| Pages:

1

..

7

8

9

10

11

..

18 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

There is some of Microtek's method in there for sure, and also some of yours. For this experiment I did the freebasing with just a few drops of water

and no alcohol until the end, all in an erlenmeyer with a ground glass stopper. It is sort of a combination of Microtek' s method and yours, with a

twist.

A book I have been reading states that it is inferior to do the freebasing in alcohol. According to Leonid Lerner

in "Small scale Synthesis of Laboratory Reagents", there is a large amount of insoluble gel produced when freebasing in alcohol because the sulfates

are insoluble in alcohol. This insoluble sulfate gel locks in Hyrazine Sulfate, and prevents it from reacting with the hydroxide, which lowers yield.

I think in small quantities and with a bit of trituration, the alcohol method is probably ok. In larger scale synthesis no alcohol is definitely best.

In regards to the yield, I wasn't using my best scales so I could be off a percent or two I guess. My scales weighing heavy by 0.05g would lower the

yield by about 1.2%, if heavy by 0.1g then the yield would be lower by about 2.5%. I have compared these scales on several occasions to better ones

and they were not off more than that.

I just took the mass of the sample again after a day of drying to see if it had lost any more moisture, it hadn't.

Is KOH really the limiting quantity with a 76% yield, if using a stoichiometric quantity? According to the same book as above, I could have gotten a

yield of 86% KN3 or 90% NaN3 by this method.

I just went through the stochiometry, and there was about 5% excess of KOH used. I think there may have been some NaOH carry over from the freebasing

too (slight excess used there as well). I was using my notes that I used before for the NaOH method, and just increased the amount to adjust for the

heavier potassium cation, so I must have used an excess with the NaOH method as well. Now that I am actually looking at the bottle of KOH, it says

Potassium Hydroxide Reagent, Assay (KOH) 87.4%, Potassium Carbonate (K2CO3) 0.81%, and a list of other trace contaminants all totaling 88.24%. The

balance must be water. The container is well sealed.

I guess I could be off by a certain amount, but I don't think it is more than a couple percent. Thanks for pointing that out, I hadn't thought it all

through actually.

I am very happy with this method. It isn't quite as quick or as easy on alcohol as your method, but it is simple and straight forward using only a

flask as equipment (a stirrer helps a lot to dissolve the hydroxide in the alcohol though). Potassium Hydroxide might be a little harder to obtain

than NaOH for some people.

BTW, we may need to add a couple more percent to the yield. I kept the reaction liquid after collecting the crop of potassium azide. I just looked

now and there is another small amount which has precipitated in the last day or so. If I am going to keep saving it, I have got to stop keeping it in

plastic bottles.

[Edited on 8-8-2011 by Hennig Brand]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Just did a little more reading in "The Book". The KN3 synthesis in the book uses 85% KOH. They added enough KOH, even with corrections for purity, to

be in excess of a stoichiometric amount by ~6%. I didn't add enough, if the author is correct. He claims to get a yield of 86% for the KN3 synthesis.

The method in the book uses ethanol as the reaction medium though.

[Edited on 8-8-2011 by Hennig Brand]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Freebasing of hydrazine hydrate from hydrazine sulfate definitely is an art of careful manipulation of additions, stirring, moisture content, heating,

and solvent volume, all being done with due regard for air exposure being minimized because it destroys free hydrazine. Sodium ethoxide in ethanol

would probably work well to complete the freebasing after the half neutralization slurry paste of dihydrazine sulfate. There is probably a certain

mole scale and optimum sequence which is easiest, for the particular alcohol and base. At medium scale

I use added heating to keep the hydrate slurry from setting up like cement.

I have some teflon stoppered 2 liter Erl's and 4 and 5 inch stirbars which hopefully I can use in the future to try a larger scale freebasing. I have

components for some high gauss high torque low speed mag stir hotplates

of a custom variety but haven't had time to put 'em together and try them yet.

Most bench scale lab equipment is way underbuilt for what it costs. To get serious lab equipment that isn't cheaply built crap you either build it

yourself or spend many thousands to basically hire it done by the few companies that specialize.

Yeah a few percent excess sounds about right ...not too much, a discrete excess ....it is also a safety against free HN3 which could ruin your whole

day.

[Edited on 8-8-2011 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

reference #15 for Carbamoyl Azide article

Die Zersetzung des Carbaminsäureazids NH2CO.N3 für sich und in aromatischen Kohlenwasserstoffen

Theodor Curtius, Friedrich Schmidt

Journal für Praktische Chemie

1923, Volume 105, Issue 1, pages 177–198

DOI: 10.1002/prac.19231050115

Attachment: Die Zersetaung dos Carbarninslureadds NH,CO. N8 fir sioh nnd in aromatisohen Kohlenwasserstoffen.pdf (958kB)

This file has been downloaded 1008 times

Also attached

Ueber Semicarbazid

Johannes Thiele, Otto Stange

Justus Liebigs Annalen der Chemie

1894, Volume 283, Issue 1-2, pages 1–46

DOI: 10.1002/jlac.18942830102

Attachment: Ueber Semicarbazid.pdf (1.6MB)

This file has been downloaded 967 times

[Edited on 10-8-2011 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thought this might be of interest. It has much detailed information about materials and methods to sensitize Silver Azide. It also discusses ways of

sensitizing Lead Azide, mostly for comparison purposes between it and Silver azide.

