| Pages:

1

..

4

5

6

7

8

..

10 |

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

I am glad I dug up that original item about making carbon refractory with kitchen chemistry! It looks like it is going to be one of those long

threads.

About that which we cannot speak, we must remain silent.

-Wittgenstein

Some things can never be spoken

Some things cannot be pronounced

That word does not exist in any language

It will never be uttered by a human mouth

- The Talking Heads

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

I would have to agree. This is accessable, cheap, quick and fun. Not to mention the multitude of variations in feedstock, treatments, and intended

uses. Truely seems like you can tailor the stuff to your needs.

Just brewed a batch of coffee and wondered about the leftover grounds... AC perhaps? Same with rice grains or friggn gold fish crackers for that

matter. But my travel-with-me hobby stuff is only electronics and tools. So I have no way of testing the actual activation level of the produced

carbon. I'm having to buy all my chemicals for this from hardware stores, which is nice as they are low tech and widely available. That can't be

said for so many other chemistry topics.

There are some interesting vids on youtoob from individuals with little knowledge, about graphene production, buzzwords galore. Many buy graphite and

"intercalate" it with acid, prior to microwave "expansion" or "exfoliation". All the while "few layer graphene" is just on the other side of the

blender, as it were. failure = "graphene oxide" when some dont see the conductivity they crave.

Regardless of all the nonsense, microwave heating of the carbon scaffold causes high temps in micro regions during electrical discharge in the 1000℃

area results in graphitic ordering. Those patents with chelatants imbeded to hold metal cations had a microwave step. Causing reduction of the metal

salt or oxide, dissolution of carbon and precipitation of graphite on cooling. (One) Reason why graphitization is lowered from >2000℃ to 800℃.

Any one have a spare/chem microwave to try. It would still have to be sealed from O2. Perhaps a sacrificial yogurt container flushed with

a small amount of volatile hydrocarbon could exclude oxygen. Your carbon could arc its heart out and then be tested for conductivity increase.

Any how back to actually doing the science, not just postulating ideas. I will edit this post later tonight with valuable data from the field. Or..

outstanding failure, either way something will come of it.

_______________

Starting to smell toasty  got a pile of things crammed into the SS cup this

time. Soggy bread with boric acid, same with Mg(OH)2, charred bits with some of each, same bread with nothing on it, couple cotton balls

and a couple mystery items to show when its all cooked. Fingers crossed for excellence. got a pile of things crammed into the SS cup this

time. Soggy bread with boric acid, same with Mg(OH)2, charred bits with some of each, same bread with nothing on it, couple cotton balls

and a couple mystery items to show when its all cooked. Fingers crossed for excellence.

[Edited on 20-11-2016 by violet sin]

_________________

Just a touch over 2 hrs in charcoal briquette fueled heat, choked a good deal by stainless pot cover( thanks thrift store 1.5$). Results are:

Control toast, Mg toast, B toast, bannana, cotton balls, wasp nest, wasp nest II.

This super cheap white bread is pretty hard without modification, the two test dopings were sub optimally attempted. Room temp saturation of well

water by epsom salt and boric acid separately. Test slices were set in plastic liner and doused with each. After soaking, ammonia (10%) was dribbled

in Mg sulfate side to ppt. Mg hydroxide in bread pores. No attempt was made to wash, but it was drained. Then both were set in aluminum boats on top

of my stainless cover to dry a touch. Probably stupid as it soggied them up too. Pre-charred bits of sourdough were dosed with each dopant in a

similar manner, except this time the boric acid was dissolved in MeOH. Both dried with white staining.

The boric acid toast doesnt seem to be noticibly affected structurally. Perhaps a touch softer. The Mg(OH)2 toast seems a touch stronger

and the pre-charred seems noticibly stronger/slightly heavy.

The cotton balls are nondescript, charred all through, still feel roughly the same. Nice because they offer a compact/moldable shape(pre fire) and

are absorbant. Could be fun on a few levels.

The bannana was on a whim, figured they have a ton of fiber. However shrinkage leads me to believe that freeze dried would be the way to go here. It

looks pretty structurally sound, but like water loss defeated this on shrinking as it cracked but bits were strong. It also had a nice blue tinge

fading to gold in some areas. Ravens feather if you will. The center was more large pores and the exterior had smaller fiberous areas. Could be

really cool if structure was preserved in cooking = freeze dried first. Not in my capability.

