| Pages:

1

2

3

4

..

33 |

dave321

Harmless

Posts: 45

Registered: 22-11-2012

Member Is Offline

Mood: No Mood

|

|

you appear to have got a nice product.

I think the main problems people have are with the preparation of the picramic acid.

could you post the actual process you used and quantities of reagents.

also what reducing agent did you use (again amounts would be useful).

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

DDNP improved density crystals

Here is a possible file of interest from Blaster, et al

An alternative approach is also attached

US2408059 crystallization modifiers

Attachment: DDNP improved crystals.pdf (101kB)

This file has been downloaded 1828 times

Attachment: US2408059 crystallization modifiers.pdf (367kB)

This file has been downloaded 1605 times

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Quote: Originally posted by dave321  | you appear to have got a nice product.

I think the main problems people have are with the preparation of the picramic acid.

could you post the actual process you used and quantities of reagents.

also what reducing agent did you use (again amounts would be useful). |

https://www.sciencemadness.org/whisper/viewthread.php?tid=43...

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thanks for the files Rosco. His materials do look different than mine, but color etc can vary from what I have read. I have a controlled evaporative

recrystallization experiment on the go right now. Acetone is being used as the solvent and the solution was placed in a little glass bowl covered in

aluminum foil with a couple small holes in it. I am hoping it produces nice crystals.

The importance of free flowing crystals is clearly important from a commercial prospective, since it makes the material so much easier to handle and

load. I wonder how important it really is to the hobbyist however.

[Edited on 29-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

According to Rosco on the other DDNP thread, the free flowing character is necessary to enable self confinement of the material in a cap that doesn't

have special confinement, only pressing. I think for the hobbyist less grit could be used but you'll want a confining cap.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

You will see a difference as improved performance for the increased density variety. For a material where the performance is marginal it makes a

practical difference for which form will be found useful.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I tend to believe you, that larger well defined crystals giving a higher density product will perform better, since you usually have the right idea

about these sorts of things. I was originally thinking that as long as the less dense material was pressed to a high density in a cap that it would

perform well. I don't completely understand it, but it does seem logical that a higher bulk density of the loose material would be advantageous from a

performance perspective.

Regarding evaporative recrystallization, after a couple hours of waiting, the level of the solution was not dropping at all so I poked more holes in

the aluminum foil covering the small glass dish. It has been about 16 hours now since I poked all the holes in the aluminum cover and there is still

about 5 mL or so of the 22 mL of acetone remaining. Ambient temperature is, and has been, about 20C.

[Edited on 30-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The perforated aluminum cover was taken off the evaporating dish at about the 18 hour mark. There was still 1 or 2 mL of acetone left. Water was added

to precipitate any remaining DDNP (no more seemed to precipitate) and wash the crystals. After filtering, the filtrate was very red (which I forgot to

get a picture of). Yield from the recrystallization was about 95%. A more accurate value for yield could not be determined with the scales available

to me at the moment. A small amount of material was not recovered from the sides of the evaporating dish, so the yield was likely closer to 97-98%.

The density has been increased immensely. Dark brown tabular crystals formed on the walls of the dish, which had largely fused together by the end of

the evaporation. A small amount of lighter brown/yellow material was at the bottom of the dish, in the 1 or 2 mL of acetone, and looked to be cubic

crystals.

The density difference really is amazing. The second picture is of the damp, high density, material right after being removed from the evaporating

dish. The third picture shows one gram of unrecrystallized material on the left and one gram of recrystallized material on the right.

Contrary to my earlier perception, it seems that this method does also purify the DDNP. Yield is also obviously very good with this type of

recrystallization. Yield would be 100% (all solute recovered) if all the solvent had been evaporated. I believe some impurity was removed by adding

water before the last bit of acetone had evaporated, however, given the appearance of the filtrate.

