Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

Titanium attached to MMO?

i was wondering how do people manage to attach titanium or MMO as for electrolysis...?

i have titanium plate and a MMO piece in which the part that leads the electricity to the anode just keeps corroding, and ive really tried hard to

make it last but it seems impossible

bring me all you got.. industrial aswell as simple ways to attach it at home!

i did a search for it, but as i expected it would be impossible to seperate out threads about electrolysis with titanium and MMO / general talk about

titanium with MMO coating etc

ive considered soldering, but as ive worked with metal for some time i just dont see the possibility of this, also lead would get corroded, wouldnt

it..? i did solder my previous attachment on the anode and epoxy glue and many other things to keep the chlorine out

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

1/2" titanium tube with a slot cut along it's length about 1.5". Insert MMO into slot and carefully flatten the tubing to conform. Drill entire unit

and insert a titanium nut and bolt. Fill the tube with molten tin and allow it to harden. You can then drill and tap the tin for your electrical

connection.

This setup can handle just about all the amperage that an amateur can throw at it.

[Edited on 20-10-2013 by hyfalcon]

|

|

|

cyanureeves

National Hazard

Posts: 737

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

blue RTV silicone lasted longer than epoxy in my case and i used alligator clips that i would detach after they eventually got corroded.an exhaust

tube for chlorine gas helped too which of course could only be used if an air tight lid was in place.

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I assume you are talking about the connection that is submerged in cell liquer. Spot welding of the Ti current collector to the MMO mesh is the only

foolproof way of creating a durable anode setup. Forget about bolting and covering the connection with silicone or any other resin. The connection

will passivate and corrode as the polarisation rises. As for the connection outside the cell the tin filled Ti tube method that hyfalcon described

will do a god job. Or you could use a full Ti rod of required dimensions....whichever one is easier to realise.

Exact science is a figment of imagination.......

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | | I assume you are talking about the connection that is submerged in cell liquer. Spot welding of the Ti current collector to the MMO mesh is the only

foolproof way of creating a durable anode setup. |

Not the _only_, but definitely the most accessible. You

could also TIG weld it (a process I didn't know could be done without a vacuum chamber until this last year), but that's not nearly as accessible a

process.

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

thanks for the input, i would suspect titanium being somewhat difficult to work with due to its properties somewhat relative to magnesium when it

comes to combustible hazard? i will soon have a place where i can for a short amount of time use the machinery and what not, a motor factory, so TIG

welding is not only something i have done alot in but also im sure they have it at that place, but wouldnt that have to be a special TIG welder.. no..

wait a second..

thats brilliant!! the MMO has titanium underneath!!

hope others than me will find this thread useful, i was considering to take a strip of titanium plate and then bending that through the MMO anode and

pressing it really hard to get a proper grip, but if TIG welding will work then thats the way i will do it, hoping that my titanium plate can somehow

be TIG welded without breaking

i did also consider a titanium rod, then the thickness of the MMO anode cut through it, and the MMO inserted with decent force so it would stay in

place, but again i would need to order a titanium rod aswell as first find one

thanks alot guys! (:

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

Use the 'pdfbq' method. As shown by him you do not need to weld the titanium current runner tp the piece of MMO covered Titanium (the anode proper).

Simply bolt (you need the proper grade of Titanium in the bolt) or rivet a piece of grade 1, or 2 or 3 or 4 Titanium to the MMO anode and all will be

ok so long as you keep the actual connection submerged in the electrolyte.

Dont use grade 5 or any grade that has Al in it.

See www.amateurpyro.com for details. See this board for details also.

There is no need to weld but if you have access to a welder then by all means do.

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

Did I mention I didn't think that method up? If I remember correctly it was Swede that came up with that connection method that I use.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Antiswat  | | if TIG welding will work then thats the way i will do it, hoping that my titanium plate can somehow be TIG welded without breaking

|

The key is that you need a jig to get shielding gas to the back side of the weld, adding to the shielding

gas coming in only to the front side from the nozzle. Plenty of internet video clips on the subject matter; make sure to look around a bit before just

plunging in. There's a bit of special gear required to get the shielding gas to the back side, but nothing overly fancy.