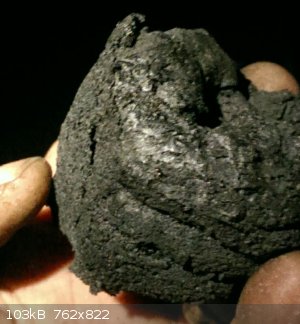

And my favorite effort, a portion of a yellowjacket comb stolen from a colony dying back for the season. All empy celled and unattended. I failed to

safely cook them. Like an idiot, I pulled the tin out by had when nothing convienient presented it self to aid extraxting it = dropped from 2" up and

fell over. ALMOST made it, lol. But the sample survived enough to see structure was preserved, surprisingly strong and dellicate simultaneously and

easily catches a breeze.

____________

Thoughts:

dont get your bread soggy trying to dope it with structural modifiers. A single piece of bread weathers poorly in a round tin. Seems reasonable to

cook them flat if you want something stackable for a refactory lining. Better yet toast a section of un-sliced bread then quarry you shape from that.

It is more practicle to strengthen it after shaping. Only down side is the interior doesnt get coated if all the cells are charred closed. Maybe a

normal(edible) toasting followed by an alcoholic suspension of sorts. Still soak into all the pores, but the shape is possibly preserved and quick(er)

to be dry- untested as of yet.

Reinforced bread feels like it could be good structurally. Slabs of such might be able to be permanently assembled with a (honey/syrup/starch)

binder if it could be re-fired.

The cotton will have to be toyed with more, but so far I like it. Some of my reading indicated cotton ball cellulose were difficult to dissolve

because of more crystalinity. I wonder if that translates into easier to char towards graphite? Metal salts(liquids in general) would deffinitely

absorb on them easily. no direct use yet.

Wasp nest thing opens more windows. Hard to come by and delicate, though many other natural shapes are more common and robust. If the back closed

portion is sawed off, as I did, the open nature, low air resistance and relative strength in that direction could make effective catalyst support.

Cars prove the shape is right. Nowhere near the same force could be supported, but I can see it working in some lab sized model.

______

Next on the to-do list:

1) glue slabs together with sugar, starch etc.

2) attempt to wrap a charred bit with cotton and reinforce with MgO.

3) try just sugar etc. on edible toast as a sealant. (Close the structure off)

4) paste of sugar & graphite powder

Rolling around for later

-sodium aluminate, sodium sillicate and sodium phosphate on char bit.

-Magnesium citrate in alcohol, structural dopant.

-seeding graphite growth with lubricating powder from hardware store

-microwave treatment to test possible increase in conductivity from graphitization

-insects whole, freezedried from pet store.

[Edited on 20-11-2016 by violet sin]

[Edited on 20-11-2016 by violet sin]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Awesome efforts there violet sin !

The wasp nest is intriguing in that it managed to retain any shape at all.

Car catalytic converters definitely use the honeycomb pattern.

The idea of toasting then adding X then toasting again is probably a good one.

Dunno why, just 'feels right' somehow.

My last Toast attempt with CaCl2 gave ~20 ohms resistance - maybe that can be improved on.

Density is probably a thing.

Maybe toasting once, powderise (smash up) then compress with a hydraulic jack, then toast again would do something different.

Think i'll try that after the trophies are finished.

Edit:

Was thinking about the cotton + honey thing and BANG the word 'Baclava' arrived !

Wafer thin sheets of wheat-pastry infused with honey !

Dragon's Hair candies too ! (2048 strands of honey & cornflour)

[Edited on 20-11-2016 by aga]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Odd. Went looking for carbon in a microwave and found this :

https://www.youtube.com/watch?v=Q176cmHGywo

Ground charcoal in a microwave.

The carbon 'sparked' a bit as reported in the video.

With the pyrolysed bread the arc light was so intense you'd need a welding mask to even look at it for more than a split-second.

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

found a fun substance to try this time. Went to the dollar store again to get some little tuppers for doping trays that can seal ammonia in. Had in

mind something like homogenous solid or regular enough on the individual particles, that a sugar wash might glue them. Had tapiocca prills in mind.

