| Pages:

1

..

7

8

9

10

11 |

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

I came across a store that sells the single MMO electrodes, for those who have bought pool chlorinator electrodes, how do they compare in cost?

http://www.jumpinjackflashpyrosupplies.com/servlet/the-20/MM...

|

|

|

chloric1

International Hazard

Posts: 1070

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Thats why I want to sell if we get the coating just right. I mean that is like $5 worth of titanium.

Fellow molecular manipulator

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by The_Davster

I came across a store that sells the single MMO electrodes, for those who have bought pool chlorinator electrodes, how do they compare in cost?

|

I think many people these days are buying MMO and platinised Ti electrodes for chlorate and perchlorate. Certainly those who are seriously into

pyroechnics are, just check out the pyrotechnics sites.

As I pointed out in the ?perchlorate thread my platinised Ti anode has made over 3Kg of KClO4 so far and cost about $50.

My MMO chlorinator electrodes are performing extremely well and they cost...... nothing...

In Australia, chlorinator assemblies cost about A$200 - 300 new, for that you would get 5 - 7 electrodes, each with a surface area several times that

quoted for the MMO anode you have found. I did come across somewhere that was selling individual electrodes, but I can't find it now, I think they

were about A$80

http://www.directpoolsupplies.com.au/category9_1.htm

Click on the blue subcategories to see the variation in range!

I think commercially available anodes will become more common, whenever there is a niche market, someone will step in to fill it.

Of course this doesn't preclude one making one's own, I find it a challenge and an enjoyable pastime. Certainly if a coating can be found it will

likely only cost a few cents, and the Ti will probably last a lifetime.

My current anode (Hubert) is doing very well at making KClO3 and the coating must have cost all of 10 cents...

Just like any field of human endeavour there will always be a range of options available to suit the individual, from buying chlorate and perchlorate

directly or making the simplest and cheapest of anodes themselves.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Did you see the rest of their catalog here? I was wondering how long before somebody starts selling complete cells...now I know.

BTW, Xenoid, are you running your platinized titanium anode perchlorate cell in a "batch" type process (i.e., you go from high to low ClO3

concentration) or are you using a more-or-less "continuous" process?

[Edited on by jpsmith123]

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

There is a legal problem with selling products made using techniques covered by patents. Much as I would like to see someone selling good perch anodes

for a reasonable price, it does set a bad example. Noone is likely to complain, though, and at least some of these patents are past their expiry date.

[Edited on 4-1-2008 by tentacles]

edit: that said, I would probably still buy one if reasonably priced.

[Edited on 4-1-2008 by tentacles]

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Thanks Xenoid..

And is funny because before I tried , I was suspicious that this resistance method , as simple as I've pretended never will work.. I tried and this

was pure true..

But this is past and even if I was able to get a proper resistor, probably I would not be capable of get smooth current and therefore not be able to

do proper calculations regarding current/mols of NaClO3 produced.

| Quote: | Originally posted by Xenoid :

Yes, for you, the best thing is to solder directly to the remaining copper! You'll need a fairly heavy duty soldering iron. A lightweight electronic

iron doesn't develop enough heat, well mine doesn't anyway. Put silicone grease on your connections, make sure no electrolyte gets on them...

|

Can I seal electrodes/lid joints with hot melt glue and after this put some silicone grease ? And can I replace silicone grease by hot-melt glue to

seal wire/electrodes connections?

Thanks!

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by Aqua_Fortis_100%

Can I seal electrodes/lid joints with hot melt glue and after this put some silicone grease ? And can I replace silicone grease by hot-melt glue to

seal wire/electrodes connections?

|

Yes, seal everything with hot glue if you want...... but it will still corrode.....

Do you have a vent tube attached, for gasses and fumes. You'll need to be able to add water every few days.

@ jpsmith123

I ran the perchlorate in simple batch mode, I just did a rough calculation and ran it about 50% longer.

BTW when you get that chlorinator cell running, use KCl, you'll be able to watch KClO3 building up, and up, in the bottom of that big jar. I should

have used a taller cell for Hubert because pretty soon I'm going to have to stop it and remove the KClO3.

@ tentacles

Why would there be any legal problems! The company has most probably got one of the Indian or Chinese anode manufacturers to make a batch of anodes to

their own specification.

