| Pages:

1

2

3

4

5

6

..

14 |

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

thefips,

Ive found this myself but I dont know if its just something that apears in books as a pinch of this, pinch of that reaction to demonstrate the

relationship between phenol and benzene, or if its a process that can be done in decent yeild large scale.

Phenol can be made from oil of wintergreen, but its a lot of steps from that to benzene even if this works.

John,

Quoteing entire posts and adding one line is not nice to read and one post per person replied to isnt good netequette either. Please quote as little

as required for your answer to make sense and put all replies in the same post.

2 C6H5COONa + 2H2O -> C6H5-CO-CHOH-C6H5 + 2NaOH

Left hand side, 6 oxygens, right hand side, 4.

More electropositive metals than zinc may also be thermodyanically favoured for the reduction of phenol, but you also favour other reactions like

liberation of hydrogen and formation of a salt. In organic chemistry if the references say one specific metal every time, there is usually a reason.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

IPN, what temperature do you recommend as being not to cold (no benzene) and not to hot (oil)?

I am right if I assume that you want to say the mixture shall be heated slowly just to point decomposition starts? How hot is this?

More NaOH might help, I heard an excess of base is favorable, adding CuSO4 might be worth a try too.

If this works out fine, say clean benzene after two redistillations over a Vigreux in or near to the claimed yields, I admit this being the best

method for benzene up to now, beating my toluene disproportionation by far.

It would be a real charm.

ORG

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Re my post of 16th August: I have had another look at the possibility of hydrolysis of sodium benzoate and subsequent coupling of radicals by way of

boiling in aqueous solution, to produce benzoin:

2 C6H5COONa + 2H2O -> C6H5-CO-CHOH-C6H5 + 2NaOH + O2

However, because it involves partial reduction of two carboxyl groups to a C-C bond (via a free-radical mechanism) and a C-H bond. while leaving one

C=O and one C-O bond unchanged, with removal of oxygen, such a reaction would be thermodynamically possible only in the presence of a strong reducing

agent which takes up the O2 removed. At the same time, this reducing agent would have to be one that is not dissolved by NaOH, which rules out Zn or

Al and all other amphoteric metals, and dies not react too rapidly with water, which rules out nearly all more electropositive metals. The only common

metal that therefore just might be usable as a reductant is Mg, as a powder:

2 C6H5COONa + 2H2O + 2Mg -> C6H5-CO-CHOH-C6H5 + 2NaOH + 2MgO

Other possibilities are use of some non-metallic reductant which is not affected by H2O or NaOH, and is stable in boiling aqeous solutions, although I

cannot think of any offhand.

Even then, competing reactions may result in formation of other compounds like benzaldehyde, benzyl alcohol, toluene, benzodiketone, 1,2-

diphenylethane, and, in the presence of gaseous oxygen, benzoyl peroxide.

Of course, the usual method of synthesizing benzoin is by the self-condensation of benzaldehyde, involving an oxidation rather than a reduction, in

the presence of KCN - but the use of KCN is very hazardous, so alternatives would be desirable if they culd be found.

John W.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

JohnWW: After my experience the theoretical approach to determine reactions is mostly futile - these stupid molecules just dont behave as they are

thought to

Therefor in Chemistry - in organic chemistry at least - reactions are first done and afterwards a nice explanaition WHY it did yield certain products

in certain amounts is produced. In the article written afterwards this order is changed of course - looks much better.

This limits the scope of your theoretical considerations as you will agree - not that I dont see them as interesting.

regards

ORG

|

|

|

IPN

Hazard to Others

Posts: 156

Registered: 31-5-2003

Location: Finland

Member Is Offline

Mood: oxidized

|

|

| Quote: |

I am right if I assume that you want to say the mixture shall be heated slowly just to point decomposition starts?

|

You assume correctly. I didn't have the possibility to monitor the temperature of the decomposing mixture, but it can be easily seen that too

strong heating will start to produce some sort of thick orange vapour which will condense in to that oil. Then again when you heat it slowly, it will

first melt nicely and then start to decompose, this will take time but the benzene will be purer. One thing to keep in mind is the intimacy of the

mixture. The reagents should be ground to a very fine powder (preferably in a ball mill for few hours). This will reduce the erosion of the flask and

speed up the reaction.