Found green blocks of floral foam. label says "caution: flammable. Keep away from open flames"... googling, I believe they are phenolic foam, a

delightfully regular, small pore, easily shaped and cheap materia. Available were one large ish block, four smaller blocks, rings or cones of which I

purchased the first two.

All said and done, I have spent less than 50$ with various, and at times unneeded, dopants included. Bread cheap, cooker free, various bits n

charcoal and aluminum foil for cooker <10$.

The goal for today is to try and make something actually usefull instead of testing different forms.

holy flying pyrex  that was a crazy vid. Still wish people would seal the

carbon from air while trying this... that was a crazy vid. Still wish people would seal the

carbon from air while trying this...

------------

Crazy stinky fumes going on. It was quite dense and yellowish. Just stayed up wind. Fume caught fire for a bit, then seems to have subsided. Hope

to be past major burn-off at the 1 hr mark now. Shooting for two like before.

-------------

Ahhh dissapointment, I know ye well. As it turns out,... my hopes of greatness were dashed. The stuff went from a block that barely fit in my

container to about 1/50th of that. Bummer. My guess is that it got too hot too fast and 2hr may be too long. Reading a couple papers about phenolic

foam indicated they use REALLY gradual temp increases, 20℃/hr, not possible for me in this setup. Going up as far as 900℃ like that, then

100℃/hr to max temp of 1,400℃.( the max temp checked, min was around 350℃). But still it reflects a slow transition.

On the bright side it is porous and wettable, so doping is a possibility.

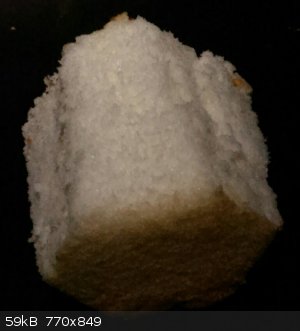

1) as bought, 2) stuffed in, 3) remains

There was a paper divider which the mass stuck to. It is quite fiberous where it stuck to the walls and paper. Side note, cotton covered in sugar

water seems sturdy. This was on the other side of the paper divide. Cotton wrapped around stainless tube, covered in sugar water/sugar. wont come

off the tube easily.

Spent the time to carve a nice crucible and lid in preparation for a sucessful outcome. Set back to trying samples with reinforcement to see how to

modify it to save my effort. Something to give structure but not close all the pores. Dissolved cellulose maybe?

Foam test II: another as purchased small block aranged differently. some wire mesh was added like a hammock across opening that keeps the SS cup about

4" above the coals instead of dirrectly on. Coals are dying out some anyway, as the rain starts again. It was also wrapped in foil inside the cup

with a bottom spacer.

The crucible I hope to save just fits in the tupper so a dosing is possible. Blue copper/ammonia complex is waiting to eat cotton balls, but I have

major doubts I will get an acid wash too deep in the pores. So may just ppt cellulose on outer edges. It may also attack the resin. Unknown as of

yet. Small bits will be tested if I can. Running low on charcoal and time.

___________

1 hr residence of second foam block ~4" above coals = no physical changes apparent. Still green and new looking, but the odor isnt plesant. I added

the last of my charcoal, lowered the cradle some and set the SS cup against side of cooker leaning on the cradle. So it is closer, like 2-2.5" above

coals. Maybe 3" considering the spacer, between foam and coals.

Looks like a narrow window between nothing changing and failure.

Another hour and perhaps 30-45 min elapsed at the lower position. Was raining so left it past the timer. Nada, no change again. Green and new

looking. Last of coals burning out and time to put stuff away.

I find this quite frustrating. Most papers on reinforcing phenolic resin foam obviously do it in production, not after the fact. Seems like a

usefull product if it would carbonize like bread. First attempt at schweizer's reagent has littile visible effect on cotton or paper towells, nice

blue though. Material for second attempt is settling after first rinse. See if it does any better with a stronger sollution in terms of copper

present.