SENSITIZATION OF HIGH DENSITY SILVER AZIDE

TO STAB INITIATION

Attachment: Silver Azide report.pdf (1MB)

This file has been downloaded 1522 times

Most of us probably don' t want these materials more sensitive, but understanding how it works is beneficial.

Here is something on Lead Azide sensitivity.

FRICTION SENSITIVITY OF PRIMARY EXPLOSIVES

Attachment: Lead Azide Sensitivity Testing.pdf (677kB)

This file has been downloaded 1268 times

I have another pdf with lots of information on the different forms of Lead Azide among other things, but it is about 5.2MB.

[Edited on 11-8-2011 by Hennig Brand]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

freebasing hydrazine related

With regards to the freebasing of Hydrazine Hydrate from hydrazine sulfate, there are possibly some refinements upon the method that could be done to

improve it, but I have not tried this. I will have to do more reading for this idea to be further contemplated. Anyway at the midpoint of the

neutralization of hydrazine sulfate before actual freebase hydrazine hydrate is produced, the hydrazine is in the form of the so called neutral

hydrazine sulfate or Dihydrazine Sulfate which is highly soluble. A half mole of sodium sulfate byproduct has also been produced ......or is it a

mole of sodium acid sulfate, sodium bisulfate, that is the actual byproduct ? Anyway, I'm thinking half the byproduct H2O

exists already at the midpoint where the Dihydrazine Sulfate

exists because the hot mixture liquifies in the nascent byproduct water. And separately present in mixture is the

sodium ?sulfate byproduct. It may be possible and it could be helpful to separate the Dihydrazine Sulfate and isolate it

before further freebasing of it alone, since it is basically one third of the components present, thereby eliminating half the

byproduct water for the overall freebasing, and half the overall byproduct alkaline salt.....so a more compact and more concentrated "lode" of

hydrazine salt source material

is then present for the final freebasing. Maybe the extra trouble would be worth the effort if it improved the process particularly for larger

batches. What I am thinking is that there is known a low solubility double salt formation of calcium sulfate and sodium sulfate which is a method

used

to remove the highly soluble sodium sulfate byproduct from solutions containing a product wished to be isolated free from sodium sulfate. This trick

of using the calcium sulfate complexation double salt may work to produce a greatly cleaned up residual solution of Dihydrazine Sulfate, which

could be dried by evaporation to the anhydrous neutral salt.

Freebasing that neutral salt would likely be easier for the greatly reduced volume of solid byproducts. There are other reactions for which the

neutral Dihydrazine Sulfate is actually very useful and required, or for half neutralization of the monohydrazine sulfate to be done in situ, so that

is definitely a second reason for me to be thinking about a possible dual usefulness for the neutral salt making it possibly worthwhile to isolate the

neutral salt in advance for whatever use. As a side note, if I recall correctly, a rough neutralization of the monohydrazine sulfate using aqueous

ammonia will produce the neutral hydrazine sulfate and byproduct ammonium sulfate, but the aqueous ammonia is not a strong enough base to continue the

neutralization further. So maybe one of the double ammonium salts could also have have a low enough solubility compared with the extreme solubility

of the Dihydrazine Sulfate, that could also be exploited to facilitate isolation of the neutral hydrazine sulfate. Attached is an MSDS for

Dihydrazine Sulfate

Attachment: dihydrazine sulfate MSDS.pdf (33kB)

This file has been downloaded 872 times

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I was going to post a how-to, but for now I thought this basic overview might serve as a sort of chemical road map which should help one sort out a

method. There is a lot of procedural information that was left out, which should be ironed out before attempting a synthesis. Keep in mind a lot of

this stuff is very poisonous.

I referenced a book a couple of posts ago that has a couple of excellent chapters on the topic.

Hydrazine

Urea Method to produce Hydrazine

(H2N)2C=O + NaOCl + 2 NaOH → N2H4 + H2O + NaCl + Na2CO3

(I have seen it stated that a 62% yield can be obtained)

Acidify to neutralize the Na2CO3 and to precipitate the N2H4 as N2H4.H2SO4 (Hydrazine Sulfate) or maybe more properly writtten as N2H6SO4

Rosco's 2 step method seems like the best using HCl first, neutralizing the sodium carbonate and producing a very soluble sodium chloride by-product.

Na2CO3 + 2HCl → 2NaCl + H2O + CO2

Next Sulfuric Acid is used to precipitate the hydrazine sulfate.

N2H4 + H2SO4 → N2H4.H2SO4

Azides

1. Freebasing Hydrazine Sulfate to yield N2H4 (free hydrazine), KOH could also be used here. A slight excess of hydroxide is best.