Basically just heat slowly with a small flame and you'll be fine.

|

|

|

ordenblitz

Hazard to Others

Posts: 259

Registered: 18-7-2004

Location: Northwest

Member Is Offline

Mood: Bohr'd

|

|

Second attempt using 7 gm sodium hydroxide and 25 gm Sodium Benzoate roughly crushed together in a mortar and pestle.

The mix placed in a 500 ml rb flask, in mantle equipped with a condenser. Heat was applied in a slow manner for 30 minutes before a slightly

orange/yellow low viscosity condensate began to collect. The process continued for 35 more minutes until no more was collected.

The product was then redistilled rather quickly, easilly separating the orange solid from the desired material.

The final result was roughly 8 ml of, by all apperances, is a fairly pure product.

No visable damage to the flask was noted even though the reactants were not milled to a fine state as was suggested.

|

|

|

FrankRizzo

Hazard to Others

Posts: 202

Registered: 9-2-2004

Member Is Offline

Mood: No Mood

|

|

Would heating a mixture of NaC6H5COO and H2SO4 produce a yield?

2NaC6H5COO + H2SO4 -->Na2SO4 + 2C6H6 + CO2 ??

I'm worried about damaging expensive glassware with NaOH..

[Edited on 23-8-2004 by FrankRizzo]

[Edited on 23-8-2004 by FrankRizzo]

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

I have done some more digging n textbooks as regards possible ways to decarboxylate carboxylic acids including benzoic acid and benzoates. Carboxylic

anions do not decarboxylate readily; but carboxyl radicals, RCOO•, do, by losing CO2 and leaving an organic radical:

RCOO• -> R• + CO2

Such carboxyl radicals can be generated by:

(1) the Kolbe electrolysis, in which an alkali metal carboxylate is electrolysed. The anion loses an electron at the anode to produce the carboxyl

radical, which loses CO2 to produce an organic radical as above, and two organic radicals then usually combine to produce a dimer:

R• + R• -> R-R

In the case of benzoates, this would result in biphenyl, (C6H5)2. Catalytic hydrogenation of the C-C single bond between the rings (which is longer

and weaker than normal C-C bonds) under mild conditions (insufficient to hydrogenate the C6 rings) would probably result in benzene, although I cannot

find a reference to the hydrogenation of biphenyl.

(2) In the Hunsdiecker reaction, an Ag (not sodium) carboxylate is heated with Br2 in CC4, resulting in the first instance AgBr and Br• and

RCOO• free radicals, and then the carboxylate radical decarboxylates to R•, after which the R• and Br• combine to form an

organic bromide. The net reaction is:

RCOOAg + Br2 -> RBr + CO2 + AgBr

An attempt to remove the Br from the bromobenzene produced, using an electropositive metal to reduce it, would probably result in biphenyl again; or,

in the case of Mg in ether or THF being used, a Grignard reagent, C6H5MgBr. This Grignard reagent would react, when added to water, to produce

benzene:

C6H5MgBr + H2O -> C6H6 + MgBrOH

John W.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

Ok. Now we will see.....

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

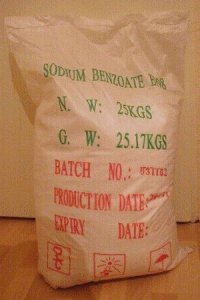

Large quantities of sodium benzoate are produced as a food preservative, and to some extent as an antiseptic. How much did that 25 kg bag cost?

John W.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

It is an universal antioxidant and used in large quantities for passivation of metals.

About 30 Euro. incl. VAT and delivery. EU/Jap food grade.

|

|

|

ordenblitz

Hazard to Others

Posts: 259

Registered: 18-7-2004

Location: Northwest

Member Is Offline

Mood: Bohr'd

|

|

I did some experimenting today with different hydroxides in combination with sodium benzoate for the production of benzene. Sodium, potassium and

calcium were tested the results as follows.

7 gm. CaOH + 25 gm. C7H5NaO2 = 6ml C6H6

7 gm. KOH + 25 gm. C7H5NaO2 = 6.8ml C6H6

7 gm. NaOH + 25 gm. C7H5NaO2 = 7ml C6H6

Working with small amounts and the typical losses in the distillation these numbers are so close I call it pretty much a tie. The CaOH was the easiest

to prepare since it is already a fine powder. However it has a higher melting temperature and did take a bit longer to go to completion.

