Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Preparation of n-Caproic Acid

In this preparation I used the 32.9g of diethyl n-butylmalonate (DNBM) recently prepared. The procedure found in Brewster (ref 1) was followed except

for the reflux times where the longer times of Vogel’s procedure (ref 2) were used.

The scale of the Brewster procedure was 0.15X that of the one in Vogel for this acid, and the one in OrgSyn for preparing an analog, 3-methylpentanoic

acid (ref 3). Brewster’s procedure specified 30g of DNBM so I scaled up all reagent quantities by the factor 32.9/30 = 1.097.

A. Saponification

32.9g KOH mixed with 32.9 ml H2O

DNBM 32.9g

The DNBM ester is first saponified with KOH. This was done by heating the reactants at reflux for 3 hours. A ml was withdrawn and mixed with a ml of

water. It completely dissolved. Therefore, per Vogel, I assumed the saponification was complete. The products are the potassium salt of the diacid,

n-butyl malonic acid, and ethanol.

saponification

B. Ethanol Removal by Distillation

add H2O 87.7 ml

distil off 71.3 ml H2O/EtOH

Ethanol/water was removed by simple distillation. This is necessary to prevent esterification of the n-caproic following the decarboxylation.

C. Decarboxylation

Add 36.2 ml con H2SO4 mixed with 71.3 ml H2O

The resulting diacid malonic acid is then converted to the monoacid n-caproic acid by heating at reflux for 4 hours. The reactants were clear for

about 2.25 hours. After this the mix was turbid indicating to me that a second phase now existed, ie, the water insoluble n-caproic acid. Following

this about a 3-4 mm layer of organic material could be seen floating on top of the aqueous phase.

decarboxylation

D. Workup

The product mix was poured into a 250 ml separatory funnel. The aqueous phase was drained off leaving 37.6g of very crude n-caproic acid, smelling

distinctly of rancid butter.

crude n-caproic acid separation

Brewster said to extract the aqueous phase with 3X100 ml of benzene. I substituted 3X50 ml of lab grade toluene. A literature source indicated that

the association constant for benzene is 96 and that for toluene is 94 (ref 4).

The combined crude n-caproic acid and the toluene extracts were then washed with 10 ml of water. Brewster specified 20 ml H2O. This where I ran into

problems. I expected the water to separate out as the heavier phase in a 2 phase system. What I got instead was two phases with the toluene on top

and a large phase on the bottom, apparently n-caproic acid and water.

I added 3g of NaCl to try and salt out the water. It didn’t work. Then I added several grams of anhydrous MgSO4 in a further attempt to salt out

or absorb the water. This also did not work.

F. Discussion

At this point I don’t know what else to do but distill off the toluene then isolate the n-caproic acid by further distillation. Brewster says to

take the fraction boiling in the range 196-206°C, with the bp = 202°C. I may use vacuum distillation to keep the temperature down.

If any of you have any suggestions as to what else I could do to isolate the n-caproic acid they would be much appreciated.

This is a reminder of just how easily things can go wrong in organic chemistry. Chemistry is indeed a subtle science.

G. References

1. Unitized Experiments in Organic Chemistry, 1960, Brewster et al.

2. A Textbook of Practical Organic Chemistry, 3rd ed, Vogel, p. 486 (1956).

3. 3-methylpentanoic acid, OrgSyn, Coll. Vol II, p. 76(1931)

4., “Partition Coefficients and Their Uses,” Leo et al, Chemical Reviews, Vol 71, No. 6, Dec 1971.

[Edited on 9-7-2014 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Dr.Bob

International Hazard

Posts: 2659

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

I would add a small amount of acid to the water/toluene mix, this will help to keep the organic acid protonated, thus help to keep it in the organic

layer.

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@ Magpie

Nice write up, I'm glad to see someone keeping the practical site of chemistry alive. I wondered why you were trying to make Diethyl butylmalonate in

your earlier post, now I see. Is this method of accessing hexanoic acid preferable to say oxidation of n-hexanol or where you more interesting in

experimenting with this particular technique?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by Dr.Bob  | | I would add a small amount of acid to the water/toluene mix, this will help to keep the organic acid protonated, thus help to keep it in the organic

layer. |

Thanks, Dr.Bob, I was thinking of that myself. I'll try it tomorrow. Please excuse my late reply. I just returned from a 4-day vacation, during

which time I purposely did not touch a computer, watch TV, or read a newspaper.

@Boffis: Thanks. Yes, I'm just seeing if I can get this technology to work. The best way to get hexanoic acid would likely be to buy it.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Nice Work Magpie.

For extracting the caproic acid from water, I recommend that you try diethyl ether as a solvent instead of benzene or toluene.

The choice of benzene as an extractant strikes me as odd, since a medium-chain carboxylic acid like this one is quite polar.

Et2O would be my first choice of solvent for this extraction.

I once had a similar problem involving the preparation of 4-chloroaniline. After steam distillation, I had the crude product as a mixture of

solidified droplets with water. I added some low-boiling naphtha in order to extract the product, but the naphtha only dissolved a small part of the

product upon shaking, leaving most of the product still floating around as solid beads. I separated the organic phase and added some Et2O, which

worked a treat and immediately dissolved all of the solids.

The polar properties of Et2O sometimes make it impossible to replace by cheaper nonpolar solvents.

|

|

|

mr.crow

National Hazard

Posts: 884

Registered: 9-9-2009

Location: Canada

Member Is Offline

Mood: 0xFF

|

|

Its nice to see a malonic ester synthesis! I remember reading about it in my textbook.

Can also use ethyl acetoacetate (easy to make in a home lab) to create ketones.