N2H4.H2SO4 + 2NaOH → N2H4.2H2O + Na2SO4

2. Alcohol extractions of hydrazine are performed leaving behind insoluble Na2SO4.

3. The resultant alcoholic solution of hydrazine needs its volume increased by adding alcohol until it will dissolve an amount of sodium hydroxide (or

potassium hydroxide) which will satisfy the equation below. Actually, a small excess of hydroxide should be used.

4. The isopropyl nitrite is added last. How it needs to be added depends on what alcohol is used as the reaction medium. The type of alcohol used will

also dictate what the reactor requirements will be. Depending on the alcohol used, the reactor may need to be fairly sophisticated.

The main reaction producing azide:

N2H4 + CH3CH(NO2)CH3 + NaOH → NaN3 + CH3CH(OH)CH3 + 2H2O

Isopropyl Nitrite is needed for the above reaction. It is the ester of nitrous acid and isopropyl alcohol. Other alkyl nitrites can be used, but

because of its lower vapor pressure isopropyl nitrite is relatively easy to make and use.

CH3CH(OH)CH3 + HNO2 → CH3CH(NO2)CH3 + H2O

Note:

Potassium Hydroxide could be used to do the freebasing as well as in the final reaction to produce KN3. I did one experiment where I used NaOH for the

freebasing and KOH to produce KN3. The KN3 would have been contaminated with NaN3, but this was not a big concern for me.

[Edited on 24-8-2011 by Hennig Brand]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Glauberite byproduct possibly useful in freebasing

In my preceding post I mentioned the possible use of a double salt of calcium sulfate and sodium sulfate to reach the half neutralization point in the

freebasing of hydrazine sulfate. Attached is a patent US1343443 describing the usefulness of Glauberite CaNa2(SO4)2 which might be

a useful byproduct from the conversion of hydrazine sulfate to dihydrazine sulfate. The solubility optimum for this manipulation would need to be

guessed and then the best amount of dilution with water determined by experiment. What is anticipated should work is to use for each mole of hydrazine

sulfate, one quarter (1/4) mole of Ca(OH)2 and one half (1/2) mole of NaOH, the aqueous reaction mixture heated and stirred to produce a resulting

concentrated aqueous solution of Dihydrazine Sulfate which may be decanted from the precipitated (1/4 mole) of crystalline Glauberite. This

CaNa2(SO4)2 double salt is anhydrous, unlike usual sodium sulfate or calcium sulfate. The decanted concentrated solution of Dihydrazine Sulfate may

then be evaporated with heating to leave a residue of Dihydrazine Sulfate which is also anhydrous. By means of this scheme half of the byproduct

water of neutralization as would result from the freebasing of (mono) Hydrazine Sulfate is instead eliminated during the conversion of the

monohydrazine salt to the dihydrazine salt. A more concentrated solid "lode" of hydrazine precursor material is present as the Dihydrazine Sulfate

having twice the relative hydrazine content to become available when further reacted with a given amount of caustic alkali. In effect the Dihydrazine

Sulfate is already halfway there with respect to neutralization requirement for freebasing, compared with the usual (mono) Hydrazine Sulfate.

The idea here involving the Glauberite is to improve the process chemistry of the freebasing to address a water solubility / water content issue which

complicates things.

Refining the process with regards to freebasing may make the physical manipulations easier and could improve the yields. I haven't tried this, but it

just seems like it should

work okay and would definitely make a good experiment

as a refinement on the process. Dihydrazine Sulfate is itself a useful reagent and required for some other syntheses, and there are descriptions of

it being formed in situ from

the more common mono hydrazine sulfate by adding a half equivalent of base. If my hypothesis about the possible usefulness of forming Glauberite as

the half neutralization byproduct is correct, then it should be possible to easily isolate the Dihydrazine Sulfate reasonably pure as a concentrated

solution, which can be evaporated to provide the solid Dihydrazine Sulfate as a residue good for whatever further use, including completion of

freebasing to release the hydrazine from a more compact mixture of solids which should be more easily separated from a more concentrated

lower water content hydrazine hydrate.

The deliberate targeting of byproduct Glauberite as the desired byproduct of even a complete freebasing may work better than the use of a single

caustic alkali, since the Glauberite is more dense and is by nature an anhydrous material, it is probably less likely to pull hydrazine hydrate to

itself along with water of hydration, as would occur for a byproduct sulfate derived from a caustic alkali which will go on to try to form hydrated

salts, unless precipitated from hot solutions, and/or having that hydration tendency upset by alcohol.

It is unknown if the common ion effect of sulfate will cause an unexpected solubility for the Glauberite in the Dihydrazine Sulfate which could

interfere with a clean separation and isolation of relatively pure Dihydrazine Sulfate. My hope of course is that the great solubility in H2O for the

Dihydrazine Sulfate will substantially nullify the common ion effect for the

Glauberite which will be driven out of solution, crystallizing as its anhydrous double salt. There is nothing else I have found generally in the

literature for guidance or illumination concerning whether such a scheme will work for Dihydrazine Sulfate. So there is only the attached patent

US1343443 and

my educated guess this may work that I can share at this point.