I think that little bit of lighter brown material sitting on the bottom of the evaporating dish was probably the result of my not being careful enough

to ensure that absolutely all of the low density crude DDNP had dissolved before putting on the aluminum cover. Next time I will be a little more

careful to verify that all material has dissolved.

[Edited on 30-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

dave321

Harmless

Posts: 45

Registered: 22-11-2012

Member Is Offline

Mood: No Mood

|

|

you could make some nice lead free bullet hits with that material

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I guess you could. I am hoping that it will also be a good initiator of secondary explosives. I am quite sure that lead azide is still higher

performance and a more practical primary, in general, but it is still interesting to experiment with others.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

DDNP Testing

Test 1:

Cap:

0.5 g PETN base charge

0.2 g DDNP primary (high density material from evaporative recrystallization)

~0.05-0.1 g basic lead picrate as flash igniter

Witness Plate Thickness:

40 thousands of an inch (~1 mm) steel plate (painted green)

A cap was made using 3/16” id aluminum tubing with about 25-27 thousands of an inch wall thickness. The PETN base charge was pressed to 1.45 - 1.5

g/cc by hand with a small wooden rod. The DDNP was pressed with approximately the same pressure as was used to press the PETN. The basic lead picrate

was very lightly pressed.

In test 1 the 0.2 g of DDNP failed to initiate the PETN base charge. A picture of the witness plate after the first test can be seen with only a

slight bend in it. It appears as though the bend is from the DDNP and basic lead picrate detonation.

Test 2:

Cap:

0.5 g PETN base charge

0.4 g DDNP primary (high density material from evaporative recrystallization)

~0.05-0.1 g basic lead picrate as flash igniter

Witness Plate Thickness:

40 thousands of an inch (~1 mm) steel plate (painted green)

The cap was made from the same materials as was used in test 1 and loaded in the same way as in test 1. The PETN base charge was successfully

detonated this time. The 2 pictures of the hole blown through the witness plate are from test 2.

DDNP definitely doesn't detonate easily in small quantities, without confinement, the way lead azide does. So far DDNP isn't looking any better than

mercury fulminate. The literature says that it is, however it also states that significant confinement is needed for DDNP to function at high

performance. It is possible I need to learn how to work with it, and design caps a little differently when DDNP is used. I am pretty sure at this

point that initiating picric acid with DDNP would be quite difficult the way I presently design and load my caps. It could be though that once over a

certain minimum quantity of DDNP is used that it works great (I don't know). It would make sense that DDNP would require more charge weight (column

height/length), than lead azide, to get up to speed.

[Edited on 30-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

3/16" ID for the cap is a critical diameter concern IMO for efficient DDT of the DDNP. 5/16" ID would be better or in actuality even 3/8" would be

less critical for improvised detonators. Reasonable expectation for an improvised detonator is that it won't be achieved even nearly close to the

economy of usage of materials as is achieved in the highly refined commercial detonators where everything about the configuration is optimized for

economy of materials, and still have a reliable configuration for the improvised detonator. Using cheap materials it doesn't matter that limitation

applies, to compensate it is easiest to simply increase the dimensions of the device beyond that used for commercial detonators and the improvised cap

will not be so picky about the grit size of crystals and loading pressures and confinement but will be subject to a more generalized scheme where the

desired effect occurs simply as a result of the ordinary and not so highly optimized performance of the materials.

Economy and miniaturization are achieved only for a highly engineered and highly refined configuration derived from a great many tests. DDNP is a

confinement sensitive primary having a DDT behavior similar to HMTD where

it will get the job done of pregressing from ignition to high order detonation but requires confinement and a generous amount of material to be there

which is consumed during the run up where accelleration from ignition through low order detonation and progressing to high order detonation is

occurring. The material has to reach high order detonation with sufficient mass remaining which will high order detonate to deliver the required

initiatory impulse to the target base charge. So most of the initiator is burned as kindling for the fire that is the high order detonation. A

larger diameter column geometrically increases the quantity of materials present but greatly decreases the linear distance for the run up

accelleration when near the critical diameter, and improves the intensity of the impulse when the transition to high order occurs. There is a kind of

"sweet spot" diameter range for unreenforced detonators using low sensitivity base charges like picric acid that is about 9mm or 3/8" and that

diameter lowers for more highly sensitive base charges to 6mm or 1/4" for unreenforced detonators.

