| Pages:

1

2 |

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Filling gas flasks at home using a fridge compressor

I bought a very old and quite large fridge compressor which originally ran with R12 (CF2Cl2).

I wanted to know how much pressure this thing can develop.

With some hard solder, copper pressure piping, a 60 bar manometer and some bought parts I threw together an adapter that allows the pressurizing of

common gas flasks and displays the current pressure.

I turned on the compressor with closed valve first and couldn't believe my eyes: the manometer climbed straight to 50 bar!

I filled the gas flask to 40 bar (at this pressure the pump volume stream becomes very small and pressure rises extremely slowly, also leaks started

to show at such a pressure- the parts were originally designed for 15 bar), which took 5 minutes (volume of the flask was 0,5 L).

Then I released a hurricane in my garage by opening the valve.

That thing is awesome, I can now fill my gas flask with gases like hydrogen (gonna have to purge the pump and flask with hydrogen first before letting

it build up pressure to eliminate explosion risk) and ammonia (this would actually liquefy inside the flask and allow for huge amounts to be stored).

To fill the flask with gas, I would collect the gas inside a freezer bag (after washing and drying), turn on the compressor (also connected to the

bag) as soon as the bag is full until the bag is empty. Then wait again until the bag is full and turn on again etc.

I could also make a pipe-bomb autoclave and pressurize with hydrogen to run catalytic hydrogenations- 40 bar should be enough for reactions with

raney-nickel if the reaction time is long enough.

Pictures of my setup available here:

http://versuchschemie.donau-it.de/topic,4697,0,-Gasflaschen+...

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Very nice. Yes, refrigeration regularly runs in the 200PSI (low side) to 500-600PSI (high side) range.

1 bar = 1 atm = 14.7 PSI so that's circa 41 bar. Sounds about right

Tim

|

|

|

Twospoons

International Hazard

Posts: 1280

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Compatability of some gases with the compressor oil may be an issue - check each one. I would also suggest an oil mist filter on the outlet - collect

the oil and return it to the compressor intake.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

That's pretty impressive. As you say it opens up all kinds of possible syntheses normally considered beyond our scope.

I have some questions: 1) those "gas flasks," - are they what are called lecture bottles? What are they rated for in pressure and volume.

Do they come in different styles, wall thickness, etc, depending on the gas to be stored? Where do you get them?

Can compressors be found that are oil-less for compression at these pressures? It seems that would eliminate contamination with oil - if this is

indeed a problem.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Could empty propane tanks be refilled with the gas of your choice? I do not mean the big white BBQ ones, but the small ones we all have lying around

from our torches.

Would chlorine be rather difficult to store as it would react with most metals causing destruction of the bottle, or would the reaction passivate the

metal surface stopping all futher reaction?

Very cool(pun intended) indeed.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Throw on some phosphorous pentoxide it looks like.  Or should I say...

metaphosphoric acid. Or should I say...

metaphosphoric acid.

http://www.worksafesask.ca/files/ccohs/cheminfo/cie85.html

| Quote: | Corrosivity to Metals:

At ordinary temperatures, dry chlorine is not corrosive to most common metals, including steel, stainless steel, cast iron, nickel and its alloys,

copper, brass, bronze, lead, platinum and tantalum. Dry chlorine attacks aluminum, tin and titantium at ordinary temperatures and is corrosive to most

metals at high temperatures (121 deg C and up). Moist chlorine is strongly corrosive to most common metals. Platinum, tantalum and titanium are

resistant. Tantalum is the most stable metal to both dry and wet chlorine.(24,25,28,35) |

The irony is, just above it says:

| Quote: | | Liquefied chlorine can react violently, explosively or ignite on contact with carbon disulfide and iron, bismuth, dibutyl phthalate, drawing wax,

gasoline, glycerol, linseed oil, white phosphorus, polydimethylsiloxane, silicones, sodium hydroxide, tin, titanium and vanadium powder.(33,34)

|

I guess they emphasize powder, as how aluminum is pyrophoric in 23% O2, particularly when unpassivated.

