| Pages:

1

2 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

It is a good question Garage Chemist. For my normal household (water) pipefitting I use Ace's TFE (Teflon) dope. I've stopped leaks with

it that Teflon tape wouldn't.

But for the ammonia I talked to a technician who maintains a large ammonia cooling system for an ice-rink. He said not to use the PTFE dope but get a

dope especially made for ammonia. So I asked my industrial supplier and he recommended Leak Lock, which is blue. IIRC it is good for acetone also -

it better be  . I have also found a supplier of valves and guages specifically

sold for ammonia - good prices too (agricultural supplier - not scientific). But I think any steel will be good. The main thing is to avoid copper

and its alloys (brass) for any long term use. . I have also found a supplier of valves and guages specifically

sold for ammonia - good prices too (agricultural supplier - not scientific). But I think any steel will be good. The main thing is to avoid copper

and its alloys (brass) for any long term use.

[Edited on 12-11-2005 by Magpie]

I have an inquiry into Highline (who makes Leak Lock) about compatibility with acetone. Perhaps I should have used my own research conclusion which

was that Gasoila-100 pipe joint compound would have been the best. Its specifications are pretty impressive.

[Edited on 12-11-2005 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Very strange. PTFE not suitable for ammonia?

PTFE is resisrant to every chemical except molten alkali metals and elemental fluorine (it breaky C-C bonds, making CF4).

I'm absolutely sure that teflon will work for your ammonia cylinder.

What did he say about copper? The valve of my gas bottle is made of brass. It turned black/blue from exposure to the ammonia.

Is the attack only superficial and will eventually come to a halt (passivation of the surface) or will the brass slowly be eaten away and turn my

ammonia cylinder into a toxic time bomb?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I agree that the PTFE (Teflon) particles themselves are inert as you say to ammonia and almost everything else. So the tape would be OK. I have just

not had good luck sealing with Teflon tape on relatively coarse steel pipe threads. Brass would probably seal better as it is softer and will deform

better as you tighten the connection.

I think for the dope (paste) it is the carrier liquid that is vulnerable to ammonia attack - not the Teflon particles.

As for the brass - well, I went out of my way not to use it. I can't answer your question directly. You should research that. I don't

think you'll find any brass in commercial ammonia systems.

I can tell you a story about a brass fitting that corroded through overnite. It was a drain valve on a tank holding some acidic concoction. It

caused a significant discharge of Cr+6 to the soil environment. The poor young engineer who specified that valve did not work there much longer. I

felt very sorry for him. He should have had more support from his senior mentors.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

I think teflon tapes resist chemically to ammonia, but are permeable to most gases, including ammonia. In fact, teflon tapes seem to be permeable even

to lighter solvents. I know that from experience.

I liked the project IrC posted! I always wanted to have a cold water generator in my attic, and I have plenty of experience with compressors.

However:

-propane, specially compressed, makes me worry about explosions or fires. I would worry a lot really;

-ammonia may corrode the compressor mechanics, specially if it has a chance to absorb moisture from air;

- I would think of home-made methyl bromide, widely used in the past as fumigant, but a methylating agent nevetheless.

Ideas?

Sorry to be off-topic.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Methyl bromide is very toxic and also damages the brain and nervous system. Plus it's odorless, increasing the danger. Using it in a

refrigeration unit sounds like a terrible idea.

Methyl chloride, on the other hand, would be a better idea. The toxicity is much lower.

A different refrigerant, also used in the pre-CFC days, is, besides ammonia (which is very good as a refrigerant, extremely effective systems can be

made with it), sulfur dioxide.

Its boiling point is remarkably high and the pressure above it at room temperature is only 3,5 bar (compared to 9 bar for ammonia). It could actually

be stored without risk in a Coke PET bottle (the CO2 from the drink produces a pressure in excess of 3,5 bar).

But the best choice would still be propane.

The advantages outweigh the disadvantages.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Tacho don't give up on NH3 too quickly. It is used as a refrigerant (R-717) all the time. Yes, you would have to carefully select your

materials, but I don't think water would necessarily be a problem. IIRC the RV refrigerators actually use ammonium hydroxide as the refrigerant.

I did see stress corrosion cracking as a potential problem with ammonia in steel. The solution: add about 5% water!

Offhand I would much rather have traces of NH3 loose in my living quarters that methyl bromide.

[Edited on 12-11-2005 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

I forgot to mention but if you click on his beginning page at the bottom he has more projects, including making your own cheap and simple expansion

valves for the refrigerant. He did not mention much about problems using the propane but then again he did take a can and used it to mow his lawn, so

he may be a little too cavalier in his experiments.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Garage chemist asked:

| Quote: |

When you immerse the cylinder in the CO2/acetone bath to precool it, won't the acetone dissolve the plastic sealant in the threads of the pipe?

|

I received a reply from Highline Chemicals on the applicability of Leak Lock (the blue paste) to -80C acetone for 1/2 day at 5"H2O WC pressure.

