| Pages:

1

2

3

4

5

6

..

10 |

Sickman

Hazard to Self

Posts: 98

Registered: 9-5-2004

Member Is Offline

Mood: Icy and I see!

|

|

Rosco,

Thank you for posting your research findings on methods of preparing sodium sulfide for the reduction of picric acid. It is encouraging that

these methods can open a greater avenue for furthering research on the production and improvement of such picramic derivatives as DDNP.

I'm curious as to wether or not your renewed research in this area signifies that you are hopeful that DDNP can be produced in a form and improved in

a fashion that will allow it's use as an "unequivicol", outstanding, primary explosive that we can all be proud of and be able to say that it is

"absolutely reliable and useful as an initiator of secondary explosives in a firing train".

The great majority of the literature seemingly holds up DDNP in a place as high and note worthy as lead azide and mercury fuminate. By way of some of

your postings in the thread "DDNP" it appears that your own conclusions about DDNP, at least in the form(s) that you were working with, indicate that

you think the literature overvalues and makes more of DDNP than DDNP really has to offer as an initiator of secondary explosives. So do you think it

can be managed to produce DDNP in a form (density) and in a fashion (unequivicality) that will rightly equate it with lead azide and mercury fuminate

as a true and undeniably reliable, initiator of secondary explosives? Or does DDNP's value lie more in some other application than as an initiator?

I think the second possible method you suggested for the production of sodium monosulfide looks to have very interesting potential. Your concern for

the glassware's corruption by hot, concentrated sodium hydroxide is understandable. I'm thinking that the glass would certainly be badly frosted if

not completely cracked and destroyed. Because of this I think that the use of a steel, stainless steel, or even a copper vessel could be used with

excellent results in this procedure. The only disadvantage of using vessels of these materials is that the visual observation of the reaction is

impaired by their not being transparent.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Sickman

Rosco,

Thank you for posting your research findings on methods of preparing sodium sulfide for the reduction of picric acid. It is encouraging that

these methods can open a greater avenue for furthering research on the production and improvement of such picramic derivatives as DDNP.

|

Yes it was clear early on that for any usefulness to be realized concerning DDNP ,

that two things would need to be optimized , the preparation of precursors , and the preparation of the DDNP from them in a crystalline form of

increased density .

I am still looking at the sodium monosulfide synthesis ,

which needs some work yet . It appears that the mixing

of the sodium hydroxide and sulfur as solids is certainly

on the right track . But it looks like that for the monosulfide to form

as the prinicipal product requires an excess of theory

for the NaOH , as little dilution and/or byproduct water as

is needed to maintain the melt , as high a temperature as is

manageable to drive the reaction , and for as long a time

as is convenient ......all while minimizing exposure to air .

After that reaction is deemed complete and diluted then

the excess alkalinity has to be adjusted with sodium bicarbonate .

I believe the hot phase of this reaction

would best be done under a high boiling solvent , perhaps

kerosene or white mineral oil for example .

| Quote: |

I'm curious as to wether or not your renewed research in this area signifies that you are hopeful that DDNP can be produced in a form and improved in

a fashion that will allow it's use as an "unequivicol", outstanding, primary explosive that we can all be proud of and be able to say that it is

"absolutely reliable and useful as an initiator of secondary explosives in a firing train". |

No , I have no such confidence in DDNP even optimized

being able to compare favorably with azides , but it may be

a still usable if marginal initiator , and some of its derivatives

or composites with other materials could have usefulness .

| Quote: |

The great majority of the literature seemingly holds up DDNP in a place as high and note worthy as lead azide and mercury fuminate.

|

Yeah the literature is way wrong in its favorable comparisons about DDNP

just the same as it is wrong about HMTD , both will work as initiators ....but they both are very minimal compared to lead azide or azo-clathrates ,

or other medium to high performance initiators .

| Quote: |

By way of some of your postings in the thread "DDNP" it appears that your own conclusions about DDNP, at least in the form(s) that you were working

with, indicate that you think the literature overvalues and makes more of DDNP than DDNP really has to offer as an initiator of secondary explosives.