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I think it can be quite tricky to Tig weld the MMO mesh to the current connector, but if you can pull it off then thumbs up  I would suggest to remove the MMO coating in the places that you intend to weld as it

can interfere with the Tig process (I do not know for sure as I never tried to actually tig weld the mesh). I opted for the spotwelding method since

that exposed the mesh to heat and pressure in only very limited areas and minimized damage to the oxide coating. As for the "simple" ti to ti

connections I can say that for example the VT1-0 alloy behaves quite similar to stainless steel when tig welded. Providing shield gas to the backside

of the detail is also not strictly required when you only intend to tig weld in spots and the metal is not very thin (less than 1,5mm thickness). It's

better if you do provide full shielding of the entire detail, but I managed without it quite well...simplified things considerably I would suggest to remove the MMO coating in the places that you intend to weld as it

can interfere with the Tig process (I do not know for sure as I never tried to actually tig weld the mesh). I opted for the spotwelding method since

that exposed the mesh to heat and pressure in only very limited areas and minimized damage to the oxide coating. As for the "simple" ti to ti

connections I can say that for example the VT1-0 alloy behaves quite similar to stainless steel when tig welded. Providing shield gas to the backside

of the detail is also not strictly required when you only intend to tig weld in spots and the metal is not very thin (less than 1,5mm thickness). It's

better if you do provide full shielding of the entire detail, but I managed without it quite well...simplified things considerably  I'll try to pull some pictures of the connections I made in my setup... I'll try to pull some pictures of the connections I made in my setup...

Exact science is a figment of imagination.......

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

my plans for TIG welding it will be to simply put the Ti plate piece on a solid piece of metal, which will then absorb the heat that hits the titanium

plate hopefully sucking up most of the heat so the plate wont be molten apart, the MMO will ofcourse be removed at first as a key in TIG welding of

what i recall to have learned is to have clean surfaces as close as possible, tho i even managed to annoy the guy running the workshop by doing some

impossible gap weldings with tig welding, but thats just me

the thing is just that -- yes a bolt would be much easier and i wouldnt die abit mentally over having to remove MMO coating, but titanium parts i

doubt i can get in my city and all, a welding is always what you prefer to have made as it just lasts longer mechanically

ill report back with results hoping i will have a TIG welder at hand, otherwise i might just wrap a titanium metal sheet strip through it, should do

the job also but would be be quite loose

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

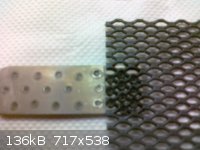

My KClO3 reactor setup:

Ti cathodes

Laserreds MMO anode

5l glass cell

70A power supply (operated at 50A)

Current collectors from VT1-0 Ti alloy, joined with spotwelds and Tig

The electrodes have been operational for over a year now. No apparent signs of wear. All the welds on Ti look as shiny as on the day they were made.

The cathodes are detachable from the current collector by stainless bolt....enables the easy use of different cathode materials if needed:

[Edited on 22-10-2013 by markx]

[Edited on 22-10-2013 by markx]

Exact science is a figment of imagination.......

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

that looks very effective, what is the average yield and runtime of this?! also, did the titanium weld straight onto the MMO coating??

also, seemingly you just use a plastic plate put ontop of your cell, you do run this thing outside, right?

ive thought about similar rough design with a tube, no fitting lid and just simple gravity keeping it all together..

not to mention, the power supply, looks quite dedicated to electrolysis, did you buy that somewhere?

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I usually run the cell for 3-4 days straight, depending on how effectively I manage to replenish the chloride. To be honest I have not really been

keeping track of the yield and efficiency so far. Concentrated more on creating a functional harware. But I recall that the results of first syntheses

were around 400-500g. The product really piles up with this cell

And yes, the cell cover is just a plastic plate....it actually seals the system very effectively. Condensing water vapour forms a sealing layer

between the plastic and glass, effectively trapping the liquor mist inside. I actually ran the cell indoors last winter....inside the bathroom with

the exhaust vent on. Did not really smell that much, like a spa with a chlorinated pool

Then again I did not use pH control, once you tune down for the neutral region the smell becomes quite heavy.

Power supply is customized. The supply is a standard 5V 350W switching unit from ebay. You can get it for 37$ and for the money it really is quite a

piece of hardware. Rated at 70A max and adjustable output voltage (I have pushed it to 95A for short periods with no harm done). I also coupled

digital volt and ampmeter with it and now it is really perfect for the purpose of electrosynthesis.

pH control will be the next step that I will incorporate into the system. Time to push the efficiency and yield of the setup(even though it does work

very well and provides more product than I could ever need just as is). I received a nice small peristaltic running off 5V, so I can couple that to

run from the main power supply to replenish lost electrolyte and keep pH down. Just have to figure out a timing system for the pump....a simple timer

without any feedback from cell seems like the way to go without complicating things too much.

Exact science is a figment of imagination.......

