| Pages:

1

..

4

5

6

7

8 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

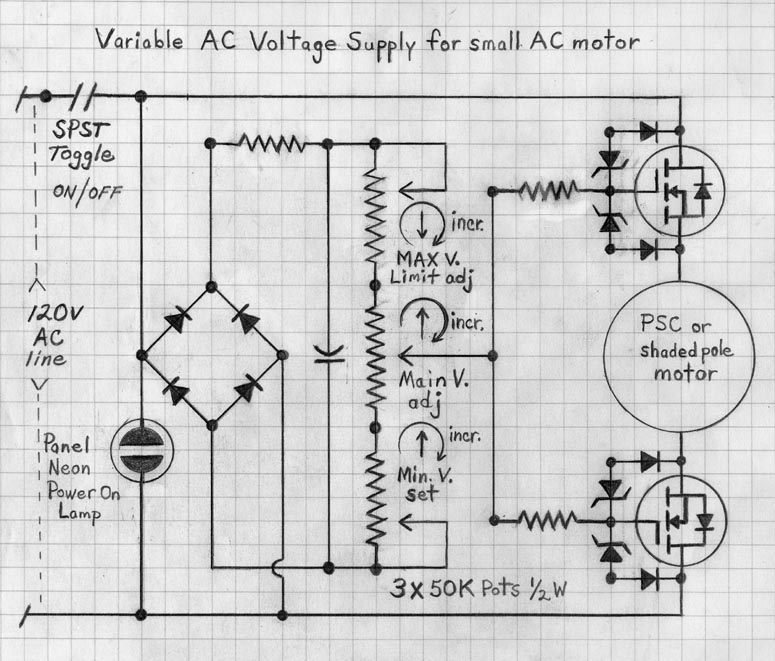

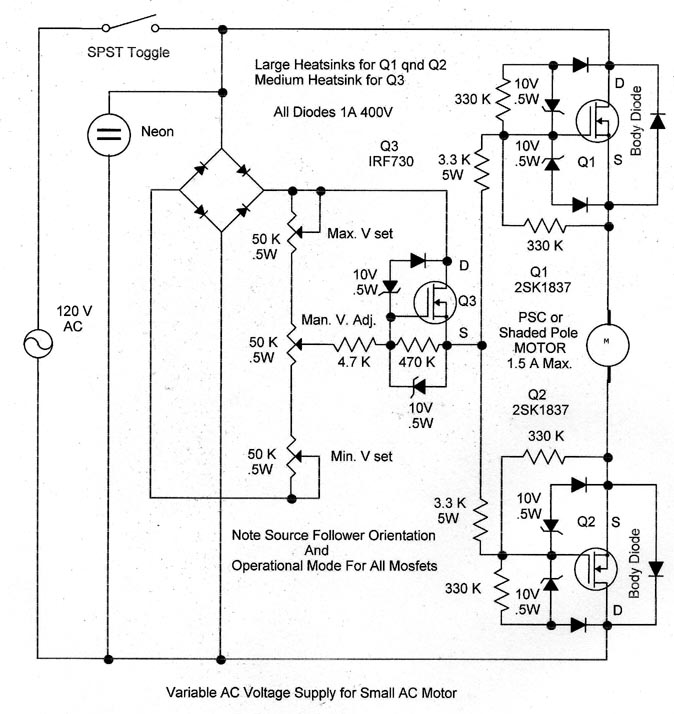

Here is the latest revision . The changes are to

make the biasing more assertive so that the

circuit will have better performance near the

zero crossing and will also deliver closer to

full voltage at the maximum setting . A better

output waveform should result , having

less noise and less heat from the mosfets .

An upper voltage limit setting has been added

in order to allow full control over defining the

response range of the Main Voltage adjustment

which is the " speed control " .

The power resistors for idle current to the motor

have been deleted to simplify the configuration ,

and large enough heatsinks for the mosfets will

manage any heat dissipation when the motor

is at idle speed .

A power switch and power indicator lamp are

shown on this new schematic . A value for the

capacitor and its charging current limiter resistor

have not yet been calculated . The idea is that

this capacitor will charge nearly to the peak 170 volts

on the first half cycle , and hold that higher voltage

across the divider string of the control pots so

that the V ref to the source follower stays at a

more constant and higher voltage and supplies

this steady high level signal to the gate of the

source followers , so that they switch on suddenly

and in saturation at the zero crossing , reducing

that part of the cycle where they would otherwise

be operating unnecesarily in a linear mode , if

following always 3 to 5 volts below a gate signal

varying synchronously with the line voltage .

