| Pages:

1

2 |

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

What about "glassy" carbon as an anode material in a chlorate or perchlorate cell?

I haven't seen this material discussed here before for this potential usage.

According to the abstract of US patent #4,802,959:

"Peroxydisulfuric acid and its salts are produced electrochemically from an aqueous acid sulfate solution using a glassy carbon anode in the

presence of fluoride ions dissolved in the anolyte. A low cost alternative to platinum is provided and high current efficiencies are obtained".

Apparently the inventors feel it is an improvement over lead dioxide (at least for making persulfates):

"Attempts have been made to use cheaper materials to substitute for the expensive platinum anodes. Beta-lead dioxide and various

dimensionally-stable anodes have been tested but none exhibited standtime under the extreme conditions of persulfate electrosynthesis".

The question is, what about for making chlorates and or perchlorates...has anyone tried it?

|

|

|

Esplosivo

Hazard to Others

Posts: 491

Registered: 7-2-2004

Location: Mediterranean

Member Is Offline

Mood: Quantized

|

|

My question may sound stupid, but what is 'glassy' carbon?

Theory guides, experiment decides.

|

|

|

MadHatter

International Hazard

Posts: 1332

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Glassy carbon

Found this using google:

"Glassy carbon is a composite consisting of amorphous carbon

and one or more additional materials that possesses unique

properties and chracteristics. Glassy carbon is formed

by carbonizing phenolic resins which are made by reacting

phenols with cellulosics, aldehydes and ketones (that is

special organic carbons).

It is a kind of synthetic polymer of carbon. that can substitute

graphite as an electrode.

Different electrodes have different usages, that define the

applications. Some glassy carbon electrodes have gold and platinum

deposits, combining both types."

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

So essentially making Bakelite in the shape you want your electrode, then going at it with a blowtorch until it is all carbon? Sounds too easy...

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Yet Another Related Idea

Supposedly electrolysis of methanol using high voltage can produce a marginal quality diamond-like carbon film on an immersed substrate. If I remember

correctly, the films are "defective" enough that they conduct electricity.

I wonder what effect, if any, such a thin DLC coating would have on a carbon anode in a chlorate cell? Maybe it would last longer?

Attached is a paper re electrolysis of methanolbject, in case anyone is interested in this.

Attachment: Electrolysis of Methanol.pdf (132kB)

This file has been downloaded 1441 times

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Rogue Chemist, as far as I know, phenolic resins are pretty much bakelite. I searched for a long time for phenolic resins used for high temperature

crucibles, but didn't find much, only that there are 2 kinds; resols and novolacs. The difference has to do with whether an alkaline or acidic

catalyst is used, and each has different curing properties, but that's all I remember.

If anyone can figure out a OTC way to produce these resins, I'd be really happy, because glassy carbon is VERY useful for refractory

compositions, crucibles, and other high temperature stuff. Apparently glassy carbon used to be made from pitch or tar, but the yields were lower than

phenolic resin, only 15% or so of the carbon in the pitch remains, as opposed to 30% in phenolic resins, IIRC.

I'm not sure where to obtain pitch. But in any case you would definitely want to heat it in a neutral or reducing atmosphere to prevent it

oxidizing away from nothing.

BTW, I recently fired all those lead dioxide ceramic substrates, and got some nitric acid for free, so I'll begin testing lead dioxide anodes

soon.

Cyrus

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

BTW I found a usenet discussion where someone stated that glassy carbon can be used for ClO4 production:

http://groups.google.com/group/rec.pyrotechnics/browse_frm/t...

Now my question is, where can glassy carbon rods or plates be gotten cheaply?

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

As I hinted at above, you may want to try heating tar in a reducing atmosphere until it decomposes completely.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

For right now I would just like to buy a glassy carbon rod to experiment with. (Especially since I don't have access to a vacuum or controlled

atmosphere furnace). Unfortunately though, it seems glassy carbon products are hard to find and very expensive.

|

|

|

Twospoons

International Hazard

Posts: 1280

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

I was thinking a boron / nitrogen doped diamond film could be good for perchlorate. I remember reading somewhere that the oxygen overpotential is

higher than platinum. Diamond film production in the garage looks do-able - its only a mix of hydrogen, methane, sometimes CO2 or H2O, at moderate

pressures with a tungsten filament.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Hello Twospoons,

From what I've been reading, conductive diamond film coated electrodes would really be the "cat's ass", so-to-speak.

