| Pages:

1

2 |

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

Manganese Mediated Electrochemical Oxidation of Ethanol

1. Procedure

The electrolyte is prepared by dissolving 64g MnSO₄*H₂O, 30g (NH₄)₂SO₄, and 193ml 17.5M H₂SO₄(aq) in 100ml H₂O. This electrolyte is

loaded into a three necked flask which is attached to a distillation rig. The remaining 2 joints are used for attaching two lead electrodes, each with

a surface area of approximately 1400mm². Next, 19V @ 4.7A is run through the electrodes and the reactor is run for 30min to ensure that all

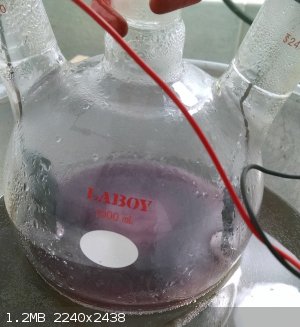

components function properly. During this time, a purple color is observed in the electrolyte. Following this, 100ml 12.0M ethanol is than added to

the reactor. The reactor is run at 60*C until no more distillate condenses in the receiver. Note that these steps may be repeated as many times as

desired due to the electrochemical regeneration off the oxidizing agent.

An image of the purple color observed.

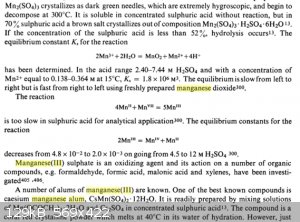

An image of the apparatus. On the left is a PID used to maintain the temperature at 60*C.

2. Notes

This procedure can be greatly improved by utilizing a more efficient method of stirring. A magnetic stir bar was used in this procedure, but it

quickly became useless due to the formation of a white precipitate in the bottom of the flask. A similar procedure was attempted utilizing Cerium

instead of Manganese, but this reaction failed because the ethanol was over oxidized to ethanoic acid.

3. Discussion

4. References

1.Sciencemadness Forum Thread (http://www.sciencemadness.org/talk/viewthread.php?tid=6882)

2.US Patent 80895 (http://www.google.com/patents/US808095.)

[Edited on 2-19-2016 by nlegaux]

|

|

|

Metacelsus

International Hazard

Posts: 2531

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

What was the (approximate) surface area of the electrodes you used? (Also, your image links don't seem to be working.)

I would appreciate more characterization of your acetaldehyde fraction (b.p. and density). The odor of acetaldehyde is by itself not a very good

indicator of purity.

Besides toluene and ethanol, I wonder if these oxidation conditions can be used on other substrates.

Having personally done this with toluene, I can agree that a strong stirring mechanism is necessary. A quite large magnetic stir bar was sufficient

for me, but mechanical stirring is likely the best option.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

This doesn't belong in prepublication, IMHO.

|

|

|

Texium

Administrator

Posts: 4508

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Comments like this don't belong in prepublication, IMHO.

It's called prepublication because it is not yet published though the intention is for it to be eventually. If you don't think it's at that level yet,

why not offer some advice or constructive criticism? Or if you don't have anything to add to it, just don't say anything...

I think that it's an interesting and potentially quite useful procedure. The write-up could use some better formatting and more details in general.

Also, it is necessary to undertake better characterization of the product (at least a BP), and possibly a workup procedure to purify it since it is

discolored and likely also contains some unreacted ethanol.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by zts16  |

I think that it's an interesting and potentially quite useful procedure. The write-up could use some better formatting and more details in general.

Also, it is necessary to undertake better characterization of the product (at least a BP), and possibly a workup procedure to purify it since it is

discolored and likely also contains some unreacted ethanol. |

So do I. But it adds very little to the procedure already described in the first link, which is where I do honestly believe this work would be an

interesting addition. Furthermore only one in three links work and there's no product characterisation whatsoever.

So I stand by what I wrote: interesting work by all means but no need to go into prepublication.

[Edited on 17-2-2016 by blogfast25]

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

Link No 1 & 3 worked for me.

As far as 2nd link is concerned, knowing the US patent number is enough.