Using this scenario the mosfets will switch on

in saturation at the zero cross and stay in saturation

until their sources attain a voltage 3 to 5 volts

below the constant V ref being supplied their gates ,

which will reduce the heat dissipation of the mosfets

by allowing them to operate more efficiently during

that earlier part of the cycle where they can .

Any suggestions / justifications for the value of the

capacitor , limiter resistor , and the gate resistor values

is welcome .

[Edited on 9-2-2006 by Rosco Bodine]

|

|

|

froot

Hazard to Others

Posts: 347

Registered: 23-10-2003

Location: South Africa

Member Is Offline

Mood: refluxed

|

|

Just looking at that circuit Rosco I would be very nervous about parasitic oscillation when I flick the switch. As previously mentioned the input

impedence to the FET's needs to be as low as possible to prevent this. With the bias resistor configuration you have there appears to ensure an

unfavourable situation for stable operation although the DC outlook looks fine. My immediate thought is to keep the rectifier but have variable

voltage regulators to bias the FETs, having a much lower output impedance, basically use that circuit as it is with common emittor transistor or

darlington driver configuration, biased in class AB (about 10mA in class A) in front of the resistor devidors. I would try 1,5K for the gate

resistors.

The driver transistors would dissipate about 2W on idle and may need a small heatsink.

It's very interesting to see how the circuit has evolved, makes me wonder what the very first lightbulb looked like

We salute the improvement of the human genome by honoring those who remove themselves from it.

Of necessity, this honor is generally bestowed posthumously. - www.darwinawards.com |

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The idle voltage for the motor is always going to exceed

the voltage of the zener regulation on the gates , so in reality each mosfet has its own local zener regulated power supply directly on its gate .

The gate input impedance of a mosfet is so high that it makes little difference what series gate resistance there may be added externally , the " felt

impedance " of that entire signal lead will be several megohms to tens of megohms . A sufficient resistor value should be used to

prevent any overcurrent damage to the gate protection

circuitry in the event of an abnormal signal condition ,

but even a 1 Mohm or more gate resistor can be used

if wished to bias the high impedance gate . I am looking at 220K to 470K as candidate gate resistors . You have to consider how much decrease of the

level of V ref will

be caused by the current through the zener from

gate to source , ( or alternately from gate to drain ) which will appear as a load tap on the divider string composed of the potentiometers . The

value of the gate series resistor must then be pretty high to prevent undue voltage drop on the selected V ref . by putting too much load on the

divider string setting that reference voltage . At the reference voltage tap on the Main v. adj . potentiometer appears a load

which consists of the sum of the two currents required to

bias the zener at the gate with the current limited by

the series gate resistor . The mosfet itself is essentially

invisible as a load on the biasing circuit , since its gate

requires virtually no current at all , but is biased essentially by the voltage alone across the zener .

Acting as a source follower with the source voltage rising to meet the absolute V ref. , when the zener drops out

of zener conduction , it will unload the signal lead of the zener current and a slight positive rise in the Gate voltage will reenforce the rise of

the Source voltage

towards the selected V ref. So the feedback here is

in the proper positive direction to supply switching hysteresis , and noise immunity as is desired .

I think it's a good circuit , but time will tell , and the proof is in the pudding . I've designed and built way more complex stuff than this which

works fine , so I have confidence it will work as intended , and the

parasitics be damned  With intelligent lead routing , With intelligent lead routing ,

or even a Faraday cage , steel box for the circuit if

necessary , and this baby should work .

The one place I can see adding a Darlington pair . or really just a simple NPN emitter follower , something like a 2N2222 might be fine , is to

current amplify the V ref signal from the wiper on the center pot to the tied together gate resistors

for the mosfets . The collector of the NPN would go to the

top end of the divider string composing the pots , the base lead would go to the wiper , and the emitter would go to the

tied together + feed ends of the gate biasing resistors . This

current amplification of V ref selected would prevent loading

of the divider string by the gate biasing resistors which could be much lower resistance value . Is this what you are suggesting to do ? Because I

agree it would be better biasing and less susceptible to oscillation to current amplify the gate signal in such a way with a unity voltage gain one

or two transistor current amplifier , the good old emitter follower . It seems excessive to have to dump 2 Watts from

a mosfet biasing amplifier . I'm looking at it and it really

depends on just how hot you want to run the gate bias resistors and the zeners . I'm thinking a tenth that 2 watts

would be plenty sufficent to get rock stable gate biasing ,

and I'd like to stick to signal circuits that require no heatsinking as if they were power devices

[Edited on 9-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Holy hell, now you've slowed down the bias with a cap, AND killed the slew rate even more by upping the resistor divider to 150kohms!

