| Pages:

1

..

39

40

41

42

43

..

60 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by watson.fawkes  |

... In the reaction you're using it for, I'd worry about the mineral content of a ceramic acting as a reagent. For example, I wouldn't use talc,

because it's a hydrated mineral. I'd have to guess that hot gaseous phosphorus would dehydrate it, reducing your yield. |

Talc is (OH)2Mg3(SiO5)2. According to Norton's Fine Ceramics - Technology and Applications, p.250, talc dehydrates at 900-950C to

protoenstatite and glass. Therefore water should not be present after firing of the vessel, preliminary to use in the phosphorus reaction.

I don't know if that would be a problem with the protoenstatite. Do you?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Magpie  | | Talc is (OH)2Mg3(SiO5)2. According to Norton's Fine Ceramics - Technology and Applications, p.250, talc dehydrates at 900-950C to

protoenstatite and glass. Therefore water should not be present after firing of the vessel, preliminary to use in the phosphorus reaction.

|

Ah. I had been thinking that you could find a mixture that you could ram up and then fire in place the first

time it was used, rather than pre-firing it. It would save a step. Sorry; I hadn't thought to say that.

I'd guess a magnesia-silica ceramic would be fairly resistant to molten boria. But as with all these ideas for ceramic liners, it'd need to be tested.

It might be a good idea to run a test with just melting boria without reaction first, in case there's some rampant incompatibility.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I have just finished preparing a paint can lined with 90%talc/10%EPK kaolin. It will take a day or two to dry then I will fire it to as high as my

furnace will go - likely ~1000C.

@ watson: I will make a second lined can using a red fireclay as a base as you proposed. I also have on hand nepheline syenite (K2O/Na2O), custer

feldspar (K2O), EPK kaolin, alumina, and a fine grog. What ingredients and in what proportions would you recommend?

-------------------------------------------------------

Edit: I suspect that the red fireclay is not what I should be using. What I think you are suggesting is a high alumina fireclay, which I would guess

is either the Lincoln that you mentioned or a Hawthorne (Missouri) fireclay. I will research this. Let me know if my assumption is correct.

Today I prepared a 2nd paint can lined with Rutland's "Chimney Sweep" furnace cement. This rammed in nicely.

----------------------------------------------------------

2nd edit: After 48hr in NaOH at room temperature the boria hard-as-a rock slag has disintegrated to a brown floc. I will test a piece of slag in

boiling NaOH tomorrow.

----------------------------------------------------------------

3rd edit: A small piece of boria slag completely disintegrated in boiling 10%NaOH in less than 1/2 hr. Initially, as before, there was a great

quantity of small bubbles emitted - likely due to unreacted Al.

[Edited on 29-9-2012 by Magpie]

[Edited on 29-9-2012 by Magpie]

[Edited on 29-9-2012 by Magpie]

[Edited on 29-9-2012 by Magpie]

[Edited on 29-9-2012 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Reading back the last pages I came across this:

Quote: Originally posted by watson.fawkes  |

And it seems thermodynamically unfavorable to reduce to B instead of P. There's still the issue of the Al not completely oxidizing. But if you're

lucky, the borate might further oxidize to perborate with oxidation state B5+. |

B(V)? The (simplified) electron configuration of boron (Z = 5) is 1s<sup>2</sup> 2s<sup>2</sup> 2p<sup>1</sup>.

For the pentavalent state the inner electrons 1s<sup>2</sup> would have to get involved! The structure of ‘perborate’ (e.g. NaBO3)

doesn’t involve pentavalent boron.

Also, has it occurred to anyone that both SiO2 and B2O3 are reducible by Al? For SiO2 the reduction with Al is exothermic by about – 200 kJ/mol

(Standard Enthalpy of Reaction). For B2O3 I don’t know but I know AlB12 is synthesised by reaction of boric oxide and aluminium.

So, are we sure that it is ‘thermodynamically unfavorable to reduce to B instead of P’?