So do you think it can be managed to produce DDNP in a form (density) and in a fashion (unequivicality) that will rightly equate it with lead azide

and mercury fuminate as a true and undeniably reliable, initiator of secondary explosives? Or does DDNP's value lie more in some other application

than as an initiator? |

Oh it has value as an intitiator , but like I said it is more

comparable with HMTD in its power .....and no it will never

be an unequivocal primary initiatior like lead azide .....

but is a DDT initiator like lead styphnate . Even lead styphnate is an initiator if you don't mind using three grams of it in a reenforced cap , just

to get a gram of picric acid base charge going .....so you see it is the reasonable quantity minimum to surely do the job ,

which makes an initiator worthwhile . DDNP could do the job , but it would be more useful with the more sensitive base charges , where its impulse

would be sufficient so that a more reasonable minimum quantity would be required .

| Quote: |

I think the second possible method you suggested for the production of sodium monosulfide looks to have very interesting potential. Your concern for

the glassware's corruption by hot, concentrated sodium hydroxide is understandable. I'm thinking that the glass would certainly be badly frosted if

not completely cracked and destroyed. Because of this I think that the use of a steel, stainless steel, or even a copper vessel could be used with

excellent results in this procedure. The only disadvantage of using vessels of these materials is that the visual observation of the reaction is

impaired by their not being transparent. |

Yeah copper is exactly what I have been thinking about too ,

something like a small copper pot with a lid , deep enough

to put a layer of kerosene over the melt .

The molar ratio seems like it should be 8 or 9 NaOH to 3 S1 ,

perhaps even 10 to 3 , and run the reaction with supplemental heating

for at least 30 minutes , having it between perhaps 175C to 300C at the end ,

followed by a dilution and cooling to perhaps 150C when the NaHCO3 in an amount needed is added gradually to convert excess hydroxide to normal

carbonate , and precipitate Na2S . I am studying what I can find about the solubilities and cosolubilities possible in such a system to try to guess

the optimum dilution/s and filtration temperatures and sequence which should give the desired

Na2S from the unconventional mixture . If this can be done

reasonably well , then it will avoid the alternative of having

to use manganous or ferrous or zinc sulfate as a precipitant

of their insoluble monosulfides , as a precursor for an H2S

generation scheme to treat an NaOH solution and obtain

the product that way .

Reacting NaOH and sulfur does produce some of the active

reducing sulfur compounds desired , Na2S and Na2S2 are

both Zinin reagents ....but of course to get the yields of

picramic acid increased , the monosulfide is the desired product .

The minor problem is that the reaction mixture

is inclined to form a lot of higher polysulfides which are quite stable like Na2S4

....unless the reaction towards the lower sulfide is forced with excess alkali , high temperature , and reaction time , with the reactants in high

concentration .

Trying to get these atoms to jump through the hoops and

sit on their appointed stools awaiting further commands ,

does require cracking the whip for this reaction

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

A bit more complicated , but technically superior

The reaction dynamics involving the formation of Na2S

have been further reviewed and considered . I think I have

( finally ) devised the plan that should work best , a sequence which accommodates and exploits the natural tendencies of the reactions involved in

order to minimize losses , and maximize the overall economy and Na2S yield for a labscale synthesis , while bringing the reaction mixture requirements

to a milder reaction condition which shouldn't be destructive to labglass . But you don't get something for nothing , and handling a toxic H2S gas is

unavoidable for this alternate method ....the advantages otherwise however should make the extra effort worthwhile .

So here's the plan . The reaction between NaOH and Sulfur

most easily , quickly , and efficiently forms Na2S4 polysulfide by the general method of the Thiokol patent , but modified with the Dry Method

strategy for speeding the reaction with fairly high initial temperature and concentration , probably in

20 to 30 minutes the polysulfide reaction is pretty well complete . I still think that performing this reaction hot

and under a covering layer of kerosene or perhaps white mineral oil would be best .

Since the Na2S4 forms relatively easily in high yield , and without excessive alkali or other extreme conditions , then that is what we make . And we

don't even try to isolate Na2S4 after formation , but simply dilute the completed reaction mixture enough to keep it from setting up on cooling .

The proportions which would seem a good starting point

are for 6 moles NaOH , 9.4 moles S ( as S1 ) .

A quick 100ml beaker reaction exotherm melt test concerning those proportions would be on a weight basis 8 grams NaOH and 10 grams sulfur .

It is not known for certain that this polysulfide is the fastest forming polysulfide or the one which goes furthest to completion soonest . The

Thiokol patent is ambiguous about this , and only states that the polysulfides from a ranking of 2 to 5 form faster than the monosulfide , not which

of the

higher polysulfides is fastest . So Na2S2 or Na2S3 or

some intermediate mixture may prove by experiments to be

optimum . The ease of mixing and the way the melt behaves

is of some importance also , so the ratio of NaOH to S may be

varied for physical reasons , to obtain a melt which forms smoothly . The quantity of NaOH could range upwards to 16 grams per 10 grams of sulfur .