And you've fucked up the gate limiting even more. What is wrong with ONE ZENER!?

I don't even want to get into that PV thing. You can calculate yourself how slow a 5nF gate charges at 10uA.

Tim

[Edited on 2-9-2006 by 12AX7]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@12AX7 ,

You are right about the slew rate for only the first half cycle , although it will be of little effect .

I could swing that low value limiter resistor for the cap CCW into a position in series with the vertical conductor for the cap and that will fix that

without much drop on

the V peak on the top of the divider string for the Pots .

Also I am looking at a " one shot " fading transient vactrol clamp for the V ref , so that upon initial power up

there are a few cycles of full power AC applied to the

motor to give it more starting torque at the lower speed settings . If I do that , the initial charging of that cap

will have no effect on a signal already bypassed to

maximum for way longer than the time it takes that cap to charge .

So far as the diode count and arrangement , I'm not going through that again . You build yours biased the way you see it surveying the components ,

and if it

works fine great . Dittos for mine , but what you see there , are the diodes that are going on what I'm building , until I see some compelling

justification for

how they aren't needed .

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

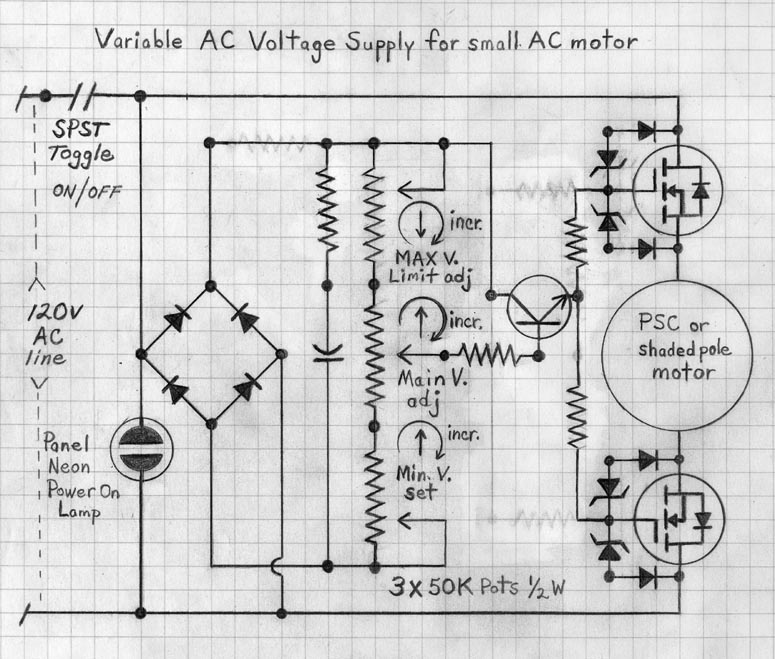

Thanks to froot for suggesting a lower impedance mosfet biasing , as has been mentioned before .

And thanks to 12AX7 for suggesting better placement

of capacitor charge current limit resistor .

The changes hoped to address these two matters are

shown in the attached revision of the schematic .

Do you gentlemen see any problem using an NPN emitter

follower the way I have it shown with the collector

tied to a 170 volt supply ? Ordinarily the reverse BE

breakdown voltage limit for the NPN might not allow this ,

but the ordinary diodes which I have straddling the mosfets

should be protective , so it is good they are there hmmm ?

HeHeHe .....

looks like they may be good for something after all

I guess it might be worth looking at all the other voltage

limits too , because I'm not sure this will work anyway .

This is a new one on me , so please speak freely .

Looking at CE Max V and thinking about the voltage allowable to be dropped across the collector to emitter for a

common NPN , I doubt any usual bipolar tansistor would survive even a fraction of the voltage encountered here .

But a high voltage Mosfet could , so what I will probably end up with here is using a high voltage rated signal mosfet in the place of the NPN , if

the original biasing scheme really

needs this change involving a signal amplification intermediate stage , so the output mosfets can be

operated off a low impedance biasing scheme .

One can see a small perplexity here because this signal mosfet certainly can't be low impedance biased either , or else it may as well be omitted

entirely and the main output power mosfets biased directly using V ref from the main pot .

Using an intermediate signal current amplifying mosfet

is also going to cost 3 to 5 volts drop in the maximum voltage output possible from the main power mosfets ,

but a lot of stability and noise immunity would be gotten

in return .

