Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Preparation of Phosphoric Acid (from calcium phosphate)

by Magpie

January 5, 2013

A. Introduction

This procedure provides a method for producing about 160mL of 25% phosphoric acid from Ca3(PO4)2 and con H2SO4. It is loosely based on the “Dorr

strong acid” industrial process (ref 1).

Ca3(PO4)2 + 3H2SO4 + 6H2O ---> 2H3PO4 + 3CaSO4•2H2O

B. Chemicals

• 207.4g of Ca3(PO4)2 (0.669 moles)

• 110 mL con H2SO4 (1.98 moles)

C. Equipment

1000mL beaker

1000mL suction flask

15cm Buchner funnel w/filter paper

1000mL RBF (pot)

500ml RBF (receiver)

distillation head

water cooled condenser

vacuum adapter

ebulliator tube w/thermometer adapter

heating mantle w/variable power supply, or other heating device

magnetic stirrer/hotplate

large magnetic stir bar

aspirator or other vacuum source

plastic kitchen spoon

stiff stirring rod

fume hood (strongly advised) or face shield

lab coat or long-sleeved heavy cotton shirt

lab apron

heavy rubber gloves

D. Procedure

I. Reaction

1. Add 500mL of DI water to the 1000mL beaker. Stir and heat to a boil on the magnetic stirrer/hotplate.

2. Don all safety apparel (labcoat, apron, gloves, and face shield).

3. Carefully spoon 103.7g of Ca3(PO4)2 into the boiling liquid to form a slurry as shown in the picture below. Be careful of hot steam releases.

Ca3(PO4)2 slurry

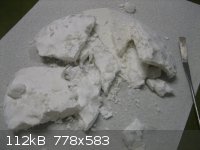

4. Carefully and slowly drip 55mL of con H2SO4 into the slurry. Dangerous spattering due to localized high heat of dissolution can

occur. Continuous stirring and slow addition of the acid will prevent this. When the slurry becomes too thick to stir remove the beaker from the hot

plate, remove the stir bar, and stir by hand using a stiff stirring rod until all the acid has been added and thoroughly mixed into the slurry. When

finished the slurry will look like stiff cottage cheese as shown below. Its temperature will be ~ 75°C.

slurry following precipitation

II. Filtration

5. Using the plastic kitchen spoon, place all of the slurry in the Buchner funnel.

6. Apply suction while pressing the filter cake. Wash the cake by pouring 4x25mL of DI water onto the cake during suction. The pressed cake is

shown in the picture below.

removal of CaSO4 by filtration

7. Discard the cake. To appreciate the volume of the pressed cake see picture below.

CaSO4 filter cake

8. There should be about 470mL of filtrate. Place this in the 1000mL beaker and top off to 500mL with DI.

9. Return to step 2 above and repeat this procedure (once), this time using the filtrate in place of DI water, and stopping after step 7.

III. Removal of Settled Solids

1. Set the filtrate aside overnight to allow any CaHPO4, etc, to precipitate and settle to the bottom of the flask. (ref 2.).

2. If precipitate is present, remove it by decantation or filtration.

IV. Vacuum Evaporation

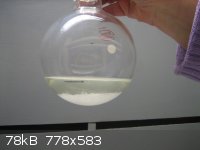

1. Draw a line indicating the 160mL level on the pot using a marking pen.

2. Set up for vacuum distillation using the 1000mL RBF as pot and the 500mL RBF as receiver. Ice-water for the condenser and an ice-water bath for

the receiver are recommended.

3. Install the ebulliator tube in the distillation head as shown in the picture below. (See note 2.)

Vacuum distillation apparatus

Make sure all safety gear is in place before placing labglass under vacuum.

4. Warm the pot somewhat then place the system under vacuum.

5. Open the pinch clamp on the ebulliator to provide a full stream of tiny air bubbles to enter the pot near the bottom. This will significantly

moderate the bumping.

6. Bring up the heat on the mantle slowly until adequate boiling is achieved. Monitor closely for excessive bumping. A picture of

the bumping is shown below.

Controlled Bumping

7. Continue to remove water by evaporation until about 160mL of phosphoric acid remains in the pot as indicated by the line drawn earlier.

8. Bring the system pressure up to atmospheric by slowly allowing air to enter. Turn off the heat.

9. Let the acid sit overnight then remove settled solids by vacuum filtration.

Mrs Magpie holding H3PO4 with settled solids just before final filtration

Attachment: phpWt8Ilb (63kB)

This file has been downloaded 1555 times

Final product - 25% H3PO4

E. Determination of Acid Molarity

1. Titrate a sample of the acid with 0.1N NaOH to a methyl orange endpoint to determine the molarity.

H3PO4 + NaOH ---> NaH2PO4 + H2O

2. Consult a handbook table to determine the %H3PO4 based on the molarity determined.

F. Determination of %Yield

1. Determine the moles of H3PO4 produced by multiplying the volume of acid produced in mL times the molarity/1000.

2. %yield = (moles produced)/[(0.669)(2)] multiplied by 100%. The expected yield is ~ 63%.

