Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

DIY heating mantle

I've made a simple and inexpensive heating mantle as follows; a $1 no-stick coated iron pot (Wal-mart) which fits around a 500 ml round bottomed

flask with about 1.5 cm gap on each side is used as the container. The rbf has a coil/spiral of wire from an old hair dryer hot glued onto its

bottom hemisphere, and is inserted into the iron pot. The space between the rbf and the pot is filled with phosphate bonded dental investment casting

cement, and once this is cured, the flask is removed. The wires are connected to a standard cord that plugs into wall sockets. Then 2 layers of

fiberglass matting are placed over the castable refractory and glued in place with sodium silicate.

For the power controller I simply used a fluorescent light dimmer (1000 watt rating, $5.) in conjunction with a 5 amp fuse. The controller is placed

inside of a dollar store box and has a plugin to accept the cord from the mantle, and a standard cord leading to the wall socket.

Everything is working almost as planned, except for one really obvious problem; the wires have hot glue all over them. I was probably not thinking too

clearly when I put the hot glue on, but now it has to come off! The wires are also embedded partially in the refractory layer, so they won't be

easily moved. I was thinking that solvents might be a good choice. Any ideas? I'll test acetone and ethyl and isopropyl alchohol (the only

solvents I've got currently.) I also thought I could just turn the heating mantle on high and burn the hot glue off. I was expecting that with

heat it would flow easily and run out, but unfortunately it is too viscous and boils before it really begins to flow.

Cyrus

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

Seems you're on the right track here!

Just let the glue burn off by very slowly raising the heat being careful not to overheat the resistance wire.

The carbon residue should then fall off easily maybe needing a little coaxing.

You didn't mention the wattage. You may need to limit the dimmer by adding more minimum resistance in series with the potentiometer to protect

the wire. Commercial mantles use 450deg max wire temp. This also protects the flask.

Be a real bummer to melt or soften the flask if accidently set too high.250-500 watts should handle anything up to 3 or more L for almost all

purposes.

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Thank you for sharing this example of do-it-yourselfness. I, for one, am inspired (somewhat).

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

Just an idee of a heating mantle

Just an idee of a heating mantle, wich I have not tried out yet.

1.- Make a long 0.5 - 1.0 cm Spagetty string of Bees-wax (maybe more than one meter long). The core of this Spagetty string may be Glass-wool.

2.- Wind a coil of Nichrome-wire around this Wax spagetty string with a sepperation distance (coil winding distance) of about 0.3 - 0.5 cm. Paint

molten Wax over it, and let it harden. By carefully heating it with a rapidly moving gas-torch, the Wax will flow evenly over the surface.

3.- Put this Wax-spagetty-nichrome wound fabrication into a mold.

4.- Pore a heat resistant Ceramic castable mix over it, and push a distillation flask into it, to get a round intentation of the flask in the mold.

Your round flask distance to the Wax-coil of Nichrome wire should maybe be no more than about 0.5 cm. Let this mold harden by letting it dry.

5.- Heat this dried mold with a gas-tourch, and let the molten Wax drip out, then heat it all redhot in the flame to evaporate all remaining Wax. This

will give lots of smoke. By doing it under Sand, you will be able to prevent the wax burning on the surface of your mold.

6. - Cover this cast mold with a Glass-fibre cloth, wich may be glued to the surface with a Sodium or Potassium silicate solution (?). Use your

distilation-flask to press the Glass-fibre cloth firmly against the mold-wall, and let it dry.

Remark:

The Nichrome wires may be lead through a Bead of Ceramic material out of the mold. These Beads can be found in electrical heating appliances.

Castable Ceramic material:

http://www.cotronics.com/vo/cotr/cm_castable.htm

[Edited on 24-7-2005 by Lambda]

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

.......2.- Wind a coil of Nichrome-wire around this Wax spagetty string with a sepperation distance (coil winding distance) of about 0.3 - 0.5

cm...........

Good luck doing this. NiCr is like a spring steel and very brittle with memory for it's previous shape. You might be able to use the hair fine

gauge and pull this off but it is a real trick working with that small of wire.

Soft mantles are EASY to make and work well.They can sit right on the magnetic stirrer , just keep the bottom insulation thin enough to match your

stirrers power.

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

....1.- Make a long 0.5 - 1.0 cm Spagetty string of Bees-wax (maybe more than one meter long). The core of this Spagetty string may be Glass-wool.

Addition to "Just an idee of a heating mantle":

You can allso prewind the coil on a metall rod. The dimension must be smaller than the dimension that you want your coil to be, for it will expand a

bit after removal. If you want to wind the coil over a metall rod without it expanding, then heat it with a gas burner (torch) to anneal it while

winding.

Bio2, giving a solution to a problem, will be much more helpfull.

I have Nichrome-wire from 0.01 - 2.5 mm diameter, and the annealing process works fine for larger diameter Nichrome-wire.

You will have to work it out what will work best for the Nichrome-wire you may have.

[Edited on 24-7-2005 by Lambda]

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

I think that getting the coil of wire is the easy part, guys. It's keeping the wire in the right spot while you pour castable refractory

that's difficult.

