| Pages:

1

..

3

4

5

6

7 |

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Well lemme see here. 10" dia., 10" tall, say 15 turns, wire gauge doesn't matter but call it #20 (AWG for Cu I think), stainless steel resistivity

(close enough), the calculator program I have shows 44uH and 5.2 ohms DCR (not unreasonable). At 60Hz, that's 0.017 ohms reactance, or a Q of

1/313th. (An intentional inductor has Q = 50 or better, a difference of 5 orders of magnitude or so!  ) )

One thing you'll notice is, for a solenoid coil, you will have 5 or 10 or 50 amps through 10 or 20 turns, and that's 50 to 1000 amp-turns, enough to

make a piece of iron buzz when energized.

(My induction heater is currently around 1kW power output and runs up to 2000 amp-turns at 21kHz, enough to make a piece of aluminum or copper, placed

in the coil, stand on end from the repulsive force!)

Tim

|

|

|

Cloner

Hazard to Others

Posts: 150

Registered: 7-12-2004

Member Is Offline

Mood: apocalyptic

|

|

OK, nothing beats an example Thank you. Thank you.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

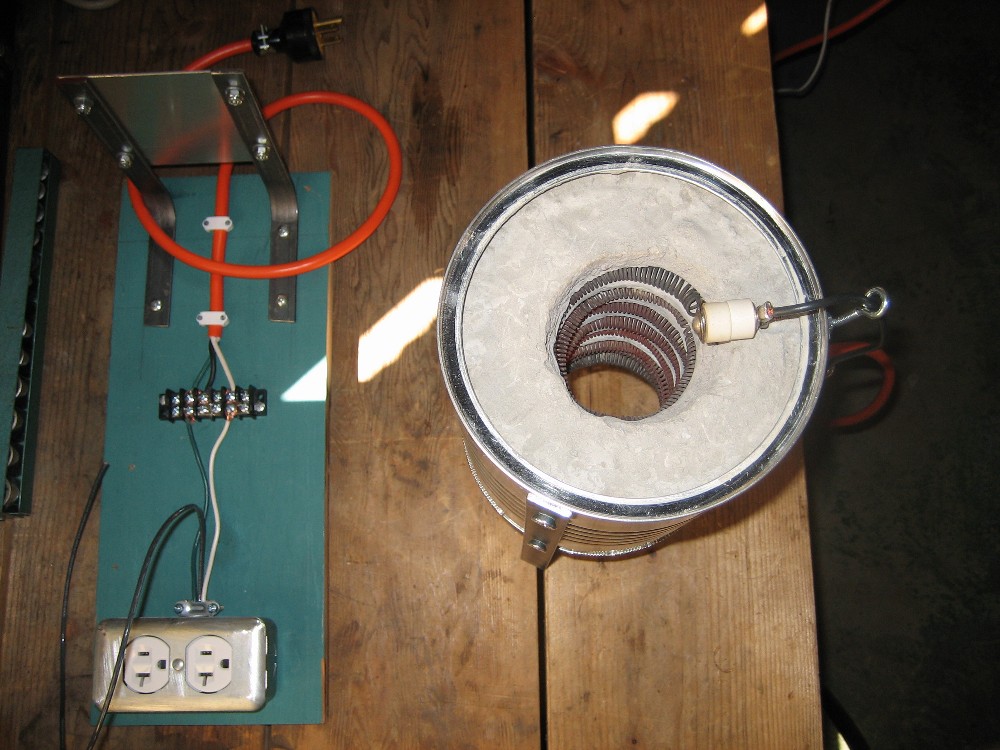

I have been wanting to build a tube furnace for some time. This would be a significant project using a horizontal clamshell design with castable

insulating mortar and a castable refractory. It would also have a temperature controller and be capable of developing 1300C.

I decided to build a small scale furnace as a first step to get some experience with hightemperature materials and fabrication techniques, as well as

provide a furnace for another project. I built this furnace as a "vertical tube" furnace using a 3lb coffee can as shell. The dimensions are:

H=7.5", OD=6", and ID=2.5". The refractory was made using axehandle's formula. The heating coil is a 5000w, 240VAC, D = 0.5", L =6', salvaged from

one of the banks of the furnace that formerly heated my house. For my coffee can furnace I run it at 120VAC, 1250w.