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

xenoid: I mean if forum members are producing anodes for sale. That company may have had a batch made, but they don't look like anything used in

industry, and the shape (tubes) makes me think they are made from some Ti scrap. It's still possible, though. But if he did go to the trouble of

ordering a bunch of anodes from india (or whereever), why didn't he order some of those fabled long lasting industry LD anodes? Certainly the

companies that make platinized and MMO anodes nearly always also make LD versions as well. (especially considering that MMO interface layers seem

needed for Ti substrate LD)

[Edited on 4-1-2008 by tentacles]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ tentacles

Sorry, I misunderstood what you were getting at!

I would imagine LDO anodes are just around the corner.

One problem with this widespread availability of cheap anodes, is that perhaps the "operation of a cell to manufacture

hazardous oxidisers" will become illegal....

There is not much point banning the sale of chlorates and perchlorates, if people can make their own at home, even cheaper.

Where will it end, a ban on the sale of NaCl and KCl ....

|

|

|

chloric1

International Hazard

Posts: 1070

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

| Quote: | Originally posted by Xenoid

Where will it end, a ban on the sale of NaCl and KCl ....

|

Yeh right! If they go that far then they would be better to rule themselves intrusive and fiscally inefficient! Refering to DHS, DEA or some other

alphabet soup collection of pencil pushing bureumonkies.

Fellow molecular manipulator

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

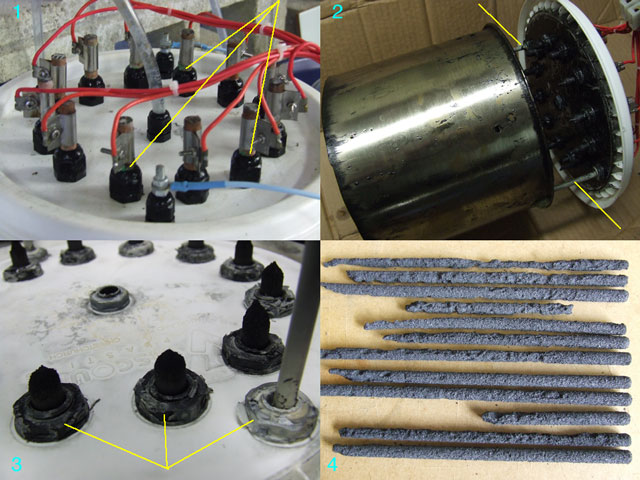

10 litre chlorate cell

As a follow-up to my post a few months ago, earlier in this thread (see page 7), on the construction of a 10 litre NaClO3 cell using gouging rods, I

offer this footnote. It's been sitting on my computer for months so I thought I better post it, in case someone is buiding a cell based on this

design.

The calculated run-tme for my 10 litre "Big Bertha" chlorate cell (see earlier post) was about 21 days (at about 3.2 - 3.5 volts and 24 - 25 amps).

However, I was planning on letting the cell run for several more days until the gouging rod anodes were fully consumed. However, on the 22nd day the

cell died. The cell was remarkably trouble free, only requiring a top up with water every few days. The cell was completely odourless and gas tight,

and only slight corrosion occurred over the three weeks of running (Image 1.). A little green corrosion product developed on the copper plate, just

above the cable gland on several electrodes, this did not effect the electrical characteristics at all.

When the electrode assembly was removed, there was no evidence of cathode corrosion (Image 2.). The new "L" shaped cathode connection rods can be

seen. These are made from threaded rod, and covered with black heat-shrink tubing (this is now grey due to the bleaching effect of the cell).

The cable glands on the underside of the lid (Image 3.) were quite badly bleached. These are described as "UL Approved NYLON 94V-2", however a flakey,

bleached layer had formed. The glands should, however, be good for several more runs, as the effect is shallow.

When the cell liquor was poured off, the reason for the shortened run-time became obvious. At the bottom of the container, remnant lengths of all 12

anodes were found (Image 4.). All the rods had worn through at a point level with the top of the annular SS cathode, clearly this was a region of

extra high current density. A rough estimate is that 25% of the rods were not consumed. This had happened on some of my smaller cells, and I had

modified the annular cathodes into a slightly conical shape, with good effect. I did not however, feel it was necessary on this larger cell because

the cathode was quite low slung and I assumed the anodes would erode from the bottom up.