Attachment: US1343443 Glauberite_CaSO4 - Na2SO4 double salt.pdf (103kB)

This file has been downloaded 933 times

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That is interesting. It also emphasized something in my mind: using KOH to do the hydrazine sulfate freebasing adds a lot of water. I just did a quick

and dirty calculation and it looks like you will end up with ~46% more water after freebasing when using KOH with 15% water, as opposed to using NaOH

with 1% water. If you use the same KOH to make KN3 there is a little more water again, bringing you up to ~68% excess water total.

The method I am using uses quite a large amount of isopropanol, so a little extra water probably doesn' t make a big difference. For example when

starting with 6.5g of hydrazine sulfate and using KOH the whole way (freebasing and right through to KN3), the water produced during freebasing and

the water added with the KOH would bring the alcohol concentration in the reaction mixture down by ~2.5%. I am not sure how big a deal this is. It

would effect the solubility of the azide product in the reaction mixture, but I am unsure of exactly how much. There would be much less dilution of

the reaction mixture when using NaOH, one of the big reasons being that there is a lot more isopropanol to dilute, because of the much greater amount

needed to dissolve the NaOH. I can see that with a smaller volume reaction mixture, like when using methanol, the extra water would be more

problematic.

[Edited on 25-8-2011 by Hennig Brand]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah freebasing hydrazine into alcohol is definitely a tricky manipulation requiring good technique for it to go well, and there are probably some

ways that freebasing can be refined and this seemed like one easy possibility. The use of an alcoholate for the post freebasing additional

requirement of added alkali would also strip more water from the hydrazine hydrate extract. But these things are added steps and added work, which is

exactly what was causing me to look at the nitrosation of semicarbazide to carbamoyl azide alternative, knowing the entire reaction there is done in

aqueous solution and theoretically the carbamoyl azide will convert to ammonium azide in aqueous solution, by simple hydrolysis. This would be

simpler in terms of the required manipulations if it works well.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

As I understand it, the reason we are concerned with minimizing the amount of water in the reaction mixture is to reduce product loss in the post

reaction mixture. The product loss comes from the greater solubility of the alkali azides in alcohol which has been diluted with water. I think you

said before that sodium azide precipitates better and more completely from anydrous or near anhydrous alcohol. This is the main reason isn' t it? Are

there other reasons?

So the Di-Hydrazine Sulfate has good chemical stability and resistance to oxidation similar to Mono-Hydrazine Sulfate (I assume), and there is only

half the water produced when freebasing it relative to what is produced when freebasing Mono-Hydrazine Sulfate. Di-Hydrazine Sulfate sounds like it

could be a more desirable hydrazine source, especially if one had a choice when purchasing, for instance. It seems like freebasing it might be a

little more risky, with only just enough water to tie up the hydrazine as hydrazine hydrate. Yeah, if I had started out experimenting with

Di-hydrazine sulfate I probably would have poisoned myself much worse than I did with the mono. I guess with a well sealed reaction vessel for

freebasing (which is needed to exclude oxygen anyway) and some ventilation in the work area everything would be fine.

That is a neat trick to isolate the di-hydrazine sulfate, it seems like it would work quite well too.

[Edited on 25-8-2011 by Hennig Brand]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah the Dihydrazine Sulfate reportedly is stable. The reason the acidic salt, the monohydrazine sulfate is the common form is because it is the low

solubility product precipitated from acidic solution which facilitates its isolation in relatively pure form from synthesis. So the monohydrazine

sulfate is the common form of commerce, and the common form for the reagent. But definitely there are other forms of further processed hydrazine

which are also stable and may be required for certain syntheses. It is a similar story for ammonia and other bases where various salts and/or even

the anhydrous base are stable but have their various differing properties and reactivity and storage requirements, toxicity, volatility, ect. ranging

from benign conditions to extreme. To make an analogy, hydrazine sulfate corresponds with ammonium bisulfate or sodium bisulfate and Dihydrazine

Sulfate is the neutral salt corresponding with ammonium sulfate or sodium sulfate which more correctly and precisely in reality are Diammonium Sulfate

and Disodium Sulfate.

As for the danger aspect of working with smaller volumes of material which should be easier to manipulate with the endproduct being the same hazard

....usually a simpler process manipulation of a smaller amount of raw material increases safety and is not any more risky ....so it seems it would

about the same or lower risk. I can't really report an observation on this because I haven't actually done this yet to confirm. What works on paper

doesn't necessarily always materialize that way in the experiment. But this one seems pretty straightforward like it ought to work okay.

There is another calcium salt of possible interest with regards to hydrazine conversion to azide and this is another possibility for experimentation

which was mentioned in another thread.

http://www.sciencemadness.org/talk/viewthread.php?tid=874&am...