I have included pics of the residue from re-distillation. It is rather pleasant smelling somewhat reminiscent of naphthalene and soap perfume.

|

|

|

Esplosivo

Hazard to Others

Posts: 491

Registered: 7-2-2004

Location: Mediterranean

Member Is Offline

Mood: Quantized

|

|

| Quote: |

7 gm. CaOH + 25 gm. C7H5NaO2 = 6ml C6H6

7 gm. KOH + 25 gm. C7H5NaO2 = 6.8ml C6H6

7 gm. NaOH + 25 gm. C7H5NaO2 = 7ml C6H6

|

Quite good yields I see. Working out on these yields organikum could be swimming in benzene soon  Kidding apart, could you try a mixture of bases instead? I mean in literature a mixture of CaOH/NaOH is commonly used

for decarboxylation, this being known as sodalime. The fact is that most propably it sort of lowers the melting point of the CaOH which is difficult

to melt. Maybe a better yield could be obtained. Kidding apart, could you try a mixture of bases instead? I mean in literature a mixture of CaOH/NaOH is commonly used

for decarboxylation, this being known as sodalime. The fact is that most propably it sort of lowers the melting point of the CaOH which is difficult

to melt. Maybe a better yield could be obtained.

Theory guides, experiment decides.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

If I did the calculations right, this says about molar 40-50% yields.

25g benzoate being about 0,17 mol

7ml benzene being about 0,08 mol

(correct me please if I got it wrong - it was a quicky... ) )

Wasnt the classical method starting from calcium-benzoate and CaO ?

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Yes, 3 or 4 gallica refs say 3 parts(wt) CaO to 1 of benzoic acid. Yet all the later textbooks and practical lab books that I've seen (5 or 6)

say NaOH.

Nice purchase.

Might as well paste these though they don't say much. From Noyes' Organic Chemistry for the Laboratory:

82. Preparation of a Hydrocarbon by Distillation of

a Salt of an Acid with Soda-Lime.-Benzene, C6H6.

(Phen.)

Literature.--Mitscherlich : Ann. Chem. (Liebig), 9, 39 : Mar-

ignac: Ibid, 42, 217; Wohler: Ibid, 51, 146; Berthelot: Ann.

Chim. Phys. [4], 9, 469; Hofmann ; Ber. d. chem. Ges., 4, 163;

Baeyer : Ibid, 12, 1311 ; V. Meyer : Ibid, 16, 1465.

20 grams benzoic acid.

40 grams soda-lime.

Mix 20 grams of benzoic acid with 40 grams of soda

lime by grinding together in a mortar. Put the mixture

in a small flask, connect with a condenser, and distil

over the free flame. Separate the benzene from the

water, dry it with calcium chloride, and distil. If per-

fectly dry benzene is desired, distil it a second time over

metallic sodium. Yield 8 to 9 grams.

Benzene solidifies at a low temperature, and melts at

5.42°: It boils at 80.36 ° .

This method of preparation is no longer practically

used, but it was of very great importance in the early

study of the aromatic hydrocarbons, and illutstrates a

method very general in its application.

From Norris' Experimental Organic Chemistry:

169. Preparation of Benzene from Benzoic Acid (Section 440).

--In a 6-inch evaporating dish place 10 grams of sodium

hydroxide and 25 cc. of water. Heat over a free flame and stir

until the sodium hydroxide dissolves; then stir in gradually

12 grams of benzoic acid. Evaporate to dryness over a free flame,

which is kept constantly in motion; this will take about 10

minutes. Grind the mixture of sodium benzoate and sodium

hydroxide in a mortar, and transfer it to an 8-inch test-tube.

Clamp the test-tube in an inclined position so that the mouth

of the tube is slightly lower than the other end; this will prevent

any water given off during the heating from running back into

the tube and cracking it. Connect the tube with a condenser

and receiver, and heat with a free flame kept constantly moving,

until no more liquid distils over. Measure the volume of the

benzene and calculate the number of grams and the percentage

yield obtained. Separate the benzene from the water, dry it

with calcium chloride, and distil, noting the temperature.

Benzene melts at. 5.5 °, boils at 79.6 °, and has the density

0.878 20C/4C. The yield should be about 6 grams.