Using one Mosfet to drive the biasing of another Mosfet is

something like using Mosfets in a Darlington pair configuration , a thing which generally doesn't make a lot of sense when one of the things the high

impedance input of a single mosfet is good for , is eliminating the need for a Darlington pair . But this scenario may be the exception where it

actually does make sense to have one Mosfet used as a driver for 2 other mosfets . Can you say " fanout " ?

It's done in IC's all the time so why not

Guess we all know what is going to get substituted for the

NPN on the next drawing . Almost there !

Thanks for the help .

[Edited on 10-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Are you familiar with the "TransZorb" product? It's a proof-by-existence that a bidirectional voltage limit gate-source is sufficient protection for

the gates.

Is it a requirement that the parts count be very very low? There are a couple of things that could be done to drive the gates with a lower impedance

voltage limited signal.

Are you aware that the circuit as presented will require a minimum of Vth + Vdiode across it - say 5-8 volts to operate? The motor will never run at

full speed.

Here's a version which should be quite linear.

OK how do I upload a GIF?

[Edited on 10-2-2006 by densest]

|

|

|

Twospoons

International Hazard

Posts: 1282

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Sorry to burst your bubble, Rosco, but your circuit as drawn just plain doesn't work. I ran it through a SPICE simulator, as analysing these things

in your head is just too damn hard. At any setting of the pot, the AC voltage on the motor stays the same - pretty much full on.

I use Simetrix for the simulation, as they have a free demo version.

[Edited on 10-2-2006 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Twospoons - thanks for the simulation effort!

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@ Twospoons

It's going together anyway and when it works

you can take it up with the simulator authors

and let them figure out how to rewrite their

simulation software .

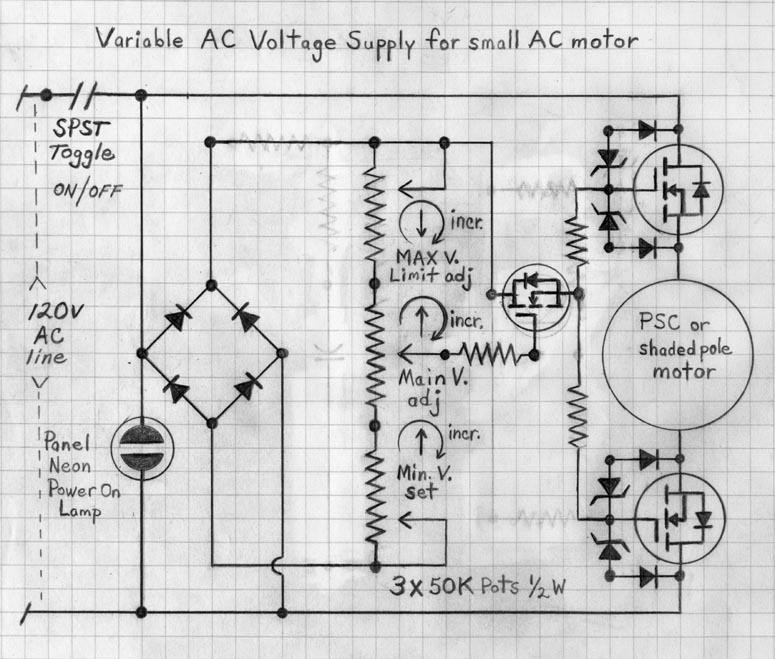

Edit / update

Sorry to be grumpy , this can be frustrating ,

and I do see why the simulation probably said it

won't work , and why it actually wouldn't work properly ,

though I disagree with the nature of the predicted

fault behavior .

I discovered this defect which I didn't see earlier , specific to

the idea of using a capacitor to bring up the voltage

to a constant level in the signal stage ......

the ground return path for that strategy is blocked in the bridge rectifier which charged the capacitor negative side . There is no DC " return path

" for the circuit allowing the

increased voltage across itself to be referenced to line ,

The DC return path is blocked by the lower right diode in the bridge which originally allowed the capacitor to charge .

It's a subtle thing hiding there in plain sight , and it got by me .

So inserting the capacitor and trying to increase

the biasing voltage and hold it constant is a dog

that won't hunt , it just won't work the way I have

it drawn above . The bridge output has to be allowed

to rise and fall with the line voltage . That

synchronization is the only thing that gives the

positive voltage out from that bridge rectifier an

instantaneous value referenced to the line outside

the bridge .

So the capacitor idea is hereby deleted .