BiO2, I'd like to hear more about your methods for making "soft" heating mantles. I'm assuming you just use a layer of glass cloth

around a layer of glass fiber insulation. I was going to go this route, but I had 3 problems; 1- how do I attach the heating wire to the glass cloth?

Sodium silicate is not a good idea because we want flexibility. I was going to use a strand of glass fiber from the glass cloth to sew the wire to the

cloth, but I'm not a seamstress, and the glass fiber breaks when tightly bent. 2 -the glass fiber insulation usually has stuff in it that burns

off = yuck, and the glass fiber gets, well, glass fibers everywhere. 3 I can wrap a piece of glass cloth nicely to form the top half, but if one

large piece is used then the bottom half will be really crinkled and hard to hold together. Sew it? I thought about using 1 piece for the top and 1

for the bottom, but then they would have to be sewn together...

I burned off all (I hope) of the hot glue. It took several hours, and building a fire inside of the heating mantle didn't help much, nor did

heating it with a propane torch. (The hot glue was too recessed for that to work well.) That was nasty.

|

|

|

runlabrun

Hazard to Others

Posts: 172

Registered: 4-12-2004

Member Is Offline

Mood: No Mood

|

|

nice work, i love diy stuff.

Could you possibly post a picture to show us what your creation looks like?

Great work!

-rlr

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Right now it looks really nasty because of the carbon all over the inner surface, but that willl all get covered. Oh, I also just made my own

magnetic stirrer and "upgraded" a standard Walmart $7 hot plate which has those metal heating coils like a cheap stove. I just put a

ceramic tile (Home Depot, $.90) on top, now it's a real ceramic hot plate.

I *might* be able to get some pics, though.

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

Woven Silica fiber products can take temperatures as high as 1100 degrees celcius and shortly as much as 1650 degrees celcius. This would definitely

work out. You can buy Ceramic Sleeving as woven Ceramic mats.

Ceramic Sleeving:

http://www.cotronics.com/vo/cotr/fc_sleeving.htm

[Edited on 26-7-2005 by Lambda]

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Ah, I have a few sq. ft. of 2" 2700 deg. F. kaowool, but... could I use some on such a "lowly" project? Actually, it looks like

I'm going to use a "soft" heating mantle after all.

While I was burning out the hot glue, I discovered that one of the heating wires somehow contacts the outside pot. (which has a layer of no-stick

stuff on both sides.) I found out that it conducts the hard way.

Also, where the wire enters the hot plate I used a plastic coated wire. Not a good idea. In normal operation it took several hours for the

connection to even get close to "dangerously" warm, but I was trying to use the mantle to heat up some NaCl/CaCl2 to see if it reached the

necessary temperatures, and so heavily insulated the top. That meant it reached really high temperatures really fast, causing the plastic to melt- I

noticed some smoke and then wiggled the connection.... BAM! 3 cm wide bright orange flash! I decided it was a good time to unplug this thing....

And I didn't even melt the salt mixture...

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

Regular glass cloth or fiberglass wool is no good for this application as it WILL burn.

Lamdas idea is good and I use ceramic blanket with an asbestos paper shell. Rockwool is OK and Zetex tape also.

Commercial soft mantles have very fine wire woven (sewn) into the inner liner or flexible heat tape can be purchased. I made a couple this way and

initially used too heavy wire which caused some obvious problems. The finer the better, just keep the current density down (follow Thermolines specs)

If you try this make a little test piece first or a minimantle (test tube)to work the bugs out.

I have been using 60watt 18inch very flexible heating cords from $5 warming plates woven into the insulation blanket. Two or three of these with

switching gives a lot of variability combined with a dimmer. These cords can also be wrapped directly around beakers and Erlenmeyer flasks, wrapped

with glass or ceramic cloth and connected to a dimmer.

|

|

|

jt2oux

Harmless

Posts: 1

Registered: 7-8-2005

Location: USA

Member Is Offline

Mood: No Mood

|

|

I am interested in bulding a heating mantle and have been reading and researching my options. I really like the commercial soft heating mantle type

for its ease of use and eleminating the water/oil bath. I assumed a soft mantle was out of reach for the average do-it-yourselfer but after reading

this post I see that it may be possible. But do the overall costs and availability of materials justify the project? Hmmmm....

For those with experience in this particular area: What is the material of choice? Is the soft material lining some sort of silica material or glass

cloth? The company link provided for the high temperature cloth is very interesting. Is this the best option for obtaining such material for the job

or are there alternative routes others have found useful?

I am interested in these heating cords that Bio2 refers to. They sound useful and economically priced. More information on this product would be

helpful. After browsing walmart I couldn't find anything that resembled the description given.

This topic has been very informative. Thanks for everybodies effort to take the time to share thier experiences.

Any other relevant information on the topic is greatly appreciated.

jt2oux

|

|

|

Cloner

Hazard to Others

Posts: 150

Registered: 7-12-2004

Member Is Offline

Mood: apocalyptic

|

|

I have made a somewhat functional heating mantle using fireclay, nichrome wire and rockwool.