As I mentioned in an earlier post, it seems possible to coat conductors with a diamond-like film by high voltage electrolysis of methanol.

I wonder if adding a little boric acid to the methanol might incorporate some boron into the film? (If only I had a place to work, I would try it

today).

Anyway, I'm attaching another paper on the subject.

Attachment: Electrolysis of Methanol_2.pdf (531kB)

This file has been downloaded 1439 times

|

|

|

10fingers2eyes

Harmless

Posts: 10

Registered: 26-6-2016

Member Is Offline

Mood: No Mood

|

|

Thought I'd add this link to this paper as it is related. Someone electroplating DLC from Acetonitrile.

http://www.sciencedirect.com/science/article/pii/S0169433212...

|

|

|

ficolas

Hazard to Others

Posts: 146

Registered: 14-5-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Cyrus  |

If anyone can figure out a OTC way to produce these resins, I'd be really happy, because glassy carbon is VERY useful for refractory compositions,

crucibles, and other high temperature stuff. Apparently glassy carbon used to be made from pitch or tar, but the yields were lower than phenolic

resin, only 15% or so of the carbon in the pitch remains, as opposed to 30% in phenolic resins, IIRC.

I'm not sure where to obtain pitch. But in any case you would definitely want to heat it in a neutral or reducing atmosphere to prevent it oxidizing

away from nothing

Cyrus |

This may be a dumb question but... why don't you just use an old something (like cuterly) made out of bakelite, cut it the way you need it and then

blowtorch it? Would it not be pure enough?

Its definitelly easier than getting phenol and formaldehide, and less messy.

For the pitch, maybe you can get some big cans and a good fire, and try to perform a dry distillation of wood to get it?

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by jpsmith123  | Hello Twospoons,

From what I've been reading, conductive diamond film coated electrodes would really be the "cat's ass", so-to-speak.

As I mentioned in an earlier post, it seems possible to coat conductors with a diamond-like film by high voltage electrolysis of methanol.

I wonder if adding a little boric acid to the methanol might incorporate some boron into the film? (If only I had a place to work, I would try it

today).

Anyway, I'm attaching another paper on the subject. |

Wow I surprised methanol can be electrolysed and even more surprised it deposits carbon. Perhaps with 1.5kV surprising things happen though I suspect

that's required to get the current thru the methanol. I will try it today.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