When power is applied it comes up to a red-orange heat. Since the insulation is not very thick the shell of the furnace gets pretty hot also. This

is not good and will likely limit its lifespan. I have not kept it at full power for more than a few minutes so far. I have attached a picture

below, and one in the next post.

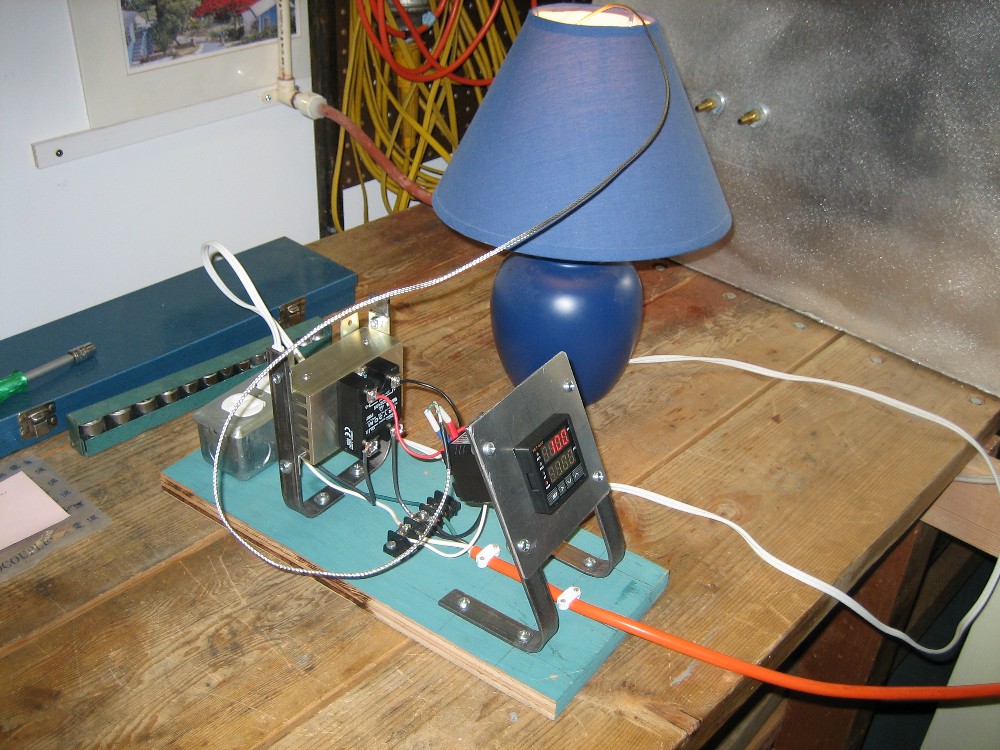

I also am building a temperature controller for this furnace which will be suitable for any furnace revisions as well as the horizontal tube,

clamshell type that I want to eventually build. The controller framework is shown along with the top view of the furnace in the next picture. It is

complete except for two components that should arrive any day now: (1) a solid state relay, and (2) a PID controller with type K thermocouple.

(These controllers now are surprisingly cheap.)

A few comments on axehandle's refractory formula: Making/using this was different from any of my past mortar, grout, or concrete experience. First

of all it was very fluid. This is contrary to my other experience where I only used enough water to make the material workable. Second, the pearlite

floated to the top and the sand sunk to the bottom so the mix was not homogeneous. So I just let it set for a few hours, occaisionally stirring and

checking its stiffness. Eventually it did stiffen enough that I felt it was reasonably homogeneous but still pourable and workable. After hardening

it is not strong like concrete. But so far it has only developed minor cracks and seems to be doing the job for which it is intended. Until someone

else comes up with a better formula this is the best we have, and is cheap, OTC, and at least so far, is doing the job for me. So .....thank you,

axehandle.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's the 2nd picture:

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I just received the PID (with auto-tuning) controller for my furnace temperature controller. I connected everything up and tried it out by

controlling the temperature of the outside of a lamp bulb to 100F. It works well. This controller should be suitable for most any furnace. I

assembled this controller for about $100.

[Edited on 27-9-2006 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Those Watlows are nice, the one that's four times bigger (92 or 93?) are awesome, programmable, self-adjusting, the works. Can't say I'd like to pay

for one though!