Could just be a dead end for my equipment as I still need to find the sweet spot temp wise even if I do manage to strengthen the stuff. Low temp

decomp of additive, prior to foam failure is required. That will be some stinky science to undertake. papers suggest phenolic foam may be stable to

200℃ so a long roasting around 150 with starch is an option. Prob need that just to drive off the water that put it there. Could also just lead to

a condensed wad of crud as they shrink together. Fast and cheap is the goal here, not mind numbingly time consuming and frustrating. Then again, if

something this consistant and available can be mastered, it will make a nice refactory. (Maybe just use poundcake and forget this mess)

[Edited on 21-11-2016 by violet sin]

|

|

|

Morgan

International Hazard

Posts: 1660

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

Perhaps of interest although not a foam.

https://www.youtube.com/watch?v=ki1aCdkMSeo

Maybe it would be possible to make flexible carbon foam fiber hybrid of some sort.

|

|

|

DrP

National Hazard

Posts: 625

Registered: 28-9-2005

Member Is Offline

Mood: exothermic

|

|

Hi aga - I would try the pyrolysis under an inert gas like Argon or Nitrogen. The article suggests that and I would expect that it would stop the

disintegration from oxidation. Maybe that will give a more sturdy and flexible char?

I might try this out myself.

\"It\'s a man\'s obligation to stick his boneration in a women\'s separation; this sort of penetration will increase the population of the younger

generation\" - Eric Cartman

|

|

|

DrP

National Hazard

Posts: 625

Registered: 28-9-2005

Member Is Offline

Mood: exothermic

|

|

Sorry - long time since I visited this site - I just realised I posted this suggestion without reading the entire thread. lol. sorry.

I still might try it under N2.

\"It\'s a man\'s obligation to stick his boneration in a women\'s separation; this sort of penetration will increase the population of the younger

generation\" - Eric Cartman

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

violet sin is currently at the Cutting Edge on this one, and it wasn't even my idea to begin with.

All so very easy to do if you can make Fire and have access to Bread.

Access to inert gasses are entirely optional.

Ability to exert Effort and actually do this simple-1-hour-thing is mandatory, or your bread remains just bread.

Without the Effort required to try it with and without an inert gas, we will never know if it makes a difference to the outcome.

[Edited on 23-11-2016 by aga]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

@violet sin:

The green stuff is called 'Oasis' and is used in flower-arranging.

A bit of googling and it seems that 'Oasis' is a 'phenolic foam' which can be a bit of a mix of stuff.

MSDS copied here : https://gorgeousandgreen.wordpress.com/2011/08/16/msds-flora...

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

Phenols are awfully stable. Could be a lot of the structure just de-polymerizes and gets emitted as vaporized phenol.

This is a guess.

However making phenol by potassium fusion at around 300C used to be a common organic chemistry class lab assignment, so the stuff really holds

together at high temperatures.

Don't know what vaporized phenol smells like, but if memory serves phenol can corrode flesh without causing much pain, so be careful.

The MSDS for this stuff doesn't look too bad, but they're not really addressing destructive distillation.

BTW: You have impressive foam carving skills. On first glance at that picture i thought, "Where did she buy THAT?"

|

|

|

j_sum1

Administrator

Posts: 6219

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

"She" has very manly hands. (As well as an impressive beard IIRC.)

But I concur. Nice work all round VS.

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

Quote: Originally posted by j_sum1  |

"She" has very manly hands. (As well as an impressive beard IIRC.)

But I concur. Nice work all round VS. |

Yes, I noticed the manly hands, but wasn't sure if that meant a man or a woman who might be sensitive about her masculine meat-hooks.

Sorry for the gender confusion, violet sin.

Thanks j_sum1.

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

Yes sir, I have a nice size beard. But of course no ofence was taken. Not much time today, I did get charcoal and a cheap angel food cake.

Today's charcoal was the lump mesquite natural kind. Just chared wood bits of various size. Harder to estimate fuel use and heat and still its

pretty easy to eyeball a comfortable hot but not blazing temp. For any one keeping track I bet single press lump stuff would be easier to record.

The first run was 2hr usual but had a slower start as the cup went in right when the fire started, no preheat. Results were actually quite strong

where it didn't stress crack under strain. Kinda spawling off shallow flakes were noticed.

The second run, I considered why not for a shorter duration. Wanted to take it down to one hour and see if I could still get stiff carbon without

breaking, but went for the safer half hour. If it were only partially carbonized then maybe a 10-15min break might ease strain. But it was already

carbonized, with less cracks on first inspection. Have not had a chance to cut either yet or any other testing.

Pretty regular, shrinks a noticable amount. Not too bad. More work will have to wait. Cooking a chunk of bolete stem, check tomorrow.