It has seemed possible to me that an organic nitrite may facilitate the reaction somehow and is more selective in converting hydrazine to hydrazoic

acid than is free nitrous acid. It has therefore seemed possible that something like sorbitol or glycerin or isopropyl alcohol in an aqueous solution

of a neutral hydrazine salt such as Dihydrazine Sulfate, might react as a regenerable intermediate organic nitrite with Basic Calcium Nitrite

Ca(NO2)2 - Ca(OH)2 to yield an aqueous solution of Calcium Azide over precipitated Calcium Sulfate. The Calcium Azide solution might then be converted

to a solution of Sodium Azide with precipitation of Calcium Carbonate, by treatment of the solution with Sodium Carbonate. This is another

completely hypothetical and untested idea for an experiment.

It may not work at all in a beaker even though it seems to work fine on paper.

Attached is US4294813 which describes a synthesis of Basic Calcium Nitrite from Sodium Nitrite and Calcium Nitrate

Attachment: US4294813 Calcium Nitrite from Sodium Nitrite.pdf (103kB)

This file has been downloaded 1159 times

[Edited on 26-8-2011 by Rosco Bodine]

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

Quote: Originally posted by Rosco Bodine  | The experimental part of the attached describes the reaction of nitrous acid and semicarbazide producing a 70% yield of Carbamyl Azide.

A translation of the relevant portion would be helpful if anyone may assist, thank you.

Über die Ultraviolett-Absorption und Konstitution von Tetrazenen aus Aminoguanidinsalzen

Ruth Hofsommer, Max Pestemer

Zeitschrift für Elektrochemie und angewandte physikalische Chemie

Volume 53, Issue 6, pages 383–387, Dezember 1949

DOI: 10.1002/bbpc.19490530612 |

The method given there they state is originally from the referenced Thiele and Stange. But they mixed an aq. solution having 22.2g

semicarbazide-hydrochloride with a solution of 14g NaNO2 in 25 ccm H2O, under a lot of stirring then saturating with ammonium sulfate, then repeated

extraction with ether, to obtain the azide in 70% yield. They also recrystallized it from hot ether. The azide is hydrolytically unstable and

according to the article hydrolyzes to CO2, NH3 and HN3.

The other article from Curtius and Schmidt states carbamoyl azide is pretty easily soluble in cold water. Boiling decomposes the solution: NH2CO.N3 +

H2O = NH4N3 + CO2. Some urea forms as a side product. Although carbamoyl azide can also be melted with slow heating without explosion, in

circumstances (e.g. copper powder can catalyze decomposition) it can explode with the force typical of the azides.

The other compound briefly mentioned in Beilstein in the hydroxylamine nitrate thread with two azide groups, N3.C=O.N3, is extremely dangerous, and

volatile from what I've read. It's the azide analogue of phosgene. It is like but maybe worse than nitrogen triiodide, and closer to RDX in power.

Carbamoyl azide preparation is one molecule less nitrite removed from forming carbonyl diazide.

Quote: Originally posted by Rosco Bodine  | Also back on page 3 and 4 of his thread S.C. Wack posted some attachments which are are scans of articles relating to oxidation of hydrazine sulfate

with H2O2 and nitrous acid and other oxidizers. Some more legible scans are now available and these are also attached as an update.

A New Synthesis of Hydronitric Acid (attached)

The Oxidation of Hydrazine (attached)

|

I would say this method is a waste of sulfuric acid, not more than a novelty interest. The residual H2SO4 would have to be purified by distillation.

And you would need a lot of H2SO4 for just a small amount. I have also tried it some time ago using their suggested 3% H2O2 as the oxidant, I was only

able to obtain several gas bubbles of hydrogen azide even after heating the apparatus for some time over the hot plate.

On that note, I've overestimated the hazard of hydrogen azide. It is the anhydrous pure (and maybe near pure) substance and not its solutions and

water vapor containing vapor which make hydrogen azide bizzarely dangerous to work with. Curtius, the inventor of the stuff has said something along

the same lines. Hydrogen azide is a nasty toxin though, a waft of air from the amount in the reaction flask that was heated before, immediately caused

me to stop breathing out of my nostrils.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Thanks for the insight gotten from the german text. Isolation of the carbamoyl azide was something which I never anticipated doing, but contemplated

simply heating the completed semicarbazide nitrosation reaction mixture to accomplish the hydrolysis of the crude carbamoyl azide to ammonium azide,

followed perhaps by reaction with calcium hydroxide to drive off ammonia and leave a solution of calcium azide, then treated with sodium carbonate to

precipitate calcium carbonate and leave a solution of sodium azide, evaporated to obtain the solid, or keeping the sodium azide solution for use as

such. From the description it appears the carbamoyl azide is marginally stable the same as guanyl azide, and its reactions have been described as

being analogous also. It has been my expectation and curiosity if the carbamoyl azide crude reaction mixture resulting from the nitrosation of

semicarbazide would further react with cyanamide or dicyandiamide to form 5-aminotetrazole, via hydrolysis of the carbamoyl azide to ammonium azide

which should then react further in the same way as would sodium azide. If not then perhaps a conversion to the sodium azide solution as described

would enable the process starting from semicarbazide, leading to first sodium azide, and later if desired to 5-aminotetrazole, having semicarbazide as

a versatile starting material for sodium azide, convertible by further reaction to 5-aminotetrazole as a one pot perocess for either. An additional

curiosity has been if the crude carbamoyl azide would form a picrate as does guanyl azide picrate, and if carbamoyl azide can also form salts such as

a nitrate and a perchlorate similarly as guanyl azide forms salts. Anyway it is an interesting possibility to be able to use semicarbazide as a

starting material, leading to azides and tetrazoles, if it could work as I have been thinking it may work.