[Edited on 28-9-2012 by blogfast25]

[Edited on 28-9-2012 by blogfast25]

Edit: based on NIST Webbook HoFs, for B2O3 + 2 Al ===> 2 B + Al2O3 the SEoR is 1273 – 1676 = -403 kJ/mol. Methinks you might be

producing boron in there! And thus of course also less P4…

I think it might be worth running a test without any slagformers like SiO2 or B2O3, you might get surprisingly high yields...

[Edited on 28-9-2012 by blogfast25]

|

|

|

White Yeti

National Hazard

Posts: 816

Registered: 20-7-2011

Location: Asperger's spectrum

Member Is Offline

Mood: delocalized

|

|

Perhaps you could consider a mix of carbon and aluminium powders. The aluminium would warm up the reaction enough for the reduction with carbon to

take place.

"Ja, Kalzium, das ist alles!" -Otto Loewi

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by blogfast25  |

Edit: based on NIST Webbook HoFs, for B2O3 + 2 Al ===> 2 B + Al2O3 the SEoR is 1273 – 1676 = -403 kJ/mol. Methinks you might be

producing boron in there! And thus of course also less P4…

|

This might be at least a partial explanation for the poor yield of P when using SiO2.

We don't know yet what the yield of P would have been with the boria due to the blowout of the retort. Hopefully we will soon find out with a

hardened paint can retort.

Quote: Originally posted by blogfast25  |

I think it might be worth running a test without any slagformers like SiO2 or B2O3, you might get surprisingly high yields...

|

The slag could contain significant AlP. One would have to be careful not to let that contact water due to PH3 generation.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Magpie  | | The slag could contain significant AlP. One would have to be careful not to let that contact water due to PH3 generation. |

The HoF of AlP is referenced by Wolfram Alpha as a mere – 166.5 kJ/mol, not a lot.

I think that in a stoichiometric mix (NaPO3 + Al) the formation of AlP isn’t very likely, for that reason. And AlP doesn’t react very fast with

water, so the risk of phosphine generation is fairly small too.

I don’t recall this entire lengthy thread but I’ve a feeling the SiO2 kind of got carried over from the initial Ca triphosphate + cokes + silica

very high temperature method. I’m not sure whether in the lower temperature reduction using aluminium silica still has a role to play. I’ve seen

great strides forward being taken (by Magpie) in terms of reactor/condenser design that haven’t really materialised in great gains in yield. Maybe

we’re overlooking something?

[Edited on 29-9-2012 by blogfast25]

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

magpie, in some of my experimentation, i have ground up my slag and tested it with water and HCl and noted no gas generation. this has been quite some

time ago (over a year) but the test was negative, all the same. that is not to say that the formation of AlP is not possible given differing ratios of

reactants and differing grain sizes ect. but only that i personally did not encounter it. also, i wonder if it is possible at all for alumina to form

as part of this reaction...would not the heat required to form alumina render the reaction vessel completely destroyed on the first run?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Roger, I usually see some bubbles emitted when cleaning up the condenser in 5% NaOH. I keep the hood fan on then place the bath outside for a couple

days. I also see bubbles when placing the boria slag in HCL or NaOH. I think these bubbles are most likely due to unreacted aluminum. So whether

PH3 is a real problem or not I cannot say. I will assume it is a potential problem until I'm convinced otherwise. I do not see any PH3 burning,

however - but this may be because everything is at room temperature.

I know we talked about the need for SiO2 way upthread to allow complete conversion to elemental P and prevent the formation of AlP. I need to reread

those posts.

I made a run with boria today (#6), which was successful. I'll report the results tomorrow.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

A deeper search for the HoF of P2O5 yielded two values, one of – 3382 kJ/mol (which sounds inordinately high compared to other pentoxides!) and one

derived from:

3 Ca + 3/2 O2 == > 3 CaO ….. 3 x – 635 kJ/mol (NIST)

2P + 5/2 O2 == > P2O5 …. Say, X

3 CaO + P2O5 == > Ca3(PO4)2 …. Say, Y

Sum:

3 Ca + 2P + 4 O2 == > Ca3(PO4)2 ….. – 4132 kJ/mol (Wiki)

So according to Hess we’d have – 4132 = 3 x (- 635) + X + Y

Assuming Y to be small compared to the other values, then X ≈ - 2227 kJ/mol.