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

3-4 days thats pretty neat, especially with ~450g at each batch!!

but, if the condense water traps it, how come the bubbles are not pushed through the water, there would be an increasing pressure if not, wouldnt

there?

i have heard that MgCl2 should be capable of acting as balancer, i havent tried it myself, the person who told me about it says its used industrially

but he couldnt find any references to it :/

why dont you try making it into ClO4 some time? if you decided to make NH4ClO4 from that you might have quite some profit out of this with those

yields (:

infact seemingly (abit offtopic) NaClO4 + NH4Cl should be decently easy to seperate out by decanting when crystals of NaCl appear at 100*C then

letting it cool down and then recrystallize it out, only problem would be to be sure having pure ClO4

also for pH control i guess you have heard about dichromates being used?

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

For sure the cell releases the overpressure of hydrogen....there is no hermetical seal, but the mist stays trapped in the liquid layer and salt creep

buildup. Some of it eventually gets through too, but the amount is really minuscule. I used to run a primitive open cell setup (graphite anode,

silicone covered copper connections, 12V power supply etc) for a short period of time years ago in my workshop and I can tell that this really

provoked an outbreak of corrosion on all metal surfaces.

MgCl2 acting as a balancer of what? Cathodic reduction of ClO3-I presume...similar to dichromates?

As a matter of fact Ca++ ions also presumably act as ClO3- cathodic reduction prevention agent by forming a film on cathodes....that is why I

deliberately use hard water for preparing the cell liquor. I also had references to this claim, but I lend out my photocopied sections of the russian

applied electrochemistry book to a dear friend of mine. I hope he has not misplaced the article

I also found the pics of my first documented yield of KClO3 with this cell from last year (I did dry it in two portions ):

[Edited on 26-10-2013 by markx]

Exact science is a figment of imagination.......

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

the best part i'd say is if you let it SLOWLY recrystallize out in a large beaker with sunlight as background.. found myself spending many hours

literally staring at the precipitation

for the MgCl2, yes, as with dichromate, im not entirely sure how it works, so i cannot disagree with you.. perhaps i should make an attempt on

understanding how dichromates helps efficiency of the cell some time

oh btw, about water for cells.. be careful, there is flourides in drinking water pretty well around the entire globe, which will very slowly eat up

the MMO

but again.. very slowly..

also another thing... you could dump some cotton wool on the edges of your cell and wetten it (with oil or just regular water?) and then place the lid

on top and some weight or just push down, i have an idea this could potentially work better isolating..

another thing i have considered was to place the cell with minor leaking in a container larger than the cell and then a weak solution of ammonia,

which would then remove the escaping chlorine gas, but also create chloramines and traces of hydrazine (!!) due to the reaction of NaClO (or KClO)

with NH4OH (or NH3)

btw about the chlorine.. if i dont keep lid on my ~2 amp 2 litre cell, i wont be able to be in the room within short time without gas mask on.. you

mention something about the neutral region causing more chlorine to form as free gas? how did you control this or is this just as the reaction starts

or ends? (:

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

i recall having said to up my results with TIG welding Ti-Ti (Ti- MMO(Ti))

it went to luck, although i could have controlled it more if i understood the different settings before starting up

it went alot easier than expected however.. i just pulled the button once and it was attached against all odds

it was just all getting blown together, however it worked, twice in row infact

http://imgur.com/xqDvjIS

http://imgur.com/zf8urXs

http://imgur.com/c4vUOiO

i would prefer to TIG weld it because it seems to last very well, being perfectly molten together, not knowing how well spot welding welds it together

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

M'key....I rigged up the pH control system:

A small 5V multifunctional timer unit (pretty nifty with a display and all  )

that runs off the main power supply and drives the little peristaltic according to the programmed cycle, that's it. Just connect to a container with

HCl solution and fire on )

that runs off the main power supply and drives the little peristaltic according to the programmed cycle, that's it. Just connect to a container with

HCl solution and fire on

Exact science is a figment of imagination.......

|

|

|

Fantasma4500

International Hazard

Posts: 1677

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

i have since last time thought about either Mg + TiO2 or just general thermites welding titanium together

.. should be doable, most others than titanium would just tear up in a cell

also your very crude cell design seems to work, i usually add wettened cotton to the edge of my cell to keep the gas in abit more but even without

works well

another thing... the unreacted chlorine..

wouldnt it be better to sorround a MMO anode with titanium cathodes, so that the chlorine wouldnt escape?? i already have quite minimal escaping

chlorine, im thinking even having a cathode bent at the bottom, going behind the anode would mean alot of difference as the solution would get

agitated and disperse the chlorine

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Thermites for Ti welding....perhaps doable for crude joining of large details, but not the most practical option to be honest. With intricate details

like the components of an electrochemical cell I see little application for such method.

Exact science is a figment of imagination.......

|

|

|