Double, double toil and trouble; Fire burn, and caldron bubble

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks garage chemist for your input. Vogel also specifies using benzene for the extraction but says that ether may be used instead. OrgSyn uses a

special separator to remove the bulk of the caproic acid from the water, then extracts the water with ether. It then says to add benzene to the crude

product where it serves to remove water azeotropicaly during a final distillation.

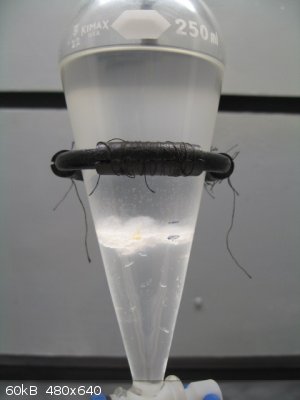

This morning I added 1 ml of con sulfuric acid and shook well. The picture below shows what I now have. The upper layer is toluene, the middle layer

is likely n-caproic acid, and the lower layer is the aqueous inorganic salt solution.

edit:

My revised plan is to drain off the lower aqueous layer and save it for possible extraction with ether. The combined upper layers will be distilled

for recovery of the n-caproic acid.

edit 2:

The cloudy white layer in the middle is an insoluble (in toluene) crystalline solid, likely formed from the NaCl and/or MgSO4 that I added. I removed

it by filtration.

[Edited on 14-7-2014 by Magpie]

[Edited on 14-7-2014 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

This n-caproic acid (n-CA) synthesis was completed this morning. After draining off the water the upper layer (toluene/n-CA) was filtered to remove

crystalline solids, likely MgSO4 hydrate.

The toluene was then removed by simple distillation. This came over at 88-118°C, the first portion being an azeotrope with water (bp 84°C) most

likely. At 118°C there was very little condensate coming over. There was a fair amount of foam but it was not a problem, as shown below.

foam during toluene removal

The residue was then subjected to vacuum distillation at 2 mmHg. The first distillate came over at 75°C as expected and held there for a few mls.

n-CA bp at P=2 mmHg

I stopped the distillation at 81°C. There was a few mls left in the pot as can be seen in the picture below.

recovery of n-CA by vacuum distillation

The final yield was 8.3g of n-CA. This is a 47.0% yield. It likely would have been better if the water wash/separation had gone well. Comments,

questions, and recommendations are welcomed.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Dr.Bob

International Hazard

Posts: 2659

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

On a small scale, anything near 50% is generally good, as lots of material is lost in distillation and extractions on small scale. There are ways

around that, but not trivial. Sometimes adding a much higher boiling material to the pot will help to allow you to drive off more of the product, or

using a short path condenser for higher boiling materials. That distillation apparatus likely has a ~1-2 ml holdup of material in the glassware.

But for sciences sake, it works fine. In larger scale, you often do a quick distillation in a short path to get the crude product in high yield, then

redistill in a better apparatus, but you can nearly fill it to capacity or reuse the pot with a second batch to avoid losing much material. Or

sometimes even wash the condenser out back into the next batch with a little solvent. Just depends how valuable the material is.

|

|

|

Ascaridole

Hazard to Self

Posts: 67

Registered: 11-9-2013

Location: Hawaii, USA

Member Is Offline

Mood: Searching for glass....

|

|

Rather than work up perhaps distillation from the reaction flask is more practical as the Org Syn article points out that other extraction methods

proved unsatisfactory.

Sounds like they used a fancy distillation head that allows them to steam distill the acid over with a return path for the aqueous phase. Also they

did use ether for extraction of the final aqueous fraction.

Distillation from the reaction flask sounds advantageous for yield considering you may have lost almost a gram of product in the aqueous phase

discarded from the reaction mix.

Ascaridole, the masked bandit of chemistry!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

The distillation system that OrgSyn recommended looked like too much trouble for my small scale experiment.

Yes, I probably lost 1-2g of product due to solubility in the aqueous phases.

Something very curious happened during the workup: I separated the original aqueous phase from the toluene extract. Then washed the extract with 10

ml of water. But the resulting aqueous phase that then separated from the toluene was ~ 40 ml. Now, how could that have happened?

I tried to minimize any transfers to fresh containers. But I did mess up one time by catching the final distillate in an unweighed rbf.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Ascaridole

Hazard to Self

Posts: 67

Registered: 11-9-2013

Location: Hawaii, USA

Member Is Offline

Mood: Searching for glass....

|

|

The larger phase is not a sign of a bad extraction, weird crap happens when you are working with medium/long chain molecules in water. Simple repeated

extractions more than likely would fix the problem, maybe....

If the purpose of the wash was to remove salts / lingering sulfuric acid use of a saturated sodium sulfate solution rather than d. Water. The theory

behind that is sulfuric acid will preferentially form the bisulfate from the sodium sulfate and the high ionic strength will hopefully keep most of

your product in the organic phase and prevent any funky emulsions.

Personally I see no real need for the wash. I would have rather extracted the aqueous phase from the reaction mix and left it at that. Or better yet

steam distill as I pointed out above.

Initially I thought Dr. Bob's suggestion of acidification of the aqueous phase would work as it made perfect sense however considering the solubility

of the acid in water and it's average carboxylic acid pKa I doubt enough of the acid is soluble in water to make disassociation a significant concern.

Even if it is of concern presence of the bisulfate with its pKa 1.9 should be strong enough to push the equilibrium to favor the originated acid.

Overall I agree that purchasing hexanoic acid is more practical however you have outlined a beautiful procedure for synthesis of other carboxylic acid

derivatives starting with 1,3-propan diol as the substrate. Also your synthesis is a clean one, not many byproducts to worry about.

Ascaridole, the masked bandit of chemistry!

|

|

|