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

Triazoles and urazoles (triazolidindiones) has been done from semicarbazide. These are already interesting starting points. Nitrotriazolone (NTO) is

about as strong as RDX. Apparently nothing has been done with urazoles as far as energetics are concerned.

There are no indications of carbamoyl azide forming any salts, the only thing mentioned in Beilstein is hydrolysis by heating with aq. NaOH, or dilute

acids, which is similar to water hydrolysis.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah it was unclear if during the hydrolysis ammonia was liberated separately and was volatile or if it actually neutralized the hydrazoic acid

simultaneously forming ammonium azide....it has been described both ways so it was some uncertainty if a separate base like calcium hydroxide or

sodium hydroxide may be necessary to be present during the hydrolysis to guarantee sequestration of the liberated hydrazoic acid as a non volatile

azide salt in solution. Not enough of the German could I follow well enough to find the subtle details like that. However it does seem possible to

go further from hydrolysis of the carabamoyl azide to the 5-aminotetrazole and this tie in with the discussion in the tetrazole thread too, where

nitrosation of guanidine leads to unidentified but interesting products.

Obviously there are some potentially useful methods possible to be found in these related reactions which might be sequenced in a way not yet

reported, as a simplified route to both azides and tetrazoles. So this seems very interesting, also interesting that such a scheme hasn't been

reported yet, at least to my knowledge, it may just be obscure or in a different language journal waiting to be found. So I may be reinventing the

wheel a bit for that reason.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

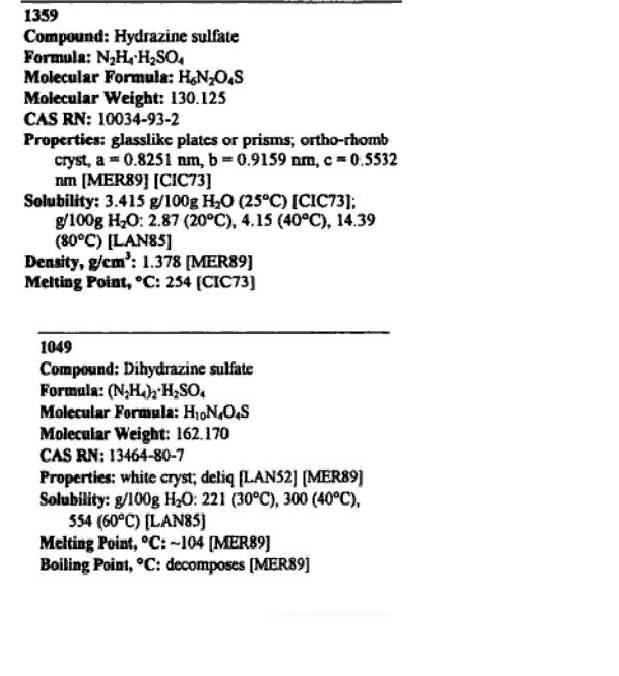

Should probably put this here too....Solubilities for Hydrazine Sulfate and Dihydrazine Sulfate

Can't find a chart for the solubility curve, so I borrowed this excerpt via printscreen screenshot, you know sort of ripped it ......sharing is caring

|

|

|

Bhaskar

Hazard to Self

Posts: 64

Registered: 6-10-2011

Location: India

Member Is Offline

Mood: Like nitro runaway!

|

|

Quote: Originally posted by Polverone  | | Quote: | Originally posted by froot

I found an interesting route to NaN3 and HN3 from a old book called 'Van Nostrand's scientific encyclopoedia'

Word for word as follows;

Hydrazoic acid is formed (1) by reaction of ethyl or amyl nitrite in NaOH solution (sodium azide formed), then acidifying with dilute H2SO4 and

distilling. Hydrazoic acid is recovered mainly in the early portion of the condensate |

I am sure that the first reaction is wrong. There needs to be hydrazine in there. Alkyl nitrite + NaOH just results in an alcohol and sodium nitrite.

|

Are u completely sure on the ethyl nitrite and sodium hydroxide forming hydrazoic acid reaction? Because i

realy wanted to synthesis my first azide...

|

|

|

AndersHoveland

Hazard to Other Members, due to repeated speculation and posting of untested highly dangerous procedures!