Depending upon the combination of materials chosen it is predictable that the device ID dimension will commonly be found in that range for a practical

device of an improvised nature that is not a highly developed and highly engineered commercial design. This is a kind of general parameter and will

not hold true for the exception when exotic materials being deliberately used may offset the usual limitations. It is especially challenging to make

improvised detonators that are reliable and have good performance and at the same time are physically small in dimensions. Of course it is possible to

do, but for that to be accomplished requires the same precision about every component involved to be duplicated as would be done by a licensed

commercial manufacturer and that level of involvement with production ventures into an area of formalities and legal concerns where various licensing

and regulation issues could arise as concerns beyond the science and engineering as would be the attention of a usual inventor or experimenter.

Another test which might be worthwhile, would be to increase ID to 5/16" and use a quarter gram basic lead picrate as a loose charge atop the DDNP

having been just lightly pressed. The basic lead picrate will low order as a flash charge and will self compress in situ the increments below as the

sequence is occurring.

[Edited on 30-1-2014 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I have always wanted to make small detonators, but yeah I think your right I may have gone too small in this case. I have used these same casings

though with PETN and lead azide for initiating plastic explosives, but DDNP is different than lead azide as I am finding out more and more.

Rosco, something else that was really interesting was the color change of the DDNP going from low density material to high density material. From

evaporative recrystallization the DDNP went from a yellow/brown type color to a much darker brown. When I pressed the DDNP some of it got crushed up a

bit and became lighter colored again. When I looked in the cap, after pressing some DDNP, there was a mix of dark bits and lighter crushed bits. This

really drove home that concept, from the azo-chlathrate thread, where the color of basic lead picrate depends on the density and crystal size.

[Edited on 30-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There are several primary explosives which can be good initiators only under rigidly specific conditions of diameter and confinement because they lack

self accelleration. A property about primary explosives exists where even the tiniest crystal or a very few crystals of a few milligrams "critical

mass" will self confine and high order detonate with brisance almost instantly when touched by a glowing splint. I call the property of primary

explosives like silver fulminate which exhibit that property as being "unequivocal" primary explosives, and you can sort primary explosives into 2

general groups, those that are unequivocal primary explosives and those that are not. DDNP is not an unequivocal primary explosive, but lead azide

is. And the property has nothing to do with the ultimate power output possible because in this case the DDNP wins, that is DDNP is ultimately "more

powerful" than lead azide once it gets going, but that is the problem you see, the conditonal or equivocation involved in "getting it going" from

ignition through DDT to high order. Lead styphnate behaves similarly and is "more powerful" than lead azide but is a worse initiator because of its

low self accelleration. However, mixed with lead azide 60/40 the mixture is more powerful than lead azide alone because the lead azide has a

synergistic effect and kicks the lead styphnate as a homogenous booster. A similar effect is likely for DDNP in admixture with an unequivocal primary

explosive. A parallel effect should occur if a sensitive secondary explosive given easily to "cook off" like ETN is grained with the DDNP which acts

as a flash charge to thermally shock the sensitive nitroester and then together a faster DDT and high order detonation.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I do understand the concept and you have worded it well. I don't know how to quantify it exactly at the moment, but DDNP seems to be somewhere half

way between lead azide and lead styphnate in terms of unequivocality. I would really like to know how the military and industrial people design their

DDNP caps.

According to TM 9-1300-214 “Military Explosives”, “an unconfined sample (of DDNP) burns with a flash if ignited but even the slightest

confinement causes a transition from burning to detonation. A charge of DDNP undergoes detonation when ignited if pressed into a blasting cap shell

with a reinforcing cap and a piece of black powder safety fuse crimped in the shell. A spark falling into the open end of such a blasting cap causes

only ignition and flashing of the DDNP.”