He said that, over time, Leak Lock is affected by ketones. But at my conditions it would be OK. So I will give it a try. (He offered to send me

free samples of Leak Lock for testing if I requested them on my letterhead  ). ).

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

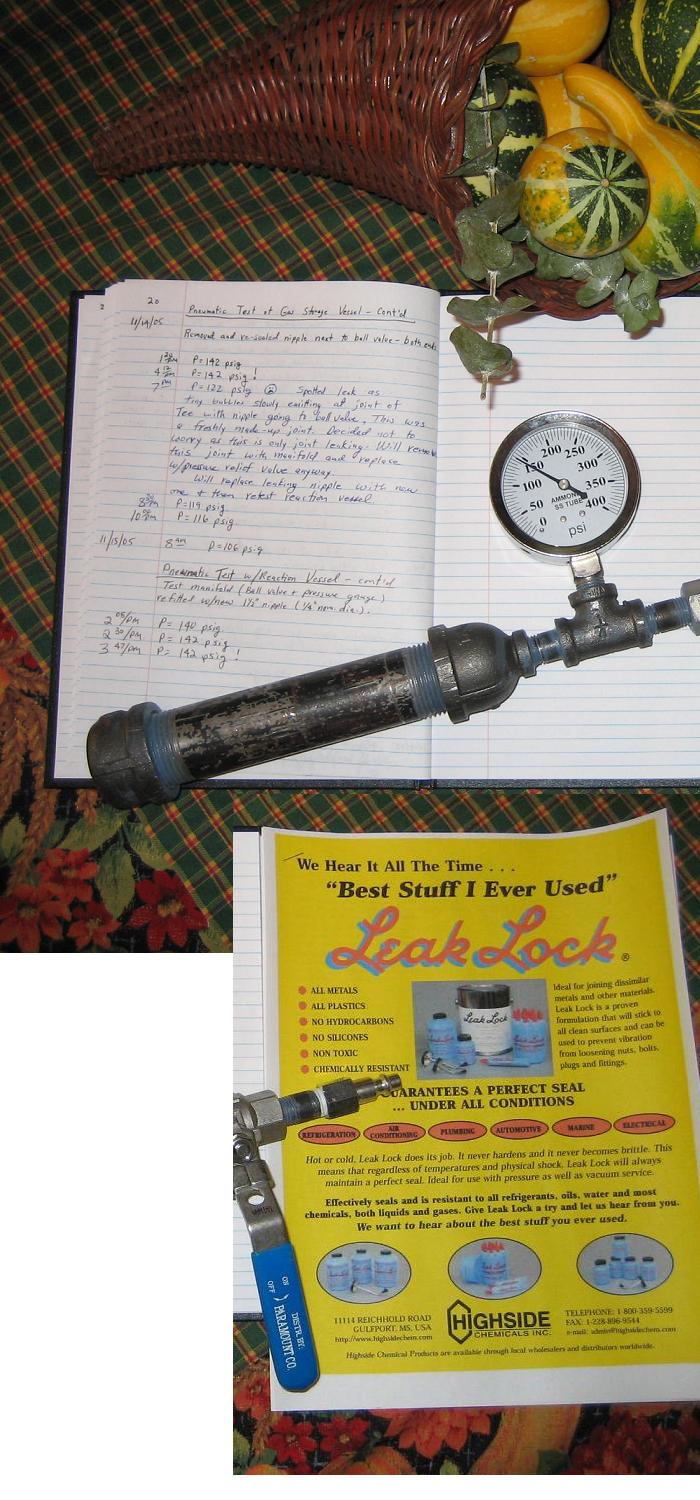

I finally have achieved success in pneumatic (air) testing of my homemade pressure vessels for gas tightness. I learned some things along the way:

(1) dope both surfaces and use plenty of it (2) turn the joint down "all the way home".

When the tests were failing I noted that the pressure loss rate was similar on both vessels. This made me think that the leak was in the test

manifold. So I replaced a suspect nipple in the manifold and remade other joints on the 1/4" piping.

I think I'm ready to go now and will assemble the equipment in the fume hood for NH3 liquifaction.

Here's a picture of the last test. I kept it in original format so people could read the data in my notebook if desired. Sorry for any seasickness.

Lest anyone call foul it is still at 142 psig after 4 hours.

[Edited on 16-11-2005 by Magpie]

[Edited on 30-1-2007 by chemoleo]

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

NH3 liquidfied and stored today!

I knew this experiment was going to teach me a lot about high pressure and cryogenics - I just didn't know how much.

The liquifaction train is shown in the picture below. I used a 30mm glass tube 2 feet long for a drying column per garage chemist. I put 13 "

of flake KOH in the tube supported on some SS scrub pad. Probably way too much KOH.

RBF is 500 mL. In the 1 liter dewar is a cold trap used to protect vacuum pumps. Sorry the picture is out of focus.

