| Pages:

1

2

3

4

5 |

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Well, if it's got any C in there, which it should have, and they get lopped off, it could be interesting.

Maybe makes it cross-link more, release some methyl groups which then react with excess ClI making a bit of methyl iodide or chloromethane ...

Best try a very small amount.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Dumb-bell shapes are easier to work with than straight bits too.

More stretchy-snappy results:

Definitely not getting anywhere near 211% E@B.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@aga:

I think that more or less settles it: even with dumbbells the E@B is well below a 100 %, far from the 211 % advertised.

Even allowing for differences in testing protocols (theirs is likely a very tight ASTM or ISO Standard) the found differences in E@B must be due an

error on their part.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Might be an error on the part of the testing house that actually tested it rather than the manufacturer.

I read on the website something about the current product being 'F10' which i assume means 'formulation #10' so there may have been confusion between

formulations tested, or possibly they tested the un-cured material (!) which probably will go to 200%+, although the TS would be crappy.

Three weighed pieces of cured material are swimming under an aliphatic solvent (zippo lighter fluid) to see what happens.

1 sample left unopened.

Would you like the uncured portion tested for elongation ?

Not sure that Clamping would even be possible, although Shaping would be easy

[Edited on 21-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

Would you like the uncured elongation results ?

Not sure that Clamping would even be possible, although Shaping would be easy

|

That requires a different testing protocol: uncured elastomers are high viscosity non-Newtonian liquids. So no.

The Zippo resistance should be interesting though.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Duration ?

Soaking started ~2 hours ago.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

About 3 days, I'd say.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

So, when 72 hours are up, does it need to be dried thoroughly, simply wipe it with kitchen towel, or do you just weigh it wet ?

Not trying to be pernickety here, just that i do not know what should be done to get the most accurate measurement possible in an amateur setting.

[Edited on 21-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | So, when 72 hours are up, does it need to be dried thoroughly, simply wipe it with kitchen towel, or do you just weigh it wet ?

Not trying to be pernickety here, just that i do not know what should be done to get the most accurate measurement possible in an amateur setting.

|

By all means be 'pernickety', we're trying to do science here.

Wipe with kitchen towel to remove any superficial solvent clinging to the sample. Then weigh immediately. Reading will decrease a little in time as

absorbed solvent evaporates slowly but that's OK.

Keep the unopened sample for a special occasion!

[Edited on 22-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

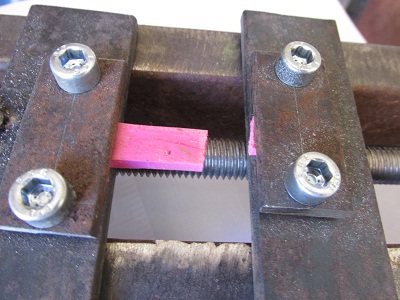

Ask and ye shall receive !

Quote: Originally posted by aga  | I'll email them and ask if we're wrong ...

These things never turn out well, but needs must ... |

I was totally wrong to be so pessimistic !

Samuel from the Sugru people (FormFormForm Ltd) emailed back with very informed, helpful and positive comments, clearly having read this thread.

Personally i am really pleased that they have responded so positively. If only all customer service were anywhere near as good !

It is a refreshing change to encounter a manufacturer willing to take the time to discuss anything, let alone what may appear to be a challenge to

their product's specs.

They very kindly supplied the exact measurements of their own dumb-bell test pattern, so a mould has been made to the same dimensions and the last bit

of Sugru material has been used to make a more accurate test sample, which is curing now.

The aluminium sheet is 2mm thick, screwed to a nylon baseplate.

Centre portion is 12.5mm wide by 75mm long.

The Sugru was 'kneaded' for 20 seconds then forced into the mould, then rolled to the thickness of the aluminium with a wetted steel rod, so the

result will be 2mm thick +/- curing shrinkage.

I just hope it won't stick like crazy to nylon.

Once cured, the middle section has to be trimmed down to 3.86mm wide to form the desired shape.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Huh, and I thought this stuff was from a crappy start-up. they may have something to them...curious to see how the stuff holds up.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Why would they be assumed to be a 'crappy' start-up ?

Starting a business is a complicated and difficult thing to do, especially for a Manufacturer of a new product.

To be 'crappy' in any way would certainly mean failure, which equals lots of lost $.

As the Product works, and at least i bought some, and the customer service post-sale was, well, Superb, i can only assume that all the possible

Planning was done years ago, eliminating any suggestion of 'crappiness'.

Anyone wanting to start a new business can U2U me their Business Plan and i'll go over the figures for them for free.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The Sugru Saga!