The nichrome wire is coiled using a rod which I put in an electric drill.

The clay is made to fit a pot I get beans in from the supermarket. It is made inside a plastic flowerpot of appropriate size.

The wires are put in spiraling up and down the clay and the clay is formed around them. This contraption has a certain resistance which is too little

for wall outlets but a PC power supply I made to work using information from this forum did nicely, on 12 volts.

The wires had to be divided into four parts with a contact at the beginning of each part, with alternating + and - contact. later, I divided again,

getting four connectors for + and - respectively. Doing this halves resistance of each track thus quadruples power in them. How many divisions are

needed depend on resistance and desired power.

Clay becomes brittle if heated too much too early, so this is done carefully. The nichrome elements provide heat that somehow sinters the clay with no

oven needed. Not very wel, pieces can be chipped off but so far the contraption seems to hold and that is with red hot wires. The only disadvantage is

that uneven wrapping of the coils makes it hotter in certain spots than elsewhere, thus weakening the coil's heat resistance. Certain tracks have

died already but since I divided it in eight to begin with, enough heat is transferred for boiling water easily.

Rockwool is needed for insulation because clay gets terribly hot once the initial hardening is done. So in the end, this has become a somewhat bulky

device, but that's no problem to me.

[Edited on 11-8-2005 by Cloner]

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

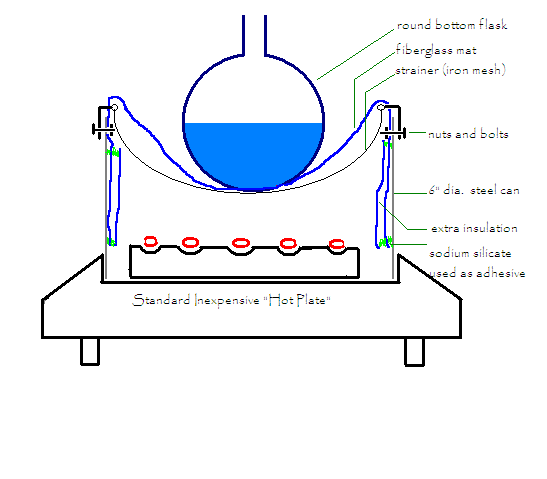

complete success

I decided to keep this next design simple. Essentially it is an air bath heated by a standard $10 Wal-mart "hot plate", except that the air

bath is only on the bottom half of the flask, like a soft heating mantle. This way I can see the contents of the flask, which is of course important.

See diagram.

The steel "coffee" can section is 6" wide by 3" high. Although it is all metal, some fumes came off on initial heating, so

removing the outer tin layer may be a good idea. (After a few minutes of slight fuming, everything was ok.)

The strainer fits nicely inside of the can, fits flasks from, oh 200 mL to perhaps 2000 mL, and has 3 steel loops on it's perimeter (to set it

over pots) which were bent down and used to bolt the strainer to the can.

The fiberglass mat was cut larger than it would need to be, and the extra pieces were used to provide additional insulation on the inside. The sodium

silicate glue used foamed a little bit on heating, so I would recommend heating it very slowly. The fiberglass mat turned slightly brownish and stiff

except where it contacted and was cooled by the flask. I don't believe this is a problem.

Well, that's all there is to it. It's simple, much cleaner than sand baths/oil baths, extremely easy to construct, inexpensive, durable,

and each part is easily replaceable if need be.

It has been tested 4 times so far and works perfectly.

As an added bonus, when the heating coil heats up enough, the reddish orange glow makes the glass mat appear to be glowing- a nice effect.

Cyrus

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Nice job. What was the final bill on this thing, ~$15?

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

My mantle

~~~~~~~

Materials:

-- old toaster, at least 800 W

-- clay from art shop that can be either baked or just air dried

-- bit of silver

-- #16-#12 copper wire

-- properly sized clay pot

-- fiberglass

Procedure:

-- take heater from toaster

-- usually toaster wire has sections running in parallel; rearrange so it runs in series, thus it cuts wattage and won't get red hot and melt the

fiberglass; if toaster doesn't have sections in parallel, get two toasters, or use other nicrhome wire

-- braze wire sections together and to thick copper wire using small amounts of silver and a propane torch; adding a bit of solder will decrease

melting point, but too much will make it so low that it will not withstand the temperature of the mantle in operation

-- shape clay over a bowl with outer diameter larger than the largest flask you intend to use, and as it begins drying, embed spirally the heater wire

-- cover insides with fiberglass; it's best to use cut up fiberglass cloth or cloth tubing, embedding the edges in the clay

-- put assemblage in the clay pot, with fiberglass insulation in between

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

The cost was about $3 for a good strainer, $5 for enough fiberglass mat to make 8 mantles, and $7 something for the hot plate, which is used for other

stuff as well.

Quince, I just couldn't bring myself to use unfired clay in labware....

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Cyrus, I think your design is brilliant! The best idea for a DIY heating device I've seen so far.

Congratulations.

|

|

|