With it goes the hope of driving the mosfets harder

so that they acted as saturated switches through the

below peak voltage conduction times . It would be nice

if that idea had worked out , but it just doesn't work as

hoped . That is not to say the entire circuit lacks validity .

It just means the capacitor and the charging current limit

resistor have to be deleted .

The usefulness of a single mosfet source follower

signal current amplifier in the place of the NPN emitter

follower shown above is going to be explored and is shown

in the revised circuit attached .

This sorting out of the ideas and details which I have been

doing with fellow members help is leading to a valid circuit , even if it is a halting sort of progress where three steps forward reveals a snag

causing one step backwards , it still produces a net gain of two steps in the forward direction ,

so progress is being made .

Ever since the revision of the circuit which departed from the dual pots and began using the bridge rectifier and single pots , I have had some

reservation about the DC reference

to ground / return path to ground sorts of visualizations ,

looking at instantaneous AC values as a snapshot showing

a DC circuit behavior during a half cycle , and trying to keep it all straight when the inverted picture occurs for the next half cycle . It is

maddening to try to mentally keep track of the

expected and intended behavior as inverted snapshots depicting the half cycles in reversal of polarities . I am in the right place for this

....Science Madness , and hopefully what will distill from this exercise is something useful .

In the interim I ask your forebearance with my smudges and

scribbles and revisions and corrections on this work in progress . And I thank you all for your criticsms and ideas

and suggestions , even simulations

Speaking of sims , try the corrected circuit attached here

on the sim and see if the results compute . This one

should fare better . Pay attention to the orientation of

all the mosfets as " source followers " , as they are absolutely inverted to their usual configuration when

used as switches . I estimate the voltage output of this

source follower bridge would be about 108 volts from

a 120 volt line .

[Edited on 10-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by densest

Are you familiar with the "TransZorb" product? It's a proof-by-existence that a bidirectional voltage limit gate-source is sufficient protection for

the gates. |

That would be something like back to back zeners in a single package ? Fine for the usual applications where that is what is needed .

| Quote: |

Is it a requirement that the parts count be very very low? |

Yes , it is highly preferred that the circuit be kept simple .

| Quote: |

There are a couple of things that could be done to drive the gates with a lower impedance voltage limited signal. |

I'm listening .

| Quote: |

Are you aware that the circuit as presented will require a minimum of Vth + Vdiode across it - say 5-8 volts to operate? The motor will never run at

full speed. |

Yes , I am aware of the drops across a source follower

used to deliver a positive power feed to a load .

FYI , full voltage is not required to run an asynchronous motor at full speed under reduced load . Full voltage is only required to run a motor at

full speed while delivering rated torque output at rated rpm .

For an asynchronous motor application where the motor is going to be run derated by 30 to 40% power output at 70% of its peak rpm , certainly a 10 to

15% reduction in available

label rated voltage presents no problem . Remember the

application is going to run the motor in any untypical way ,

on the " stall slope " as some have termed it . So an inherent reduction in the maximum voltage available is a power limitation which may be

supplemented even further by a control pot setting for an upper limit , set even lower than the point where the 10-15% drop in label voltage may be

insufficient decrease in power to limit motor speed to the

desired operation rpm range on the " stall slope " . So it is no disadvantage that there is an inherent 10-15% voltage loss provided by the source

follower , " off the top " when

it would be dropped by that much later using deliberate regulation anyway .

| Quote: |

Here's a version which should be quite linear.

OK how do I upload a GIF?

[Edited on 10-2-2006 by densest] |

I can't make any sense of that schematic .

@ froot

There actually are some ten cent signal transistors

which have a 300 volt rating and a Beta of 40 ,

which could be used as Darlington pairs and have

a fourth the signal voltage drop , when used as

an emitter follower , as would be dropped across

one high voltage mosfet used as a source follower .

The cheap high voltage TO92 packages are available

as complementary NPN / PNP versions , MPSA42 and

MPSA92 , and are typically used in high voltage display

and indicator circuits . These should be staple design

items where signal level high voltage needs to be

handled . These devices are made by Motorola , Fairchild ,

and others .

Are there similar high voltage rated Power Transistor

versions which are the counterparts of these little

signal level TO92's ? , likely so but I don't have the numbers ,

Anybody ?

Edit/Update : Just found what looks to be the next level higher power counterpart for the signal level NPN MPSA42 , a TO-220 cased 1 Amp , 40W device

, having similar beta and voltage , listed as a Motorola TIP48 . BU406 was a 200 Volt

NPN , 7 Amp , 60W , Beta 50 device which could be useful also .