Don't use small disposable bottles, they aren't meant to be filled. Yeah, so that's just the D.O.T.'s suggestion...well, maybe

they know something we don't, or something. I think you can get pretty small "real" tanks though.

Tim

[Edited on 9-29-2005 by 12AX7]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

The bottle is an empty oxygen tank rated for 200 bar. Its original purpose is unknown to me, most likely for welding. I got it on Ebay.

I only have this one flask, and it is only made for oxygen. But I don't think that hydrogen or ammonia will pose problems.

Now that it's contaminated with oil, it cannot be used for oxygen any more.

Chlorine is impossible to compress with this sort of equipment, as it would immediately destroy the compressor.

Oilless resistant compressors might be available, but far beyond our budget.

I want to know what can be done with a fridge compressor and not with a special ultra-expensive pump!

My next step will be to make a new filling apparatus which is airtight (the current construction is highly improvised and has some small leaks).

Then I'm going to try hydrogen, made from NaOH and Al and dried first by condensing most of the water in a dimroth cooler running with icecold

water and then with silica gel.

If this works then nitrous oxide could be the next step, this will pose more problems as

proper washing and drying is important.

And then ammonia.

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

Very cool! Looks like my fridge compressor will soon be going to work

I don't think refilling old propane cylinders would be a problem as long as the pressure is stopped at 250psi (17 bar). That is the pressure

propane cylinders are designed for, bring it higher is a unneccessary risk in my opinion.

|

|

|

mick

Hazard to Others

Posts: 338

Registered: 3-10-2003

Member Is Offline

Mood: No Mood

|

|

I am not sure what CO2 fire extinguishers or pub CO2 cylinders are rated at but I think it is quite high.

I have also read that dry chlorine is OK in steel, there has not been any reports of them failing due to storage. Old fluorine cylinders after about

10 years have been found to build up a pressure over 3000 psi and fail.

mick

|

|

|

mick

Hazard to Others

Posts: 338

Registered: 3-10-2003

Member Is Offline

Mood: No Mood

|

|

If you want to pressure test some general gas equipment the way I was shown was to fill the kit with water and use a good quality car brake master

cylinder rigged up to a long handle. If you can pressurise to twice the working pressure it should be OK. If it goes when it is full of water there is

not a problem, if it goes when it is full of gas that could be a problem.

mick

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I plan to test my homemade black iron (steel) ammonia cylinder hydrostatically 1st and then with air (at a lower pressure) to check for gas tightness.

Following mick's advice I stopped at a brake repair place to ask if they had a used master cylinder. I couldn't believe it - they did and

gave it to me for nothing -what luck on the 1st try!  It even has a vacuum

assist which I can hook up to my aspirator if needed. It even has a vacuum

assist which I can hook up to my aspirator if needed.

I don't want to use brake hydraulic fluid as a test liquid and think that leaving water in the master cylinder can't be good as it would

rust. So I'm wondering if the denatured alcohol sold at the auto parts place for brake system cleaning would be a good permanent working fluid,

something I could just leave in the master cylinder reservoirs.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I have completed assembly of my hydrostatic testing device. I have 2 jpg pictures that I would like to show but can't get them inserted in my

post for some reason.

I've been trying to use the "Attachment:" and "Browse..." at the bottom of the page. This pulls up the photo addresses OK

but they don't show up when I "Preview Post." I'm new at this and some guidance from forum members would be much appreciated.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Now I have successfully filled my gas bottle with ammonia.

If you tilt the bottle you can feel the liquid sloshing around, very nice!

Pics of my setup available here, with detailed description in german:

http://versuchschemie.donau-it.de/topic,4697,60,-Gasflaschen...

I used 1,4L 20% NH3 solution, in four portions of 350ml each. Each portion took one hour to extract the ammonia from.