That’s also a real whopper but significantly smaller than the – 3382 value. The latter would make the reduction of P2O5 with Al

endothermic, the - 2227 value would make it exothermic, so really I’m still none the wiser. High temperature and

the escape of one of the reaction products would always push the reduction equilibrium to the right but if highly endothermic then yield could be

small and other reduction reactions (silica, boria) might be favoured. But right now that can’t be stated with any certainty…

It all does seem to indicate that the HoF of P2O5 (and hence also of phosphates) is very high and that it might be very difficult to reduce it to P

with high yield in relatively low temperature conditions. The carbothermic reduction has two gaseous reaction products and is carried out well above

Magpie's temperatures.

[Edited on 2-10-2012 by blogfast25]

[Edited on 2-10-2012 by blogfast25]

Another thing that puzzles me is that thermodynamically speaking Na2O is quite easily reduced by Al, so that the reduction of NaPO3 (well, (NaPO3)6)

should go all the way: NaPO3 +2 Al == > Na + P + Al2O3. This is not the case with Ca phosphates because CaO is not reducible by Al.

[Edited on 2-10-2012 by blogfast25]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | | B(V)? The (simplified) electron configuration of boron (Z = 5) is 1s<sup>2</sup> 2s<sup>2</sup> 2p<sup>1</sup>.

For the pentavalent state the inner electrons 1s<sup>2</sup> would have to get involved! The structure of ‘perborate’ (e.g. NaBO3)

doesn’t involve pentavalent boron. |

Unlike percarbonate, perborate isn't an adduct. See Wikipedia on sodium perborate. So apparently the 1s electrons do hybridize. Boron is a complete outlier here. The hybrid only seems possible because there is

no "1p" electron state that would have energy between 1s and 2s. Apparently the ion is tetrahedral, though I can't cite a definitive reference (I

looked; nothing very handy).

The peroxocarbonate ion CO42- has one oxygen in the configuration O-O-C and the carbon atom coordinates its bonds with three

oxygen atoms, as with carbonate. It's certainly conceivable that a tetrahedral CO42- ion exists at high pressures, after a

phase change.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@watson:

Interesting, very much 'outside the box'.

Any thoughts on my other musings?

|

|

|

arsphenamine

Hazard to Others

Posts: 236

Registered: 12-8-2010

Location: I smell horses, Maryland, USA

Member Is Offline

Mood: No Mood

|

|

re: aluminothermic boron reactions: a calculated exothermic heat of reaction doesn't tell you about the energy of the transition state,i.e., that it

can be initiated. Luckily, boro-thermite reactions are an empirical fact.

re: 1p orbital classification: for consistency with prior nomenclature, its absence is a convention by decree, right up there with motion of (+)

charges in electrical circuit analysis.

I'll get back to you on Boron 1s involvement once I see the Lowdin charges.

|

|

|

arsphenamine

Hazard to Others

Posts: 236

Registered: 12-8-2010

Location: I smell horses, Maryland, USA

Member Is Offline

Mood: No Mood

|

|

Expired equine flagellation:

The optimized geometry with VanDerWaals spacing is shown below.

The overall electron density plot is very similar.

Ab initio calcs on Li2perborate.trihydrate show very slight Boron 1s involvement. Non-involvement would give a 1.99 or 2.00 Lowdin charge, as you'd

expect. I get 1.96. (Lithium computations don't take as long as sodium, isoelectronic valence shells, etc.)

Renderings using Jmol show spherically symmetric boron 1s orbitals, meaning either a full or half-full shell. 1.96 Lowdin charge sez full.

While you're at it, grab a copy of JMOL for molecular rendering and editing.

Structure was optimized using Mopac2012 at the PM7 level; orbital groveling was at 6-31++G(dp) with GAMESS May2012(Rev.1).