NOTE.--By converting the benzoic acid into sodium benzoate in the pres-

ence of an excess of sodium hydroxide, an intimate mixture of the two sub-

stances is obtained. In this condition the compounds enter into reaction

more readily and at a lower temperature than does a mixture of the acid

and soda-lime; such mixtures are commonly used in the preparation of

hydrocarbons from acids.

The benzene prepared in this way contains a small amount of biphenyl,

which may be isolated from the residue left after the distillation of the hydro-

carbon. The residue on crystallization from alcohol yields crystals

of biphenyl, which after two sublimations melt at 71C.

[Edited on 4-9-2004 by S.C. Wack]

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

Thanks, S.C.Wack!

Very helpful!

I did some quick calculations again and something up.

-Sodalime is a mixture of CaO and 5-20% NaOH. It contains usually 6-18% water.

This speaks the Merck. The Merck doesnt tell why the CaO doesnt react with the water present, is it bound by the NaOH so strongly that thus is

prevented?

- The calculations with the second procedure posted by S.C.Wack showed that there a far bigger amount of NaOH was used than ordenblitz had in his

experiments.

It might be favorable to double numbers on the NaOH to use.

Say 14g NaOH to 25g sodium benzoate.

He talks of about whopping 75% molar yields, this Norris guy, wow, promising, very promising......

Intimate mixing will help. I will yank the benzoate together with the hydroxide through my trusty secondhand coffeegrinder model "socialistic

realism" and will hope this suffices.

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

S.C. Wack,

Where did you get those two textbooks you gave as references? Can they be downloaded anywhere?

John W.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

The Merck is being cryptic.

Sodalime is made slaking quicklime with a concentrated solution of sodium hydroxide, so most of the water does hydrolyse the quicklime.

I understand its particually good for gas phase reactions because sodium hydroxide itself would melt at a (fairly) low temperature presenting a low

surface area. Sodalime keeps a high surface area even at high temperatures but otherwise behaves much like sodium hydroxide.

I look forward to hearing about this decarboxylation being done large scale.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

Some observations whilst trying a 100g benzoate batch:

Tried 100g benzoate intimately mixed with 60g sodium hydroxide in a 500ml flat bottom flask placed in a sandbath. (actually a saltbath, NaCl, but

makes no difference)

Upon slow heating benzene started to come over, perfectly as it seemed at 80°C.

But not very much.

Then temperature rised and yellow stuff came over at about 90°C.

Huh?

The content of the flask seemed to be not molten at all?

It was found that the lower part of the mixture has molten but the upper part formed a kind of cover not falling down to the bottom. Some agitation

with a strong wire brought this down, some more benzene came over, but the amount is to small to be called a satisfying result.

The first fluffy then sticky consistence of the benzoate/hydroxide mixture seems to cause problems.

I will try again using an Erlenmeyer which seems to have a better suited shape for this kind of reaction.

If this doesnt help much I will mix some NaCl in or on top, maybe this provides enough weight to get the mixture down.

Other ideas are welcome.

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

New run:

- 1000ml Erlenmeyer, 100g benzoate, 60g sodium hydroxide, about 50g tablesalt.

Hydroxide and some salt where grinded together in the coffee mill and admixed with the benzoate by the ol´ "inflated plasticbag" (tm)

method, whereby some ungrinded salt was added.

Into the Erlenmeyer, put in a sandbath isolated with glasswool and heated up.

Clear distillate comes over at about 85°C - regarding the known misreading in this constellation I can say thats pretty ok.

Tomorrow I post quantitative results on this, after washes and redistillation, but I am optimistic on this.

Also tomorrow I will try something else which is thought to solve the problem of clogging and heatdistribution. No, not sand mixed by, as I am not

sure if thats a good idea with molten NaOH.

What? Surprise, surprise.

And pictures so it works

|

|

|

Organikum

resurrected

Posts: 2329

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: busy and in love

|

|

Glasswarekiller

This is a real killer of glassware.

Dont try this with expensive labglass! I did and every try cost me one flask up to now.

Not during the reaction but afterwards whilst cooling down/cleansing.

The fused mass clings so badly to the glass that the different thermal expansion breaks it whilst cooling down. A thickwallet roundbottom might

survive it, but its not me to try it.

