| Pages:

1

2 |

bolbol

Hazard to Others

Posts: 167

Registered: 3-1-2015

Member Is Offline

Mood: No Mood

|

|

Best Acid that will get rid of rust quickest without harming iron?

I've tried coke, vinegar, nitric acid, NaOH

None worked the way I wanted it. They failed at getting rid of thick rust sediments, except nitric acid but then again nitric acid got rid of the

metal too  . .

What I haven't tried so far is Conc HCl, Conc Acetic acid, Conc Sulfuric acid.

I've heard Phosphoric acid and HF are good too but they create a passivating layer on the iron which is not what im looking for.

So anyone knows of any fast acting acids that will get rid of rust leaving behind shiny iron?

|

|

|

gdflp

Super Moderator

Posts: 1320

Registered: 14-2-2014

Location: NY, USA

Member Is Offline

Mood: Staring at code

|

|

Hydrochloric acid will dissolve the iron as well as the sulfuric acid. Glacial acetic acid would most likely work, though you might need to dilute it

slightly. Phosphoric acid and hydrofluoric acid will also both work, but be careful, HF is really nasty.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Old fashioned wrought Iron? Cast Iron? Or mild steel?

Bases may be a better choice than acids, depending on what you want to do with the metal after-

Materials for Iron conservation

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

CHRIS25

National Hazard

Posts: 951

Registered: 6-4-2012

Location: Ireland

Member Is Offline

Mood: No Mood

|

|

I have used HCl on steel and it worked beautifully, about a 6M solution on a heavily rusted replica medieval sword, clean as a whistle.

‘Calcination… is such a Separation of Bodies by Fire, as makes ‘em easily reducible into Powder; and for that reason ‘tis call’d by some

Chymical Pulverization.’ (John Friend, Chymical Lectures London, 1712)

Right is right, even if everyone is against it, and wrong is wrong, even if everyone is for it. (William Penn 1644-1718)

The very nature of Random, Chance development precludes the existence of Order - strange that our organic and inorganic world is so well defined by

precision and law. (me)

|

|

|

Hellafunt

Hazard to Self

Posts: 65

Registered: 2-12-2014

Member Is Offline

Mood: No Mood

|

|

have you considered using electrolysis to remove rust? i have done it a number of times, and it is super easy, very safe. you only need sodium

carbonate as an electrolyte, and you can use a "wall wart" for a power supply. saves a lot of elbow grease. there is mucho info on line.

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Phosphoric acid is the acid of choice in most commercial rust removing products (Naval Jelly, etc.).

HCl is probably not popular due to its volatility.

|

|

|

DraconicAcid

International Hazard

Posts: 4278

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

I've read that oxalic acid can be used, but I've never tried it. You could also try EDTA.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

I've soaked rusty bumper brackets in dilute oxalic acid solution. It worked very well, with periodic brushing and rinsing. In a 5 gallon pail, I

mixed in probably 100 grams or so. It took a few days overall for it to work.

|

|

|

alive&kickin

Hazard to Others

Posts: 100

Registered: 10-11-2012

Member Is Offline

Mood: No Mood

|

|

I've used oxalic acid numerous times, being here on the beach (seems like everything rusts), and like DraconicAcid says, I can attest to the fact that

it works like a champ. I let the metal soak in a saturated solution for as long as it takes (depending on the amount of rust), and it seems to help

prevent any new rust from starting back. Haven't done any actual testing but that's just what I've observed over the years.

|

|

|

bolbol

Hazard to Others

Posts: 167

Registered: 3-1-2015

Member Is Offline

Mood: No Mood

|

|

Im actually trying to de rust a differential housing.

I can also get my hands on dilute perchloric acid but would it work?

and NaOH so far worked the best of all the ones I listed. It actually softened the rust pretty nicely but then again still lots of work to carve it

all off.

I might try glacial acetic acid later, never worked with it tho.

|

|

|

gdflp

Super Moderator

Posts: 1320

Registered: 14-2-2014

Location: NY, USA

Member Is Offline

Mood: Staring at code

|

|

GAA isn't too bad, just wear eye protection and gloves(any should be fine) and work outside. You can work with it inside, but it will make a room

smell like vinegar within a minute of having an solution exposed to air. I would assume perchloric acid would be overkill and attack the iron as

well, similar to the nitric acid.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

The thing is that you don't want something that the bare iron will react with. Oxalic acid won't attack the iron without the presence of dissolved

oxygen, and it's a pretty slow process. It will dissolve rust quickly by comparison.