[Edited on 2-10-2012 by arsphenamine]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

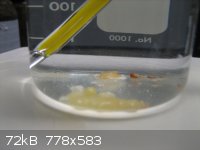

A 25g charge using boria was run yesterday (run#6). The paint can retort was lined with 1cm of Rutland’s “Chimney Sweep” furnace cement. After

ramming the cement in place the retort assembly was heated slowly to 260C per Rutland’s instructions to cure the cement. The assembly was then

heated to 750C to burn off the tin plating on the can and to drive off remaining water from the cement. The finished pieces are shown below:

Retort with furnace cement

Ground Boria was mixed with the aluminum and ground NaPO3 by mixing in a capped bottle to keep out moisture. The mix was placed in the retort,

previously back-filled with argon. The assembly was placed in the furnace, the thermostat set for 750C, and heating was begun. When 750C was reached

there was as yet no reaction so the temperature was held there for 15 minutes. The thermostat was then set for 800C. Shortly thereafter the reaction

began and a steady, slow production of P, burning PH3, and white smoke occurred. The P was of very good quality, ie, white and uncontaminated. The

weight of P was 1.0g for a yield of 27.8%. The P is shown in the picture below:

Run#6 phosphorus

Today the retort was removed from the furnace. It was covered with velvet colored rust as shown here:

Run#6 fired can with rust

The fired weight of the assembly was 2.9g heavier than the unfired weight. This could be due in part to the formation of that rust. Also, the ~530g

weight of the assembly is at the upper limit of my scale’s capability, which may be introducing some inaccuracy.

The assembly was then opened. This was done with difficulty as the lid was stuck to the can. You can see that the slag vacuoles are very large. The

inlet to the snorkel was again about 50% plugged with slag. The opened assembly is shown here:

Run#6 retort assembly opened

The final picture shows the snorkel and lid being removed from the condenser. The technique shown here is now routine:

Removal of snorkel & lid from condenser

Discussion

I decided to cut the charge in half from the previous run because the furnace cement lining had consumed nearly half of the can’s available volume.

I believe this lining width (1cm) could be cut at least in half for future runs. The cement is a very tough material and was completely undamaged by

the firing.

The 27.8% yield is the best I have achieved with any of my phosphorus making runs. It is also noteworthy that the production was slower and steadier

than that of any of my previous runs.

-------------------------------------------------------------------------

In rereading the posts of not_important and Strepta I find that they assumed a different borate reaction product and therefore used 1/2 the boria that

I've been using. Also, Strepta recommended a 15% excess of aluminum.

So my next run (#7) will use Strepta's assumed reaction (p.14 upthread) and the 15% Al excess. I will cut back the thickness of the retort lining to

0.5cm, and increase the charge size to 35g. I know this is poor experimental technique in regard to changing too many variables at one time, but at

this point I'm after production.

Questions, comments, and recommendations are welcomed, as usual.

[Edited on 3-10-2012 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

I can't make much sense of the thermodynamic figures by themselves. It's

clear that activation energies are at play, given that Magpie has reported "ignition" temperatures, very indicative of overcoming an activation energy

level with thermal excitation. But upon mulling over one of your observations, there's like more energies yet at work. Quote: Originally posted by blogfast25  | | Another thing that puzzles me is that thermodynamically speaking Na2O is quite easily reduced by Al, so that the reduction of NaPO3 (well, (NaPO3)6)

should go all the way: NaPO3 +2 Al == > Na + P + Al2O3. |

Molten boria and phosphorus oxides form a solvent

system for Na+ ions. There's almost certainly something like a heat of solvation happening here. If the Al can't reach an Na+

ion because of steric hindrance from coordinated B and P oxides, it can't reduce it. And even if it could, it's not clear to me that taking the

Na+ ion out of solution doesn't turn the net Al-Na redox reaction endothermic.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@Magpie:

Nice work, even though yield still isn't great. One has to wonder what it would do on scaling up...

One banal question: how do you remove the slag from your improved retort? That stuff must be rock hard, no pun intended!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks. Yes, I think %yield should increase with increasing charge size. I have to cautiously sneak up on the upper limit as I don't want another

blowout and consequent furnace fire.

I am limited to a 1/2 pint (250mL) paint can due to the size of my furnace box. The box is wide enough to double that size but expendable cans with

compression seals don't come in that shape.

