| Pages:

1

..

9

10

11

12

13

..

18 |

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Ooh, toasty. And that's like what, two hundred bucks of metal, up in smoke all its own!!

Tim

|

|

|

tumadre

Hazard to Others

Posts: 171

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

we almost need a separate thred on NAOH vs. NACL

I am continuing work on my hot NACl project

my current plan is to make a four cell system, the steel cathode from the bottem through the ceramic,

riser pipe above it, and carbon rods(12 per cell) surrounding the riser pipe.

I plan on 80 amps @36 volts if the salt can take the current / salt resistance, if not, then just short out the fourth cell.

yes thats 12 moles per hour, ~260 grams per hour.

limitation: the ceramic material itself, and sealing the ceramic/steel at the base of the cell.

whether I use three or four cells is determined by the strength and practicallity of the cell structure, if one centimeter is thick enough then use

four cells,

if 2 cm is needed then three would be better, the space I have avalible inside my oven is 9 inches wide, 12 deep by 9 high

another difficulty is if the calcium plugs up the tube off the riser pipe

the Cl2 is 144 liters/ hour, absorbed by slacked lime (CaO) to become bleaching powder (CaOCL).

the slacked lime is in a rotating 8 inch PVC pipe 6 feet long, I would be pulling the CL2 through the Cao, from the oven, and a completely sealed

setup at that

the oven is fire brick, the kind used 70 years ago in the local creosote plant long gone ( BTW Not insulating brick)

idea: put the heating element in the liquid salt.

i plan on running this for 40 hours straight, to get about 25 pounds of sodium, ~120 pounds of bleaching power

next question: how much is 25 pounds of sodium worth?

i hope to get the ceramic fired by the 20th , and the cell running by the 22th of september

the power source is 30.5 volt transformers rectified, and a combo of inductors or caps to get the most power.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

A couple hundred dollars. I heard of 6lbs logs going for about $200 on eBay, a good deal at that.

Tim

|

|

|

Zinc

Hazard to Others

Posts: 472

Registered: 10-5-2006

Member Is Offline

Mood: No Mood

|

|

A little OT but does K dissolve in KOH if it is heated to a certain temperature as Na dissolves in NaOH?

|

|

|

Chainik

Harmless

Posts: 6

Registered: 22-5-2005

Member Is Offline

Mood: No Mood

|

|

Improvised production of Na metal

From: http://www.roguesci.org/theforum/showthread.php?t=5724&h...

<...>

The best and safest way to produce sodium metal is to make what I call a SodaBomb. It looks like a pipe bomb but is used to produce Na instead.

A steel pipe that is threaded on both ends, ~2in. dia x ~12in. long with matching end caps is needed. It is essential to remove whatever coating there

is (most likely zinc) so that only the iron contacts the molten Na.

The top cap needs to have steel or other suitable tubing welded to a hole in the cap, it needs to be ~12in. long so the heat wont affect the vacuum

tubing. Next a hole is drilled for the graphite anode which needs to be long enough to reach well into the molten NaCl sol. Then attach a wire to the

steel tube as the Steel tubing itself will be the cathode.

Now the Bottom cap is attached and the apparatus is filled to within 1" from the top with NaCl and a suitable heat source applied. When the NaCl is

thouroghly liquid carefully attach the top cap and apply vacuum to the reaction vessel (an aspirator is best). then apply the correct DC current (you

need to work this out for yourself).

When the reaction is done let the vessel cool down with vacuum stil applied and when cool submerge the entire vessel in a nonreactive fluid, (i.e.

mineral oil, kerosene etc.) Then you can remove the end caps and cut the Na out or if possible heat the oil sol. slightly to melt out the Na metal.

<...>

Sound fairly plausable to me, though i am not an expert. I can see some logistical difficulties in making a tight, yet electrically insulated seal

between the steel cap and the graphite rod, which could sustain 800C temperature for a number of hours. Some kind of fire proof cement would probably

work. Heating coul be supplied by a propane furnace with a few burners to distribute heat around the lenght of the pipe, which would be secured in

place vertically. A recirculating water aspirator station should provide the sucktion nesessary to remove the chlorine gas. Water in the station

should be periodically drained and replenished, as i would imagine it would absorb the chlorine. Current could be provided by a 12V car battery

connected to a charger perhaps?