G. Discussion

Six years ago when developing this procedure I found that the hydrated CaSO4 produced was slimey and difficult to filter. However, during recent

minor tweaking of the procedure I noted that the precipitate was indeed voluminous, as expected, but not slimey, and it filtered easily. This was

such an improvement that I decided to write up the procedure for Prepublication. Later, in reading some patents for the industrial processes I saw

that increasing the hydrated CaSO4 particle size to facilitate filtration was a major objective. Evidently my procedural changes increased particle

size. My guess is that the formation of the dihydrate of CaSO4 (by having plenty of water available) instead of the hemi-hydrate increased the

particle size.

Another goal of industry was to reduce the evaporation load on the plant. This was done by using dilute phosphoric acid to make up the phosphate

slurry instead of water. This was also done to increase the CaSO4•2H2O particle size. Noting that this technique would cut my evaporation load in

half, I incorporated same into this procedure.

It is the intent of this procedure to carry a slight excess of Ca3(PO4)2 into the filter cake. This should reduce the amount of sulfuric acid

contamination of the product phosphoric acid. (1.98 moles of 18M H2SO4)/(0.669 moles of Ca3(PO4)2) = 2.96.

The concentration of the final product H3PO4 could be increased well above 25% by further evaporation. However, increasingly severe bumping must be

anticipated.

The composition of the settled solids found in the product just before the final filtration is not known. It appears to be a uniform substance with

well defined crystal structure. It might weigh ~2g.

Notes

1. Strong phosphoric acid at high temperatures can corrode glass. Vacuum is used to reduce the boiling temperature to prevent this.

2. A proper ebulliator tube does not use a piece of rubber tubing and a pinch clamp. Instead, the glass tube is drawn to a hair sized opening (ref

3).

References

1. US Patent 2049032 (1936) “Dorr Strong Acid Process,” by Weber, Shafor, and Roberts.

2. http://www.destructve.com/bromicacid/experiments/september20...

from BromicAcid’s site.

3. Macroscale and Microscale Organic Experiments, (2010), KL Williamson and KM Masters, p. 117. http://books.google.com/books?id=934SaXmEDcIC&pg=PA117&a...

[Edited on 6-1-2013 by Magpie]

[Edited on 7-1-2013 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

BromicAcid

International Hazard

Posts: 3227

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Nice to see this done right! I notice you referenced by site, I also tried this (prior to the attempt on my site) using bone meal. Now that was a

nasty mess!

|

|

|

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

Very nice, Magpie, as usual; a comprehensive and detailed write-up of your work.

How long did you find the vacuum evaporation took?

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks. The evaporation took 1.5 hrs. The limiting factor was my condenser which is a 19/22 size about 20cm long. A 24/40 condenser would have

shortened this time.

Yield would likely be increased by using more dilution liquid than the 500mL I specify. The price of this would be increased evaporation time,

however.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Austentic stainless steels (314, 316) are unaffected by phosphoric (which is why big food uses 85% phosphoric extensively for cleaning), as such your

concentration phase need not be performed under vacuum (to save the glass) but rather more simply in an open 316 tray heated from underneath. The temp

of the solution being a measure of its water content, 158C I believe will be 85%, after that further concentration need be performed under vacuum

otherwise thermal degradation into all those polyphosphoric compounds begins in earnest.

That said I recall concentrating an 85% solution to 95% at 150C under vac in a schott reagent bottle with almost no etching evident afterwards. I

think hot phosphorics reactions with borosilicate glass are overstated, perhaps simply a carry over from older glasses of a century or so ago. I don't

really know.

Any decent catering equipment supplier will have multiple tray configurations of 316 used in Bain Marie'(those steam devices used in hot buffets and

the like).

|

|

|

PirateDocBrown

National Hazard

Posts: 570

Registered: 27-11-2016

Location: Minnesota

Member Is Offline

Mood: No Mood

|

|

I like that you used the word "ebulliator". Seems "bleed tube" or just "bubbler" has been more common terms lately. The Latin makes us sound more

awesome.

I use a 2 neck flask in such a set up, and the ebulliator is just a Pasteur pipette. I still use a screw pinch ("Hoffman") clamp, for control.

|

|

|

Fluorite

Hazard to Others

Posts: 132

Registered: 26-12-2018

Location: United Arab Emirates

Member Is Offline

|

|

Aaeemmm any ideas if sodium bisulfate can be used instead? The reaction should produce calcium sulfate sodium sulfate and phosphoric acid right? Or am

I missing something?

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

Quote: Originally posted by Fluorite  | | Aaeemmm any ideas if sodium bisulfate can be used instead? The reaction should produce calcium sulfate sodium sulfate and phosphoric acid right? Or am

I missing something? |

Sodium bisulfate and phosphoric acid have very nearly the same pKa, so there's not much happening to drive the equilibrium towards the side you want.

You also obtain a much more water-soluble byproduct than using sulfuric acid, which is a problem for purification.

|

|

|