Posts: 1986

Registered: 2-3-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Bhaskar  | | Are u completely sure on the ethyl nitrite and sodium hydroxide forming hydrazoic acid reaction? Because i realy wanted to synthesis my first azide

|

The encyclopedia entry obviously made a mistake. They seem to have confused the common procedure, which is to first react the alcohol, NaNO2, and the

acid to make the nitrite ester, then react with hydrazine hydrate and NaOH to get the sodium azide.

Reacting aqueous sodium hydroxide with ethyl nitrite will only form sodium nitrite and ethanol.

|

|

|

Bhaskar

Hazard to Self

Posts: 64

Registered: 6-10-2011

Location: India

Member Is Offline

Mood: Like nitro runaway!

|

|

thank you

|

|

|

Bhaskar

Hazard to Self

Posts: 64

Registered: 6-10-2011

Location: India

Member Is Offline

Mood: Like nitro runaway!

|

|

Can somebody to direct me to FTP2 under upload/rogue chemist/Lead azide please?

|

|

|

Bhaskar

Hazard to Self

Posts: 64

Registered: 6-10-2011

Location: India

Member Is Offline

Mood: Like nitro runaway!

|

|

where can i find FTP2 under upload/rogue chemist/Lead azide??

|

|

|

Ral123

National Hazard

Posts: 735

Registered: 31-12-2011

Member Is Offline

Mood: No Mood

|

|

Here's a video of the tests I was able to make with the very rare primary-lead azide.

http://www.youtube.com/watch?v=V3wejJ23LLs&feature=youtu...

It has very short ddt and is also has unbelievably good storage stability compared to conventional primaries. The very high density I guess also adds

self-confinement effect.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

This may be of interest WRT the possible route to sodium azide via nitrosation of semicarbazide. A caveat should be understood that this information

is untested by me, but his is what I am understanding from the literature, which provides the information in a piecemeal fashion. What would be the

overall efficiency or safety of such a route to sodium azide as I am describing I do not know, but it appears to be reasonable.

http://www.sciencemadness.org/talk/viewthread.php?tid=3248&a...

Likewise nitrosation of hydrazodicarbonamide leads to carbamoyl azide,

http://www.sciencemadness.org/talk/viewthread.php?tid=6729&a...

but it appears that semicarbazide as the precursor may be the easier intermediate.

Edit: Actually the hydrazodicarbonamide ( Biurea ) is not difficult. It may be made from hydrazine sulfate and urea, or by other methods.

US2692281 Biurea from hydrazine sulfate and urea

US3227753 Biurea or Hydrazine from Hypochlorite and Urea

The patent GB790066 describes a very interesting method of producing what is probably semicarbazide sulfate from a reaction of equimolar amounts of

hydrazine sulfate and nitrourea in an aqueous system with nitrous oxide being evolved as a byproduct. The patent description is not very

comprehensive so here I am doing some "reading between the lines" hopefully with understanding that is correct.

Semicarbazide sulfate would seem to be desirable as a prescursor for carbamoyl azide via nitrosation with sodium nitrite. The sulfate could be

removed from the reaction mixture by use of hydrated lime or perhaps calcium nitrate.

The glauberite precipitation scheme for sulfate removal may be useful here, but I have not checked this to be sure.

http://www.sciencemadness.org/talk/viewthread.php?tid=1987&a...

The filtered carbamoyl azide solution should upon heating decompose to a solution of ammonium azide, which may be obtained upon evaporation as a

stable non hygroscopic crystalline solid. Or the ammonium azide may be converted to sodium azide by addition of NaOH or perhaps in the alternative

sodium carbonate or bicarbonate, and boiling to expel byproduct ammonia, eavaporating to dryness to obtain the sodium azide.

Attachment: GB790066 Semicarbazide from Nitrourea and Hydrazine Sulfate.pdf (361kB)

This file has been downloaded 1284 times

Attachment: US2692281 Hydrazodicarbonamide from Hydrazine sulfate and Urea.pdf (76kB)

This file has been downloaded 742 times

Attachment: US3227753 Biurea (Hydrazodicarbonamide).pdf (254kB)

This file has been downloaded 743 times

Some help is needed for translation of the German to English for the nitrosation of biurea (hydrazodicarbonamide) to carbamoyl azide, as described in

the article attached above Ueber Semicarbazid. Page 40 is what appears to be of interest.

http://www.sciencemadness.org/talk/viewthread.php?tid=1987&a...

[Edited on 29-3-2013 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

review of untested possible aqueous reaction system methods

Quote: Originally posted by Rosco Bodine  | Yeah the Dihydrazine Sulfate reportedly is stable. The reason the acidic salt, the monohydrazine sulfate is the common form is because it is the low

solubility product precipitated from acidic solution which facilitates its isolation in relatively pure form from synthesis. So the monohydrazine

sulfate is the common form of commerce, and the common form for the reagent. But definitely there are other forms of further processed hydrazine

which are also stable and may be required for certain syntheses. It is a similar story for ammonia and other bases where various salts and/or even

the anhydrous base are stable but have their various differing properties and reactivity and storage requirements, toxicity, volatility, ect. ranging

from benign conditions to extreme. To make an analogy, hydrazine sulfate corresponds with ammonium bisulfate or sodium bisulfate and Dihydrazine

Sulfate is the neutral salt corresponding with ammonium sulfate or sodium sulfate which more correctly and precisely in reality are Diammonium Sulfate

and Disodium Sulfate.