The dimroth condenser was run with icecold water, and the drying column (custom made by a glass blower) is filled with KOH. This worked very well,

only the first 10cm of the KOH became wet and the upper 20cm remained dry, indicating complete drying of the ammonia.

The 20% NH3 solution begins to "boil" at 50°C and the boiling temperature gradually rises as ammonia is given off. I boiled until it was at

95°C, at which point the NH3 evolution becomes too slow to be of use.

The bottle got very warm as the ammonia condensed inside it, and the pressure over the liquid which was at 10 bar initially later rised to 20 bar due

to this.

A 6L freezer bag was used as the intermediate storing container, it was connected to the gas generator and the compressor via a "T" adapter.

The brass valve of the bottle was attacked somewhat, the filling construction too, as seen in the last two pics.

Copper and its alloys are definately not a good metal for use with ammonia!

When I was done filling, I unscrewed the bottle from the adapter and a huge amount of ammonia came out. The copper pipe and the adapter became cold as

ice, and smoke was produced from the intense cold!

The cotton oil mist filter was completely soaked in liquid ammonia and continued to smoke for a while.

My garden must have stunk like hell... but I smelled nothing, thanks to my fume hood.

Now I need dry ice to condense some ammonia and produce some solvated electrons by adding sodium metal!

I also want to make NaNH2 by adding a catalyst (iron compound) to the blue solution.

I have a pressure reducer designed for oxygen, I'll have to see how good it will hold up to ammonia. Maybe add a few drops of oil to minimize

corrosion?

I tested it without oil and it produced a blue hue on the brass inlet pipe of the reducer.

I hope the valve doesn't get attacked.

When I bubble ammonia into water, it gets absorbed very vigorously, the bubbles collapse immediately as they form, producing a peculiar sound.

[Edited on 3-11-2005 by garage chemist]

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Magpie, I juste tested the attachment feature and it's working.

- Type your text;

-Click on the browse (edit) button- a window opens;

-Select the file;

-Click on the "open" button in the selection window - the window closes;

- Click on the "Post Reply" button.

Maybe the file was too large. Most digital cameras produce enormous files. If that's the case, do this:

- Put your picture on your screen the size you think is convenient;

- Press the "Print Scrn" key in your keyboard;

- Open the "Paint" program that comes with windows;

- click the paste button;

-An image of your screen should be pasted - cut your image the size you want and paste it in blank page- Make sure the white background is not larger

than your picture

- Save in .jpg format

Now you have a much smaller file.

[Edited on 3-11-2005 by Tacho]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Congratulations garage chemist on your good work. I hope to have similar results very soon as all my parts & pieces have arrived. I will be

constructing and pressure testing (hydrostatic to 300 psi) my gas cylinders today.

Thanks very much Tacho. I shall give your procedures a try pronto. FYI the file sizes are 99KB and 539KB. I didn't think these would be too

large as the FAQ guideline says only that they must be <1MB.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Garage chemist, I'm very impressed with your work too. Congratulations.

Don't forget to post your results with pictures!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

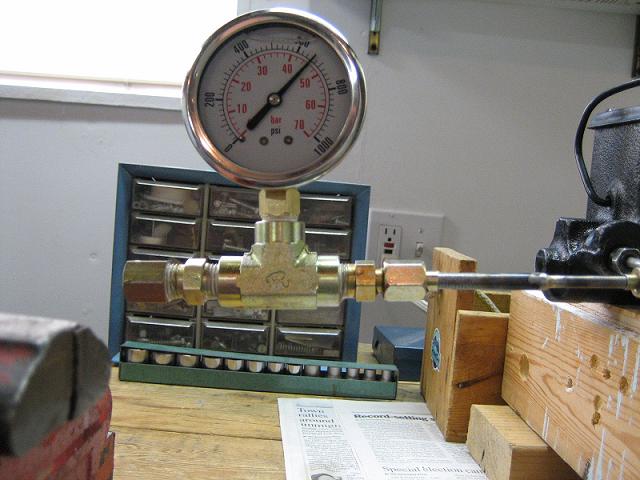

Here's the 2 pictures of my hydrostatic testing device made from a brake master cylinder. Turning the 3/8" nuts gets me about 200 psi/rev. Although

my pressure guage only goes up to 1000 psig I'm sure the device is good for at least 2000 psig.

