| Pages:

1

..

10

11

12 |

Thraxx

Hazard to Self

Posts: 71

Registered: 15-10-2016

Member Is Offline

Mood: No Mood

|

|

[/rquote]

Maybe use the Na or K salt instead of the NH4 salt?

Anyway, it is not the favoured synthesis pathway for a reason...probably the low yield.[/rquote]

-I am looking for some RDX method with better yields in comparisson to fuming nitric acid,not to precursor like in industry.

Problem is,that this method has poor yields of both views.

The patent is talking about ammonium salt.The K salt was described in this thread like W method and the last step needs SO3 or P2O5.

Described method with ammonium salt like patent need either

SO3 or 100% acid.These conditions are very simmilar.It seems me,that the precursor is hygroscopic and is very complicate to dry it and the acid is not

100%.Lower concentration of reaction mix lead to inconspicious oxidation with bubbles.(no Nox,simply bubbles).

Attachment: RDX from sulphamic acid.pdf (203kB)

This file has been downloaded 620 times

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Thrax?

Please, could you add time and temperature range information to your lab notes?

The claimed 75% yield method with straight nitric acid in the patent description mentions a desirable range of temperatures, and a specific reaction

time before drowning the mixture in cold water.

The claimed "quantitive yield" method with SO3 does not provide an actual description of weight achieved, or sufficient information for me to derive

that for myself? Or do I need more coffee....

I did not yet see the method with P205/nitric acid mentioned, is this elsewhere in thread? Could you add a link, if so-

Going back to looking for Bambi now. Too cold to type without gloves.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Thraxx

Hazard to Self

Posts: 71

Registered: 15-10-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Bert  | Thrax?

... time and temperature range information to your lab notes?

... range of temperatures, and a specific reaction time before drowning the mixture in cold water.

...I did not yet see the method with P205/nitric acid mentioned, is this elsewhere in thread? Could you add a link, if so-

|

Method with P2O5 you will find in this thread,page 2,author: Polverone.(I saw simmilar description on the EWF forum and elsewhere I archived it.)

To my experiments.I did Step 2 (precursor) two times and Step 3 three times .In each step I did mistakes.

My mistakes :

Mistake in Step 1-first experiment-precursor was prepared in described temperatures.For to keep it between 30-40 C I musted cool and heat.But I did it

exactly.It was very long reaction-5 hours. In this case I didnt mistake and the product was clear solution.After one day by 20 C on the glas plate I

saw there

small crystals,after two days there was very long and nice crystals .

- second experiment- I prepared 50 g of ammonium ASA with 74,5ml formaldehyd ,all was right at the time of adding,but I must go to

another room and as I returned,there was 90 C and in the beaker was something like white gelatine.I cooled it and dryied it .I saw there no crystals

and the drying was not easy,twice I gave there ethanol,but I thought,that if it was on the 90C,then I can it heat on this grades.And after it seems me

dry,I did Step 3.

Mistakes in Step 3.

- in the first experiment I used the first (good)precursor and 30 ml acid.It was more,there should be 30 g acid (about 20 ml).During

reaction rose temperature for one moment over 30 C.It was in half time of addition.Followed addition was in the range 5-10 C.I drowned it short time

after last addition.I should wait 30 min.

- in the second experiment I did no mistakes,it was with 20 ml acid,then added between 5-10 C and waited for 30 minutes.This time I

saw,like the clouded acid is more clear and clear and some bubbles are there.And after drawing it to ice there was shit.Clear watter.

- in the third experiment I prepared into the beaker 10 ml of liquid Mg(NO3)2 melted at 170C,because I told me,that there was a watter

because not good dryied precursor.Well. Then was the same like before-holy shit and clear watter.

Result-the second precursor, either wet or dry, was bad.May be,if the first experiment with good precursor would done without

thermical excess (30C)and waited for 30 min., it could be more succesfull.

((SO3 method--if I remember ,SO3 is available from thermical decomposition of FeSO4,but there is an philosophical question,if the RDX is

good enough for such smell and wasting of acid and time.))

[Edited on 15-10-2016 by Thraxx]

[Edited on 15-10-2016 by Thraxx]

|

|

|

Thraxx

Hazard to Self

Posts: 71

Registered: 15-10-2016

Member Is Offline

Mood: No Mood

|

|

Nitrolysis under pressure

I had a rest of abbout 30 ml nitric acid (vac. fum.)and I gave there 10 g of hexamin.Unfortunatelly it slumped me there big amount of hex and

temperature was rose now at 60 C,big flame and smell (gray smoke and brown nox).Acid was clear like watter.I cooled it and at 20-30 C added the rest

of hex.And after addition I put the beaker under pressure 120psi of compressed air for one hour without cooling.After I opened the pressure

bottle,there was on the bottom of the beaker a small amount of white crystals and after diluting in 150 ml watter there was a very good yield.Try it

too.