BU931 was an interesting NPN Darlington array I also

encountered while looking this up .

Attached is an example of a Darlington Pair

NPN Power Module for high voltage operation .

Haven't checked the list price on these .... am almost

afraid to look . But two of these modules ,

could possibly substitute for the mosfets and

be driven from a signal amplifier Darlington made

from two of the MPSA42's mentioned above .

The use of these lower voltage drop bipolar devices

would result in full power output having half to

one third the power loss of the same circuit using Mosfets .

I haven't really looked hard at using bipolar transistors

of these high voltage ratings since they are not as

common surplus items which can be scrounged at

cheap prices , while surplus power mosfets are abundant

and cheap .

[Edited on 10-2-2006 by Rosco Bodine]

Attachment: ESM2030DV 300 Volt 300 Beta 150W NPN Darlington .pdf (122kB)

This file has been downloaded 763 times

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Hi Rosco,

Re: strange schematic

The diodes make things look more complicated than they really are. The intent of the circuit is to bias Q3 dynamically to drop a fraction of the

input line voltage as set by VR1.

R2, C1, and ZD1 make a sort-of-regulated power supply which can drive the gate of Q3 even with very little voltage across Q3 source->drain.

Q1 and Q2 form a differential pair with R3, R4, and R7 which subtracts the instantaneous voltage across the "rheostat" sampled by R5 and R6 from the

instantaneous fraction of the line voltage sampled by R1 & VR1.

The output of the differential pair drives the output power transistor Q3. The circuit depends on the threshold voltage of Q3 being greater than the

saturated voltage at the drain of Q2, set by the ratio R3 parallel R4 vs R7.

Is this clearer?

Re: high voltage BJTs

Most manufacturers no longer make high voltage BJTs. The IGBT has replaced the BJT for most power applications.

Check industrial surplus sites for parts salvaged from motor drives and so on for high power (> 100W) transistor modules for very little $$.

Do be aware that BJTs and their derivatives (IGBT) often cannot be used at the upper end of their voltage range to pass much current. Second

breakdown, a phenomenon where the electric field is sufficiently nonlinear to cause local overheating, restricts the safe operating area of most BJTs.

The magnitude of the problem depends on the geometry and doping of the device and is usually specified in the data sheet. If there is no SOA chart for

a transistor, assume that the SOA drops 2x as fast beyond Vce > 10V on a log log diagram.

FETs (mostly) are immune to second breakdown due to their different current geometry.

[Edited on 11-2-2006 by densest]

[Edited on 11-2-2006 by densest]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@ densest

That image is clearer but still leaves some

of the connection paths to the imagination .

I gave up on circuit maker software and

resorted to pencil and paper . I have seen

some very good circuit graphics on the web

and I wonder is there some CAD program

or dedicated software for circuits that can

be conveniently stolen for personal use

I haven't looked on the FTP yet , and maybe its already there . Some of these programs even run

very sophisticated color graphic animated sims

with highlight frames showing what is occuring

in certain branches , waveform graphics and all ....

like an inset frame for a virtual oscilloscope . I have

got to have me one of those , to keep from

working the virtual Tektronix screen running

inside my head

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Which connections are unclear? T-connections are always connected. Crossings (4-way) are never connected. I'd like to fix anything ambiguous.

I use open source stuff like xfig, xcircuit, pcb, etc., which aren't the elaborate commercial software but do work.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Where does the bottom of the bridge rectifier go ?

What are D1 , D2 , R1 , R5 , R6 , and ZD1 ,

and where do they connect ? Where does the

end of the pot connect ?

Never mind , I just resized the screen and everything

appeared .

ZD1 simply shorts out the circuit as you have it drawn ,

it is upside down . If you want regulation of the capacitor

as a virtual battery outputting 15 volts then rotate

ZD1 180 degrees .

I sometimes put the arrow going the wrong way

on some things and then catch it later , for example

the minimum voltage set on my circuit shows the

wiper moving the wrong direction for increase .

I'll look at something several times and it looks okay ....

and then the needed correction is recognized later .

[Edited on 12-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Twospoons

Sorry to burst your bubble, Rosco, but your circuit as drawn just plain doesn't work. I ran it through a SPICE simulator, as analysing these things

in your head is just too damn hard. At any setting of the pot, the AC voltage on the motor stays the same - pretty much full on.

I use Simetrix for the simulation, as they have a free demo version.

[Edited on 10-2-2006 by Twospoons] |

@ Twospoons

If it wouldn't be too much trouble , would you mind

running that simulation again with these specific values ?