I have it loaded with DOT3 brake fluid and will likely keep it that way and just fill my cylinders with water. The when done I'll just bleed some

brake fluid through to purge the device of any water.

Thanks Tacho for your help with the attachments - it seems I had them all along but was faked out as I did not see them on the "Preview Post."

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Oops! Here's the 2nd picture for the above post.

I wanted to mention that the vacuum assist (that big bell shaped item) is really not needed for this application. You get plenty of force with the

clamp like affair that I assembled from 1/4" (6mm) steel plate on the right side. This is driven (against itself) with 2 each 3/8" nuts on

bolts about 5" (12.5 cm) long. As the screws are tightened the far right plate drives the 1/4" rod attached to the brake pistons.

[Edited on 3-11-2005 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Sorry for so many posts on this thread but I'm imbedded here by now. Be sure to see garage chemists last post where he has great pictures of his

successful liquid NH3 bottling.

The picture below is a pressure test of my homemade high pressure reaction vessel. The fittings are "150 lb" which are normally considered good to

300 psig at room temperature. I inadvertantly tested it at 350 psig. Messing with high pressures is a little exciting. Makes you feel like a kewl

again.

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Forgive my car mechanics ignorance, but let me see if I got it straight:

If you press the axis of the brake master cilinder (on the right of your picture) with nuts and bolts, you end up with 350 psi in those copper tubes

coming out of it?

That sounds very interesting. A flexible capsule inside your test vessel would be under 350 psi of pressure!

Nice place you have BTW Magpie!Clean and tidy... so far.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes Tacho you have it straight. The tubes are steel brake lines. I had a hydraulic shop fabricate the manifold. The fittings are hydraulic and not

available at a hardware store. Same for the hydraulic hose.

Thanks for the comment about my shop/lab. I was talked out of building a stand-alone lab in my backyard so compromised by using my garage. I have

been working all summer on it. I probably owe the forum a lab tour now that I have a camera.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's a final picture of my hydrostatic pressure testing: the testing of my gas (NH3) storage cylinder. As you will note I had to add a check valve

(right before the pressure guage) to build pressure. With the other vessel I could do this with the in-line ball valve.

I accidently ran this one up to 430 psig.

Will now test to 150 psi with air to test for gas tightness.

[Edited on 9-11-2005 by Magpie]

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Maybe this could help liquify a gas?

http://home.earthlink.net/~lenyr/refrig.htm

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

That's a neat project IrC. In my research on NH3 I noticed that RV refrigerators use NH3 as refrigerant as well as do many cold storage

facilities. The RV systems looked pretty simple. The vapor pressure of ammonia at room temperature is around 120 psig whereas that for propane is

around 200 psig. Also NH3 is almost non-flammable compared to propane. So if I was to build a refrigerator I would likely try NH3.

As you probably know garage chemist liquified his NH3 using a fridge compressor. I have chosen a different route - I'm going to liquify it using

an acetone/solid CO2 bath in a dewar flask. Then I'll just pour the liquid into my pre-cooled gas cylinder and screw on the cap. That's

the plan, anyway.

[Edited on 12-11-2005 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

When you immerse the cylinder in the CO2/acetone bath to precool it, won't the acetone dissolve the plastic sealant in the threads of the pipe?

Or is this teflon tape?

I'm asking because the blue tape in your pipe threads looks strange to me.

My teflon tape is white.

|

|

|

| Pages:

1

2 |