This is not critical but would only affect the time of reaction to complete , and the adjustment of stoichiometry being applied to the remainder of

the reactions , subsequent to the formation of whatever

ranking of polysulfide proves best . In some of my preliminary melt tests I found an equimolar mixture of

NaOH with Sulfur gave a smooth forming melt . So this is the one area where some tweaking of proportions and experiments would still reveal what is

the optimum ratio ,

all things being taken into account .

We generate H2S by acidifying the completed Na2S4 containing reaction mixture , by running it into a hot solution of sodium bisulfate or ammonium

bisulfate , or dilute sulfuric acid . Three quarters of the "soluble sulfur" , the 3S "polysulfide" content of the Na2S4 polysulfide , those 3

sulfurs which are in excess of the one S chemically combined S as Na2S , are simply split off and precipitated as free sulfur , when the mixture is

acidified to form H2S , but sulfur is cheap . If desired it can be settled out and filtered , recycled , but hardly worth the effort for a labscale

process .

The H2S is bubbled into an NaOH solution where it is neutralized to form Na2S as the first product , and if gassing

is continued then NaHS is the resulting solution , which can be converted back to Na2S simply by adding an equimolar

amount of NaOH to again form the neutral salt . The completion point for the NaHS formation can be detected when blowthrough causes insoluble FeS to

appear as a precipitate in a final scrubber bottle containing ferrous sulfate . When this occurs , an equal amount of NaOH

as was used to make the solution originally is added ,

and that reactor is now full of a hot solution of Na2S .

The end result of this method is pure Na2S crystals via

a process which although it is inefficient compared with

industrial methods ....is however manageable in a labglass

environment for a labscale method leading to a good yield

of the pure crystalline material desired , via a process

that is stoichiometrically predictable and should have a yield

estimated at 95% , perhaps better .

The use of tubing and stoppered bottles , anti-suckback

traps , and a final bubbler jug of NaOH or ferrous sulfate solution as a reactor half reaction completion point and blow through indicator , and final

scrubber for any excess H2S which may slip through the reactor ....would be required .

I would probably put a small forward flow of hydrogen ,

or perhaps even air through the system ....to nullify

any suck-back problems . Using small bore tubing greatly eliminates suck-back problems anyway for these sorts or

gas reactions .

This method involves no really extreme conditions or equipment requirements ,

however ...

H2S is a highly toxic and dangerous gas so that is a disadvantage and it would require careful handling ....

but otherwise this strategy is straightforward and

absolutely should work .

[Edited on 5-2-2007 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Sorry for bringing up this old thread.

Recently I tried the reduction of picric to picramic acid using polysulfide. The polysulfide was produced by the earlier mentioned dry melt of NaOH

and S, kept at 150 deg. C.for half an hour after the initial exotherm in an airtight container.

The melt was dissolved in about 8 times it's volume of water and added to a near saturated solution of sodium picrate, produced by neutralizing double

recrystalized Picric Acid with PA grade NaOH. The mixture was allowed to stand at room temperature for about 48 hours. Red crystals of sodium

picramate collected at the bottom of the beaker. The crystals were washed thouroughly using ice water and dried. I noticed a distinct sulfur smell

though, so I dissolved the crystals again in the least amount of water after which 10% HCl was added slowly to precipitate the pure picramic acid.

Now, there were several things that were unexpected:

1 The pure picramic acid collected as a fine amorphous BROWN powder, while PATR mentions a distinct RED color. Is this simply because of it beeing

amourphous? What is the colour of picramic acid from others experiences?

2 The sulfur smell still is quite noticably

In the article: "The Preferential Reduction of Nitro-groups, etc. Pavt III, J[1]. Chem. Soc., 1945, 663 - 665" They mention brown dyes, called "

sulfur dyes", as the by product of the partial reduction of Picric to Picramic acid using the sodium carbonate/sulfide process. Does anyone know what

these sulfur dyes could be and which condition favour there formation? Could this relate tot the persistent sulfur smell?

Thanks...

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

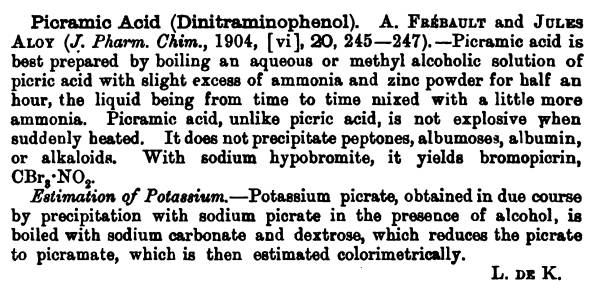

additional methods of possible interest

(1)Here is another variant on the method using H2S which I was proposing in the previous post.

See attached file.