For uninitiated the patent is attached.

gsd

Attachment: US808095.pdf (322kB)

This file has been downloaded 447 times

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

I should be able to begin work on further characterizing the product tomorrow. As far as organization goes, what is suggested? I haven't seen any

clear outline of what should be done.

Thank you,

nlegaux

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

@nlegaux

AFAIK there are no clear cut written guidelines for Pre-pub, nor is the format specified.

However I would suggest that you take a look at posts made in that section. All well written posts follow a certain format and syntax which makes them

extremely readable.

I would especially recommend any post made there by magpie as a template to follow.

You are working on a very interesting project and it would be very nice to see it is presented in structured and organised way.

gsd

[Edited on 18-2-2016 by gsd]

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

This is a cool project given the obnoxiousness of preparing acetaldehyde by other means (jones oxidation for example). I think you need to fractionate

the distillate to remove any ethanol that co-distilled and then give us a weight of pure acetaldehyde obtained.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@nlegaux:

Assuming you have these photos on your HD you can upload them to SM and show them directly in your post. In Preview Post mode, choose the file from

your HD, then click Preview Post again. The file will appear at the bottom as 'file ####', cut and paste this into the body of your post, where you

want the picture to appear. No need for imgur.

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

Thank you for the advice blogfast! I updated the procedure with embedded photos. I will take a closer look at the formatting of some of the other

posts in prepublication and update this one ASAP.

I went ahead and began a workup. I recorded the boiling point at 23.4*C (lit. 20.2*C), but the amount of product that distilled is too small for me to

accurately obtain a density for. I will probably rerun this procedure this weekend. I believe adding the ethanol dropwise rather than in batches may

increase yields by giving the oxidant more time to regenerate (now just to find a way to add an addition funnel and still have the apparatus fit into

my small fumehood  ). ).

nlegaux

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@nlegaux:

Much better already.

Do you have any idea what the white precipitate is? Lead sulphate seems like a reasonable guess, in which case a different electrode material may be

worth considering. I see nothing in the Patent that explains lead is mandatory...

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

I'm not sure, but when I rerun it this weekend I will collect some and attempt some characterization. If it does turn out to be a lead salt, I will

investigate alternative electrode materials.

nlegaux

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

I think the ability of Mn(+3) to oxidise alcohols to aldehydes (but not to carboxylic acids):

R-CH2-OH + 2H2O ===> R-CHO + 2 H3O<sup>+</sup> + 2 e

2 x [Mn<sup>3+</sup> + e ===> Mn<sup>2+</sup>]

... might also be used without any electrolysis.

In this rather long thread, woelen, me and Xenoid established that Mn(+3) can also be prepared via another method:

http://www.sciencemadness.org/talk/viewthread.php?tid=11309&...

MnO2 is reacted with 98 % H2SO4 to form a green and insoluble mangani - sulfato complex. On dilution with

water the complex dissolves and forms a solution of Mn2(SO4)3. Excess acid used in the first step stabilises it.

Adding the equivalent amount of alcohol should then result in its oxidation to aldehyde and would be distilled off.

The manganous sulphate could be recovered by precipitation as Mn(OH)2 and re-oxidised by air to MnO2.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Another quite interesting possibility was explored by ChemPlayer: the oxidation of benzyl alcohol with 'fresh' MnO2 in DCM solvent:

https://www.youtube.com/watch?v=HrZAMlj0kPM

Starts at about 4:31 (first part is preparation of MnO2).

Presumed reactions:

Ph-CH2-OH ===> Ph-CHO + 2 H<sup>+</sup> + 2 e

2 MnO2 + 2 H<sup>+</sup> + 2 e ===> Mn2O3 + H2O

I wonder if such a reaction would work for EtOH, perhaps even w/o DCM and with bit of conc. H2SO4 thrown in as presumed

catalyst.

[Edited on 19-2-2016 by blogfast25]

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

That is quite interesting. I once attempted using MnO₂ to oxidize 4-aminophenol (from hydrolyzed Pararcetamol) to benzoquinone (similarly to the

prepchem procedure found here http://www.prepchem.com/synthesis-of-p-benzoquinone/). Instead of benzoquinone, however, all I got was a terrible sticky black residue to clean

out of my flask.