I plan to refurbish "Big Bertha", fit new gouging rods and get it up and running again. The only real modification to the design will be to cut some

slots in the SS cathode, so it can be bent closer to the bottom of the anodes, this should result in the anodes (gouging rods) corroding from the

bottom up, and thus lasting longer.

After pressure filtering to remove the black carbon detritus, about 3.2 Kg of moist NaClO3 crystals were obtained fairly easily, using a series of

concentration, precipitated NaCl removal, and crystallisation steps.

[Edited on 26-3-2008 by Xenoid]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Looking at the picture it would appear that the anodes have wore, and broke, at the top of the liquid as opposed to level with the top of the Cathode?

Dann2

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Hi Dann2

No, they wore through at the level of the top of the cathode. The remaining stubs which would have been about 7-8 cm long, continued to wear up to the

liquid level, leaving the 1-2 cm stubs visible in the image. The longest of the broken-off rods exactly match the height of the cathode. Bit of a

bugger, really, as the cell would have produced about 4 Kg of chlorate if it had run for, say, 28 days.

It was a real pleasure to run this cell, no trouble at all. I think I'll tweak the design and run it again, just for the hell of it. Not that I need

another 4 Kg of chlorate....

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Here's a bit more "guff" I put together a while back, on the running of the cell .....

One advantage of running a large chlorate cell, is the ease with which large amounts of NaClO3 can be obtained. This may seem obvious, but really, for

a little more work than is required for, say, a 1 litre cell, a 10 litre cell can be processed. With a 1litre cell only 1 or 2 crystallisation steps

are worth performing, since the "law of diminishing returns" comes into play, but with a larger cell several hundred grams are recovered with each

step. Three or four concentration, and crystallisation steps can be profitably carried out!

The 10 litre cell ran for a total of 12672 Amp hours, and the overall efficiency, based on say 3.2 Kg of NaClO3 produced, was 38.2%.

The consumable cost was about $4.50 for gouging rods, $1.80 for salt, about $7.50 for electricity and $3.50 for gas used during the "boiling down" and

concentration phases. So about $5.80 per Kg.

Oh! I forgot my labour, say 10 hours at $50 per hour, that's $500 so really more like $173 per Kg.

No, really it was a "labour of love" so I don't include that!

The attached image shows a pyrex bowl (30 cm diameter) containing 3.22 Kg of moist, crude NaClO3 from the 10 litre "Big Bertha" cell, the jar on the

left contains, precipitated salt, ready for recycling, and the jar on the right is the remaining "mother liquor" (about 1.2 litres) still saturated

with NaCl and NaClO3

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Is guff = waffle???

Here's some more Whoredom (as suggested in 'forum matters')

Graphite is inclined to get a bit of a bashing from the BYCM* (or indeed the FYCM) when it comes to making Chlorate. It is a good way to go. Perhaps a

lot of the bashing stems from using it in cells with far too low Chloride conc => lots of erosion.

The more I think about it, the more I think it would be worth the bother of pH controlling a (big, as you suggest) Graphite cell.

The amount of Graphite that gets worn in industry for a quantity of Chlorate is small.

8 to 30 grams per kg Chlorate made, I have read.

I wild-ass-guessed the Graphite in your cell is 255 cubic cm. Subtract 10% to allow for bits at top etc gives 230cm cubed. Thats approx. 230 x 2 =

460 grams Graphite. (assum G density 2g/cm cubed). That lot should make (or would make in industry) 460/30= 15 kg Chlorate in pH controlled cell. Less

mess per kg Chlorate to clean up too.

I am assuming pH control will give less erosion.

Froggots page goes into Graphite erosion.

http://www.frogfot.com/synthesis/chlorateel.html#anodes

quote;

Graphite anode corrosion rate also increases with decreased concentration of NaCl in the electrolyte. As example, at NaCl concentration of 200 g/l the

corrosion is 2 times lower than at 120 g/l. It is therefore advised to never run cell to completion, in the end of electrolysis the electrolyte should

contain at least 10 %-w/v NaCl.

end quote

If pH control is realizable with a bag/drip it would be worth the bother IMHO. Syringe pumps are great for experimenting with but probably too much

cash outlay for the average Chlorate maker, especially if a bag/drip yoke will do the job.