The purification of the crude picramic acid for removal of

sulfur would be avoided entirely by a different reduction method. Ascorbic acid (sodium ascorbate)

works as a reducing agent, and reducing sugars in alkaline condition and ferrous sulfate or possible better ferrous ammonium sulfate may also work as

reducing agents, leading to a more easily purified product.

(2)Here is yet another reported method which may be done using powdered zinc to reduce ammonium picrate in H2O solution made basic with excess

ammonia. I speculate that perhaps if some ammonium nitrate is present that this may improve the reaction via formation of nascent ammonia, but this

would have to be tested by experiment. At the end of the reduction using zinc, I would expect that the reaction mixture would have to be acidified and

digested with dilute HCl or H2SO4 to decompose the zinc picramate and precipitate and isolate the free picramic acid, leaving the soluble zinc salt

and other byproducts as filterable solution. The original French pharmaceutical journal article probably has more detail on this.

[Edited on 22-2-2009 by Rosco Bodine]

Attachment: picramic acid preparation via H2S.pdf (180kB)

This file has been downloaded 1254 times

|

|

|

Axt

National Hazard

Posts: 778

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Just a couple interesting abstracts on the ascorbic acid reduction.

<b>Colorimetric determination of ascorbic acid</b>. Di Bacco, Giulio. Bollettino Chimico Farmaceutico (1953), 92 115-19.

Abstract

Dissolve 0.235 g. picramic acid in 400 cc. H2O and 25 cc. 2% NaOH. Heat and bring the cooled soln. to a vol. of 1 l. Mix 5 cc. of a soln. of

ascorbic acid contg. 1 mg. per cc. with 3 cc. 0.1% picric acid soln. and 2 cc. 2% NaOH soln. In another tube mix 8 cc. of the picramic acid soln.

with 1.8 cc. 2% NaOH soln. and 0.2 cc. H2O. Heat both tubes 3 min. at 100, cool, and compare colorimetrically. Five mg. of ascorbic acid reduces

picric acid to form 1.884 mg. picramic acid which is exactly the quantity used for comparison

<b>Ascorbic acid: a Jaffe interference</b>. Viraraghavan, Saroja. Regina, SK, Can. Bulletin of the Chemical Society of Japan

(1992), 65(4), 1101-8.

Abstract

The effects of ascorbate, the interference of the Jaffe reaction was individually studied by polarog., spectrophotometry, and TLC. Picramic acid

formed in all ascorbate:28.4 mmol dm-3 picrate test solns. which explained the obsd. pos. interference of ascorbic acid. No fluorescent product was

formed in ascorbate:picrate test solns. The reactivity of ascorbate:picrate test solns. confirmed that ascorbate was a powerful reducing agent.

2-Furaldeyde which has been listed as one of the degrdn. products of ascorbic acid, is not identified under the exptl. conditions.

[Edited on 23-2-2009 by Axt]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

amalgamated sheet zinc may possibly work

I am wondering if a variation upon the powdered zinc reduction method may work as well using amalgamated zinc sheet scavenged from an ordinary carbon

zinc battery and left in a split cylinder form standing in a beaker.

For an expedient method I was thinking this could be useful if it works and if the amalgamated zinc isn't too active a reducing agent, which it may

not be at mild temperature. The idea would be to first clean and lightly etch the sheet zinc using HCl and then amalgamate using HgCl2. The

amalgamated sheet zinc is immersed in a beaker containing a stirred solution of sodium picrate and ammonium nitrate solution is added dropwise to

accomplish the reduction.

I am proposing to use sodium picrate instead of ammonium picrate because of the much better solubility. Magnesium picrate may also work.

After the reduction is complete, the product will be a picramate salt or mixed picramate salts, sodium, zinc, ammonium, ect. and the spent reduction

mixture will need to be acidified with HCl and digested to solubilize the cations as their chlorides and precipitate the little soluble free picramic

acid which may be filtered.

With regards to the sulfide reduction schemes which have been discussed earlier there is an attached article which should be posted here with this

thread. It has also been posted in another thread in answer to a problem reported using thioacetamide in an unsuccessful attempted reduction

of sodium picrate to sodium picramate. Evidently the reduction is pH sensitive and requires an alkaline reaction condition, because the actual

reduction occurs via an alkaline sulfide intermediate formed in situ via reaction with H2S when H2S is used as the presumptive reductant.

[Edited on 22-2-2009 by Rosco Bodine]

Attachment: American_Journal_of_Science 1861 pg188.pdf (145kB)

This file has been downloaded 1149 times

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The brown sludge, presumed to be picramic acid, was diazotized using KNO2/HCl as described in literature, and yields some even darker brown stuff that

appears to be DDNP. However, the sulfur smell is still quite noticable, and I have come to believe that this is not due to additional sulfides/sulfur

or thiosulfate present as a left over impurity.