I would love to try this, but have to build a furnace first...

Regards.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

How does the chlorine bubble out without re-burning with the sodium? Sodium does float.

The combination of molten salt and vacuum seems rather silly to me. Salt has a rather high vapor pressure.

Tim

|

|

|

BromicAcid

International Hazard

Posts: 3227

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Sounds like a pain in the butt. And drawing off the chlorine under vacuum using an aspirator? That would put a slight vapor pressure of water in the

reaction vessel which would be quickly reacted away drawing in more water vapor (albeit tiny amounts). All of this sounds similar to what I tried

with potassium hydroxide/magnesium reduction, if scaled up, the whole apparatus could have been put into mineral oil and product scraped out.

|

|

|

Chainik

Harmless

Posts: 6

Registered: 22-5-2005

Member Is Offline

Mood: No Mood

|

|

I suppose the apparatus could be designed with a circular (pipe) shield surrounding the graphite electrode, and the chlorine outlet positioned in the

area between this electrode and the shield. But then isn't the whole thing is really starting to become a downs cell with suction chlorine removal?

The only advantage of doing it this way, IMO, is the vessel design (metal pipe and screw caps - readilly available) and the product removal (cooling

the pipe down and opening it under mineral oil...

|

|

|

tumadre

Hazard to Others

Posts: 171

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

The easiest way is the way I tried to finish before moving on with my life.

A steel/copper funnel with pipe drawn off the top suspended over the steel electrode (-) inserted through the bottom of a ceramic vessel. and graphite

electrodes (+) suspended in the liquid salt by the copper screw connection to the top of the rod.

To start the system from dry salt, expenditary rods are inserted so that they touch the steel rod, and using a 4 or more car batteries to provide the

initial current to heat and melt the salt.

BTW this will only work if the ceramic vessel is at least a few liters in volume as you will crack the ceramic.

any clay/ceramic can be used if only one cell is used and if the ceramic is not exposed to any electrical potential diference.

yes you can position an iron pipe over the graphite anode and suck off the CL2, use a copper rod and ceramic perforated disks to hold the graphite and

copper rod centered in the pipe so it don't touch the steel pipe, and send the electricity down the copper rod to the graphite, extend the pipe ~30 cm

and afix the copper rod to a silicone seal through the steel pipe

more later-

|

|

|

indigofuzzy

Hazard to Others

Posts: 145

Registered: 1-10-2006

Location: DarkCity, Bay of Rainbows, Moon

Member Is Offline

Mood: Distilled

|

|

Out of curiosity, would glass stand up to having molten salt and/or molten sodium metal in it? If so, than with some time and glass blowing skills a

cell could be made with the electrodes passing through the glass, which would keep the electrically isolated.

|

|

|

BromicAcid

International Hazard

Posts: 3227

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Of course it wouldn't stand up to sodium hydroxide on a chemical level for very long but glass does stand up to sodium. The problem though being the

heat required to keep everything liquid with a different electrolyte and the glass becoming soft under that heat. At least that's the main problem I

see with the idea.

|

|

|

ziqquratu

Hazard to Others

Posts: 385

Registered: 15-11-2002

Member Is Offline

Mood: No Mood

|

|

Ahoy sodium enthusiasts!

Just stumbled across this article, which I find DAMN interesting. The is (as the title suggests) designed for lab scale work, and gives nearly 100%

cathodic efficiency (ie. almost 100% yield of sodium based on current used). An added feature which I find nice is that the anodic efficiency is much

lower, 20-30%, meaning less chlorine is produced than would be expected.

The feedstock is a 30:70 mixture of sodium chloride and aluminum chloride. The temperature is around 250 *C, and the currents they use are anything

between 1 and 10 amps. So, using 1A, approximately 1mol of sodium can be produced per 24h!