I also noticed, like alive&kickin, that it doesn't seem to activate the metal the same way that other acids do. If you

use hydrochloric acid, after rinsing the acid off the metal, you will immediately see a thin film of rust flash on the metal as it dries. I have the

same problem with phosphoric acid to a lesser extent. With oxalic acid, the bare metal part can sit in a dry garage for a while without seeming to

rust. It should still be prepared with a standard metal prep before painting, though.

I would recommend staying away from anything that contains chlorine. Chloride is bad news as far as metal corrosion is concerned.

You can get oxalic acid from a marine or boating store. It is used extensively for rust removal in these applications. I get mine at West Marine.

|

|

|

Fulmen

International Hazard

Posts: 1693

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Inhibited hydrochloric acid (Clarke's solution) is another option that eats rust like a champ without affecting steel. It's basically hydrochloric

acid with antimony trioxide and stannous chloride added:

http://www.ecfr.gov/cgi-bin/text-idx?c=ecfr&sid=f1491021...

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

Boiling in citric acid may work it is slow but will work.

|

|

|

Metacelsus

International Hazard

Posts: 2531

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

Quote: Originally posted by CHRIS25  | | I have used HCl on steel and it worked beautifully, about a 6M solution on a heavily rusted replica medieval sword, clean as a whistle.

|

When I tried this a few years ago (on some pliers), it got the rust off just fine, and the metal was nice and shiny. However, after a week or so, the

rust was back, and it was even worse! I think the residual chloride ions (and yes, I did wash it in deionized water) served as an electrolyte to speed

up rusting.

|

|

|

cyanureeves

National Hazard

Posts: 737

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

sodium hydrogen sulfate or maybe just sodium sulfate. i use sodium hydrogen sulfate on rusted tools and it works great except it leaves the steel jet

black.black as ink and it also stains my hands black but it gets rid of rust for sure.sodium hydrogen sulfate is what the label says on our sewer

drain cleaner and it's also on Rust Out brand label.

|

|

|

CHRIS25

National Hazard

Posts: 951

Registered: 6-4-2012

Location: Ireland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by WGTR  | If you use hydrochloric acid, after rinsing the acid off the metal, you will immediately see a thin film of rust flash on the metal as it dries. I

have the same problem with phosphoric acid to a lesser extent.

I would recommend staying away from anything that contains chlorine. Chloride is bad news as far as metal corrosion is concerned.

You can get oxalic acid from a marine or boating store. It is used extensively for rust removal in these applications. I get mine at West Marine.

|

What kind of Iron/steel composition are you referring to here? I use HCl due to its speed. And I have used it all the time and have never had

returning rust. The only thing you need to do is to Thoroughly rinse with tap water, a good rinse. then I always dry with a hairdryer to get the

metal hot enough to expel any possible unwanted residues that might be in in any microscopic pores.

[Edited on 13-1-2015 by CHRIS25]

‘Calcination… is such a Separation of Bodies by Fire, as makes ‘em easily reducible into Powder; and for that reason ‘tis call’d by some

Chymical Pulverization.’ (John Friend, Chymical Lectures London, 1712)

Right is right, even if everyone is against it, and wrong is wrong, even if everyone is for it. (William Penn 1644-1718)

The very nature of Random, Chance development precludes the existence of Order - strange that our organic and inorganic world is so well defined by

precision and law. (me)

|

|

|

bolbol

Hazard to Others

Posts: 167

Registered: 3-1-2015

Member Is Offline

Mood: No Mood

|

|

I used a solution that apparently sucks the iron from rust forming a complex polymer as explained by the label but that thing is pure pure garbage.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

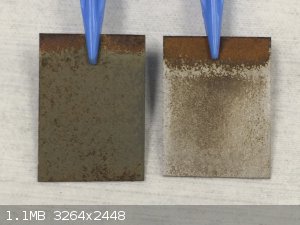

I ran a test with some mild steel coupons.

They were cleaned with degreaser, scrubbing them with a plastic bristle brush. They were thoroughly rinsed in DI water, and then blown off with

nitrogen until dry.