I did a bit of work with the cell yesterday, and in the process I corroded one of my electrodes to a point that it is no longer useful. I think I will

make a few more lead electrodes for experimentation in the immediate future, but I will definitely need to investigate more corrosion-resistant

electrode materials (perhaps platinated titanium?).

Also, would it be more appropriate to move this thread to organic chemistry or technochemistry until I have created a finalized procedure?

nlegaux

[Edited on 2-19-2016 by nlegaux]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by nlegaux  |

Also, would it be more appropriate to move this thread to organic chemistry or technochemistry until I have created a finalized procedure?

|

I think that is a good idea until you can verify your target product and quantify a yield.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by nlegaux  |

I did a bit of work with the cell yesterday, and in the process I corroded one of my electrodes to a point that it is no longer useful. I think I will

make a few more lead electrodes for experimentation in the immediate future, but I will definitely need to investigate more corrosion-resistant

electrode materials (perhaps platinated titanium?).

Also, would it be more appropriate to move this thread to organic chemistry or technochemistry until I have created a finalized procedure?

|

You're probably anode oxidising lead to lead sulphate. Not a big problem but better avoided nonetheless.

PtTi sounds expensive and may not even be that effective, unless the coating is very good. Ti is corroded easily to purple/blue

Ti<sup>3+</sup> (a strong reducing agent) by warm dilute H2SO4.

Why not consider good old graphite, for anode?

Re. your last point, that's a moderator's responsibility (contact Bert or zts16 or Nicodem) but I'd favour splicing this thread onto the first link in

your post. It would revive an old but interesting thread, until your method's teething problems have been sorted out.

[Edited on 19-2-2016 by blogfast25]

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

Mn(OH)2 to MnO2 by air oxidation sounds interesting!

Could you please site a reference or an experimental procedure showing how to do it?

gsd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by gsd  |

Mn(OH)2 to MnO2 by air oxidation sounds interesting!

Could you please site a reference or an experimental procedure showing how to do it?

gsd |

Simply dry the Mn(OH)2 slurry (moist filter cake), preferably with some alkali in it, on a hot plate: it oxidises to MnO2 almost

as quickly as Fe(OH)2 to Fe2O3.

Keep stirring and turning until it's all brown/black, wash out the (optional) alkali and dry and semi-calcine.

Of course it's almost instantaneous if you use bleach (hypochlorite).

<hr>

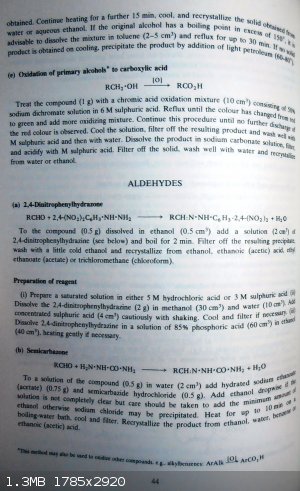

And then there's this, from a google book:

It's the reference to:

MnO2 + Mn<sup>2+</sup> + 4 H<sup>+</sup> <===> 2 Mn<sup>3+</sup> + 2 H2O

... claimed to be fast from left to right that I find interesting.

[Edited on 20-2-2016 by blogfast25]

|

|

|

Texium

|

Thread Moved

19-2-2016 at 17:17 |

Texium

Administrator

Posts: 4508

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

I moved the thread to Organic Chemistry since it was requested by the OP.

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

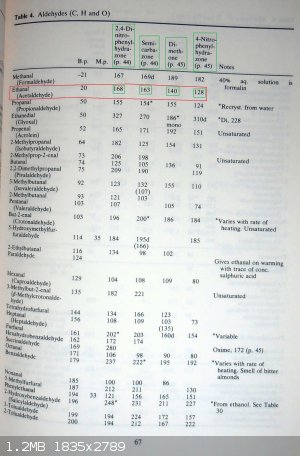

For the characterization of acetaldehyde...