Dann2

*Back Yard Chlorate Maker

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Hi Dann2

Hmmm.. perhaps I shouldn't have used "guff", I just looked it up in the dictionary; "empty or foolish talk; humbug; nonsense"

Dann2, I don't think you can compare graphite and gouging rod erosion rates.

When I first started making chlorate cells, I used genuine graphite anodes "electrode quality". They were 12" x 1/2" rods. One of my first cells used

4 x 6" lengths of these. I ran the cell at about 8 amps for about 2 - 3 weeks, when the cell failed. When I dismantled it, I found it had been running

on only one of the four rods for virtually all the time, because a non-conducting layer had formed underneath the electrical "clamp" connections of

the other rods. So, really, the high quality graphite performed very well! These rods were only a few US$ each from the "graphite shop", I have never

ordered anymore because the freight charges quadrupled the cost. Tim's (12AX7) graphite chlorate cell seemed to run for a long time as well.

Gouging rods are just rubbish in comparison, they are coarse grained and mine even have longitudinal cracks in them!

If the 10 litre cell had used the "genuine" graphite rods, I think they would only have been about 25% eroded at the end of a month.

If the 12 gouging rods only cost about $5 and I can get them to last a month, I don't think it's even worth messing with pH control of any type. I

didn't even add any "additives" like dichromate etc.

|

|

|

chloric1

International Hazard

Posts: 1070

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

At $50 per hour you are expensive Xenoid  . Yeh not using dichromate does seem like a good idea. Not having to add barium chloride and worry about barium ions

in your final product. It did seem to remember that after filtering the chlorate liquor after adding BaCl2 the excess Ba++ deposited when boiling

down before the NaCl dropped. . Yeh not using dichromate does seem like a good idea. Not having to add barium chloride and worry about barium ions

in your final product. It did seem to remember that after filtering the chlorate liquor after adding BaCl2 the excess Ba++ deposited when boiling

down before the NaCl dropped.

Fellow molecular manipulator

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

@Markgollom: I just wanted to ask what type of MMO/DSA anodes have you got. What was there original application etc.

About high temperatures in Chlorate cells, it is my opinion that there is no advantage in having warm/hot cells (75C say) in the non pH controlled

cell as there is not going to be any reactions going on in the bulk of the solution. This is were Chlorate is made in Industrial set up's. In our non

pH controlled cells it all happens at the anode surface.

If you cells go to that temperature on their own I suppose it is not going to do any actual harm, with DSA anyways.

It is a challange to seals etc though, as you stated.

DSA may get damaged in hot cells when the pH is allowed to go up to 9 or 10 (wild assed guess/speculation BTW)

Perhaps you plan to pH controll, in that case it is a big advantage to run hot. Lots (most) of Chlorate formed in the bulk of the cell.

Dann2

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Hello Xenoid, nice pics and results!

My small cell (~1,9 L) was running a very long time (~ 605 h... ~ 1938,4 Ah ) , with dichromate added and large excess of chloride (I started with

590g NaCl and then added during the whole procedure more 130g) and even so the gouging rods not survived! .. The rods are very similair to your ones,

but still more physically damaged! Most of it breaked during the electrolyses. I recognized damage to rods due to the almost abrupt decreasing current

measured by multimeter..

I'm thinking that this result was because my anodes were not surrounded by any cathode.. Just the opposite , nickel cathodes on centre and anodes

sorrounding it (I did this since at the construction the only thing I have at hand to cathodes were some Ni rods).

A lesson was learned , in the worst way

If my math in running formula is correct I'm inclined to think that the most affecting parameters in amateur cell (using gouging rods anodes and non

controled pH setup) are not only (most) chloride ions and temperature, but also cell geometry(anodes positions and spacing,etc) and another details in

cell construction..

It was a pain in the butt to filtrate the cell liquor, since was full of very small graphite particles.. But I've done it and have a yellow/orange

liquor..

The next step will be add KCl and try to see how much was converted..