1) two hour angel food top, one half hour bottom

2) close up of knot of bolete stem above the half hour angel food cake

So the fungus bit makes it aparent that nature is far better at this than a baker. I have one in mind to fell

Happy thanksgiving everyone! Enjoy family, friends and fond memories.

[Edited on 24-11-2016 by violet sin]

|

|

|

DrP

National Hazard

Posts: 625

Registered: 28-9-2005

Member Is Offline

Mood: exothermic

|

|

OK - I was wondering what the inclusion of some powdered Ammonium Polyphosphate added to the bread mix would give in your resultant char. It should

promote further crosslinking in the char. Whether this will make it less flexible or stronger and more flexible I do not know - but it should improve

over all charring - we use it as a catalyst to cross linking in chars.

Some kind of gassing agent could help you play around with cell structure and final size of the foam. With some APP and a suitable blowing agent I

recon that char would swell to a few times it's size.... maybe.

I think the APP would need to be what is sold in industry as Phase II - which I think has polymer chains around 1000 to 2000 units long. The theory

is that it reacts with -OH groups and cross links via a condensation. With the systems I use we add pentaerythritol to provide further carbon source

and the -OH groups, but there might be enough functionality in all the bready proteans to act as cross linking sites anyway.

Violet - can you get hold of APP?

\"It\'s a man\'s obligation to stick his boneration in a women\'s separation; this sort of penetration will increase the population of the younger

generation\" - Eric Cartman

|

|

|

3DTOPO

Hazard to Self

Posts: 64

Registered: 14-2-2016

Member Is Offline

Mood: No Mood

|

|

I wonder if carbonizing wool might work better than bread?

(please spare me the lecture Aga)

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

Cotton fiber chars right up nicely. Iv'e been busy with work and fam, had to settle for reading this last week. Had no phosphoric acid, so bought

ospho corrosion stopper. 45% phosphoric acid + dichromate, the green stuff. Also bought concentrated sulfuric drain opener( remembering the sugar

demo from middle school)... It does not play nice with fungal tissue, leaves a liquid suspension instead of preserving any form.

I did manage to fell that massive bolete, froze the cap and stem separately. Trying to find a way to freeze dry the some'bitch. But it will take a

large pressure cooker to take the cap whole, and my vac is weak. Gonna ha e to keep that in the freezer untill arangements are made.

Super time crunch right now, check back in later with other thoughts, tests and results not listed.

--------

it was noted that you said wool. I drew a correlation to cotton as also being thin and dainty material. yet it carbonizes nicely.

[Edited on 5-12-2016 by violet sin]

|

|

|

3DTOPO

Hazard to Self

Posts: 64

Registered: 14-2-2016

Member Is Offline

Mood: No Mood

|

|

P.S. I said wool, but what I really meant was felt (wool or acrylic fibers). I think acrylic might carbonize very well (based on my experience with

burning out acrylic SLA 3d prints).

Unlike a lot of plastic and foams - acrylic doesn't melt - so it should hold its form...

[Edited on 5-12-2016 by 3DTOPO]

|

|

|

DrP

National Hazard

Posts: 625

Registered: 28-9-2005

Member Is Offline

Mood: exothermic

|

|

Looking forward to seeing what the phosphoric acid does. :-)

\"It\'s a man\'s obligation to stick his boneration in a women\'s separation; this sort of penetration will increase the population of the younger

generation\" - Eric Cartman

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Lidl have finally decided to stock a stainless steel carbohydrate pyrolysis kit with 2 reactors for €8.99 (just need to drill holes in the lid).

They also sell the raw chemical feedstock (bread!)

The jar on the left has about 6 slices of a Bimbo bread analogue in it, the smaller one on the right has 2 slices soaked in a

Zn(NO3)2 solution.

Simply stuffed both tins into a charcoal fire.

Overloaded i know, as the tiny barbie is way too small for both tins.

After about 30 mins the smoke coming out of the tins caught fire and burned for around another 15 mins.

The result of the untreated bread is pretty much as expected - ceramic-sounding bent carbon tiles.

Oddly the resistance is in the 1~2 kilo-ohm range per cm.

On the first go it was at 20 ohms. Damned flukes !

The zinc nitrate treated bread gives a much finer and powdery carbon.