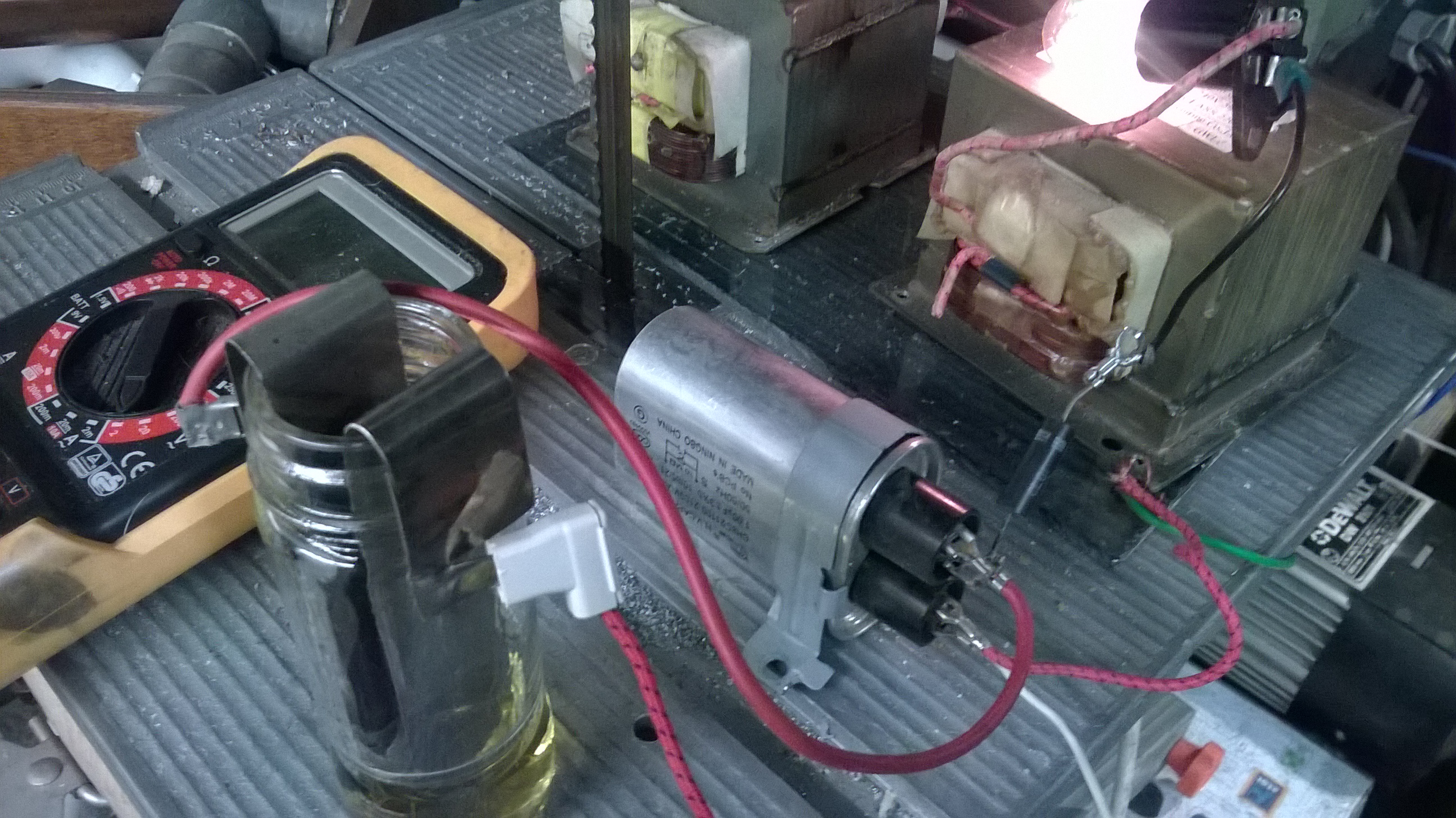

So I have given the electrolysis methanol a crude try.

Two nickel plated sheet steel electrodes approximately 20mm x 10mm area in the methanol separated by approximately 10mm.

Voltage estimated at 1.4kV from the half wave rectified output of a mot ballasted by a similar mot.

The crude arrangement is shown below.

Approximately 1mA passed between the electrodes and after 5 minutes the container was hot to the touch and the methanol had a light yellow color. No

gas bubbles were noticble and both electrodes appeared unchanged. A few minutes after that bubbles rose from one corner of the anode and a

condensation edge was see above the methanol. I assume the methanol was boiling.

The methanol is supposed to be 99.95% I need to check how dry it was. To allow a longer test I will need cooling or reflux.

The light bulb is a fuse and visual current monitor because its in series with the diode its rms current is much higher than the dc flowing between

the electrodes .

[Edited on 3-7-2016 by wg48]

[Edited on 3-7-2016 by wg48]

|

|

|

macckone

International Hazard

Posts: 2159

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

If your methanol isn't dry you can electrolyze it at a much lower voltage until current goes to close to zero then swap out the electrodes for you

desired substrate. Water is easier to electrolyze than methanol. This method can also be used to dry ethanol.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Here's a paper describing the electrodeposition of both nitrogen-doped and boron-doped DLC (the latter from a methanol-camphor-boric acid solution).

Attachment: AMPC_2013032716565756.pdf (950kB)

This file has been downloaded 636 times

|

|

|

Twospoons

International Hazard

Posts: 1280

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Great find! Thanks for posting that paper.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Yes thats an interesting paper. In particular how a none conductive substrate can be coated.