Tim

|

|

|

Al Koholic

Hazard to Self

Posts: 98

Registered: 2-12-2002

Member Is Offline

Mood: Seeking ligand

|

|

So guys, I'm also building a furnace with a lot of help from all the great work that has been done on this thread. Thanks all for the contributions!

I've got most of it hashed out and I have almost all the parts now but there is something I think we need to clear up.

How are you all connecting the element wire to the power leads? Not like series or parallel...but what kind of connectors are you using?

I ESPECIALLY like Magpie's ceramic(?) connectors. Magpie...I fear you got those from the salvaged furnace. If not, please tell me where you got

them! Many google searches have yielded little in the way of solutions. Definetly nothing as elegant as what you have there.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Al, those ceramic rings did come from my furnace. They really are just sort of there for looks in my little furnace. A bolt runs through them and

the wires are just secured with washers and the bolt, and a nut. The element ends transition from the dark, rough looking coil wire to a clean shiny

metal wire end that looks like it might be made of nickel. This is for about 1" on each end. That's the way I found the coil.

When I build my high temperature furnace I will likely be using 1mm diameter Kanthal A-1 to form my heating coils. I will likely just have to lead

the wire ends outside the furnace wall a couple inches for terminals. I don't know what else to do. This is what rikkitikitavi recommends early on

in this thread. Hope this helps.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Al Koholic

Hazard to Self

Posts: 98

Registered: 2-12-2002

Member Is Offline

Mood: Seeking ligand

|

|

Had a feeling...

Well I had a feeling they were from the furnace. I was at Home Depot today and someone mentioned a few stores I should check out so I'll try and find

those.

It wasn't so much I was wondering how physically to do it, but more what the actual connectors you all were using. I guess I'm just in love with the

way those look on your furnace Magpie.

I've got the regulator box with fans basically ready to go soon and just have to get my element wire in the mail. I'm using K-A1 20AWG (.8mm).

Should be pretty nice, I'm pumped. Too many plans to use the thing for.

Knife making (hopefully pattern-welded "damascus" style can be acheived with it) is one of the main reasons I am building the thing in the first

place. No need for worrying about flame quality or fuel quantity anymore!

I suppose I'll have to figure out how to upload some pics of my completed setup when all is said and done.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I've seen little ceramic parts (tubes, etc) on some websites for sale but can't remember for sure which ones. I think I looked under "ceramic

insulators" and found some such. They are available, just difficult to find as they are so specialized. Pottery and kiln shops would also be worth a

look.

[Edited on 29-9-2006 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

tumadre

Hazard to Others

Posts: 171

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

For knife making you still want a reducing gas mix in side the furnace

i have used 17 gauge electric fence wire (15 gauge AWG), and for some smaller stuff I have used 1/8 inch steel rod as an alternative to nicrome, it

don't last but 10-40 hours, but the cost is nothing.

as the bolt goes, i have not tried stainless, i'm sure it or something else is needed

and don't even think about exposing copper to more than 500C

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I'm interested to know how you intend to get hot enough to forge weld, without induction (hello) or fire.

Tim

|

|

|

Al Koholic

Hazard to Self

Posts: 98

Registered: 2-12-2002

Member Is Offline

Mood: Seeking ligand

|

|

Well, steel welds at a lower temp than iron; the higher % C, the lower the welding temp. I've read that in some alloys, the welding temp can be as

much as 1000F below the melting point. Usually it's around 300-400 below.

Anyway, the furnace may never reach that T, but it will still be useful for forging. All that is a long way off anyhow...

As far as a reducing gas mix, would not keeping the lid on during the heating cause the O2 to be used up by light surface oxidation forming some

scale? This is typical and needs to be brushed off in any forging of course. I'm hoping that I wouldn't need to add anything extra to the furnace to

eat O2 but it wouldn't be a big deal...little OT thought.

|

|

|

tumadre

Hazard to Others

Posts: 171

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

All the websites I've read use a carburizing furnace because the gas reduces the iron oxide as the weld is taking place, no amount of flux will work

without at least a neutral gas mix.

no amount of iron will pull the O2 out, charcoal might but i would'nt even let Nitrogen get in without a more active gas like propane floating in the

furcace

if you hold the electric element internal to the kiln at 1350C, you will be able to forge the weld, but it will take too much time to re-heat the

knife to 1100 or 1250C

IIRC iron melts at 1536C

aren't you pulling the knife out and beating it with a hammer like 300 or more times?