I also did a fast mg-scale experiment using ascrobic acid and some left over picric acid, to determine if the reduction to picramic works this way.

More than 15 minutes at room temperature after the addition of ascorbate gave virtually no colour change, while boiling for a couple of minutes

produced the same red colour as in the Zinin-like polysulfide reduction of PA . Upon addition of the polysulfide reagent however, the colour change

is instantly and might indicate that the ascorbate reduction may actually be more selective. I have no idea however what the colour is of the products

formed in the case of further reduction of additional nitrogroups.

More off topic:

The idea was to make DDNP using only common, store-bought stuff with some help of others their experiences and write ups, both here and on a Dutch

EM-related board, called Pyroforum.nl.

Since NaNO2 was the only chemical difficult to produce for the synthesis of DDNP I actually found a nice way to produce relatively pure NaNO2 from

common materials. It has been described in literature, though I have never seen actual descriptions and yields from this process on any

discussionboards. I had tried several other processes, such as the formation of NaNO2 by absorbing 1:1 mixtures of NO and NO2 (N2O3) in NaOH, though

NaNO3 is a major by product, presumably because of an excess NO2.

Instead I used the Pb/KNO3 or NaNO3 process:

Outside and wearing gloves, 250 grams of lead (20% excess) was melted in a stainless steel vessel after which 100 grams of KNO3 was added at once. The

mixture was stirred until all the KNO3 had melted and formed a clear layer floating on top of the molten lead. Some yellow/brown PbO started

immediately to form, however, upon prolonged heating there was little to no further formation of PbO.

I decided to heat the mixture stronger and within about 10 minutes a strong exothermic reaction became evident. In a beautifully controlled manner and

without any gas formation, the entire mixture became red hot. The mixture was well stirrable and this was done so for another couple of minutes to

ensure reaction of all the KNO3 present. (The lead has a tendancy to sink immidiately to the bottom again)

It is important to keep stirring to the point of solidification, since it makes extracting the KNO2 much easier! The mixture was ground together with

several additions of water, until all the PbO was present as a fine powder at the bottom and filtered to remove any PbO. The light yellow filtrate was

then boiled to dryness (takes long time, due to hygroscopicity) and yielded about 65-70 grams of KNO2.

Potassium plumbate is said to be one of the by products of the reaction, however addition of H2SO4 to the mother liquor prior to evaporation yielded

no visible precipitate of PbSO4 or clouding of the solution.

Upon addition of 5% HCl to the solution produces NO which is quickly further oxidized to the red NO2 when it escapes from the solution.

[Edited on by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

back on topic ....nitrites are a separate matter

and for that much other methods could be used for diazotization.... also another topic

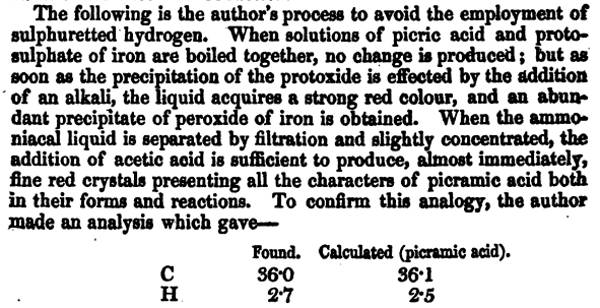

I have been looking at the early references

concerning the preparation of picramic acid from which I may post more excerpts later. Excerpt from article attached

This author, Aime Girard, named the compound picramic acid,

which had earlier been called by Wohler "reduced carbazotic acid" and had been called by Berzelius "nitrohaematic acid".

It appears the reduction is most definitely a pH sensitive reaction as observed by many researchers. In an acidic reaction system free picric acid is

reduced all the way to triaminophenol but in an alkaline reaction condition the reduction is incomplete and selective for only the one nitro group and

a picramate is the product. Even nascent hydrogen such as from electrolysis or an amalgam should

be selective for the limited reduction desired, so long as the reaction condition is kept at a basic pH. Free ammonia

either added as NH4OH or liberated in situ via an ammonium salt and an alkali would seem to me to be an applicable strategy for this reduction, though

I have not seen that specifically reported in the literature. It just seems to be a likely approach worth trying. A possible method here is using

aluminum amalgam and perhaps some ammonium nitrate or sulfate used as a source for in situ ammonia reaction byproduct to keep the reaction mixture

basic.