As for the danger aspect of working with smaller volumes of material which should be easier to manipulate with the endproduct being the same hazard

....usually a simpler process manipulation of a smaller amount of raw material increases safety and is not any more risky ....so it seems it would

about the same or lower risk. I can't really report an observation on this because I haven't actually done this yet to confirm. What works on paper

doesn't necessarily always materialize that way in the experiment. But this one seems pretty straightforward like it ought to work okay.

There is another calcium salt of possible interest with regards to hydrazine conversion to azide and this is another possibility for experimentation

which was mentioned in another thread.

http://www.sciencemadness.org/talk/viewthread.php?tid=874&am...

It has seemed possible to me that an organic nitrite may facilitate the reaction somehow and is more selective in converting hydrazine to hydrazoic

acid than is free nitrous acid. It has therefore seemed possible that something like sorbitol or glycerin or isopropyl alcohol in an aqueous solution

of a neutral hydrazine salt such as Dihydrazine Sulfate, might react as a regenerable intermediate organic nitrite with Basic Calcium Nitrite

Ca(NO2)2 - Ca(OH)2 to yield an aqueous solution of Calcium Azide over precipitated Calcium Sulfate. The Calcium Azide solution might then be converted

to a solution of Sodium Azide with precipitation of Calcium Carbonate, by treatment of the solution with Sodium Carbonate. This is another

completely hypothetical and untested idea for an experiment.

It may not work at all in a beaker even though it seems to work fine on paper.

Attached is US4294813 which describes a synthesis of Basic Calcium Nitrite from Sodium Nitrite and Calcium Nitrate

|

Identifying possible routes to azides which are workable in an aqueous system has been something that I have had in mind for 10 years because it would

simplify the syntheses for not requiring use of alcohol as a solvent and would eliminate that expense as well as eliminate the tedious extra efforts

attendant to manipulation methods and strategies seeking low water content in the reaction system.

There was brief discussion between myself and Engager in another thread linked in the quote above referencing the silver azide gotten by Hogkinson as

an indirect method reported for producing azide in an aqueous system. That method is one which I have tried and been unable to reproduce, which lets

me know it is a fickle reaction having a narrow window for conditions which will work, that I was unable to reproduce. The literature in general does

not offer much helpful and detailed information about synthesis methods for azides from an aqueous reaction system, but makes only brief references to

the azides being produced as products of decomposition of the subject material of such literature where the precursor for the azide is given the

authors attention, and the isolation of azide as the intended reaction product is not contemplated. So the available literature is very brief and not

very helpful in regards to describing any syntheses done in an aqueous reaction system where azide is the intended product. That absence of

information is the cause of interest in formulating experiments which seek to provide good information which fills that obvious deficiency in the

literature. Even textbooks, at least the older texts make oversimplified references to how azide is obtainable, generally referencing Curtius use of

KNO2 and Hydrazine Sulfate, and providing no details. So bravo to Curtius step right up and tell us all about it how it is done.  Until then we shall examine what may be "other" bona fide methods than proposed by

either Curtius or Hogkinson, frankly both of which reports I greet with skepticism born of experience having difficulty confirming their reports. I

have successfully made azide many times and different ways, but all of these variations still have involved free hydrazine in alcohol reacted with an

organic nitrite in the presence of a base. It is perplexing to identify the alternate conditions where an aqueous reaction system may be used with

good results. Until then we shall examine what may be "other" bona fide methods than proposed by

either Curtius or Hogkinson, frankly both of which reports I greet with skepticism born of experience having difficulty confirming their reports. I

have successfully made azide many times and different ways, but all of these variations still have involved free hydrazine in alcohol reacted with an

organic nitrite in the presence of a base. It is perplexing to identify the alternate conditions where an aqueous reaction system may be used with

good results.

Three possible methods using an aqueous reaction system have been identified. The method proposing use of Calcium Nitrite and Hydrazine Sulfate

perhaps in the presence of a polyol described above and in the linked discussion with Engager is one method I have contemplated but have not tested.

The other two methods are the hydrolysis of a carbamoyl azide intermediate briefly described by literature as obtainable from nitrosation of

semicarbazide or hydrazodicarbonamide ( Biurea )

From what little time I have been able to spend on this interest at times over the course of the past 10 years of following these threads and looking

at the literature this is my summary review of my own conclusions and my impression of where experiments have led and the 3 most promising methods yet

to be examined.

The methods involving alcohol reaction systems are solidly proven to work as methods for synthesis. But the possible methods involving an aqueous

reaction system remain inadequately reported and/or mostly unexplored, untested, and speculative .....for now.

[Edited on 30-3-2013 by Rosco Bodine]

|

|

|

| Pages:

1

..

7

8

9

10

11

..

18 |