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

| Quote: | | I just received the PID (with auto-tuning) controller for my furnace temperature controller....I assembled this controller for about $100.

|

What the hell?! You can build an analog PID for $10 in parts. Plus, autotuning can never be as good as good manual tuning, and, of course, real men

don't use autotuning -.-

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Al Koholic

Hazard to Self

Posts: 98

Registered: 2-12-2002

Member Is Offline

Mood: Seeking ligand

|

|

Tumadre, I'll have to see how it goes with the heating times. I didn't think it would be too long to do reheating but I'll have to see. Like I said,

this might not be a furnace I can use for forge-welding. Out of curiosity, why would N2 be a problem in the furnace?

On an interesting side note though, no you don't have to composition to begin with. You can make a stack of say, 5 layers to start and weld them.

Then you cut the result in half and restack to get to 10 layers. Then to 20, and so on. Makes getting layer counts in the 50-250 range (the range

that fold the metal over all that much if you cheat by using two steels with slightly different looks good) easier than starting with a single bar and

folding it.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

What the hell?! You can build an analog PID for $10 in parts. Plus, autotuning can never be as good as good manual tuning, and, of course, real men

don't use autotuning -.-

|

That PID cost $35. I'd be pretty impressed if you could duplicate that for $10 alright. It accepts all common thermocouples and thermistors with no

work on my part. In my younger years I might agree with you about auto-tuning. Right now I'm very glad to have it.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

You can salvage resistance wire ceramic holders from a clothes dryer,

The ends are usually welded to stainless steel terminals.

Damn, I must be getting old as I don't remember PID controllers less than about $200. Been awhile but autotuning never did live up to it,s claim.

Programming A manual sequence is the best way in my experience.

[Edited on 1-10-2006 by bio2]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Al Koholic

... Out of curiosity, why would N2 be a problem in the furnace?

.... |

Most of the resistance wire for heating is designed to work in an oxidising atmosphere. Running them in reduction may greatly shorten their life.

Running them in a neutral atmosphere, after breaking the wire in under oxidising conditions, may be OK; but if traces of reducing compounds got in you

could be back to the short lifespan probem.

|

|

|

Maya

Hazard to Others

Posts: 263

Registered: 3-10-2006

Location: Mercury

Member Is Offline

Mood: molten

|

|

Has anybody tried or thought about making or done an argon arc furnace?

This would be for melting oxygen sensitive metals over 1700 celcius

Another idea is an IR image furnace for the same application , this focuses with mirrors, concentrated light on the sample in a quartz tube to melt

it.

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

This reminds me of the infrared soldering such as http://www.aoyue.de/images/prod/Aoyue_710_1.jpg

Halogen light-type infrared source in a focusing reflective enclosure.

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

tumadre

Hazard to Others

Posts: 171

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

N2 may not be a problem.

To forge a weld, all the impurities between the steels must properly flow out as the steel joins

Flux allows that to happen, but the flux can't cover all the steel at all times, so on your first few knives you manage to make, you may lose 1/3 of

the steel to oxide. so you need something to displace the oxygen, and nitrogen won't do that unless you have a tank of it.

I remember somewhere someone mentioned a salt bath to heat the steel, but that may have been for heat tempering at lower temps.

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

| Quote: | Originally posted by tumadre

I remember somewhere someone mentioned a salt bath to heat the steel, but that may have been for heat tempering at lower temps.

|

It would have to be at lower temperatures if you're talking about NaCl as it would have too much volatility at those temperatures. I've melted

NaCl/CaCl2 before to use as an aluminum flux and it has significant volatility at only 700*C.

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

fuse123

Harmless

Posts: 12

Registered: 26-10-2006

Member Is Offline

Mood: No Mood

|

|

what about inductance furnace

any one here have any information to make it

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by fuse123

what about inductance furnace

any one here have any information to make it |

WTF, you just posted in the thread with links to many details, in fact one of approximately three such highly detailed websites on the subject on the

whole internet as far as I can tell!! Did you post this before discovering the thread or are you truely that daft?

|

|

|

| Pages:

1

..

3

4

5

6

7 |