5g. of oxalic acid (Fisher) was mixed into 120mL of DI water, and stirred on a hot plate. The solution was heated mildly to about 35°C to speed

things up. 40mL of 37% HCl (Fisher) was added to a different beaker.

One coupon was suspended in the stirred oxalic acid solution for about 6 hours. During this time the coupon was periodically rinsed and scrubbed with

a plastic brush to remove loose rust. After rinsing again, the part was re-suspended in the solution.

The other coupon was submerged in the HCl solution for a few minutes, towards the end of the other sample's cycle in the oxalic acid. The reaction

was very fast.

Both parts, at the same time, were removed from their solutions, and rinsed thoroughly with DI water. For the picture below, after rinsing they were

immediately blown off with dry nitrogen. The oxalic acid sample is on the left, the HCl sample on the right. The oxalic acid sample was taking a

while, and due to my lack of patience I did not give it enough time to clean up completely. I probably should have left it overnight. The HCl sample

is very bright and clean, and only took a few minutes to clean up.

The same samples were then dipped back into their respective acids, and then re-rinsed in DI water. They were then placed wet into an oven pre-heated

to 100°C. After drying, a thin film of DI water was re-added about half a dozen times, allowing the samples to dry before reapplication. The

complete set of heating cycles took about 30 minutes.

The results are open to interpretation. Personally, I think that the rust on the oxalic acid sample was limited primarily to the areas that weren't

cleaned off all the way. The overall sample seemed to darken slightly. The oxidation on the HCl sample appeared to spread and be quick to turn into

"red" rust.

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

I cant help but wonder why you simply don't take a grinder to it, and progressively polish it back out.

I build boats, and restore cars/bikes for a living, and acid as a rust remover will gain you nothing but added cost/trouble.

I understand it's a "science" question but a "manual" answer.

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

bolbol

Hazard to Others

Posts: 167

Registered: 3-1-2015

Member Is Offline

Mood: No Mood

|

|

Honestly, I like the HCl since its quick. I can sand it off really fast after it has dried to paint it and that will take care of the problem.

Thanks for taking your time and actually doing an experiment of such sort.

|

|

|

etoxiran

Harmless

Posts: 9

Registered: 3-10-2010

Member Is Offline

Mood: No Mood

|

|

I suggest use of citric acid with some non-ionic / anionic surfactant (even washing-up liquid will work) eventually with addition of benzotriazole (as

corrosion inhibitor). I used it on mild steel, tool steel, cast iron and similar material with good efect. Need only removing carbon black with brush

and protecting with oil.

Another option, working with almost every metal (steel, aluminium, copper, monel, SS) is hydrofluoric acid, but is very toxic and hard to get.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

If you are seeking a method based on cheap and accessible ingredients (like local household items), may I suggest mixing vinegar, salt and chlorine

bleach (NaOCl). I have not tried this reaction particularly for rust removal, but I suspect it will work, albeit slowly.

The underlying chemistry is probably on the complex side (not discussed much by pundits, at least, fear of not getting it precisely right, I suspect)

as it likely involves an electrochemical reaction mixed in with your standard chemical reactions involving ligand formation and such (via the presence

of the acetate). If you are acquainted with my half cell reactions (previously presented on SM, see http://www.sciencemadness.org/talk/viewthread.php?tid=33247#...) for the so called bleach battery consisting of NaOCl + NaCl + vinegar acting on

Aluminum metal in the presence of another metal (Copper), just envision replacing the Al with your Iron source which likely is an alloy. Both galvanic

cells produce some Chlorine, but in the case of Iron, the Cl2 does not appear to make it of solution.

Caution, your iron source will slowly and unceasingly dissolve forming a caustic mix, so do not let sit for an excess period of time. You can heat the

mixture to jump start the reaction. Good luck.

[Edited on 14-6-2015 by AJKOER]

|

|

|

gatosgr

Hazard to Others

Posts: 237

Registered: 7-4-2015

Member Is Offline

Mood: No Mood

|

|

What would work to remove sea stains? The reduction potential of Na+ is 2.7V so I don't think any galvanic reaction will work right?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Sea stains? You mean corrosion by sea water?

|

|

|

| Pages:

1

2 |