[Edited on 15-10-2016 by Thraxx]

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Could you define "a very good yield", give dry product weight?

And is there any litterature or other particular information that led you to try pressurizing the reaction?

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Thraxx

Hazard to Self

Posts: 71

Registered: 15-10-2016

Member Is Offline

Mood: No Mood

|

|

Pressurizing is my own idea and the "very good yield" is drying now,but it must be repeated,because there was the accident which I described.

the "very good yield" is 10 g.

[Edited on 15-10-2016 by Thraxx]

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

You may reduce the heat by using Hexamine dinitrate instead of Hexamine...

Since neutralization generates heat (use frozen cold saturated solution of hexamine then add frozen cold 69% HNO3)...

Final salt must be dried and can then be used for your experiment --> reducing a lot the heat of reaction.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Thraxx

Hazard to Self

Posts: 71

Registered: 15-10-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PHILOU Zrealone  | You may reduce the heat by using Hexamine dinitrate instead of Hexamine...

Since neutralization generates heat (use frozen cold saturated solution of hexamine then add frozen cold 69% HNO3)...

Final salt must be dried and can then be used for your experiment --> reducing a lot the heat of reaction. |

To work with HDN is to tolerate this hygroscopic, corrosive and stinking stuff and need to have a good dessicator/dryer,where isnt gauge for to know

if it is already dry.

Reasons for to use the HDN are two-as you told,the mild reaction and second-utilisation of spent acid from Petn.

If somebody think,that save some acid with use of HDN if he use the for acid advantageous ratio,then he use the disadvanategeous ratio for RDX and

his product contain other stuffs.(((may be if such product would be renitrated,there could be a lot of HMX )))

The first industrial method used in Italy for production of T4(which now we told RDX)used HDN:acid 1:8 and 6 h.after addition it was cooled and

vacuum destilled (after filtration?without diluting?) at 40C for to have acid or formaldehyde back.

One of author (Kraus)told,that production of Petn and RDX are simmilar-if the Petn has good nitration yields and problematic precursor,then the

RDX has good precursor and problematic nitration yields.

Therefore if we use the HDN instead of Hexamine,then we lose the advantage of RDX production.

[Edited on 15-10-2016 by Thraxx]

[Edited on 15-10-2016 by Thraxx]

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

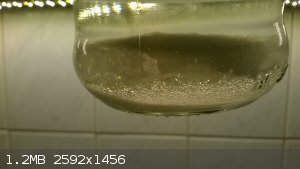

Some very energetic "diamonds" I grew in a soxlet extractor type of recristallisator....a thing of beauty

Exact science is a figment of imagination.......

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by markx  | Some very energetic "diamonds" I grew in a soxlet extractor type of recristallisator....a thing of beauty

|

Nice.

RDX, HMX or keto-RDX?

What a mysterious way of recristallisation...never heard of it; could you explain a bit more...the procedure or scheme.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

| Quote: |

Therefore if we use the HDN instead of Hexamine,then we lose the advantage of RDX production. |

I don't quite get your point. HDN is not difficult to produce, nor excessively hygroscopic. As Philou said, just add cold dilute (ca. 60%) HNO3 to a

saturated (or nearly so) hexamine solution. HDN precipitates immediately and can be filtered off. Then wash the crystals with alcohol and dry. In my

experience, air drying is not problematic, but you could use a CaCl2 drying tube to blow dry air over the product if you live a very humid place.

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by PHILOU Zrealone  | Quote: Originally posted by markx  | Some very energetic "diamonds" I grew in a soxlet extractor type of recristallisator....a thing of beauty

|

Nice.

RDX, HMX or keto-RDX?

What a mysterious way of recristallisation...never heard of it; could you explain a bit more...the procedure or scheme. |

Garden variety rdx....but the original aim of the recristallisation device was towards alpha hmx conversion to beta cristal modification. Basically it

is an improvised soxhlet extractor and the idea is to use refluxed solvent to dissolve the sample in the smaller hanging glass vessel and then carry

it to the reboiler where it slowly settles out under gentle mixing (don't let the pic fool you, the device is heated via a pid water bath, not

directly on hot plate):

What this contraption allows is the use of a limited amount of solvent that is recycled to carry over a rather sizeable sample. Not really essential

for rdx, but for hmx the conventional means of recristallisation is a lost cause. Solubility is minimal in all conventional solvents and furthermore

it displays basically zero solubility temperature dependance. Hence heating the solvent will accomplish nothing with the eight membered heterocycle.

Thus the contraption at hand will allow to use a reasonable amount of solvent to get the conversion done. Due to the less than optimized geometry of

the vessel containing the sample the whole process currently takes too long and crystals tend to grow too large, but visually a very enjoyable sight.