Those caps I made, from the above picture, were only sealed with a bit of hot melt glue at the fuse end and the cap was not reinforced. I think I can

come up with something much better. I haven’t given up on DDNP yet.

Also from “Military Explosives”, “the sand test indicates DDNP is a better initiator of detonation than mercury fulminate or lead azide for less

sensitive high explosives. The most marked evidence of this is the ability of DDNP to initiate the detonation of ammonium picrate and cast TNT. For

initiation of more sensitive high explosives, DDNP is not superior to lead azide.”

Also from “Military Explosives”, “when subjected to the sand test with ignition by a black powder fuse, the brisance of normal lead styphnate

(10.5 grams of sand crushed) is much less than that of lead azide (16.7 grams of sand crushed). “ The grade of DDNP used for military purposes,

specs taken from the same text, shall crush not less than 33 grams of sand in the sand test.

The more I read about it, DDNP sounds like it would be a great initiator for picric acid and other insensitive secondary explosives.

BTW, that Chinese primary explosive presentation, linked to in the "picramic acid from picric" thread, suggested 6mm casings be used for DDNP. It

looked like 6mm was recommended for all the primary explosive examples, but it still says something about suitable casing diameters for DDNP (I

think).

[Edited on 31-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Reinforced Detonator

I attempted to improve my DDNP detonator design today and detonate some picric acid. A reinforced detonator was constructed. Aluminum round stock was

going to be used to make the reinforced cap or insert, but was not readily available so carbon steel round stock was used instead. The outer casing

was made from a piece of aluminum arrow, with inside diameter just shy of 5/16". The inner reinforced cap/insert was turned on a lathe, from 5/16"

carbon steel round stock. It was sized so that it would fit snugly inside the outer casing and would need to be pressed into place. The reinforced

cap/insert was drilled out for 1/4" and a 1/16" hole drilled in its end as a flash hole to except fire from the fuse or igniter. Four inserts were

made, each taking about a half an hour to make.

Test

Base charge: 2.2 g picric acid from ASA (melting point indicated at least 98% pure)

Primary: 0.5 g DDNP recrystallized by evaporation

Flash igniter: 0.2 g basic lead picrate

Cap outer dimensions:

Length: 6 cm

Diameter: 9 mm

The flash igniter follow by the DDNP were pressed into the reinforced cap/insert. The picric acid was pressed into the outer cap casing (aluminum

arrow piece). About 0.2-0.3 g of picric acid was poured in last and the steel insert containing the primaries pressed firmly on top. A little black

powder was put in last follow by a fuse and a little hot melt glue as usual.

Witness plates:

base: 1/8" steel

side: 40 thousands of an inch steel

The DDNP reinforced cap failed to detonate the picric acid, which sort of surprised me. I was really expecting this to work.

The bottom half of the picric acid base charge was recovered with the picric acid still in place in the casing (about 1 g).

[Edited on 31-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The reinforced detonator description I used to help guide the design of my own came from an old technical paper put out by the bureau of mines called

"The Sand Test For Determining The Strength Of Detonators" by C.G. Storm & W.C. Cope 1916. I have attached a pdf of the 3 pages describing

construction of reinforced detonators.

Attachment: Reinforced Detonator Construction.PDF (971kB)

This file has been downloaded 1535 times

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

You don't happen to have some ETN laying around to throw in the mix.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I do where I will be in a couple of days, but I don't today. Yeah, that might be a good idea and it has been suggested a couple times in the last

couple of days. I would really like to get some inside information regarding DDNP from the people who work with the stuff for the military and

industry, but that isn't likely to happen. I doubt they are mixing it with ETN, though that doesn't mean that it's necessarily a bad idea.

If I had used the same amount of lead azide in place of the DDNP (0.5 g), in the above cap and in an unreinforced configuration, the picric acid would

have detonated. I have verified this several times before.

