viewthread.php?tid=154302...) and a graphite (or a silver) cathode (with relatively much greater surface area

than the anode) together with much added KNO3. Process in a microwave for several minutes.

Unfortunately, as the Bleach is an equal mix of NaoCl and NaCl (as industrially prepared from Cl2 acting on NaOH), the product will be a mixture of

the aqueous Nickel chloride and Nickel nitrate. However, the nitrate is somewhat more soluble (see https://en.wikipedia.org/wiki/Solubility_table#N) and with the presence of NaCl, the Sodium/Potassium/Nickel chloride should exit first on cooling

leaving Nickel nitrate.

If successful, a workable and cheap prep.

[Edited on 31-12-2021 by AJKOER]

|

|

|

Ankit1612

Harmless

Posts: 32

Registered: 2-11-2022

Member Is Offline

|

|

Hi guys,

I have 44.4g nickel in hard chunk form can someone tell me how can i dissolve it in conc. Nitric acid to make Nickel nitrate?

[Edited on 17-5-2023 by Ankit1612]

|

|

|

B(a)P

International Hazard

Posts: 1114

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by Ankit1612  | Hi guys,

I have 44.4g nickel in hard chunk form can someone tell me how can i dissolve it in conc. Nitric acid to make Nickel nitrate?

[Edited on 17-5-2023 by Ankit1612] |

ManyInterests posted a good method here.

I have used a similar approach in the past with success.

|

|

|

Ankit1612

Harmless

Posts: 32

Registered: 2-11-2022

Member Is Offline

|

|

He used 10g of Nickel strip which he had purchased from amazon.

Here i've 44.4g of nickel in chunk form, so i'm concern about dissolving it.

By the way, what if i use small amount of 50% h2o2?

will it increase the rate of dissolving Nickel?

|

|

|

B(a)P

International Hazard

Posts: 1114

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by Ankit1612  | He used 10g of Nickel strip which he had purchased from amazon.

Here i've 44.4g of nickel in chunk form, so i'm concern about dissolving it.

By the way, what if i use small amount of 50% h2o2?

will it increase the rate of dissolving Nickel? |

I still think it will work. When I make nickel nitrate I use more or less the same method as ManyInterests. I use 50% H2O2. I

also use nickel strips, the reaction is pretty vigorous I don't think the additional surface area of the nickel strips is essential. Why not take a

small piece off the side and try?

|

|

|

maldi-tof

Harmless

Posts: 36

Registered: 3-4-2019

Member Is Offline

|

|

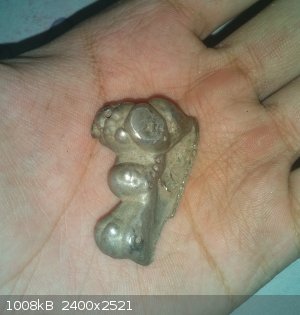

I obtained recently nickel (ii) nitrate hexahydrate crystals more or less like you did, but I started with nickel metal powder. No fumes (a part from

hydrogen gas) was observed.

The solution after the attack was still strongly acidic. I filter it to remove any unreacted nickel.

I added as well some H2O2 just for the sake of adding it, but i do not think it is mandatory.

After concentration (you need to control the density) you let it crystallize and that's it.

The yield was not the best, but mother liquors can be re-used and you obtain more product from it.

|

|

|

Raid

Hazard to Everyone

Posts: 201

Registered: 14-11-2022

Location: N/A

Member Is Offline

Mood: School

|

|

That's interesting that no fumes appeared. I have heard that using metal powders opposed to metal chunks can cause a violent reaction and lots of No2

evolution.

|

|

|

| Pages:

1

2

3 |