[Edited on 12-12-2016 by markx]

Exact science is a figment of imagination.......

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

If I understand correctly because it seems that there is solid in both récipients (inner and outsider):

1°)The initial cristals are inside the hanging inner vessel.

2°)The outside vessel contains the solvent that evaporates because warm

3°)The condenser condense the warm volatilized solvent into the inside tinier vessel which dissolve a portion of the initial cristals.

4°)The solvent level into the inner vessel goes up while cristals remains at the bottom of it; at a certain point (level) it goes out via tiny holes

and fall into the larger outer vessel with the initial solvent; doing so the dissolved compound passes into the larger recipient with the larger

amount of solvent.

5°)The outside recipient enrich itself slowly with the dissolved compound while the solvent continues its cylcus (evaporation, condensation into

inner recipient, dissolution of initial cristals and fall of solution into larger outside recipient).

6°)The outside recipient reaches the saturation level where it deposits first cristals at the desired temperature of cristallization.

Nice set-up and process. --> Bravo/Applause/Hat down.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by PHILOU Zrealone  | If I understand correctly because it seems that there is solid in both récipients (inner and outsider):

1°)The initial cristals are inside the hanging inner vessel.

2°)The outside vessel contains the solvent that evaporates because warm

3°)The condenser condense the warm volatilized solvent into the inside tinier vessel which dissolve a portion of the initial cristals.

4°)The solvent level into the inner vessel goes up while cristals remains at the bottom of it; at a certain point (level) it goes out via tiny holes

and fall into the larger outer vessel with the initial solvent; doing so the dissolved compound passes into the larger recipient with the larger

amount of solvent.

5°)The outside recipient enrich itself slowly with the dissolved compound while the solvent continues its cylcus (evaporation, condensation into

inner recipient, dissolution of initial cristals and fall of solution into larger outside recipient).

6°)The outside recipient reaches the saturation level where it deposits first cristals at the desired temperature of cristallization.

Nice set-up and process. --> Bravo/Applause/Hat down.     |

Well played, sir!  Indeed that is the absolutely correct description of the

course of events that through inevitable completion led to the cristalline result that can be seen in the previous posting Indeed that is the absolutely correct description of the

course of events that through inevitable completion led to the cristalline result that can be seen in the previous posting

Exact science is a figment of imagination.......

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Quote: Originally posted by markx  | Some very energetic "diamonds" I grew in a soxlet extractor type of recristallisator....a thing of beauty

|

Nice job! Quite an interesting method you have there.

I have a similar diamond like crystals pic on page 2 of this thread but I made mine via slow evaporating a solution of acetone however I had already

gotten the main crop of crystals and the acetone was decanted with the crystals growing over a coupe of days.

|

|

|

Thraxx

Hazard to Self

Posts: 71

Registered: 15-10-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  |

| Quote: |

Therefore if we use the HDN instead of Hexamine,then we lose the advantage of RDX production. |

I don't quite get your point. HDN is not difficult to produce, nor excessively hygroscopic. As Philou said, just add cold dilute (ca. 60%) HNO3 to a

saturated (or nearly so) hexamine solution. HDN precipitates immediately and can be filtered off. Then wash the crystals with alcohol and dry. In my

experience, air drying is not problematic, but you could use a CaCl2 drying tube to blow dry air over the product if you live a very humid place.

|

I did a lot of HDN in the past and I dont like it.May be I am lazy. Hexamine is easy and cheap to buy.

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by Thraxx  | Quote: Originally posted by Microtek  |

| Quote: |

Therefore if we use the HDN instead of Hexamine,then we lose the advantage of RDX production. |

I don't quite get your point. HDN is not difficult to produce, nor excessively hygroscopic. As Philou said, just add cold dilute (ca. 60%) HNO3 to a

saturated (or nearly so) hexamine solution. HDN precipitates immediately and can be filtered off. Then wash the crystals with alcohol and dry. In my

experience, air drying is not problematic, but you could use a CaCl2 drying tube to blow dry air over the product if you live a very humid place.

|

I did a lot of HDN in the past and I dont like it.May be I am lazy. Hexamine is easy and cheap to buy. |

HDN is just an easy option to use directly and efficiently the "dilluted" HNO3 generated by your RDX synthesis while reducing also the risk of runaway

inherent to the heat of neutralisation when using basic hexamine with concentrated HNO3...

Hexamine is even cheaper to do...mix slight exces conc NH3 solution with concentrated formol solution (both freezing cold because it heats a bit and

at first NH3 gas and CH2=O gas are unpleasant, irritant and toxic)...once it has reacted (after a few minutes no more risks).

Then evaporate and cristallize.

[Edited on 14-12-2016 by PHILOU Zrealone]

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

| Pages:

1

..

10

11

12 |