Ferrous sulfate , ferrous chloride, stannous chloride, cuprous chloride will effect the selective reduction ....again only in an alkaline reaction

system , a reaction mixture kept to a basic pH. The stannous and cuprous salts only act when freshly precipitated by ammonia, so it would seem it is

the nascent hydroxides which are the active reductant and this possibly also holds true for the ferrous compound.

Also according to Girard reportedly soluble picramate salts do not cause a precipitate with soluble iron salts so this may be a tool for purification,

possibly accomplishing removal of the occluded free sulfur microscopic particles or soluble sulfide impurity which seem to be a persistant

contaminant, via precipitation of the undesired sulfur values using ferrous sulfate solution to sequester the unwanted sulfur as a precipitated iron

sulfide which may be filtered from the solution of soluble picramate.

The behavior with respect to salts of manganese is the same,

also cobalt and nickel.

Ferrous sulfate itself may be used as the reductant for the

soluble picrate originally, if the reduction is carried out under alkaline condition, 6 of the Ferrous Sulfates required for the

theoretical, in the same way as are 6 Sodium Ascorbates,

for the theoretical conversion of 1 mole of alkaline picrate to 1 mole of alkaline picramate. The basic salts would most often be the sodium or

ammonium or some mixture of these, owing to the greater solubility making these convenient, but

other soluble salts may also work in a more diluted reaction system.

The residual sulfur contamination which is attendant to the polysulfide reduction could probably be minimized by very careful neutralization. There

is likely an optimum pH to which the filtered and redissolved sodium picramate can be adjusted with HCl or H2SO4 which will decompose any residual

sodium sulfide or polysulfide and the H2S driven away by boiling, and the free sulfur settled and or filtered

from the warm solution of sodium picramate, prior to further

addition of acid to precipitate the free picramic acid.

One reference to an industrial scale production reported that

the reduction was run at a pH kept *neutral* by a gradual

addition of acid and the reaction temperature regulated at 80C, and that the sodium picramate precipitated from this

Na2S reduction of an ammonium picramate slurry, precipitated as the monohydrate sodium picramate. If that report is accurate, then a buffered

reaction may also be feasible but what is the target pH desired I am not quite sure, and I am skeptical it is actually neutral pH which was being the

regulation point there in that one reference.

Anyway it is established it can't be acidic so there is possibly

a range there close to neutral which is workable, erring on the basic range is what the more numerous references would indicate. Also a cosolvent

system using methanol

and H2O for the reduction can increase yields by 10% or so

from the mid 80% to the mid 90% range.

[Edited on 27-2-2009 by Rosco Bodine]

Attachment: Pages from The Chemical Gazette, Or, Journal of Practical Chemistry, in All Its Applications to Pharmacy, Arts, and Manu (179kB)

This file has been downloaded 1326 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

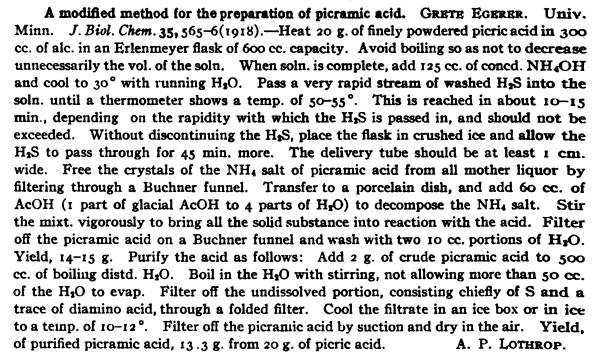

Here's an excerpt from the Egerer J. Biol. Chem. article linked five posts above, which describes H2S in reaction with an ammoniacal solution of

ammonium picrate, forming in situ the ammonium sulfide which acts as the actual reductant. Note the free sulfur byproduct mentioned as a contaminant

using this even more refined alkaline sulfide reduction method. So it would seem that given this problematic contamination with free sulfur, that

alternate methods of reduction which do not produce this contaminant as a byproduct are more interesting. This brings the entire matter full circle

back to the ferrous sulfate reduction, or possibly to alternative reduction schemes like powdered zinc or amalgamated zinc or aluminum, to be

considered as advancements over the alkaline sulfide reduction methods. Again, here the ferrous sulfate may have a value in either case, for

purification if not better for the entrie reduction.

Attached is a more extensive article by Girard

[Edited on 27-2-2009 by Rosco Bodine]

Attachment: Pages from The Chemist pg348.pdf (314kB)

This file has been downloaded 1103 times

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

In my experience, it is very difficult to get completely rid of the sulfur/polysulfides while recrystallizing picramic acid. United States Patent

6268536 describes toluene extraction of picric acid from nitration mixtures.