-acetaldehyde imine trimer (2,4,6-trimethyl-1,3,5-perhydrotriazine) should be cristaline

-acetaldehyde cyclic trimer (paraldehyde)

-acetaldehyde cyclic tetramer (metaldehyde)

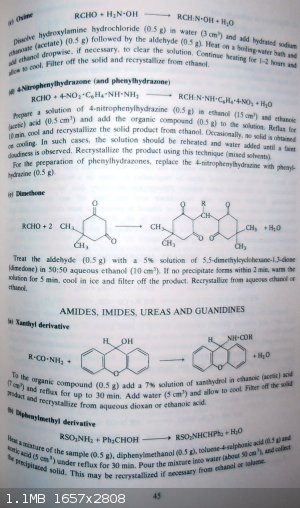

And here pertinent pages 44,45 and 67 from

"Spectral & Chemical Characterization of Organic Compounds - by W.J.Criddle and G.P.Ellis - A Laboratory Handbook - 3rd edition - WILEY"

Making of the following derivatives

1°) 2,4-dinitrophenylhydrazone

2°) Semicarbazone

3°) Oxime

4°) 4-nitrophenylhydrazone and phenylhydrazone

5°) Dimethone

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

My graphite electrodes finally came in the mail. They seem to be working quite well; after running for a few hours I see little corrosion. On this run

of the cell rather than maintaining the cell at 70*C using heating, I have placed it into a bowl of water and it maintains its own temperature at

around 50*C.

However, I have found an issue. I have not been able to collect any distillate on this run of the cell. As a test, I removed a small amount of

electrolyte and added it to a test tube. It is a brown/black clear color (see photos below) with a small immiscible layer on top. I than took about

1ml of the collected electrolyte and added about 1ml of Fehling's solution. After heating, the test was negative (which is to be expected because of

the lack of distillate). Next, I added a small amount of ethanol and repeated the test. It indicated again that no aldehydes were present.

The collected electrolyte. My apologies about the poor photo quality, I couldn't get my phone camera to focus on the test tube. The immiscible layer

is too small to be clearly visible in this photo.

Because of this information, I believe I may know what is going on. I think the ethanol is being over-oxidized to ethanoic acid which is forming an

ester in the highly acidic environment with the unreacted ethanol forming ethyl acetate (hence the immiscible layer). This ethyl acetate would not

boil off at the apparatus's operating temperature of 50*C, causing it to remain in the reactor and possibly consume the oxidant (that last part is

purely a guess. I have not been able to find any references to oxidizing ethyl acetate to carbon dioxide and water, but it certainly seems plausible.

Also, this would fall in line with the test indicating that the electrolyte was unable to oxidize the ethanol). I will attempt to distill this

immiscible liquid off in order to better characterize it. In previous runs of the cell, I was probably distilling mostly ethyl acetate with a small

amount of acetaldehyde dissolved into it, which would fall in line with my observations on the original product work up (a small amount of material

boiling at 23.4*C with the majority of the liquid left in the boiling flask). In the mean time, are there any ideas on how to remedy this issue,

assuming it is ethyl acetate formation?

nlegaux

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@nlegaux:

Ouch.

I'm now beginning to think the method may only be suitable for certain aldehydes, like benzaldehyde. The latter is of course poorly soluble

in water, while ethanal is totally miscible with it. That makes the further oxidation of the latter to ethanoic acid much easier. The

Mn(+3)/Mn(2+) system is a very strong oxidiser.

The formation of the ester is of course plausible, considering the high concentration of H2SO4 in the mix.

The formation of EtOAc may even promote the further oxidation of ethanal to ethanoic acid by Le Chatelier.

[Edited on 25-2-2016 by blogfast25]

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

Could this problem possibly be fixed by introducing an immiscible organic phase to dissolve the ethanol/ethanal?

The distillate is coming over at approximately 70*C (lit for ethyl acetate is 77.1*C, but the barometric pressure here today is about 750mmHg). It is

a slight yellow color and immiscible with water. Its odor is the same as that of a known sample of ethyl acetate I have on hand. I found the density

to be 0.954g/ml, which is similar to the reported value for a ternary azeotrope of ethyl acetate, ethanol, and water (lit. 0.901g/ml).

Worst case scenario I may be able to make an ethyl acetate producing cell

nlegaux

[Edited on 2-25-2016 by nlegaux]

|

|

|

| Pages:

1

2 |