I have made a legible schematic using an " E " CAD

software and assigned some values which should

work .

See attached file .

|

|

|

Twospoons

International Hazard

Posts: 1282

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Rosco, I recommend you get the SPICE software yourself.

Go here . Its only the demo version but should be sufficient for your purposes. There are other SPICE simulators out there too, some of them are

freeware. SPICE models for the devices you want to use should be available from the manufacturers websites. If you do the simulations yourself you

will get to see all the voltages, currents, distortion, harmonics, power disspation etc. Its really easy to play with the circuit without actually

blowing anything up (=$). You can have 4 million amps go through a simulated device!

You also get a nicely drawn schematic to share with the rest of us.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Twospoons

Rosco, I recommend you get the SPICE software yourself.

Go here . Its only the demo version but should be sufficient for your purposes. There are other SPICE simulators out there too, some of them are

freeware. SPICE models for the devices you want to use should be available from the manufacturers websites. If you do the simulations yourself you

will get to see all the voltages, currents, distortion, harmonics, power disspation etc. Its really easy to play with the circuit without actually

blowing anything up (=$). You can have 4 million amps go through a simulated device! |

Thanks for the link . I'll probably build the device and test

it in half the time it would take me to learn the simulation

software . And I'd bet good money the sim will return an

erroneous evaluation on a novel circuit it's never seen before , since it can't give a canned answer , it feeds you bullshit by default when it

doesn't really know .

Suppose I don't agree with the sim projections ?

The only things I ever burned up was from following

manufacturers schematics , before troubleshooting

the design and figuring out what they had backwards

that technicians discover later in troubleshooting and

then put the way it should be in the first place

Technicians really are the best engineers  ...... ......

maybe because they get the job later of fixing

what's broke or making work right what never

would have worked right before they got it on a bench .

| Quote: |

You also get a nicely drawn schematic to share with the rest of us. |

Open the last file I posted and resize it larger if it doesn't fill the frame , or just click print . I thought I did a clean job

with the schematic " to share with the rest of you " ......

right there .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Rosco Bodine

Technicians really are the best engineers  ...... ......

|

Well, if you consider yourself a technician, then clearly this statement of yours has been disproven.

I see you're *still* drawing those extraneous diodes.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Only " extraneous " to someone who doesn't

see them as " logic gates " which apply to

foreseeable scenarios which may arise

from switching transients but not necesarily

arise during a normal powerup and continuous

on period . Have you taken into account

what occurs when you break power to a reactive load ?

Depending upon which half cycle that occurs , one

or the other of those " extraneous " zeners is sure as hell

going to be a path for giving " extraneous " current a place to go , other than possibly puncturing the dielectric in the gate of the Mosfet . Seeing

that " potential " which could be considerable on the break , isn't it good practice to put a component there which indicates the designer has some

small idea of what he is doing ?

Therefore I have the filtering on those gates

that I want there , and if it is extraneous ....fine ,

it won't hurt one damn thing nor interfere with

the normal operation , and just maybe it will

keep the Power Mosfets from frying during transients

from breaking the circuit ....or from signaled transients

which I may introduce with added circuitry , like

a four to ten cycle full voltage startup pulse .

There are reasons I have for the gate filtering

diodes I have chosen , whether you recognize those reasons or not . Diodes are cheap and it is easy to

put a zener labrynth on a power Mosfet gate to

guarantee signal to it stays within allowable limits not

only for expected conditions but also with respect to

foreseeable anomalous conditions . So that's what

I have done .

[Edited on 14-2-2006 by Rosco Bodine]

|

|

|

Twospoons

International Hazard

Posts: 1282

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

| Quote: |

And I'd bet good money the sim will return an

erroneous evaluation on a novel circuit it's never seen before , since it can't give a canned answer , it feeds you bullshit by default when it

doesn't really know .

|

I'll take that bet! (easy money). Simulators don't need to know anything about your circuit or what it's supposed to do. A SPICE simulator models

the individual components, and their behaviour using mathematics derived from the physics of the devices. A BJT can have 30 parameters!

I have used SPICE extensively, and got extremely accurate results when modelling analog circuits. Thats how I designed a laser pulse recieve

amplifier with 16MHz bandwidth, and 1pJ pulse sensitivity, that ran on just 150 microamps. SPICE let me fix all the temperature instabilites, fine

tune the filtering, and probe parts of the circuit that I couldn't have done with an oscilloscope. And it was an oddball circuit too. I used the

bias current from the 2nd and 3rd gain stages to power the first stage. I had to explain the circuit to my collegues, as no-one else could figure out

what I'd done.