Any idea what the solubility of picramic acid is in toluene, or maybe DCM? Thinking OTC paintstrippers and one step purification...

else the same principle could more or less apply here as well. Couldn't find the answer in PATR, Urbanski or Google...

Thanks

[Edited on 17-8-2010 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Picramic acid is soluble in alcohol and probably in acetone.

Toluene might be a poor choice because sulfur is very soluble

in toluene. Sulfur and hot toluene is described here by garage chemist. I think later he became an ascended being

http://www.sciencemadness.org/talk/viewthread.php?tid=3902#p...

This is an area of experimentation which I intend to revisit, and explore uses of reducing agents other than polysulfides. I have read in many

different isolated references that many different reducing agents are effective in producing picramic acid via the reduction of picric acid, but more

correctly stated it is not the reduction of picric acid itself at all, but reduction of the one of picric acid nitro groups on the picric acid while

the picric acid is associated as a picrate salt in an alkaline medium. Therefore high pH is the reaction condition which determines that the

reduction will be limited to the one nitro group of a picrate, as opposed to the reduction of picric acid itself which would lead to triaminophenol as

the product

of a reduction carried out at low pH upon picric acid itself. So any reducing agent which functions in an alkaline condition should produce picramic

acid, or more correctly a picramate salt as the product of the inherently milder and limited reduction as occurs for reduction of a picrate salt at

high pH.

The operative issue then is one of clarifying the semantics that is confusing, recognizing that what is being done is not reduction of picric acid to

picramic acid as that mechanism does not occur. What may occur and what we seek is reduction of a picrate salt, typically sodium picrate, to produce

sodium picramate.

Many reducing agents should work for production of the desired picramate so long as the required pH range for the reduction of

picrate to picramate exists in the reaction mixture. Ferrous sulfate, dextrose, ascorbic acid, amalgamated zinc or aluminum, probably even iron

filings could be used.

Carefully done synthesis of DDNP under very specific reaction conditions which improve the crystalline size and bulk density of the product would

probably evidence better performance for the DDNP than is gotten generally for tests of DDNP which is of lesser purity and lower density. Quality

control can have great bearing on the product test results, particularly for materials that are sensitive to small variables.

Where the margin of acceptable performance is small for a material which is only useful in a particular form and quality, the quality control has to

be stringent, and I believe this probably applies to DDNP.

[Edited on 17-8-2010 by Rosco Bodine]

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Ammonium sulphide

Dinitroamidophenol is produced by treating an alcoholic solution

of picric acid with ammonium sulphide. The sol. is evaporated on

a water bath and the residual ammonium picrate decomposed

with nitric acid.... This substance was formerly used as a brown

dye.

Capt. Colver, &c.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

It seems likely that thiourea would also work, if sulfur being avoided for the reduction is a non-issue.

http://www.sciencemadness.org/talk/viewthread.php?tid=1255

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Regarding glucose (dextrose)...

J Clin Chem Clin Biochem. 1990 Feb;28(2):95-105.

Effect of glucose upon alkaline picrate: a Jaffé interference.

This abstract looked promising, although it seems less selective than either HS or sodium ascorbate, especially at higher glucose/TNP ratios, where

the reduction is carried further to produce 2,6-diamino-4-nitrophenol to some extend. They also mention other products formed, as well as unreacted

picrate, so I have a feeling that optimizing this one to consistently produce picramic acid in high yield may be troublesome. Still worth a try

though...(some day)

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Formaldehyde is another possibly useful reducing agent since it does work for some reactions in an alkaline reaction mixture, similarly as the

reaction condition

for Vitamin C and reducing sugars. If workable this would be a very easy and cheap route. Paraformaldehyde is depolymerized by warming with sodium

hydroxide resulting in a basic solution of formaldehyde and this could be added to a warm solution of sodium picrate. Hopefully the formaldehyde

would be oxidized to formic acid, which would remain in solution as sodium formate, and the sodium picramate would crystallize out.

A possible complication that could interfere with the desired reaction would be the potential further reaction of formaldehyde in some undesired way.

Further reaction could occur simultaneously or subsequently with the desired reduction. Interesting perhaps, as this further reaction, if it occurs,

might itself also lead to a useful but different product.

[Edited on 9-10-2010 by Rosco Bodine]

|

|

|

prometheus1970

Hazard to Others

Posts: 138

Registered: 14-4-2010

Location: San Antonio, tx.

Member Is Offline

Mood: happy/ inquisitively eager

|

|

A valdDNP synthesis?

I recently found this synth for DDNP can anyone tell me if it's viable or dookie?:

MANUFACTURE:

1. Mix in a beaker 90 ml warm water and 1.5 grams of sodium hydroxide until all

NaOH is dissolved.