The reaction works because it uses beta alumina as an ion-selective separator. And this, as far as I can see, is the main sticking point - does anyone

know anything about how one might go about making or (easily) obtaining a cylinder of the stuff? The other issue is that they start off with some

sodium in order to prepare the alumina surface, although there seem to be enough claims in this thread that SOME sodium can be produced easily enough,

so this may not be a real problem.

Anyway, here's the article:

Design, construction and operation of a laboratory scale electrolytic cell for sodium production using a β-alumina based low-temperature process

Journal of applied electrochemistry 2002 vol. 32, no12, pp. 1383-1390

Attachment: Electro_Na_Alumina.pdf (338kB)

This file has been downloaded 1418 times

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

This place makes an "inside-out" version of that, for injecting sodium into molten metal, using NaOH as the feed material.

http://www.ionotec.com/aluminum.htm

They sell preforms of beta''-alumina with several dopings, Na and K included.

|

|

|

tupence_hapeny

Hazard to Others

Posts: 131

Registered: 25-3-2007

Member Is Offline

Mood: continuing respiration (touch wood)

|

|

This is the 'new' method of operating a modified 'castner' type process. It uses methanesulfonyl chloride as the electrolyte, and operates above the

melting point of elemental sodium (~100C) and according to the patent operates between 100-200C, to produce elemental sodium and chlorine from a

divided cell (using glass matting or a glass frit to divide a H-Cell). As 100-200C is rather attainable (as is methanesulfonyl chloride see the

patent: Methane(g) (LPG) + Chlorine(g) + Sulphur Dioxide(g) is allowed to react in a glass tube @~15-100C under UV irradiation [sunlight/low pressure

mercury vapour lamp/high pressure mercury vapour lamp) this process would appear to be the most viable for the production of alkali metals at home.

Anyway, for the references, see this page (my post is at the bottom):

http://www.sciencemadness.org/talk/viewthread.php?tid=2105&a...

Can someone please advise me if the required gaseous mixture could be generated by mixing sodium hypochlorite and sodium metabisulphite (in the

requisite ratios) and adding Hydrochloric acid to generate both the Sulphur dioxide(g) and Chlorine(g)? IF SO, may I suggest passing LPG (Methane =

~95-97%) through the reaction vessel to collect the gasses thus generated and passing the desired ratios directly into the reaction tube?

Alternatively, add HCl to the bottom of the reaction tube (or attached reactor) and then add the required volume of LPG? With a pressure equalised

addition funnel, it should be possible to add additional reagent precursors as required.

NB if the condensate from the reaction can be collected in an inner or outer container, in such a manner as it does not come in contact with the spent

precursor/HCl mixture, it should be possible to remove it cleanly without contamination.

We are all the sum of our experiences, and our reactions to the same

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

It's not easy getting very strong solutions of sodium hypochlorite, and there seems to be a fair amount of chlorine lost to solution; I assume that

the same problem would exist with SO2. The HCl + MnO2 route seems to be better for making chlorine, perhaps a mix of MnO2 and metabisulfite would be

better.

I'd keep the gas generation entirely separate from the actual reaction area, plumb the gases over into a reaction vessel. I know you want to use the

HCl produced, a closed loop system with active pumping may be needed to do that, but I think a properly design might work OK.

I'm not sure you could get good enough control over the gas ratios that way, but it's simple enoug it might be work a try. Note that sunlight will

work in place of a lamp, you could run the reaction in one or more condensers (in series). You'll need to vent the gases to the external world to

prevent pressure buildup from non-reactive gases.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by tupence_hapeny

Methane(g) (LPG) |

LPG is propane. Methane is natural gas, rarely stored in cylinders (methane is supercritical at room temperature so is a refrigerated liquid) and

widely available through domestic gas plumbing.