Quote: Originally posted by blogfast25  |

One banal question: how do you remove the slag from your improved retort? That stuff must be rock hard, no pun intended! |

I don't. The can is expendable ($2.50 ea). That, and the lid's compression seals, are the keys to this particular technology. Only the condenser,

spacing washer, and snorkel are reuseable. The condenser is fairly expensive ($30) as I had to hire a welder/machinist to make it.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

I've been following along and have a few questions. Apologies if this has been covered - long thread!

1. Thermodynamically, what is the probability of formation of sodium phosphide(s) in this reaction?

2. What do you expect would result from addition of an alkali metal (say, sodium) to the mix?

3. What of the effects of pressure/vacuum on the reaction and outcome?

4. Could the reaction be carried out in a vertical reactor with some sort of check valve at the top. After reaction and cool down, back fill the

reactor with water and collect WP manually?

I've never messed around with WP so I don't know if it tends to stick to steel (referring to #4). As for #2, my thinking is that the alkali metal

could help to sop up some additional oxygen and possibly 'flux' the reactants. If Na3P formation is strongly favored then this would obviously be

counter-productive.

I want to take a shot at this but need some fresh ideas.

Tank

p.s. Magpie, thanks for taking the time to illustrate your experiments. Nice work so far!

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by m1tanker78  | ...

4. Could the reaction be carried out in a vertical reactor with some sort of check valve at the top. After reaction and cool down, back fill the

reactor with water and collect WP manually?

|

The phosphorus is generated as a gas at over 500C. It's going to move right out of the reactor as soon as it is generated. It won't condense until

it is cooled below its bp which is 280.5C.

Just remember the words of Rogeryermaw..."Phosphorus is a back stabbing bitch," or something like that. It's not only potentially lethal if inhaled

or ingested, but WP will ignite on contact with air, making it very much a fire hazard!

You're welcome, and thanks.

[Edited on 4-10-2012 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Magpie  |

I don't. The can is expendable ($2.50 ea). That, and the lid's compression seals, are the keys to this particular technology. Only the condenser,

spacing washer, and snorkel are reuseable. The condenser is fairly expensive ($30) as I had to hire a welder/machinist to make it.

|

Ooops. It does make for rather a lot of slag piles for relatively little product.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

<voice actor="Raul Julia"

character="Gomez Addams">It's research!<voice>

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Phosphorus run #7 was made yesterday using a charge of 35g based on the following stoichiometry:

6NaPO3 + 10Al + 3B2O3 ---> 6NaBO2 + 5Al2O3 + 6P

This is ½ the boria used in the previous run #6. To this was added 1.3g of Al for a 15% excess. This formulation is based on a report of success by

Strepta (p.14, this thread).

This run was unusual in that at first glance it seemed to be a failure. That is, only a couple of small drops of white P fell into the receiver upon

initiation of the reaction, which was quickly over. Then I noticed that the outlet of the condenser was nearly plugged. Digging with a steel rod

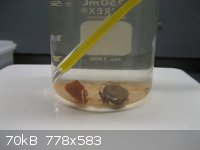

with a hooked end I pulled this plug out. It can be seen as the dark object on the right in the picture below:

Contaminated P plug

At first I wasn’t sure what this plug was composed of as it was so dark. However, upon warming to above 40C in the receiver it liquified, as would

be expected for white P. It weighed 2.5g for a yield of 41.7%! Although some of this weight is due to contamination, based on its melting and

solidifying behavior, I think it is a minor amount.

The furnace cement lining for this run was reduced from the previous run and targeted at a thickness of 5mm. This thickness, however, was an estimate,

as I had no convenient way to measure it. The dried weight of the lining was 57.9g vs 141.9g for the previous run.