[Edited on 31-1-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

This patent may provide some insight

GB572729 Improvements in or relating to blasting and like detonators

Attachment: GB572729 DDNP mesh size for DDT.pdf (669kB)

This file has been downloaded 1559 times

[Edited on 1-2-2014 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Good point, I was thinking that the material I was using was very coarse, but I was unsure of how much difference it made. I read the following a

while ago from "Military Explosives", but like I said I wasn't sure how important it was. The bolding was done by me.

"One grade of DDNP is used for military purposes:

Color: greenish yellow to brown.

Form: Tabular crystals having a maximum length of 0.2 mm.

Granulation: 100% shall pass through a No. 100 US standard sieve.

Bulk density: Minimum, 0.4 grams per milliliter.

Acidity: Maximum, 0.01 percent as hydrochloric acid.

Sand test: 0.40 gram shall crush not less than 33 grams of sand."

Particle size is likely very important, among other things.

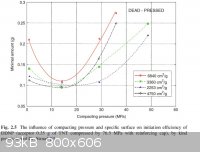

Edit: DDNP Dead Pressing

I have done a little more investigating and DDNP can also be dead pressed quite easily which is almost a non-issue with lead azide. I did a few

calculations and tests on my loading apparatus and found that I was putting close to 30 MPa of pressure on the DDNP when loading it. This is far too

much pressure for best results. Dead pressing, at the very least, results in more DDNP being required to do the same job as a lesser amount that is

properly pressed. I have attached a jpg of a graph taken from chapter 2 of "Primary Explosives" by Matyas, which shows how loading pressure and

specific surface (surface area per unit mass) effect DDNP initiating efficiency.

A picture is also shown of my loading press, which is basically just a class 2 lever. I did the calculations for a class 2 lever but I was still a

little unsure of how much force I was actually applying to the end of the lever. A test was done where an old set of bathroom scales was put at

approximately the location the cap normally would be during pressing and applied pressure in approximately the same way as I normally do. The results

were amazing, for a 1/4" dowel I was easily applying 30 MPa of pressure to the DDNP. A solution to this would be to determine the desired loading

pressure and then hang a weight from the end of the lever which would produce that desired pressure. This would be much better than guessing. I got

away with guessing with lead azide, because lead azide can handle a much broader range of loading pressures with much less effect on performance.

Formula for class 2 lever:

Fc = Fl * (Lt/Lf)

Where:

Fc = Force on cap loading dowel

Fl = Force applied to end of lever

Lt = Total lever length (from fulcrum(hinge point) to other end where pressure is applied)

Lf = Distance from fulcrum to loading dowel

Loading Pressure is, of course, the force applied to the loading dowel divided by the cross sectional area of the dowel.

The complete second chapter of "Primary Explosives" by Matyas is also attached, as it has some very good information in it that I am still digesting.

I am also trying agitated evaporative recrystallization at the moment. A picture is attached of a small homemade stirrer being used to stir the

evaporating DDNP in acetone solution.

Attachment: Primary Explosives Chapter 2 - Matyas.pdf (1MB)

This file has been downloaded 1721 times

[Edited on 2-2-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

DDNP Test Again

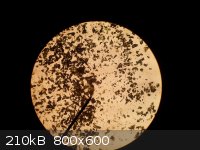

The crystals obtained from the agitated (stirred) evaporative recrystallization were nicely formed and about the size and colour specified as military

grade in the text "Military Explosives". A reinforced cap was made with the same dimensions as the one in the previous test, but this time with the

new fine crystals of DDNP and pressed with much less force. Using the above graph taken from the text "Primary Explosives" as a guide, a loading

pressure of 14 MPa was chosen. The 14 MPa loading pressure corresponds to about 100 lbs of force on the 1/4" loading dowel. Bathroom scales were set

on the loading press, under the loading jig, in order to determine when 100 lbs of force was applied to the loading dowel. As before 0.2 g of basic

lead picrate, 0.5 g DDNP and 2.2 g of picric acid was used.