Bashed it up and added HCl to dissolve out the zinc.

Currently filtering/washing a lot to remove the HCl and zinc chloride.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Every time I read about this, I'm surprised that the product is such a poor conductor of electricity. Does the bread still bend if you pyrolyze stale

bread?

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

I have to say in this one thread specifically, doing is friggn easy and leads to FAR more productive afterthoughts. I don't see why people keep

bitching about being nudged to throw in and participate. You will not get exactly how to improve or substitute unless you have done it.

Its clearly one thing to imagine wrapping some bread in foil, its another to see it try to fold and wad up. It sounds really easy but there are

lessons to learn. Some members first run may be 1000% more sophisticated than your first run, no matter. We all have diff heat, wrap and bread.

Every batch of toast I tried to fint in several things and mods at once. After each run, I'd sum up observations and plan again. Plenty of "ideas"

were basically garbage, because of impratical methods, numerous steps, poorly behaving materials and all mamer of issues. You don't want to spend all

the time and 14 steps to get to nothing... But if no one does a 14 step optimization we will never know if there is a pot-o-gold at the end of the

rainbow. There is NO gauranteed paycheck/prize/material there unless you a) find one through experimentation b) poorly copy some one elses hard

work.

I have plenty of ideas, now waiting on ancilary equipment/chems to be made. I also tried a bunch of diff materials to get a feel for the process.

Can only plan a little farther than you can see. Not everyone has the time or space to set up distillation equipment etc. Required from serious

experiments. Amlost no one has a cop out excuse for putting an already owned food material in a commonly used food wrapping in an existing piece of

machinery in an already functional setting. ( horrible sentance, I know, but functional in a sense). buck up, aga's got a point. This has been

super fun, despair not.

** And I am not aiming to seriously chastize any one. just a reminder it's not a slap in the face to be nudged into activity **

[Edited on 20-12-2016 by violet sin]

|

|

|

3DTOPO

Hazard to Self

Posts: 64

Registered: 14-2-2016

Member Is Offline

Mood: No Mood

|

|

Personally, I have professional carbon foam boards with a graphite hot face for my vacuum furnace, and don't have a need for any more carbon

insulation at this point. But it is still a subject that I find interesting, so are you suggesting that people like me not chime in with ideas?

Like I offered the suggestion of using acrylic felt, is that so wrong?

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

Well, I'm glad you have the use of some real tools, thats awesome  From my

tests, bet acrylic felt would have a tight window to retain any form. Would likely be hard to control temp well enough with out a lot of trial and

error, or a nicer setup than coals. Lol. Bare minimum a hotplate, stainless pot and lid with Al foil to spare. Maybe a toaster oven. But your nice

vac furnace would make simple work of finding the best temp. So for someone with only charcoal to work with, probably a bad idea to expect much to

work out. Not a bad idea to try, or suggest though. From my

tests, bet acrylic felt would have a tight window to retain any form. Would likely be hard to control temp well enough with out a lot of trial and

error, or a nicer setup than coals. Lol. Bare minimum a hotplate, stainless pot and lid with Al foil to spare. Maybe a toaster oven. But your nice

vac furnace would make simple work of finding the best temp. So for someone with only charcoal to work with, probably a bad idea to expect much to

work out. Not a bad idea to try, or suggest though.

Start out toasting bread, end up looking all over the place for new materials and processes. The issue being any one can toast bread, not everyone

has all the tools to go further. Freezedrying would be usefull, as would the adjustable temp. The more varried your toolchest, the more diverse

feedstock you can coax into submission.

Im not saying thought in absense of action is totally useless. Just saying it would be better to see ways in which you want to improve the outcome.

If you remember this is usefull for more than just refactory. So there are quite a few attributes possible. Well its 4:54am, time for bed.

|

|

|

Texium

|

Thread Split

20-12-2016 at 06:40 |

unionised

International Hazard

Posts: 5102

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

It's not strictly relevant to the thread but trying to measure the "resistance" of a carbon foam like these by stabbing the two probes from an ohm

meter into it just isn't going to work properly.

The contact resistance will dominate the reading.

You need to use something like this

https://en.wikipedia.org/wiki/Four-terminal_sensing

|

|

|

| Pages:

1

..

4

5

6

7

8

..

10 |