Mabus

Wiki Master

Posts: 238

Registered: 3-11-2013

Member Is Offline

Mood: Energetic

|

|

What caused the copper to precipitate as sheets?

After etching the copper from some circuit boards with FeCl<sub>3</sub>, I decided to reduce the resulting copper(II) chloride with some

steel rods from some lever door handles (I have many to spare), as I've done previous times. The copper would precipitate as a powder or short

needles, but a few times it precipitated as sheets, with a sintered-like aspect and very fragile. One time however, the copper sheets were thick

enough to not crumble when dry. My last reduction I did a few days ago also yielded some copper sheets.

Does anyone have any idea why the copper would sometimes precipitate as sheets?

Could it be impurities? The electronics I etched also contained solder, and given they are old ones, they must have tin-lead.

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

I found this PDF on Spangolite. It's a copper sulfate sheet crystal...

http://www.minsocam.org/ammin/am78/am78_649.pdf

I didn't read thru the entire PDF but I believe it applies.

[Edited on 4-2-2015 by Zombie]

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

He's talking copper (Cu(0)), not copper sulphate, Zomb.

|

|

|

Mabus

Wiki Master

Posts: 238

Registered: 3-11-2013

Member Is Offline

Mood: Energetic

|

|

I didn't have any copper sulfate, so I don't think that applies.

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

well shieeet thats crazy

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

Admittedly I have a limited understanding of this.

My thought in posting the PDF is perhaps there is something that can tie Mobus;s method into the the formation of these sheeting crystals.

Obviously there is some anomaly at play to " sometimes precipitate as sheets".

I'll catch up... No doubt.

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

If the "steel rods from some lever door handles" are indeed flat surfaced then the copper will deposit on them as "sheets", which will eventually

flake off. This will happen if the rate of copper formation is slow (low reagent concentration, e.g.)

'Nothing to see here', as far as I'm concerned...

[Edited on 5-2-2015 by blogfast25]

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

Nice.

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

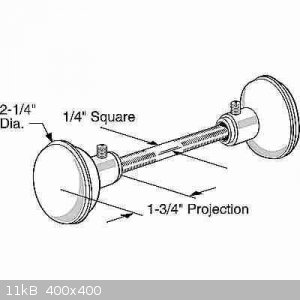

Caption competition:

'The blueprint for a set of 'ear speakers' that connect straight through the wearer's head. Volume adjustment knobs can be seen.'

[Edited on 5-2-2015 by blogfast25]

|

|

|

maleic

Harmless

Posts: 20

Registered: 24-12-2014

Member Is Offline

Mood: No Mood

|

|

Maybe it is just dirty..... Okay, In fact, I don't know the answer

|

|

|

Zombie

Forum Hillbilly

Posts: 1700

Registered: 13-1-2015

Location: Florida PanHandle

Member Is Offline

Mood: I just don't know...

|

|

The whole time I was looking right at the square stock in the Picts. I assumed it was part of the crystal structure...

Should have used Captain Obvious, rather than Competitive.

Maybe it just compacted as per BlogFast.

They tried to have me "put to sleep" so I came back to return the favor.

Zom.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

If you run this plating business in the right conditions, the copper simply sticks to the substrate. IIRW, electrolytic chroming is done on an

undercoat of copper.

[Edited on 6-2-2015 by blogfast25]

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Many steel items are plated with various thin metals to improve durability. Is this pile of steel pieces unlike your usual reductant pieces.

Delamination of such a layer may be the cause.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Dan Vizine  | | Many steel items are plated with various thin metals to improve durability. Is this pile of steel pieces unlike your usual reductant pieces.

Delamination of such a layer may be the cause. |

And if these steel bars aren't too clean that is even more likely to occur. Bits of oil or grease easily ruin adhesion of the Cu coating to the steel.

|

|

|