The explosive test was another failure. A big dent in the green side witness plate indicated that the DDNP had detonated, but the picric acid primary

did not. The surrounding snow is now very yellow. In the near future I will try a full gram of DDNP in a reinforced cap with picric acid as the base

charge. I have been experimenting with this compound almost every day for the last two and a half weeks. I am about to give DDNP the finger.

A few pictures of the recrystallized DDNP and the explosive test are attached. The microscope picture is the DDNP at 100X magnification.

[Edited on 2-2-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

But you got the DDNP to detonate... are you just hoping for a simple detonator over one with a booster. Isn't picric acid a little insensitive for

detonation. The Clark journal article about DDNP shows picric acid between tetryl and TNT for sensitivity to a DDNP cap. Could the picric acid be in

an non-optimal state? Rosco mentioned a 50/50 mix with DDNP that could be suitable as a booster (http://www.sciencemadness.org/talk/viewthread.php?tid=433&am...), both sensitive and brisant.

Off topic, but what did you use to close the bottom of the AL tube you've been using for the cap?

[Edited on 3-2-2014 by roXefeller]

|

|

|

Ral123

National Hazard

Posts: 735

Registered: 31-12-2011

Member Is Offline

Mood: No Mood

|

|

Thanks for that nice pdf Hennig Brand. I test my materials with a straw test. Can it be set off(with fuze and or AP/LA) in a straw and detonate all

the way. TNP didn't go off in a straw with AP, but it did go off with LA/Tetryl and detonated all the way in that straw.

Will the confinement of a straw be enough for the DDNP to detonate? If not, may be it's useful at 2g+ with the basecharge optional

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by roXefeller  | But you got the DDNP to detonate... are you just hoping for a simple detonator over one with a booster. Isn't picric acid a little insensitive for

detonation. The Clark journal article about DDNP shows picric acid between tetryl and TNT for sensitivity to a DDNP cap. Could the picric acid be in

an non-optimal state? Rosco mentioned a 50/50 mix with DDNP that could be suitable as a booster (http://www.sciencemadness.org/talk/viewthread.php?tid=433&am...), both sensitive and brisant.

Off topic, but what did you use to close the bottom of the AL tube you've been using for the cap?

|

The DDNP is definitely detonating, but it just isn't giving the picric acid the kick it needs. What is the optimal state for picric acid when

functioning as a base charge? I think this would mean pressed to not too high a density and finer crystals also maybe. For this last test I crushed up

my large picric acid crystals, from the above picture, to make the material finer before loading. The picric acid was put in a fold of printer paper

and the back of a spoon was run over it a few times, with pressure, to crush the large crystals.

The idea of DDNP mixed with TNP may be a good one. I wonder if having a base of picric acid followed by a mixture of picric acid and DDNP followed by

pure DDNP on top would be a good configuration. If you wanted to get fancy, the mixed DDNP-picric acid section could incrementally increase in

proportion of DDNP until the top where there would be pure DDNP.

A disc of aluminum cut from the top of a beer can was used to seal the cap bottom end. It doesn't matter how the end is sealed much anyway, in this

case, given the amount of compacted TNP pressed in on top which seals in the material above it quite well and provides confinement.

I made another 4 carbon steel reinforcing caps/inserts, so I still have six left. I will do another couple tests in the next while.

@Ral123

No problem, glad to help other experimenters.

This same picric acid has been detonated in the aluminum arrow tubing, several times, using 0.4-0.6g of lead azide.

Yeah, the DDNP might do well on it's own in 1 or 2 gram quantities in a cap without a base charge. According to the literature it has performance more

similar to base charge material than primary explosive material anyway. A couple grams (or less) of pure DDNP might initiate a main charge of picric

acid or TNT just fine.

[Edited on 3-2-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

| Pages:

1

2

3

4

..

33 |