Tim

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Ah, you are correct 12AX7, I missed that - read it as LNG which is not sold in stores this side of the asteroid belt.

|

|

|

tupence_hapeny

Hazard to Others

Posts: 131

Registered: 25-3-2007

Member Is Offline

Mood: continuing respiration (touch wood)

|

|

I missed it too, 12AX7... Perhaps I got too excited looking at the low temp sodium Anyway, provided you are on a gas grid, LNG is actually more available (in most areas) than LPG, simply take it from the gas line. I welcome criticism

of the idea, such criticism may help design a workable mechanism by which to make low temp (fairly low tech - face it, the gasses can be piped in

through stainless steel lines and fittings into a SS collar (and probably top and base) at the ends of a glass tube. Yeah, sunlight is supposed to

work.

Anyway, provided you are on a gas grid, LNG is actually more available (in most areas) than LPG, simply take it from the gas line. I welcome criticism

of the idea, such criticism may help design a workable mechanism by which to make low temp (fairly low tech - face it, the gasses can be piped in

through stainless steel lines and fittings into a SS collar (and probably top and base) at the ends of a glass tube. Yeah, sunlight is supposed to

work.

It also appears that some of the co-electrolyte can be reused after replenishing the solution with NaCl. I noticed that my links are NOW down, so here

they are again:

Methanesulfonyl Chloride

http://www.patentgenius.com/patent/4997535.html

Low temperature Alkali Metal Electrolysis using Methanesulfonyl chloride:

http://www.patentstorm.us/patents/6787019.html

I personally find the fact that the links are down somewhat surprising and somewhat unusual, however, I have noted that their (Free Patents Online) website gives the notice that it is closed for some reason

[Edited on 28-3-2007 by tupence_hapeny]

Edited again, I think it may be easier to produce a known volume of gas (SO2 form Metabisulfite and Cl2 from salt) through electrolysis, at least then

you could cut down on the cost of the entire process (extra reagents) and establish some control over the rates of generation. Face it, if you can't

generate Cl2(g) from salt solution, you probably shouldn't try to make Na from the same

[Edited on 28-3-2007 by tupence_hapeny]

We are all the sum of our experiences, and our reactions to the same

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Is there a link anywhere to PDF versions of those two patents, which would have the diagrams and illustrations, which are omitted from the HTML

versions on those two sites?

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by JohnWW

Is there a link anywhere to PDF versions of those two patents, which would have the diagrams and illustrations, which are omitted from the HTML

versions on those two sites? |

Try http://ep.espacenet.com/numberSearch?locale=en_EP

Do a search, prefix the patent number with the country code. You get a list of matches, clicking on one results in the entry for that patent being

shown. Then select the 'Original Document' tab, and after that the 'save full document' link above the patent display.

|

|

|

indigofuzzy

Hazard to Others

Posts: 145

Registered: 1-10-2006

Location: DarkCity, Bay of Rainbows, Moon

Member Is Offline

Mood: Distilled

|

|

Ok, something inside me says this sounds *way* too easy.

Hypothetically, one just needs natural gas (for the methane), a reaction that makes chlorine, sulfur burned in oxygen, and to mix the gases in proper

amounts in a glass tube, and place this in sunlight (or under a blacklight tube), yielding the necessary ionic fluid? Then dissolve the required salts

and electrolyze to your heart's content?

Is it really that simple, or did I miss the big huge GOTCHA somewhere?

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Burning sulfur to get SO2 also gives some SO3, plus there's all the other stuff in air, some purification will be needed. You need to have some

control over the proportions of the gases in the mixture, or do some design work to come up with a plant that can tolerate a lot of variation. You'll

need to distill the product, and it is an acid chloride.

A blacklight tube isn't very intense, and if you read the patent it's more in the blue range that you want anyway. High intensity mercury or metal

halide lamp is more like it.

You need to keep the electrolysis rig rather dry.

More than likely it can't compete on an economic basis with the established processes. And, yes, there may be problems with one or both parts of the

full process, many patents include a lot of handwaving and don't-look-behind-the-curtains; they may not be practical when filed and are either done in

the hopes that they can be improved or to CYA in case someone else manages to come up with an improvement.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

I carried out some prelimanry experiments on NaOH and NaCl/CaCl2 electrolysis. Turns out ther latter is a much better bet , unexpectedly, despite the

280C higher temperature. There reasons:

1) Experiment has shown that molten Na is not substantially more reactive at 580C than at 330C. The presence of Cl does not substantially change

this.