It gives more details of the set up than the previous paper such as the voltage and current. Unfortunately it does not give any details on how dry the

methanol needs to be.

I am suspicious about the current.for example 500mA at 1000V would dissipate 500W in the set up and almost certainly boil one liter of electrolyte

(its mostly methanol) vigorously in minutes. Given that the duration of each experiment was 40 minutes I would assume cooling would be required, but

that is not mentioned in the procedure. At least reflux would be required to avoid loss of the methanol. The 350K (76.9C) for all experiments looks

odd as methanol boils at 64.7C.

The deposition rate is slow 1um/40 minutes compared to even electroless nickel which is in the 20um/h range.

I will have to try this with a glass slide. It may be a simple method of putting a conductive coating on glass.

Her is a link to a paper from the same authors on depositing carbon nitride using methanol and urea.

https://www.researchgate.net/publication/260553071_Synthesis...

[Edited on 31-8-2016 by wg48]

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Just thinking out loud, one of my ideas was to use the method described in this paper (possibly with greater boron doping than what the authors used)

to put a conductive DLC layer over platinum, for example. Maybe a conductive-DLC coated platinum anode could be used to go directly from chloride to

perchlorate without touching the platinum surface.

On its face this process seems simple and inexpensive enough that you could treat the anode to another coating after every couple of runs if need be.

|

|

|

yobbo II

National Hazard

Posts: 709

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

The paper gives values of conductivity for films that range from about -10 to -22 of the In of conductivity (-10 to -22 the natural log of

conductivity) which is about 4.5 x 10^-5 and 2.8 x 10^-10.

But it does not state what are the units of this conductivity. Are they Ohm cm or Ohm meters or or mho's per meter or what? Conductivity is usually

quoted in Siemens per meter.

What do the values equate to in resistivity values. You would like something in the region of 5 x 10^-3 Ohm cm (less would do) for a nice low

voltage drop across the coating.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by yobbo II  |

The paper gives values of conductivity for films that range from about -10 to -22 of the In of conductivity (-10 to -22 the natural log of

conductivity) which is about 4.5 x 10^-5 and 2.8 x 10^-10.

But it does not state what are the units of this conductivity. Are they Ohm cm or Ohm meters or or mho's per meter or what? Conductivity is usually

quoted in Siemens per meter.

What do the values equate to in resistivity values. You would like something in the region of 5 x 10^-3 Ohm cm (less would do) for a nice low

voltage drop across the coating.

|

The paper on the doped films in its abstract states this "Electrical resistivity at room

temperature was reduced by the doping effect, from 109 Ω-cm for undoped films to 107 Ω-cm for nitrogen doped films

and 108 Ω-cm for boron doped films"

The numbers after the ten are powers of the ten.

[Edited on 1-9-2016 by wg48]

Thinking about that level of resistivity for the undoped film its an insulator, not a very good one. So I guess it is more like diamond than

graphite.

Even at 1um thickness the resistivity of the doped film would limited its usfullness as an electrode coating.

[Edited on 1-9-2016 by wg48]

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

I would think that the conductivity of the DLC coating could be increased - to a certain extent at least - by simply adding some more boric acid to

the solution. And then maybe by watching the current vs time (during the electrodeposition process) you can get an idea if it's working.

|

|

|

Twospoons

International Hazard

Posts: 1280

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

10^7 Ω-cm isn't disastrous. A 10cm^2 electrode with a 1um coating is just 10 ohms additional resistance in the circuit. It really just means making

larger area electrodes.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Twospoons  | | 10^7 Ω-cm isn't disastrous. A 10cm^2 electrode with a 1um coating is just 10 ohms additional resistance in the circuit. It really just means making

larger area electrodes. |

I was thinking that a minimum of several A/cm^2 was used. However I did find one reference for chlorate production that suggested a minimum of

0.05A/cm (5A/decimeter) so your correct for a 1um coating.

Now if the attrition rate was such that only a 1um coating was required.

|

|

|

| Pages:

1

2 |