The ingredients were prepared and loaded into the retort as in the previous run. The furnace was set for 750C, which was reached in 47 minutes. I

planned to hold it at this temperature for 15 minutes but the reaction initiated after about 5 minutes and was over in a few seconds. After digging

out the aforementioned plug the reactor was allowed to cool. After a few minutes I lowered the water bath and shut off the argon. I did this to

allow any residual P in the condenser and retort to burn off. This is an efficient and safe way to get rid of residual WP. Some small pieces fell

onto the water, floated, and burned with flaming. The rest just burnt off to a white smoke in the condenser as air creeped in. I attempted to take

a picture of this but was a little late and not much smoke can be seen:

Burning off residual P

Today the retort assembly was removed from the furnace and weighed. It weighed 455.5g vs an unfired weight of 457.9 for a weight loss of 2.4g. This

compares well to the P yield of 2.5g. The assembly was then opened for inspection of the slag and recovery of the condenser. Shown below is a

picture of the glassy slag, which is grayer than before:

Opened retort run #6

Discussion

It is apparent from the results of this run that the receiver water needs to be kept > 45C to keep the P from solidifying at the outlet of the

condenser. I’ve been thinking about providing for this over the last few runs as a small amount of solid P has always deposited near this outlet.

Although the product of this run is contaminated I am very pleased with the apparent increase in %yield. If this contamination is intrinsic to the

conditions of this run hopefully it can be eliminated, or at least minimized, in the future. At this point I don’t know its origin or cause.

Comments, questions, and recommendations are welcomed.

------------------------------------------------------------------------------

Pieces of slag were placed in 14% NaOH at 50C in a 6" test tube. Profuse bubbling ensued. This gas was shown to be flammable. Surely this is

hydrogen generated from unreacted aluminum powder:

2Al + 2(OH)- + 6H2O ----> 2Al(OH)4- + 3H2

[Edited on 7-10-2012 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

What strikes me about these new

photos is the way that gas is nucleating in the reaction mixture. There are very large, spherical voids visible. What this means to me is that the

mixture is fairly viscous with respect to the gas production rate. (It's just like over-leavened baked goods.) So it doesn't surprise me that it seems

to have boiled over into the condenser neck. I'd guess that the bulk of the contamination is simply the boria medium, mostly post-reaction.

Another aspect that interests me is that the refractory lining seems to prevent a chemical reaction with the steel liner. For whatever reason,

something about the way the intermediaries work was attacking the iron directly; I don't have any particular idea why.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

These reactions seem, once initiated, to be extraordinarily fast, like a thermite reaction. At first I thought the contamination of the P plug could

be Al powder. But I'm not all sure about that. Once melted, the color was almost like milk chocolate. Perhaps I can test some of the product.

Mostly though, I just hope I can clean it up.

With the retorts lined with furnace cement I have had no steel wall blowouts. During the preparation of the last lining, after bringing the

temperature up to 750C to burn off the tin plating and drive out the residual water in the cement (a couple ml), I found that the liner had separated

from the can at the floor, forming a sort of dome. I assume that this was due to gas generation from tin vaporizing under the liner. I didn't like

the look of this but decided to use the retort anyway. This apparently caused no problems as the liner seemed to be intact following the reaction.

I want to say a little about the hazards of making and handling phosphorus. Some may think I'm being melodramatic when referring to WP as "a

backstabbing bitch." Well, Rogeryermaw and Endimion17 probably don't, as they have found out the hard way. My 2 encounters, fortunately, have not

caused me bodily harm. In one instance I was cleaning up after a run using a damp paper towel. All of a sudden it caught fire. The fire was

vigorous and totally unexpected. Fortunately I was working over my steel sink so just dropped the flaming towel and let it burn out. The 2nd

encounter occurred this morning when I had separated out what I thought was all red P from the receiver water using a small sieve. As I was

suspicious of this residue I placed it in the open spent paint can retort from yesterday's run. Then I took this outside and placed it in the sun on

my concrete patio. In about half a minute there was a spontaneous roaring fire in that retort! The water had evaporated away and the sun had warmed

it up. Exposed to oxygen of the air the WP had everything it needed to burst into flame. Phosphorus is a very interesting element to make and

experiment with, but if you become complacent in handling WP you may pay dearly.

[Edited on 6-10-2012 by Magpie]

[Edited on 7-10-2012 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

| Pages:

1

..

39

40

41

42

43

..

60 |