I used acetone/dry ice to get the temperature down to about -38C in both that dewar and an auxiliary dewar consisting of a wide-mouth Thermos bottle.

In the Thermos I had the gas storage cylinder protected by a small poly bag from the acetone. This was at about -45C per #1 son who was helping me.

After about 1/2 hr of gas generation we could see the cold trap gas vent burp occaisionally. This worried me so I terminated the run. We

couldn't smell any ammonia in the lab but sure could smell it outside. I conclude that I was generating NH3 too fast and/or didn't have my

bath temperature low enough.

There was about 15 mL of crystal clear NH3 in the cold trap. (My target was 50 mL.) I poured this into the gas storage cylinder and screwed in a

pressure relief (liquid) valve set at 350 psi. It is shown in the 2nd picture (next message).

The main thing I learned is to have all your acetone and dewars pre-cooled before you even start NH3 generation. I learned this the hard way by

frothing over a lot of warm acetone when I added the chunks of solid CO2. Once you get everything cold the dewars do a nice job of keeping them cold.

[Edited on 18-11-2005 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

In reference to my message above here's the 2nd picture:

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Nice! Looks good.

First pic is somewhat blurred, could you make another pic of you setup? It's hard to see details there.

Only 15ml of ammonia? That doesn't sound like it was worth the effort.

Was there any dry ice still floating in the acetone? There should be.

How was the ammonia generated? Boiling of 10% aqueous solution?

If I saw that only 15ml were condensed, I'd put another 350ml of solution in the flask and generate more ammonia until I have my desired 50ml.

Will you try it again?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Garage chemist: I will set up the apparatus (without loading the vessels) and take another picture.

When I first started the NH3 liquifaction I was disappointed as it was messy and high maintenance to get the temperature down. Now I know that my

whole problem was due to failure to pre-cool my acetone, dewars, cylinder, funnel, etc. Once you get down to temperature it stays there. If I would

have turned my heater down and kept at it I could easily have gotten the 50 mL needed to fill my small cylinder.

Would I do this again. Definitely, once I have a definite need. This was mostly a "proof-of-principle" experiment and to get some NH3 to

upgrade my reagent shelf NH4OH. It is too expensive to do casually. I saved the acetone and can reuse it for this again. But I have to buy a

minimum 2.5 kg of dry ice at $7.

Keeping the dry ice well insulated (say by wrapping with cloth towels) will keep it from disappearing too fast.

Was there any floating dry ice? Well, I didn't think so but when I poured out the dewar 1.5 hours later there was an active bubbling - so I

guess there was floating CO2. Also the temperature was still down at -35C.

When I first started I was thinking how much superior your method is to mine. But then I kept thinking: "But you get to see the liquid

NH3!"

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Garage chemist here is a picture of the cryogenic components. The NH3 generator and KOH water absorber were pretty much the same as yours so I didn't

show them. (If you need info on those let me know.) The cold trap is the smaller glass tube that fits inside the larger (30mm) glass tube and is

sealed to it via ground glass fitting. This assembly is inserted into the 1 liter dewar flask. The thermometer has a range of -100C to 50C. Any

questions just let me know.

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

One last report:

I poured ~40 mL of 7N NH4OH into the iron reaction cylinder. Then connected this to the NH3 storage cylinder via hydraulic hose. When I opened both

valves I expected to see about 110 psig on the pressure guage. It spiked up to 50 psig then quickly dropped off to about 20 psig. Over the next 1/2

hr it dropped to 0 psig.

The gas storage cylinder became very cold indicating evaporation of the liquid NH3. The reaction cylinder became warm indicating the heat of

dissolution/reaction of NH3 with the NH4OH solution.

I titrated the product NH4OH at 10.9N.

It was rusty colored from reaction with the iron cylinder.

Although smaller quantities than desired were produced, this series of experiments met all of my objectives for "proof-of-principle." 2 pictures

follow:

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

2nd picture from post above:

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Have you ever noticed that if you back away from a problem for awhile the right (intuitive) side of your brain will often solve the problem? Well, I

now know why the liquid ammonia was burping in the cold trap: I had it hooked up backwards!

A similar thing happended at work once due to the plant constructor mixing up two 2" pipes. This manifested itself through severe water hammer -

lucky no one was hurt.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

mick

Hazard to Others

Posts: 338

Registered: 3-10-2003

Member Is Offline

Mood: No Mood

|

|

If you want liquid ammonia find an old camper fridge that runs on gas (ammonia). The one I have got still works by lighting the pilot light.

mick

Sorry I think I am a bit of topic having re-read the posting.

mick

[Edited on 8-1-2006 by mick]

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Don’t these refrigerators contain a concentrated ammonia solution instead of liquid ammonia? This is the design I have always seen.

|

|

|

Texium

|

Thread Moved

19-11-2023 at 10:53 |

| Pages:

1

2 |