Do you realise that all chip design is done using SPICE type simulators?

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

If you say it's good then I'll probably try it .

I think it's built in on the ECAD I used for the schematic

anyway , but I just used the schematic drawing function

and didn't set up for running a sim .

I am a novice at these sims , but an old hand with

the meter and the soldering iron .

BTW , I'll answer again defending the

" extraneous diode " , because I see both sides of

the logic , even without the sim .

The main surge on the break is going through the gate to source zener of the

Mosfet which is " on " at the instant of interruption , and the body diode

of the Mosfet which is " off " . But the surge voltage

continues up through the bridge and through the same

biasing to the Mosfet which was " on " tending to hold it

" on " . All of this reactive current path is from the motor

being deenergized and this current is dissipated in the biasing for the Mosfet which was " on " delaying its

complete cutoff , but it isn't hurt because its gate to source zener protects the gate from the surge . However the

motor is not the only reactive load being interrupted .

The line itself is reactive , and that surge is directed through the low impedance biasing 3.3 K resistor to the gate of the

Mosfet which was off . By having this " line surge " hit right

in the middle of nose to nose zeners , the easy path to ground is through the gate to drain zener , and a less easy path is also present through the

gate to source zener and body diode , but the gate is protected from the line surge

by both .

So it isn't extraneous ..... redundant yes perhaps , but there's more . The gate to drain

zener on the Mosfet which is off , keeps 95% of the line 170 peak voltage from appearing gate to drain , which I don't believe is a bad thing , not

knowing what is the actual gate to drain breakdown voltage ......the manufacturer doesn't state it , and leaves the designer to question could it have

similar value as the stated gate to source limit . So plan for

the worst is what I chose to do there as insurance against the unknown .

I do not feel comfortable about omitting that gate to drain zener in the

absence of any manufacturers specification for the tolerance of the Mosfet

to such an extreme positive 170 Volt gate to drain voltage scenario as the

Mosfet which is "off " receives .

An ounce of prevention is worth a pound of cure .

The gate to drain zener also keeps a low current load on

the side of the divider which is biasing the Mosfet which is Off . Keeping this

small current load on the intermediate V ref. follower / amplifier will benefit the stability and noise immunity

of the output , which is shared by the Mosfet being biased in its linear region where it is

sensitive to small variations on its gate voltage , amplifying those variations .

Some of the wierd biasing you may see is " initialization "

related , bleed down paths , ect . I know there are capacitances and inductances hiding everywhere in

stuff like this , where oscillations can pop up as the

unsolvable puzzle , and even zeners can be culprit

in this in spite of best laid plans . And this thing

I am working on has stray magnetics too , which is

exactly why I am running the biasing circuit hot ,

hoping that keeping that first stage driving a light

load will make it less inclined to pickup and amplify

noise . The gate to drain zeners on the two larger

Mosfets are that light load . There's not the same

purpose on Q3 so there you may have more of a

legitimate gripe about that .

When even light reactive loads are switched ,

even 30 or 40 watt loads , and there is a little

switch arcing at just the wrong time in the cycle ,

I have seen some very wierd things happen ,

and absolutely defying analysis , except in some

RF harmonics scenario involving ionization ,

spark oscillators , and other assorted equipment

destroying factors . Somebody suggested putting

a metal oxide varistor or similar spike clamp across the

motor , and maybe the rails too , and that's probably a good idea , maybe a capacitor across the switch too .

|

|

|

Twospoons

International Hazard

Posts: 1282

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Here's another circuit for you to consider - with simulation results

Its your same source-follower concept, but using one N-ch and one P-ch mosfet. Pretty simple, eh? It also works with BJTs, though you might want

darlingtons for any sizeable current.

Note there is a small amount of distortion around the zero crossing - cause by the gate threshold voltage of the fets - but its a soft transition so

shouldn't cause your motor any trouble.

Attachment: ACRegulator.pdf (14kB)

This file has been downloaded 836 times

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

That P channel device is only rated for 50 V .

so a transformer would be required .

I already knew about the Push-Pull complementary pairs

which were made for a few things using BJT's , but

finding the P type BJT's or Mosfets which have good voltage and performance ratings is difficult .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

OMGWTF? So use a better transistor! Topology is all that matters, can you comprehend that?

A quick perusal of my Mouser catalog shows about 20 pairs of N and P channel FETs over 200Vdss(max). You have NO excuse for saying that.

Tim

|

|

|

| Pages:

1

..

4

5

6

7

8 |