2) Forming Na in molten NaCl is not an issue, it forms easily, it doesnt dissolve. The only problem is collecting it.

3) Molten NaCl does not attack glass/porcelain, making collection much easier

4) Molten NaCl does not spit, there are no nauseous hydroxide fumes. If you get some on you its only good for you.

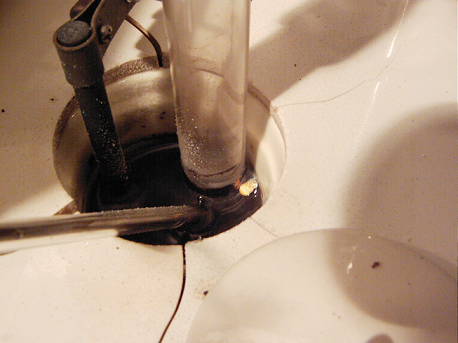

The picture shows Na globules being collected in an inverted tube under an inert atmosphere. You can not do this with NaOH.

The only difficulties are:

1) Some bubbles of Na (about 0.5cm sphere, 0.1g each) miss the test tube and break like a shinning sun on the surface (picture). Placing the -ve

electrode inside the tube, and or using gauze does not right this for obvious reasons.

2) The Na collects in the form of a multitude of such globules in the tube. They are covered by a stubborn coat of melt/carbon particles which are

very difficult to dissoldge in getting them to coalesce under molten paraffin.

[Edited on 10-5-2007 by len1]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Very nice len1. Would you mind providing more details of your cell or are you waiting until you get a production model developed?

I would like to know cell design, materials of construction, method of heating, keeping the inert atmosphere, removal of chlorine, etc.

You say:

| Quote: |

Placing the -ve electrode inside the tube, and or using gauze does not right this for obvious reasons.

|

I must be missing the obvious as I don't understand this statement.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

| Quote: | Originally posted by Magpie

Very nice len1. Would you mind providing more details of your cell or are you waiting until you get a production model developed?

I would like to know cell design, materials of construction, method of heating, keeping the inert atmosphere, removal of chlorine, etc.

You say:

| Quote: |

Placing the -ve electrode inside the tube, and or using gauze does not right this for obvious reasons.

|

I must be missing the obvious as I don't understand this statement. |

Thanks Magpie for the nice words. Your guess was spot on, my real aim is to see if I can make a small jig for making sodium continuously. Im not

really satisfied with these results so per se, except as experimentation to help fix the final design. My aim in posting this is to see if anyone can

contribute useful info as per how to coalesce dirty Na globules, and interaction of molten Na with glass.

I used an ordinary high-temp furnace, inverted for crucible use. The front shield was a ceremic tile. The crucible itself is porcelain. The -ve

electrode was a stainless steel wire inserted through a 6mm OD glass tube. The reason for the latter, is to avoid the Na forming/floating to the

surface following the wire - this would otherwise happen. The chlorine removal mechanism was my lungs! Seriously its not a huge problem for a small

set up. If you make 2gms of Na, you release 0.05 moles Cl2 gas, or 1.5l worth. For comparison, 1 liter of liquid chlorine, 5% NaOCl, used to wash

your floor releases up to 13gms of chlorine! The tube had Ar blown into it periodcally, being cold and heavier than air, it displaced the O2 in the

tube.

The liquid Na wets almost anything including glass, which it attacks also, hence the black coating you can see. The coating - whose composition I

dont know, does not seem to conduct electricity, and once formed protects the glass, which was just superficially corroded. I would be interested to

know if you or anyone else has any references to this effect of liquid Na on glass. Using a metal tube to collect the Na (which you could also do in

NaOH) would overcome this, but it cant be used around the negative electrode.

Placing the -ve elctrode in the center of the tube has the Na wetting the tube, crawling around it, and being electrically connected to the -ve,

starts formation of globules outside the tube. Len

[Edited on 11-5-2007 by len1]

|

|

|

| Pages:

1

..

9

10

11

12

13

..

18 |