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Quite the story, I gave a good portion of it a read. Good stuff

And Aga, I suppose you're right. I'd love to have a start-up, but in looking through the regulations and legalese and shite required for taxation and

employees, I'd want to do it all myself, yet would go insane if I tried. It's quite the job..

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Hmm. Reading the 'story' there's a lot of Background unmentioned.

Rather a lot of 'useful connections' and a seriously large amount of $ is skipped over.

For someone with an 'idea' who says "I mean, I gave up chemistry in school!" to get to an air-curing formulation of two organo-silanes is a bit of a

leap.

I checked the labels on all the bottles in my lab, and i don't seem to have any silane, so maybe if i mix up some stuff in a bucket of sand i might

get lucky.

To go from 1 person to a staff of 10 requires a VAST amount of money, even for a short time.

To leap the Atlantic requires enough $100 bills to float the Titanic.

Maybe more of a Riches to Riches story.

Still, a nice material, and good on yer to whoever Actually formulated it.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

@TVC if you ever Do It, do it alone, do it smart, and do it well.

Staff are expensive in time, money and emotion.

Automate absolutely everything you can = Work Smarter.

Once perfected, the machines do most of your work, leaving plenty of drinking time

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

For someone with an 'idea' who says "I mean, I gave up chemistry in school!" to get to an air-curing formulation of two organo-silanes is a bit of a

leap.

|

No, not at all. Air-curing silicone caulks are thirteen in a dozen: it's what you use to seal sinks, showers and baths e.g. It's quite 'old'

technology.

By her own story, she started mixing some of those with various powders and pigments/dyes for a Final Year project. It requires very little chemistry

because the base polymers are off-the-shelf, the rest is mainly mixing.

See also the various DIY versions of Sugru.

It's a nice little material but highly hyped: it will never be anything like an engineering elastomer or a thermoplastic elastomer (these are huge

markets). But hyped well, sold as a kind of sophisticated Bluetack in small amounts at high £/kg prices, Sugru is probably a small but viable

business.

[Edited on 23-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

...which would not naturally attract dozens of serious investors.

A London wage would be about £2,000 a month.

10 staff.

£20,000 a month, just for staff, ignoring anything else.

1 year = almost a quarter of a million pounds in that year alone.

Still qualifies as 'small' as in Small to Medium Enterprise (SME) but not quite within most people's reach.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

Still qualifies as 'small' as in Small to Medium Enterprise (SME) but not quite within most people's reach. |

How long is a piece of string? 10 is 10 x more than a self-employed person. But about 1700 x smaller than the last elastomer producer I worked for.

Capacity about 200,000 mT/year.

Where are the 'dozens of serious investors'?

From their site:

| Quote: | | Nesta, the UK’s innovation think tank, awarded the Company a £35,000 Creative Pioneer grant to get off the ground. |

[Edited on 23-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Business 'science' is a lot easier than chemistry.

SME is well defined : http://ec.europa.eu/growth/smes/business-friendly-environmen...

Most reasonably sized busesses are SME's.

Bigger ones are better called Gargantuans.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

The soak-in-solvent test is done.

3x ~1.5g strips of cured material submersed in zippo lighter fluid for ~70 hours.

After day 1 more fluid had to be added to ensure submersion.

The middle green one is the un-treated control.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

And finally ...

A 'proper' dumb-bell shape was made as close as possible to their spec and tested, giving TS=1.8MPa, E@B=36%.

The TS is pretty much spot-on, but the E@B is still miles off 211%.

That was the last one, so no more samples to play with.

[Edited on 24-6-2016 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

That E@B is an exceedingly poor value for any type of rubber. A bit mystifying, actually...

Nice work with the dumbbells.

70 w% increase in Zippo is quite high too. Not really suited for oily environments then.

[Edited on 24-6-2016 by blogfast25]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Might be an idea to check my maths.

E@B is elongation at breaking point right ?

If the starting length is 55.04mm,

length at snapping point is 74.86mm,

i get an elongation of 19.82mm = 36%

Their specs state "Strain-to-failure: 211%" so is that the same thing as E@B ?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | Might be an idea to check my maths.

E@B is elongation at breaking point right ?

If the starting length is 55.04mm,

length at snapping point is 74.86mm,

i get an elongation of 19.82mm = 36%

Their specs state "Strain-to-failure: 211%" so is that the same thing as E@B ? |

Yup. It's all good. "Strain-to-failure: 211%" IS the same thing as E@B.

I can see from the pix with your dynamometer that the E@Bs you calculate are indeed correct.

If you've got a small piece left (even one you snapped before) verify it . manually: 211 % means you should be able to stretch it at least to approx.

3 x its original length, before it snaps.

|

|

|

| Pages:

1

2

3

4

5 |