2. Stir in carefully 9 grams of picric acid in the above solution. Name it solution 1.

3. In the second beaker fill 300 ml water. Stir in 7.5 grams of sulfur and 7.5 g. of

NaOH.

Boil this solution over a heating source.

After a few minutes of boiling, the solution turns red.

Allow to cool. Name it solution 2.

4. Add solution 2, under stirring, in three portions to soln. 1 and allow to cool.

5. Filter the soln. through coffee filter.

Small red crystals should form. Discard the liquid.

6. These red crystals are added to 180 ml of boiling water.

Filter hot. Discard the crystals collect in filter paper, and name the liquid soln. 3.

7. Slowly and drop by drop add conc. sulfuric acid to soln. 3 until the soln. turns

orange-brown.

8. Add to the orange-brown soln. 7.5 grams of sulfuric acid.

9. In 2nd beaker dissolve 5.4 grams of potassium or sodium nitrite in 240 ml of water.

Name it soln. 4.

10. Soln. 4 is added in one portion to soln. 3 under well stirring.

11. Let mixture sit for ca 10 minutes.

Filter the now brown solution (pure DDNP) through a paper.

The crystals left are washed with 60 ml water.

Let dry for 24 hours.

DDNP is best stored with 25% water. Load moist in detonator

Just because you're paranoid doesn't mean everybody isn't out to get you.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Pleeeeease ......not that old improvised munitions blackbook bullcrap again.

Ultra pure ghetto class Dookie is what that would be. Do some reading in this forum for awhile and figure out that a fairly comprehensive review of

literature and a fairly extensive amount of experimentation has already been done that is a whole lot blacker galactic blackbird than any black book

starling you may run across conspicuously perched on a downtown grid line. Country boys are us.

|

|

|

prometheus1970

Hazard to Others

Posts: 138

Registered: 14-4-2010

Location: San Antonio, tx.

Member Is Offline

Mood: happy/ inquisitively eager

|

|

Thanks, I suspected as much. Every other DDNP synth I've found requires first synthing picramic acid from picric, then combining the two, etc. I got

all starry-eyed when I thought maybe I could skip that extra stuff, but it looks like DDNP will remain a synth that is probably out of my reach.

Just because you're paranoid doesn't mean everybody isn't out to get you.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Shouldn't be too difficult. Now we know that the picrate salt is what is reduced

under basic conditions to a picramate, so any one of many reduction schemes would probably work to produce the picramate precursor.

Ferrous sulfate or ascorbic acid or zinc or iron are known reductants, and many other reductants should work as well. Purification of the picramate

via acid conversion to picramic acid is probably a good idea. Then it should be easy to use the improved crystal DDNP synthesis to get a useful dense

form of the pure DDNP.

Boiling a reducing agent exposes it to atmospheric oxidation and the reducing property is thereby lost. Also the method for producing a dense pure

form of DDNP is not described by that ghetto method. What is gotten following that

oversimplified method is a very impure and unuseful low density DDNP that

either won't work well or won't work at all as an initiator. That field expedient

method is at least twenty years old and it doesn't work to produce a DDNP having the desired properties.

|

|

|

prometheus1970

Hazard to Others

Posts: 138

Registered: 14-4-2010

Location: San Antonio, tx.

Member Is Offline

Mood: happy/ inquisitively eager

|

|

I just set up an account at Sigma Aldrich so that I can buy picric acid directly. That is, assuming they will ship to a residence. Maybe they'll

have picramic acid too. Although ordering both picric and picramic acid may well throw up some red flags...

Just because you're paranoid doesn't mean everybody isn't out to get you.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

| Quote: | | I just set up an account at Sigma Aldrich so that I can buy picric acid directly. That is, assuming they will ship to a residence.

|

If you can prove you have a licensed bio-lab - sure!

|

|

|

prometheus1970

Hazard to Others

Posts: 138

Registered: 14-4-2010

Location: San Antonio, tx.

Member Is Offline

Mood: happy/ inquisitively eager

|

|

Once again there go my hopes dashed upon the rocks of reality that await hungrily below the lofty cliffs of my naive optimism.

Just because you're paranoid doesn't mean everybody isn't out to get you.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Sorry to say, but I have the feeling that nothing about the synthesis of DDNP is easy when OTC materials are used. I think finding an OTC way of

producing pure sodium (hydro) sulfate is indeed the way to go!

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Try Aldrich anyway - you might get lucky if you put a good cover-story together.

Tell them you're doing bacteriological studies and need a saturated picric acid solution.

|

|

|

| Pages:

1

2

3

4

5

6

..

10 |