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

Sciocrat

Harmless

Posts: 36

Registered: 30-3-2007

Member Is Offline

Mood: Scientifically curious

|

|

I'm having a problem with my cells. I made two chlorate cells, almost exactly as described here. I am running them on 9 volts and 3 amperes, the cells are connected in series as this picture shows. The problem is that the reaction occurs only in one of my cells (intensive gas formation), while there is no noticeable

reaction in the second cell. I would appreciate any advice or ideas you have regarding this problem.

ps. I noticed later, that the electrolyte in the cell where there was no gas formation, turned dark green, and there are dark particles floating in

the liquid.

Here is a pic of my cells

[Edited on 11-4-2008 by Sciocrat]

|

|

|

Sciocrat

Harmless

Posts: 36

Registered: 30-3-2007

Member Is Offline

Mood: Scientifically curious

|

|

This is the result after a few minutes...

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Nice work Sciocrat ...

I would say the problem is due to slight differences in the electrode geometry of the two cells. The one on the left (greenish, no bubbles) may have

short circuited or be of such low resistance that it requires less than about 2.5 - 3 volts for the 3 amps to flow.

What is the voltage across each cell, if they are being supplied from a 9 volt source, you should have 4.5 across each cell.

Can you check each cell separately, with say, a 3.5 volt source and see what happens!

|

|

|

markgollum

Hazard to Self

Posts: 53

Registered: 21-2-2004

Member Is Offline

Mood: No Mood

|

|

@ dann2

In reply to your question, I don't know for certain what the MMO anode I have is specifically designed for,

I strongly suspect that it was purpose-made for chlorate production. I bought it from the fellow that runs the online store at the top of the page

(Jumping Jack).

As for temperature, it seems to me that the rate of chlorine loss drops off at the higher temperatures.

But the main reason that the temp gets hot is that I am running 14-18 A at 3.8-3.9 volts through a 4.3L cell.

I don't think that the erosion rates of MMO anodes will increase much at very high pH since some of the literature I have read mentions MMO anodes

used in the chlor-alkali industry. (They use a divided cell but I am under the impression that, in practice, the anolyte gets quite basic)

On that note I am thinking about making a chlorine cell, this could be a convenient way to generate a constant stream of cheap chlorine over a

prolonged period (for the slower photochemical chlorinations).

Edit:

To Sciocrat

I am certain that you have a short in the non-bubbling cell.

The voltage drop across a conducting electrochemical cell is irrelevant as far as weather or not there is an electrochemical reaction going on.

[Edited on by markgollum]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello Sciocrat,

As other have said, I would be inclined to blame a short circuit. What are the lids made from (metal)?. Have you used O rings to insulate the anodes

and cathodes from the lids. Short circuit may be there.

Dann2

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

@ Sciocrat ,

Very good job you did.. Next times which you make new cells you can follow Xenoid's advise (in this thread, IIRC) for keeping at least some of the

original copper layer on gouging rods to make the connections, this will reduce the electrical resistance across the connection points. I also agree

with the (per)chlorate guys ; short circuit is what you have in your cell.. This ocurred with my cell some time ago, while I tried to put a aluminium

foil around the exposed parts of the graphite anodes ; some of the foil touched the cathode and the cell did not worked.. This is easily perceptible

since in the short circuit area a good amount of heat will be generated by joule effect.

This is why I would prefer clean and transparent cell bodies than PVC pipes or such, since you can look instantaneously if some problem is ocurring,

like the eletrodes not generating gases.

@ Dann2,

I did what you've said.. I extracted the KClO3 from the liquor using KCl solution rather than solid KCl in boiling liquor.

I'm now recrystallising the KClO3.. A very nice and pleasant thing.. Nice snow like crystals being obtained

My yield based on crude KClO3 from the liquor was more than 56%.. More since I didnt boiled the residual liquor and cooled to get more chlorate. I was

using Na2Cr2O7 additive..

Also, honestly , besides agreeing which pH control really appear to help greatly retarding the corrosion of the graphite anodes, I dont think pH

control really worth.. Gouging rods are cheap and one will loose quickly the patience bothering with pH control all day .. Well, maybe may worth, if

you have time and patience to experiment.. At least 2-3 times adding HCl to the liquor and computing Cl- , H+ ions...

It would be great if this could be automatized in amateur setup.. Lots of time and patience saved..

[Edited on 12-4-2008 by Aqua_Fortis_100%]

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

| Pages:

1

..

7

8

9

10

11 |