I will have to do an expedition to the used-glass container tomorrow to get me suited disposable glassware.

This for sure can be done in a beerbottle, but I will get me some more longnecked bottles.

Damn.

I running short on grounded glassware now.

Damn, damn, damn.

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

Sounds like you could use a guy that's handy with a glasstorch.

Cuz ground joints are only about 7 bucks apeice and/or sticking new bottom blanks

on old joints isn't exactly rocket science if you have a pair of crossfire burners (or so I have been reading) Cuz ground joints are only about 7 bucks apeice and/or sticking new bottom blanks

on old joints isn't exactly rocket science if you have a pair of crossfire burners (or so I have been reading)

Someone had suggested a method for plating borosilicate with nickel in a thread long ago in a faraway land. Would that help protect your glassware?

What about manipulating a few peices of gold foil into position, covering the bottom and sides of your flask with a stirring rod and rubber policeman?

Would that help your flasks survive? Would the gold foil be inert to the reagents at elevated temperatures?

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

ordenblitz

Hazard to Others

Posts: 259

Registered: 18-7-2004

Location: Northwest

Member Is Offline

Mood: Bohr'd

|

|

Interesting...

I've done all my testing in a 500ml pyrex single neck rb flask in a heating mantle. It seems that I have been using far higher temperatures as

well.

I don't see anything happening usually until 150c + especially when using CaOH. Cleaning really isn't a problem either, a little

carbonaceous material that comes right out with a hot water/micron soap- slosh.

I wonder what is going on.

|

|

|

BromicAcid

International Hazard

Posts: 3227

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Reminds me of decomposing lead nitrate to form nitrogen dioxide. The lead monoxide forms readily attacks the glass so you take aluminum foil and cram

it into the bottom of the flask, spreading it out with a stirring rod and then you add your nitrate, the lead monoxide thus formed does not get to the

glass to attack it.

Although aluminum is not going to cut working with hydroxide, maybe go to an arts and crafts store and pick up some gold leaf or silver leaf, might be

a little thin but then again it might work. Of course my vote goes to nickel foil

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Would slowly reducing the heat help? I am mostly through distilling now, following Norris, except using 24/40 glassware and a 50 ml RBF. So I'll

find out.

I'm using a blowtorch. Quite a bit of heat and time seems necessary, no surprise. The smell is aromatic and there is no color. So far.

The yield looks to be as advertised. My benzoic acid was sold as "lab grade" with no other comments.

(EDIT: Turning up the heat slightly only gave dark vapor that colored the distillate dark yellow as I was typing the rest of this post, with no extra

benzene yield.)

A metal bath or tube furnace would probably be best for this. Lots of room for experimentation to get this to work on a large scale.

The rest of this post is off-topic, in reply to JohnWW's post above.

JohnWW, the scans were done myself, and I would upload them if I had scanned the whole books. But I only scanned perhaps 50 pages of each. They were

from the library. The William A Noyes (1897) book was literally falling apart due to the horrible original binding. It could not have been scanned any

more than it was without having to pay for it.

The James F Norris book (1933 ed.) has been checked out since I posted, and isn't due back for 3 months. Interesting since I was the only one to

check it out in the past several years. Perhaps it will soon be seen on the FTP?

I didn't want to scan the whole books because they are so similar in syntheses to the ones already on the FTP - and to many others that also are

not - and I will be scanning a similar 550 page organic book soon. I've done enough scanning lately (other partial scans, Inorganic Syntheses,

Inorganic Preparations, Inorganic Laboratory Preparations, Glassblowing for Laboratory Technicians, Techniques of Glass Manipulation) so I am going to

be very picky about what I scan. I was going to scan a classic, but then someone said that he was going to soon. I hope he rescans the first attempt,

too. By odd coincidence, those 2 books are also not due back for 3 months.

Everyone else, there are (the computer says, this seems low) 4546 chemistry books and journals in the main local university library, one of thousands

of such libraries across the world. And there is always abebooks.com. So many books, so few scanners. There are enough theoretical books uploaded -

practical books are so much more useful. Perhaps you could be doing more for your online community?

[Edited on 6-9-2004 by S.C. Wack]

|

|

|

| Pages:

1

2

3

4

5

6

..

14 |